Professional Documents

Culture Documents

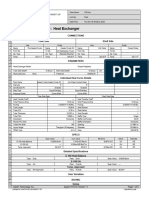

Performance of One Unit Inlet Shell Side Outlet Inlet Tube Side Outlet

Uploaded by

Mohammad Mehdi Jafari0 ratings0% found this document useful (0 votes)

62 views4 pagesThis document provides specifications for a heat exchanger unit, including:

- Performance details like fluid quantities and temperatures, pressure drop, heat transfer rates, and materials of construction

- Dimensions for the shell, tubesheet, tubes, and nozzles

- Connection details and thermal expansion design information

It contains technical specifications for a single process unit to facilitate fabrication according to standards.

Original Description:

Original Title

224450793-API-Datasheet-Heat-Exchanger.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a heat exchanger unit, including:

- Performance details like fluid quantities and temperatures, pressure drop, heat transfer rates, and materials of construction

- Dimensions for the shell, tubesheet, tubes, and nozzles

- Connection details and thermal expansion design information

It contains technical specifications for a single process unit to facilitate fabrication according to standards.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

62 views4 pagesPerformance of One Unit Inlet Shell Side Outlet Inlet Tube Side Outlet

Uploaded by

Mohammad Mehdi JafariThis document provides specifications for a heat exchanger unit, including:

- Performance details like fluid quantities and temperatures, pressure drop, heat transfer rates, and materials of construction

- Dimensions for the shell, tubesheet, tubes, and nozzles

- Connection details and thermal expansion design information

It contains technical specifications for a single process unit to facilitate fabrication according to standards.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

Client : PT VICO Indonesia Location Page 1 of 5

Process Unit : Item No. Document No.

Job No. : Fabricator

Service of unit : No. of units : …

Size : TEMA Type … Connected in … Parallel … Series

Effective surface per unit … ft2 … shells/unit … Surface/shell (eff.)

PERFORMANCE OF ONE UNIT

Inlet SHELL SIDE Outlet Inlet TUBE SIDE Outlet

Fluid Name … …

Fluid quantity, total lb/h … …

Vapour (relative molecular mass) lb/h … … … … … … … …

Liquid lb/h … … … …

Steam lb/h … … … …

Water lb/h … … … …

Noncondensable/ relative molecular mass lb/h / /

Temperature ⁰F … … … …

Density (vapour/liquid) lb/ft3

Viscosity cP

Specific heat (vapour/liquid) Btu/(lb-⁰F)

Thermal conductivity (vapour/liquid) Btu/(h-ft-⁰F)

Specific latent heat Btu/lb @ ⁰F @ @

Inlet pressure psig … …

Velocity ft/s … …

Pressure drop (alowable/calculated) psig

Fouling resistance h-ft2-⁰F/Btu … …

Average ifilm coefficient Btu/(h-ft-⁰F) … …

Heat Exchanged Btu/h Mean temp. diff., MTD (corrected) (weighted)

Heat transfer rate (required/fouled/clean) Btu/(h-ft-⁰F) …/…/…

ρV2 [lb/ft.s2]: Inlet Nozzle … Bundle entrance … Bundle exit

CONSTRUCTION PER SHELL

Tube No. … OD … in NOZZLES - No., Size and Rating

Thickness … SHELL SIDE TUBE SIDE

Pitch … Inlet … …

Length … Outlet … …

Tube-tubesheet joint … Intermediate … …

Shell diameter (ID/OD) … / … in Vent … …

Cross-baffle type … Drain … …

Spacing : c/c … in No. of crosspasses … Pressure relief … …

% Cut Design pressure psig … …

Tube support type Vacuum pressure psia … …

Long baffle seal type Design temp. (Max/MDMT) ⁰F …/… …/…

Bypass seal type No.of passes per shell … …

Impingement protection (Y/N) Corrosion allowance in … …

MATERIAL OF CONSTRUCTION

Shell … Tubes … Gaskets :

Shell cover … Shell side …

Channel or bonnet … Tube side …

Channel cover … Floating head …

Floating head cover/bolts … Spare sets req'd …

Tubesheet Stat. … Floating … Test ring req'd (Y/N) …

Baffles : Cross. … Long … Insullation : shell …

Tube support material … Channel inlet/exit …

Expansion joint type … Expansion joint material …,…

Pressure design code … Stamp … Calc. MAWP (Y/N) … TEMA Class …

REMARKS : …

Originator/ Check : … / … Approved Issue Date : Issue No.

Job No. Page 2 of 5

Client

Location

Item No.

