Professional Documents

Culture Documents

BS 970 En8 PDF

BS 970 En8 PDF

Uploaded by

sampathkumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS 970 En8 PDF

BS 970 En8 PDF

Uploaded by

sampathkumarCopyright:

Available Formats

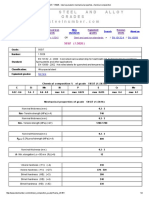

Material properties

Material En9 (United Kingdom / B.S.)

Group Structural and constructional steels

Subgroup BS 970 Carbon manganese steel; Wrought product

Comment Steel for mechanical and allied engineering purposes. Superseded by BS 970-1, BS 970-4, BS

970-5, BS 970-6

Application

Yield Stress[MPa]

Dimension Min Max Approx

Bar, billet, forging; R - Hardened and Tempered; d <= - - 463

50.8 mm

Bar, billet, forging; S - Hardened and Tempered; d <= - - 510

28.6 mm

Bar, billet, forging; T - Hardened and Tempered; d <= - - 556

28.6 mm

Bar, billet, forging; Normalized; d <= 101.6 mm - - 355

Tensile Stress[MPa]

Dimension Min Max Approx

Bar, billet, forging; R - Hardened and Tempered; d <= 695 - -

50.8 mm

Bar, billet, forging; S - Hardened and Tempered; d <= 772 - -

28.6 mm

Bar, billet, forging; T - Hardened and Tempered; d <= 849 - -

28.6 mm

Bar, billet, forging; Normalized; d <= 101.6 mm 695 - -

Bar, billet, forging; Cold Drawn; d <= 101.6 mm 772 1004 -

Elongation A5 [%]

Dimension Min Max Approx

Bar, billet, forging; R - Hardened and Tempered; d <= 18.0 - -

50.8 mm

Note: Elong. 4 sqr (cross sectional area %)

Bar, billet, forging; S - Hardened and Tempered; d <= 18.0 - -

28.6 mm

Note: Elong. 4 sqr (cross sectional area %)

Bar, billet, forging; T - Hardened and Tempered; d <= 15.0 - -

28.6 mm

Note: Elong. 4 sqr (cross sectional area %)

Page 1

All Rights Reserved © 1999-2005 INI International

Elongation A5 [%]

Dimension Min Max Approx

Bar, billet, forging; Normalized; d <= 101.6 mm 18.0 - -

Note: Elong. 4 sqr (cross sectional area %)

Bar, billet, forging; Cold Drawn; d <= 101.6 mm 12.0 - -

Note: Elong. 4 sqr (cross sectional area %)

Hardness

Dimension Hardness

Bar, billet, forging; R - Hardened and Tempered; d <= 201-255 HB

50.8 mm

Bar, billet, forging; S - Hardened and Tempered; d <= 223-277 HB

28.6 mm

Bar, billet, forging; T - Hardened and Tempered; d <= 248-302 HB

28.6 mm

Bar, billet, forging; Normalized; d <= 101.6 mm 201-255 HB

Bar, billet, forging; Cold Drawn; d <= 101.6 mm 223-302 HB

Chemical Composition [%]

Criterion Min Max Approx

C 0.5000 0.6000 -

Si 0.0500 0.3500 -

Mn 0.5000 0.8000 -

P - 0.0600 -

S - 0.0600 -

Heat Treatment

Material shall be supplied in one of the following conditions:

1) Normalizing: 810-840 C;

2) Hardening (quenching in oil): 810-840 C;

