Professional Documents

Culture Documents

12 Boosters LB

Uploaded by

Mauricio Andrés MontenegroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 Boosters LB

Uploaded by

Mauricio Andrés MontenegroCopyright:

Available Formats

PISTON BOOSTER

SYSTEMS

LB air & nitrogen booster range

(15-20 hp / 11-15 kW)

PREMIUM BOOSTER PERFORMANCE

When you need the best in booster performance and reliability, the Atlas Copco LB delivers. The LB is the

ideal booster for pet bottling or nitrogen applications in power plants or laser cutting. Its piston technology

offers industry-leading efficiency with remarkably low noise levels.

FEATURES AND BENEFITS

Quiet Optimal performance

• Silent from the core: optimal balancing and use • Innovative oil lubrication system with oil ring and

of special vibration dampers. crankshaft channels ensures better lubrication.

• No oil carryover with oil breathing system.

Increased efficiency

• Low Specific Energy Requirement: direct driven Supreme reliability

technology eliminates friction losses. • 100% designed, manufactured and tested by Atlas Copco.

• Low electrical peaks: use of soft start technology. • Based on proven, reliable LT piston compressor design.

• Low mechanical losses: half elastic motor shaft coupling • Inlet and outlet safety valve protection.

minimizes torque peaks. • Steel valve plates with innovative zinc-based

microsphate coating for additional protection.

Easy operation

• Plug-and-play, hose in/hose out solution.

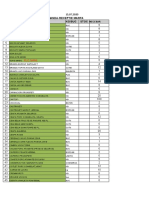

TECHNICAL SPECIFICATIONS

Compressor Maximum inlet Maximum outlet Recommended inlet Recommended inlet Motor power Motor power

Outlet flow @ 50hz Outlet flow @ 60hz

type pressure pressure flow @ 50hz flow @ 60hz @ 50hz @ 60hz

bar psi bar psi l/s cfm l/s cfm l/s cfm l/s cfm kW hp kW hp

LB 15 6 87 40 580 29 61 33 70 24.2 51 28.1 60 11 15 13 17

LB 20 6 87 40 580 48 101 55 116 40 85 46.4 98 15 20 18 24

* Electrical power ** 50hz units come standard with CE approval; *** Different voltages are available upon request.

230/3/50 230/3/60 60hz units standard with UL approval.

380/3/50 460/3/60

400/3/50 575/3/60

500/3/50

OPERATIONAL SPECIFICATIONS

2935 0804 41 © 2015, Atlas Copco Airpower NV, Belgium. All rights reserved. Designs and specifications are subject to change without notice or obligation. Read all safety instructions in the manual before usage.

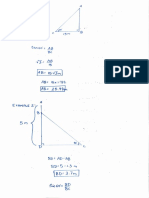

A booster is a compressor for which the inlet pressure and inlet flow are linked with the outlet pressure and outlet flow.

Selection of the booster is based on the required outlet flow and pressure.

LB 20-50hz LB 15-50hz

70 50

Outlet pressure Outlet pressure

20 bar(g) 45 20 bar(g)

60

30 bar(g) 30 bar(g)

40

40 bar(g) 40 bar(g)

50

l/s Free Air Delivery

l/s Free Air Delivery

35

30

40

25

30

20

20 15

10

10

5

0 0

1 2 3 4 5 6 7 1 2 3 4 5 6 7

Inlet booster pressure bar(g) Inlet booster pressure bar(g)

UPGRADES AND SERVICE KITS New: Atlas Copco

nitrogen skid

Rely on Atlas Copco to provide you with a complete booster package as well as a full service

Atlas Copco nitrogen

plan for the entire application chain.

generation skids are now

• Factory-mounted options: oil level switch. also available for direct

nitrogen use (40 bar) and for

• Factory-mounted and sales kits options: inlet pressure regulator (2, 3, 4, 5, 6 and 7 bar), direct use and bottling (300

high pressure 50-bar outlet filters PD/DD/QDT, inlet filters PD/DD. bar). Ask your Atlas Copco

sales representative for more

• Sales kits options: aftercooler, high pressure 40-bar vessels (270l, 500l, 1000l and 2000l).

information.

www.atlascopco.com

You might also like

- 1GRFE Engine4.0Document77 pages1GRFE Engine4.0Mauricio Andrés Montenegro71% (7)

- IPIECA - Dispersant Storage Maintenance Transport and Testing - 2017Document28 pagesIPIECA - Dispersant Storage Maintenance Transport and Testing - 2017seawolf50No ratings yet

- 325LA ENI AmplifierDocument23 pages325LA ENI Amplifierlikeike89No ratings yet

- SCANIA DC 12 Manual Del OperadorDocument58 pagesSCANIA DC 12 Manual Del OperadorMauricio Andrés Montenegro67% (3)

- $TMP MAN 102416-2001743-10 EN1 00Document639 pages$TMP MAN 102416-2001743-10 EN1 00Ricardo AzevedoNo ratings yet

- Icom IC-T2H Instruction ManualDocument50 pagesIcom IC-T2H Instruction ManualYayok S. AnggoroNo ratings yet