Document No. Issue No.

CONNECTION SCHEDULE (Optional) THERMAL EXPANSION DESIGN INFORMATION (Optional)

Shell Shell Tubesheet Tube

Mark No. req'd Size Rating Facing Description Tube press.

mean metal press. mean metal mean metal

Psig

temp. ⁰F Psig temp. ⁰F temp. ⁰F

Design

Normal

Starting

Shutdown

Upset #1

Upset #2

Steam out

Expansion joint esign life cycles

MATERIALS OF CONSTRUCTION (Optional) Corr. allow.

Shell : … in

Head : … in

Pipe/stub ends : … in

Nozzle necks : … in

Nozzle flanges : … in

Body flanges : … in

Expansion joint : … in

Support … in

Bolting (internal) : … in

Bolting (eksternal) : … in

Nozzle reinforcement : … in

Tubes : … in

Tubesheets : … in

Bonnet/channel : … in

Bonnet head (s) … in

Channel cover (s) … in

Body flanges : … in

Pipe/stub ends : … in

Bolting (internal) : … in

Bolting (eksternal) : … in

Nozzle reinforcement : … in

Nozzle necks : … in

Nozzle flanges : … in

Baffles, spacers, tie rods : … in

GASKETS (Optional) MECHANICAL DATA (Optional)

Shell side : … Thickness : … in MAWP (hot and corroded) : psi

у= psi m= MAP (new and cold) : psi

Tube side : Thickness : … in Hydrotest pressure :

у= psi m= Field : psig Shop : psig

Floating head Thickness : … in Masses : Empty : lb Bundle : lb

у= psi m= Full of water lb

Job No. Page 3 of 5

Client

Location

Item No.

Document No. Issue No.

ADDITIONAL REMARKS, SKETCHES, ETC. (Optional)

Job No. Page 4 of 5

Client

Location

Item No.

Document No. Issue No.

Fluid Name .. Ref. Pressure 1 : … psi (abs)

Pressure Temp. Enthalpy

psi (abs) ⁰F Btu/lb

Density Viscosity Thermal Sp. Heat

Vapour Vapour Cond. Vap Vapour

lb/ft3 cP Btu/(h-ft-⁰F) Btu/(lb-⁰F)

You might also like

- DS 26-101 - IsO 16812 Shell and Tube Heat Exchangers API 660 - 0900a8668013a8feDocument1 pageDS 26-101 - IsO 16812 Shell and Tube Heat Exchangers API 660 - 0900a8668013a8feFernando RomeroNo ratings yet

- Heat Exchanger Specification Sheet: Btu / H ft2 °FDocument1 pageHeat Exchanger Specification Sheet: Btu / H ft2 °FDesiree MolinaNo ratings yet

- Shell and Tube Heat ExchangerDocument1 pageShell and Tube Heat ExchangerNurulHiNo ratings yet

- T 9 HxspecenglishDocument1 pageT 9 Hxspecenglishkinjalpatel12345No ratings yet

- Shell and Tube Heat Exchanger Specification Sheet: (Inlet) Shell Side (Outlet) (Inlet) Tube Side (Outlet)Document5 pagesShell and Tube Heat Exchanger Specification Sheet: (Inlet) Shell Side (Outlet) (Inlet) Tube Side (Outlet)John BenderNo ratings yet

- TEMA Data SheetDocument2 pagesTEMA Data SheetKarthik AnandanNo ratings yet

- Units-Dimensions-Pet EngrgDocument16 pagesUnits-Dimensions-Pet EngrgolaseyeNo ratings yet

- Section 19Document97 pagesSection 19rahmat mamuriNo ratings yet

- Heat Exchanger Rating SheetDocument2 pagesHeat Exchanger Rating SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- BTÑ HTDS - H 10Document1 pageBTÑ HTDS - H 10Juan Pablo Sanchez MelgarejoNo ratings yet

- ARNU15GM1A4: Btu/h Indoor UnitDocument2 pagesARNU15GM1A4: Btu/h Indoor UnitCristian monsalve mendozaNo ratings yet

- ChE 301 PartII Lecture IVDocument45 pagesChE 301 PartII Lecture IVMahmudur Rahman RiadNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Welltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010Document4 pagesWelltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010ElrohirPendragonNo ratings yet

- Ac-8 DSDocument2 pagesAc-8 DSOwais AhmedNo ratings yet

- HX Design ProjectDocument2 pagesHX Design ProjectKashan AslamNo ratings yet

- Datasheet - Boiler-Superheater-EconomizerDocument1 pageDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNo ratings yet

- Customer Project No. by Project Tag Checked Location Date Revision ServiceDocument3 pagesCustomer Project No. by Project Tag Checked Location Date Revision ServiceAdministrador de ContratoNo ratings yet

- ARNU60GM3A4: Btu/h Indoor UnitDocument2 pagesARNU60GM3A4: Btu/h Indoor UnitCristian monsalve mendozaNo ratings yet

- STEAMcalc 12.8 RupiahDocument1,009 pagesSTEAMcalc 12.8 RupiahlightsonsNo ratings yet

- Customer Project No. by Project Tag Checked Location Date Revision ServiceDocument3 pagesCustomer Project No. by Project Tag Checked Location Date Revision ServiceAdministrador de ContratoNo ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument89 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionAsad KhanNo ratings yet

- Hexch TemplateDocument1 pageHexch TemplatejtirentiNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- Load Calculation - Bar Mill - 20 02 2020Document15 pagesLoad Calculation - Bar Mill - 20 02 2020DARA SINGH100% (1)

- ARNU243M2A4: Multi V™ High Static DuctedDocument2 pagesARNU243M2A4: Multi V™ High Static DuctedJean Carlo Arrieta100% (1)

- SB MultiVIV HighStaticDucted ARNU073BHA4!7!16Document2 pagesSB MultiVIV HighStaticDucted ARNU073BHA4!7!16Edison MendozaNo ratings yet

- Aisalmiento Termico Tablas EjemplosDocument20 pagesAisalmiento Termico Tablas EjemplosMARTIN FRANCISCO RIOS QUIÑONESNo ratings yet

- Plate Heat Exchanger Data SheetDocument2 pagesPlate Heat Exchanger Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Utility TPR2 Semi HS 3 Retort CBP32Document1 pageUtility TPR2 Semi HS 3 Retort CBP32JHONATAN ALEXANDER YANEZ CHANCUSIGNo ratings yet

- Tema Style HX DatasheetDocument1 pageTema Style HX Datasheet404FileNotFoundNo ratings yet

- Performance of One UnitDocument1 pagePerformance of One Unitkinjalpatel12345No ratings yet

- Submittal - High Static Ducted - ARNU763B8A4Document2 pagesSubmittal - High Static Ducted - ARNU763B8A4RedHammerNo ratings yet

- Fraccionamiento y AbsorciónDocument36 pagesFraccionamiento y AbsorciónWilder GanozaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- SB MultiVIV HighStaticDucted ARNU123BHA4 4 16Document2 pagesSB MultiVIV HighStaticDucted ARNU123BHA4 4 16geotatiguiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Ejectors and Jet Pumps - Design For Steam Driven FlowDocument92 pagesEjectors and Jet Pumps - Design For Steam Driven FlowtjutjuNo ratings yet

- ARNU36GTNC4Document2 pagesARNU36GTNC4Edgard Chara CarhuayoNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- SB MultiVIV WallMount Stand ARNU053SBL4 04 15 20150504133047Document2 pagesSB MultiVIV WallMount Stand ARNU053SBL4 04 15 20150504133047geotatiguiNo ratings yet

- The Production of Syrene From Methanol and TolueneDocument261 pagesThe Production of Syrene From Methanol and TolueneNizar MousaNo ratings yet

- Ssubmittal - High Static Ducted - ARNU543BRA4Document2 pagesSsubmittal - High Static Ducted - ARNU543BRA4RedHammerNo ratings yet

- Damper Datasheet FormDocument1 pageDamper Datasheet FormharishcsharmaNo ratings yet

- API Datasheet Heat ExchangerDocument4 pagesAPI Datasheet Heat ExchangerSoraya ZahraNo ratings yet

- SB Multiviv Wallmount Stand Arnu243scl4!04!15 20150504133438Document2 pagesSB Multiviv Wallmount Stand Arnu243scl4!04!15 20150504133438geotatiguiNo ratings yet

- Heat Exchanger: E-100: Connections Tube Side Shell SideDocument8 pagesHeat Exchanger: E-100: Connections Tube Side Shell SideJuan CarlosNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Ea 102Document2 pagesEa 102Najmul SaqibNo ratings yet

- Prepared By: THAMARAIKANNAN Requested By: Tuesday, February 20, 2018Document16 pagesPrepared By: THAMARAIKANNAN Requested By: Tuesday, February 20, 2018thamaraikannanNo ratings yet

- Heat Exchanger Sizing E-3010A #1Document2 pagesHeat Exchanger Sizing E-3010A #1Luis Enrique Leyva Ovalle100% (1)

- HD - Cambiador de Calor PDFDocument1 pageHD - Cambiador de Calor PDFAtomic JNo ratings yet

- Aircooled Heat Exchanger Process Data SheetDocument2 pagesAircooled Heat Exchanger Process Data SheetamitkrayNo ratings yet

- Catalogo Baylan Modelo Tk5c 40mmDocument1 pageCatalogo Baylan Modelo Tk5c 40mmJeffersonNo ratings yet

- Simple Heat ExchangerDocument9 pagesSimple Heat ExchangerAbdullah KutbiNo ratings yet

- Submittal - High Static Ducted - ARNU363BGA4Document2 pagesSubmittal - High Static Ducted - ARNU363BGA4RedHammerNo ratings yet

- Cast Iron: Physical and Engineering PropertiesFrom EverandCast Iron: Physical and Engineering PropertiesRating: 5 out of 5 stars5/5 (1)

- 2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetDocument1 page2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetMohammad Mehdi JafariNo ratings yet

- An Explanation of The Echo - To-Echo Measurement TechniqueDocument1 pageAn Explanation of The Echo - To-Echo Measurement TechniqueMohammad Mehdi JafariNo ratings yet

- Instrument Air CalculationDocument11 pagesInstrument Air CalculationMohammad Mehdi Jafari67% (3)

- 2009 Separator CalcsDocument18 pages2009 Separator CalcsneelNo ratings yet

- Distillation Theoretical Stages CalculatorDocument687 pagesDistillation Theoretical Stages CalculatorgrabettyNo ratings yet

- Hbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsDocument2 pagesHbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsMohammad Mehdi JafariNo ratings yet

- Heat Exchanger Datasheet Secondary Air Cooler E 102: Nitric Acid FacilitiesDocument2 pagesHeat Exchanger Datasheet Secondary Air Cooler E 102: Nitric Acid FacilitiesMohammad Mehdi JafariNo ratings yet

- Crane Fluid Flow Problems Hof MasterDocument280 pagesCrane Fluid Flow Problems Hof MasterMohammad Mehdi JafariNo ratings yet

- Expansion Joint: Alireza @argh53Document33 pagesExpansion Joint: Alireza @argh53Mohammad Mehdi JafariNo ratings yet

- Crane Vs Eqvlnt Length Method For FittingsDocument177 pagesCrane Vs Eqvlnt Length Method For FittingsSamuel OnyewuenyiNo ratings yet

- Design of Shell & Tube HXDocument45 pagesDesign of Shell & Tube HXAnonymous yLPPdPwNo ratings yet

- Ips C Pi 410 PDFDocument29 pagesIps C Pi 410 PDFMohammad Mehdi JafariNo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- ANSI B16.5 FlangesDocument24 pagesANSI B16.5 FlangesbrjsekarNo ratings yet

- Kta50 G3Document2 pagesKta50 G3zzapieche0% (1)

- API Separators - SolutionsDocument8 pagesAPI Separators - SolutionsnorthstarleoNo ratings yet

- Heat Exchanger Application Data SheetDocument2 pagesHeat Exchanger Application Data SheetMohammad Mehdi JafariNo ratings yet

- Kta50 G3Document2 pagesKta50 G3zzapieche0% (1)

- KTA50-G8 - PI734B mmj100Document10 pagesKTA50-G8 - PI734B mmj100Mohammad Mehdi JafariNo ratings yet

- A0V5U9 - Response To NEB IR 2 Southern Access Upstream Expansion Appendix ADocument29 pagesA0V5U9 - Response To NEB IR 2 Southern Access Upstream Expansion Appendix AMohammad Mehdi JafariNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- Amca Publication 1011-03: Certified Ratings Program - Product Rating Manual For Acoustical Duct SilencersDocument18 pagesAmca Publication 1011-03: Certified Ratings Program - Product Rating Manual For Acoustical Duct SilencersMohammad Mehdi JafariNo ratings yet

- Technical Data: 1300KW / 1625KVA 1100KW / 1375KVADocument5 pagesTechnical Data: 1300KW / 1625KVA 1100KW / 1375KVAMohammad Mehdi JafariNo ratings yet

- Kta50 G3Document2 pagesKta50 G3zzapieche0% (1)

- Smart FlangeDocument2 pagesSmart FlangeMohammad Mehdi JafariNo ratings yet

- Drawing Management StandardDocument25 pagesDrawing Management StandardMohammad Mehdi JafariNo ratings yet

- E11-Revision 6 (The 2ND Term-Units 9-12)Document5 pagesE11-Revision 6 (The 2ND Term-Units 9-12)Đỗ Cát TiênNo ratings yet

- Science QuestionsDocument1 pageScience QuestionsRhea PardiñasNo ratings yet

- Design Parameters of 10kw Floating Solar Power PlantDocument6 pagesDesign Parameters of 10kw Floating Solar Power Plantg v aparnaNo ratings yet

- Hwsol 2Document2 pagesHwsol 2Vipin GuptaNo ratings yet

- Futtsu Power PlantDocument49 pagesFuttsu Power PlantJericho CruzNo ratings yet

- Terani FormationDocument19 pagesTerani FormationMoh'd AfzalNo ratings yet

- Development of Biogas Compression System For Using in HouseholdDocument6 pagesDevelopment of Biogas Compression System For Using in Householdanand sahuNo ratings yet

- 370 688 1 PBDocument6 pages370 688 1 PBSaiful RahmanNo ratings yet

- Handout - 2 - Physical States of MatterDocument12 pagesHandout - 2 - Physical States of MatterHarun ÖzdemirNo ratings yet

- Elutriation: R K, Essen, GermanyDocument14 pagesElutriation: R K, Essen, GermanyRay CNo ratings yet

- Me 312cpdfDocument241 pagesMe 312cpdfEricson PalsarioNo ratings yet

- Lab Heat EnergyDocument8 pagesLab Heat EnergyFaruk IbrahimovicNo ratings yet

- Chapter 9 Microbial GrowthDocument32 pagesChapter 9 Microbial GrowthGeneNo ratings yet

- Reaction MechanismDocument14 pagesReaction MechanismMasterJEE SPSNo ratings yet

- Import and Export of Electrical Energy 170510Document20 pagesImport and Export of Electrical Energy 170510dumprec1No ratings yet

- Module 7 Volnerabilities of Different Elements Exposed To HazardsDocument9 pagesModule 7 Volnerabilities of Different Elements Exposed To HazardsJinky AydallaNo ratings yet

- Air Separation Process Primer - Air LiquideDocument28 pagesAir Separation Process Primer - Air LiquideОскар ЛинаресNo ratings yet

- Objectives of Learning This Subject: Integrated Building Management Systems (IBMS)Document89 pagesObjectives of Learning This Subject: Integrated Building Management Systems (IBMS)Abdulrahim NuktaNo ratings yet

- Ecosystem Threats WorksheetDocument2 pagesEcosystem Threats WorksheetDareNo ratings yet

- Determination of Degree of Saturation of Soil Samples by B Value MeasurementDocument5 pagesDetermination of Degree of Saturation of Soil Samples by B Value Measurementcamillelele100% (1)

- Week 5 - Chemistry - Third Form - Test # 1Document9 pagesWeek 5 - Chemistry - Third Form - Test # 1Miguel BonillaNo ratings yet

- Soil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteDocument23 pagesSoil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteiliavaNo ratings yet

- Chemical Reaction and Balancing Chemical EquationDocument36 pagesChemical Reaction and Balancing Chemical EquationChelsia Venice MorilloNo ratings yet

- Product Fiche: P/NO: MBM38202935 (1411-REV11) Printed in KoreaDocument2 pagesProduct Fiche: P/NO: MBM38202935 (1411-REV11) Printed in KoreaCaraman ConstantinNo ratings yet

- Jee Main-2023 - Important Replica QS - PhysicsDocument106 pagesJee Main-2023 - Important Replica QS - PhysicsAryan GuptaNo ratings yet

- Theory Change: For Community-Based ConservationDocument34 pagesTheory Change: For Community-Based ConservationhanggarPKNo ratings yet

- ECM216 BUILDING SERVICES Bab 1.2 Electrical Power SystemDocument4 pagesECM216 BUILDING SERVICES Bab 1.2 Electrical Power SystemAZUAN BIN AHMAD FAUZINo ratings yet

- MCL 730 Lab: 3 Designing With Advanced Materials Date:23/01/2019Document1 pageMCL 730 Lab: 3 Designing With Advanced Materials Date:23/01/2019Akhilesh Dadaniya PatidarNo ratings yet

- 22ESC142 Module 5Document9 pages22ESC142 Module 5Aditya Kumar SinghNo ratings yet

- Remedies Against Natural CalamitiesDocument16 pagesRemedies Against Natural CalamitiesSyed Hamdan100% (1)