Tempering: 550-660 C

Page 2

All Rights Reserved © 1999-2005 INI International

Cross Reference Table

Material Standard Country

AF 70 AFNOR NF France

C 55 E AFNOR NF France

C 54 AFNOR NF France

2 C 55 AFNOR NF France

C 55 AFNOR NF France

1055 AISI USA

1055 AS Australia

SA-29 1055 ASME USA

A 576 1055 ASTM USA

A 29 1055 ASTM USA

A 682 Grade 1055 ASTM USA

A 713 Grade 1055 ASTM USA

A 510 1055 ASTM USA

C 55 E B.S. United Kingdom

1 C 55 B.S. United Kingdom

C 55 B.S. United Kingdom

En9K B.S. United Kingdom

070 M 55 B.S. United Kingdom

55 BDS Bulgaria

12060 CSN Czech Republic

C 55 DIN Germany

C55E DIN Germany

Ck 55 DIN Germany

1 C 55 EN European Union

1 CS 55 EN European Union

2 CS 55 EN European Union

1.1203 EN European Union

2 C 55 EN European Union

1.0535 EN European Union

C 55 EN European Union

C 55 E EN European Union

ZG340-640 (ZG 55) GB China

55 GB China

55 GOST Russia

S 55 C JIS Japan

S 55 C-CSP JIS Japan

C 1630 JUS Yugoslavia

C 1631 JUS Yugoslavia

Page 3

All Rights Reserved © 1999-2005 INI International

Cross Reference Table

Material Standard Country

C 55 NBN Belgium

C 55 E NBN Belgium

C 55 NS Norway

C 55 E NS Norway

55 PN Poland

1055 SAE USA

1655 SS Sweden

OLC 55 A STAS Romania

OLC 55 STAS Romania

OLC 55 X STAS Romania

C 55 E (2 C 55) UNE Spain

C 55 (1 C 55) UNE Spain

C 55 UNI Italy

1 C 55 UNI Italy

C 55 E UNI Italy

G10550 UNS USA

1.1203 WN Germany

1.0535 WN Germany

Page 4

All Rights Reserved © 1999-2005 INI International

You might also like

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- S500 Grade Steel SpecificationsDocument2 pagesS500 Grade Steel SpecificationsSmriti Agarwalla100% (1)

- Base Plate Design BSDocument4 pagesBase Plate Design BSvinujohnpanickerNo ratings yet

- RC Product and Tech Tranining 2006Document226 pagesRC Product and Tech Tranining 2006amin peyvandNo ratings yet

- Saddle-Design-Operating - FinalDocument17 pagesSaddle-Design-Operating - FinalSiva baalan75% (4)

- MAT 2011 MCGB - Data Sheet For Suppliers Old MAT No.: 142Document3 pagesMAT 2011 MCGB - Data Sheet For Suppliers Old MAT No.: 142deepak kumarNo ratings yet

- BS 970 070 M46Document2 pagesBS 970 070 M46Dinesh GaikwadNo ratings yet

- SA-193 Grade B7 (USA / ASME)Document2 pagesSA-193 Grade B7 (USA / ASME)Boudali ElbouazzaouiNo ratings yet

- Sae J 403-Aisi 1042 1045 - ForminDocument2 pagesSae J 403-Aisi 1042 1045 - ForminKenvi AlarconNo ratings yet

- 1 5736Document2 pages1 5736solidwormNo ratings yet

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- Material Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GroupDocument1 pageMaterial Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GrouphdierkeNo ratings yet

- Metric DIN 6885 SpecDocument4 pagesMetric DIN 6885 SpecDobrica PetrovicNo ratings yet

- 20160323093435-52CrMoV4 (51CrMoV4) PDFDocument1 page20160323093435-52CrMoV4 (51CrMoV4) PDFMartin HristovNo ratings yet

- 20160323093435-52CrMoV4 (51CrMoV4)Document1 page20160323093435-52CrMoV4 (51CrMoV4)Martin HristovNo ratings yet

- Aluminum 2014-T6 2014-T651: Metal Nonferrous Metal Aluminum Alloy 2000 Series Aluminum AlloyDocument3 pagesAluminum 2014-T6 2014-T651: Metal Nonferrous Metal Aluminum Alloy 2000 Series Aluminum Alloyvishwanadh kNo ratings yet

- Polywear 60 GtawDocument1 pagePolywear 60 GtawFlori MovNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeMartin HristovNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeMartin HristovNo ratings yet

- X30 CR 13Document2 pagesX30 CR 13deepak_pokharnaNo ratings yet

- Din 17200 C45Document1 pageDin 17200 C45Afriza NurdiansyahNo ratings yet

- Polywear 50 Gtaw 1Document1 pagePolywear 50 Gtaw 1Flori MovNo ratings yet

- Code Inner Code MaterialDocument12 pagesCode Inner Code MaterialBahadır HarmancıNo ratings yet