- Icom IC-T2H Instruction ManualDocument50 pagesIcom IC-T2H Instruction ManualYayok S. AnggoroNo ratings yet

- 1104C-44T Engine PN1644Document2 pages1104C-44T Engine PN1644Ferran Alfonso100% (1)

- Breathing Air CompressorDocument166 pagesBreathing Air CompressorMohamed AminNo ratings yet

- Atlas Copco 100 HP Variable Speed Drive Vacuum Pump Proposal # 2270294Document10 pagesAtlas Copco 100 HP Variable Speed Drive Vacuum Pump Proposal # 2270294Luis Fernando Nordhausen MartinezNo ratings yet

- 900 13 082 US Liquid Hydrogen Safetygram 9Document8 pages900 13 082 US Liquid Hydrogen Safetygram 9visutsiNo ratings yet

- Electrical BOQ For Admin ExtensionDocument8 pagesElectrical BOQ For Admin ExtensionVASANTH KATHUROJUNo ratings yet

- Kata LogDocument106 pagesKata LogOscarNo ratings yet

- PPL Avocados TescoDocument8 pagesPPL Avocados TescoLu GonzalesNo ratings yet

- Bargi (Rani Avanti Bai Lodhi Sagar) Major Irrigation Project BriefDocument6 pagesBargi (Rani Avanti Bai Lodhi Sagar) Major Irrigation Project BriefGovind M.PNo ratings yet

- ZEN AIR TECH 175H ManualDocument38 pagesZEN AIR TECH 175H ManualjassimNo ratings yet

- 2921 02 023 A0188 - Radiator Cooling Fan Motor - Technical Specification - Version1.4Document78 pages2921 02 023 A0188 - Radiator Cooling Fan Motor - Technical Specification - Version1.4aplaatul100% (1)

- JLR Production Purchasing GT&Cs 01.02.2013Document35 pagesJLR Production Purchasing GT&Cs 01.02.2013HerminaNo ratings yet

- Im 03247Document8 pagesIm 03247jefersonNo ratings yet

- Principles of Sport Management First Pages Chapter 42Document39 pagesPrinciples of Sport Management First Pages Chapter 42Meenu SofiaNo ratings yet

- SIG Motorized ValveDocument6 pagesSIG Motorized ValveAlexandre FerreiraNo ratings yet

- 36 PneumaticDocument10 pages36 PneumaticSaif AbuRummanNo ratings yet

- RCD-Revision Book-June, Dec 23-CS Muskan Gupta-Yes AcademyDocument85 pagesRCD-Revision Book-June, Dec 23-CS Muskan Gupta-Yes Academyelection urgentNo ratings yet

- Mini ProjectDocument27 pagesMini ProjectAnju MuthuNo ratings yet

- Design, Construction, Modification, Maintenance and Decommissioning of Filling StationsDocument320 pagesDesign, Construction, Modification, Maintenance and Decommissioning of Filling StationsMaurizio BusuNo ratings yet

- AquacultureModule 3 Week 2 1 FinalDocument21 pagesAquacultureModule 3 Week 2 1 FinalGerald LauglaugNo ratings yet

- Material Safety Data Sheet (MSDS) : 1. Product and CompanyDocument6 pagesMaterial Safety Data Sheet (MSDS) : 1. Product and CompanySofy Y. C.No ratings yet

- Specifications: Amp CM15RDocument2 pagesSpecifications: Amp CM15ROlivér KissNo ratings yet

- Organic Gaseous FuelsDocument108 pagesOrganic Gaseous FuelsDHANUSH KARTHIK 20BME1003No ratings yet

- Module 3 Density Altitude ExperimentDocument3 pagesModule 3 Density Altitude ExperimentIvan100% (1)

- Twintex PPS-3010 ManualDocument34 pagesTwintex PPS-3010 Manual손형모No ratings yet

- Lesson Guide 2.2 Beware of Banking FeesDocument4 pagesLesson Guide 2.2 Beware of Banking FeesKent TiclavilcaNo ratings yet

- Crodasinic HT: New Sodium Hypochlorite Bleach ThickenerDocument4 pagesCrodasinic HT: New Sodium Hypochlorite Bleach ThickenerIvanNo ratings yet

- Manual Dryer - EnglishDocument16 pagesManual Dryer - EnglishJukiRudyNo ratings yet

- Whatsapp Login: Identify, Authenticate, Engage Customers Using Whatsapp, Without Sending OtpsDocument22 pagesWhatsapp Login: Identify, Authenticate, Engage Customers Using Whatsapp, Without Sending OtpsBhavik KoladiyaNo ratings yet

- Open Bionics LTD Ob Valuation Exit Opportunities 2022Document4 pagesOpen Bionics LTD Ob Valuation Exit Opportunities 2022Dragan SaldzievNo ratings yet

- ACMEDocument3 pagesACMEKatty PintoNo ratings yet

- 2021 Medical Catalog-Nanjing Ocean Medical Products Co.,LtdDocument28 pages2021 Medical Catalog-Nanjing Ocean Medical Products Co.,LtdWang BandasackNo ratings yet

- Motor Catalogue 2018Document48 pagesMotor Catalogue 2018Pandu BirumakovelaNo ratings yet

- Quickstart Hydrostar and Hypack Seabeam 3000 Rev - DDocument43 pagesQuickstart Hydrostar and Hypack Seabeam 3000 Rev - DloghanathanNo ratings yet

- Material Safety Data Sheet: Nitric Acid, 65% MSDSDocument7 pagesMaterial Safety Data Sheet: Nitric Acid, 65% MSDSFikreslasie LemaNo ratings yet

- Power Supply, Ground & Circuit Elements: SectionDocument74 pagesPower Supply, Ground & Circuit Elements: SectionederengNo ratings yet

- Pioneer PDR-509 Disk Recorder ManualDocument40 pagesPioneer PDR-509 Disk Recorder ManualStefan LaurentiuNo ratings yet

- Chemical Nomenclature 1Document23 pagesChemical Nomenclature 1HarleenaDivsNo ratings yet

- Parryware Toilet Seats PDFDocument53 pagesParryware Toilet Seats PDFSrinivas MVNo ratings yet

- Music1-Second QuarterDocument42 pagesMusic1-Second QuarterZairah Lyn SaysonNo ratings yet

- Some Applications of TrigonometryDocument6 pagesSome Applications of TrigonometryCHHATRESH P LNo ratings yet

- Nanopowders Production and Micron-Sized Powders Spheroidazation in DC Plasma Reactors PDFDocument19 pagesNanopowders Production and Micron-Sized Powders Spheroidazation in DC Plasma Reactors PDFfishvalNo ratings yet

- Elmeasure Multifunction Meter CatalogDocument4 pagesElmeasure Multifunction Meter CatalogBoddapalli suresh100% (1)

- Tabel Comanda-Receptie Marfa NR Denumire Produs Kg/Buc Stoc: Plic MareDocument3 pagesTabel Comanda-Receptie Marfa NR Denumire Produs Kg/Buc Stoc: Plic MarePorumbacean RemusNo ratings yet

- Akshay Bora HifieldDocument62 pagesAkshay Bora Hifieldsamadhan landgeNo ratings yet

- Vueling BoardingPassDocument4 pagesVueling BoardingPassAlexandru StanNo ratings yet

- Operating Instructions SZ-7552-62-P: General Description Operating Messages and Icon StatusDocument3 pagesOperating Instructions SZ-7552-62-P: General Description Operating Messages and Icon StatusSanket SinghNo ratings yet

- SOLVICOL GB - PDS Industrial - AVEBE FAR EAST PTE LTD 9389Document2 pagesSOLVICOL GB - PDS Industrial - AVEBE FAR EAST PTE LTD 9389Ubaid Sheikh InkwalaNo ratings yet

- FIVB Official Beach Volleyball Net: User's ManualDocument28 pagesFIVB Official Beach Volleyball Net: User's ManualGurupandi MariyappanNo ratings yet

- Sample PDF of STD 12th Board Question With Solutions PCMB Sampel ContentDocument20 pagesSample PDF of STD 12th Board Question With Solutions PCMB Sampel ContentSujata ChavanNo ratings yet

- Preparation of Ultrafine Rhenium Powders by CVD Hydrogen Reduction of Volatile Rhenium OxidesDocument5 pagesPreparation of Ultrafine Rhenium Powders by CVD Hydrogen Reduction of Volatile Rhenium OxidesMario Flores SalazarNo ratings yet

- Manual G B: HD Trio 4KDocument85 pagesManual G B: HD Trio 4KWłodzimierz SurdackiNo ratings yet

- HLL HITES Approved Make ListDocument39 pagesHLL HITES Approved Make ListSUDHEESH KUMAR SNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/22Document16 pagesCambridge International AS & A Level: CHEMISTRY 9701/22The ImmortalNo ratings yet

- Qu TCS 046 22 - Thiocolchicoside Ip PDFDocument1 pageQu TCS 046 22 - Thiocolchicoside Ip PDFradha gNo ratings yet

- Striver SDE Sheet (Core) Most Asked Interview QuestionsDocument40 pagesStriver SDE Sheet (Core) Most Asked Interview QuestionsDebasish Senapaty100% (1)

- World Records in AthleticsDocument52 pagesWorld Records in Athleticssisay gebremariam100% (1)

- Important Reminders: Step 1Document4 pagesImportant Reminders: Step 1Carla Louise Bulacan BayquenNo ratings yet

- CBF VLP40-38 Prima ValvolaDocument1 pageCBF VLP40-38 Prima ValvolalucaNo ratings yet

- PL 600 ManualDocument19 pagesPL 600 ManualHelder TerraNo ratings yet

- Ic-T2H Service Manual PDFDocument28 pagesIc-T2H Service Manual PDFEduardoChiavennaNo ratings yet

- HF-90 Compact Transceiver - Aug04 - WebDocument4 pagesHF-90 Compact Transceiver - Aug04 - WebMauricio Andrés MontenegroNo ratings yet

- 3l PDFDocument2 pages3l PDFعلي عبد الرازقNo ratings yet