- Callout - 10.1 - MJHDocument12 pagesCallout - 10.1 - MJHBahadır HarmancıNo ratings yet

- Datasheet For Steel Grades Carbon Steel AFNOR XC 48Document2 pagesDatasheet For Steel Grades Carbon Steel AFNOR XC 48Arpad SzeriNo ratings yet

- PDF Katalog BallscrewsDocument32 pagesPDF Katalog BallscrewsSaka WahyuNo ratings yet

- Restriction Orifice T95500enDocument2 pagesRestriction Orifice T95500enCarlos SopasNo ratings yet

- Hot Rolled Concrete Reinforcing Stretched Coils: Rivafil B500ADocument4 pagesHot Rolled Concrete Reinforcing Stretched Coils: Rivafil B500AAmro HassaninNo ratings yet

- 10BFFRM2D0Document4 pages10BFFRM2D0Diego BarriosNo ratings yet

- Data Sheet SA 517 GRPDocument2 pagesData Sheet SA 517 GRPwajdiNo ratings yet

- Drill, 15.5mm 12xD, RT 100 U, Carbide, nano-FIREX, Coolant ThroughDocument1 pageDrill, 15.5mm 12xD, RT 100 U, Carbide, nano-FIREX, Coolant ThroughFarzad MirzavandNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089farshid KarpasandNo ratings yet

- High Speed Steel Round BarDocument4 pagesHigh Speed Steel Round BarMANJEET KUMARNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General Informationabu asiyahNo ratings yet

- O-Ring CalculatorDocument1 pageO-Ring CalculatorMatyas TakacsNo ratings yet

- SAE 1060 Ficha TecnicaDocument2 pagesSAE 1060 Ficha TecnicaDECRO EIRLNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- Material Jis SS400Document2 pagesMaterial Jis SS400ramdikaNo ratings yet

- كتالوج الشيلراتDocument54 pagesكتالوج الشيلراتFathy RakhaNo ratings yet

- MS20001 MS20001: Structural Extruded HingeDocument1 pageMS20001 MS20001: Structural Extruded Hingerobiny100% (1)

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- Din 9427 - Metric Socket Button Head Cap ScrewsDocument1 pageDin 9427 - Metric Socket Button Head Cap ScrewsAlexis BarolinNo ratings yet

- En 353Document3 pagesEn 353anush_swaminathanNo ratings yet

- RK1B7 A193b7m - A193b7 A193b7m EngDocument1 pageRK1B7 A193b7m - A193b7 A193b7m EngNarimane BentyNo ratings yet

- European Steel and Alloy Grades: About Us EN 10248-1Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandNo ratings yet

- FCD 450-10Document2 pagesFCD 450-10MohammedFaisalGirachNo ratings yet

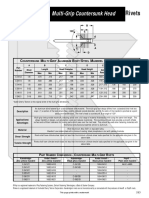

- Rivets Multi Grip CountersunkDocument1 pageRivets Multi Grip CountersunkIsrael OluwagbemiNo ratings yet

- Sumihard 500 (ASM 500)Document2 pagesSumihard 500 (ASM 500)jose wanderleyNo ratings yet

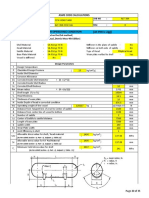

- 77e5-B005 (Hydraulic Cylinder)Document4 pages77e5-B005 (Hydraulic Cylinder)Sandeep JoshiNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Seamless Fiux Fored Wire - Megafil250Document1 pageSeamless Fiux Fored Wire - Megafil250SungJun ParkNo ratings yet

- Fluid Power Metric Catalogue 2018 780 WebDocument8 pagesFluid Power Metric Catalogue 2018 780 WebPRASHANT KANTENo ratings yet

- Cobalt Catalog Forged-Chains-SprocketsDocument12 pagesCobalt Catalog Forged-Chains-SprocketsporometalNo ratings yet

- Material Datasheet C45: 1. SteelmakingDocument1 pageMaterial Datasheet C45: 1. SteelmakingSETHUBALAN B 15BAU033No ratings yet

- Tyco Grinnell Grooved CouplingDocument4 pagesTyco Grinnell Grooved Couplingprvns0074377No ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet