Professional Documents

Culture Documents

Catalyzing Commercialization: Converting Waste Heat Into Electrical Power

Catalyzing Commercialization: Converting Waste Heat Into Electrical Power

Uploaded by

ÅdnAn MehmOod0 ratings0% found this document useful (0 votes)

5 views1 pageOriginal Title

20161214.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageCatalyzing Commercialization: Converting Waste Heat Into Electrical Power

Catalyzing Commercialization: Converting Waste Heat Into Electrical Power

Uploaded by

ÅdnAn MehmOodCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Catalyzing Commercialization

waste-heat streams of existing indus-

Converting Waste Heat into Electrical Power trial infrastructure without compromis-

ing upstream processes. Thanks to its

W aste heat is an enormous and

largely untapped source of

low-cost energy. More than half of

gap onto the PV chip. The low-bandgap

PV chip converts the IR light into elec-

tric power, similar to the way a solar

small footprint, the MTPV EBLADE

Power Platform has an ideal form fac-

tor for installation into the production

the energy consumed in the world cell converts sunlight into electricity. facilities of some of the world’s largest

escapes into the atmosphere in the Thermophotovoltaic (TPV) tech- industries, such as oil and gas explora-

form of waste heat. With global nology is not new. TPV devices were tion, petrochemicals, and chemical

energy demand projected to increase developed in the early 1960s, but processing, as well as glass, steel, and

by nearly 50% by 2040, and elec- widespread adoption of the technol- cement manufacturing.

tricity demand expected to grow by ogy has been hindered by high mate- The heat-to-power production of

nearly 70% within the same time rial costs and inherently low energy the MTPV system will be based on the

frame, the magnitude of the waste- flux. The MTPV approach changes plant’s exhaust fluegas temperatures,

heat problem becomes daunting. the economic equation by creating composition, and mass flowrates. For

With support from the National Sci- substantially more power in the same example, a furnace used to manufac-

ence Foundation, MTPV Power Corp. footprint. ture glass typically produces exhaust

has developed a device that converts By reducing the gap between the gases at temperatures of 800–1,400°C

waste heat directly into electricity. two chips, MTPV Power has signifi- at a thermal rate of 17 MBtu/hr (about

Based on the company’s proprietary cantly increased the amount of energy 5 MJ/s or 5 MW).

micron-gap thermophotovoltaic that is transferred between the emitter In a typical installation, multiple

technology, the system consists of two and the receiver. Thermal energy MTPV devices would gain access to

chips — a hot emitter chip and a cooler that would get trapped inside the the waste heat energy through ports

receiver photovoltaic (PV) chip — body of the emitter in a conventional in the flue wall, with the thermal

separated by a very small gap (< 1 μm). TPV system is instead transferred energy radiating from the hot walls to

Waste heat from an industrial facility by evanescent coupling of radiation. the emitter chips. As many as 20 or

directly heats the emitter chip, which Because the gap is so small, energy more MTPV systems can be placed

radiates infrared light across the small transfer rates significantly higher than in each flue, and with two flues per

conventional TPVs can be achieved. furnace, the expected power output

The patented approach to creating (from recovered waste heat) from

and maintaining this gap at extreme each glass furnace is up to 200 kW to

temperature differentials is key to the 1 MW. This power would offset up to

commercialization of the technology. $600,000 in annual electricity expenses

MTPV’s compact, modular sys- at the U.S. average industrial cost of

tems can be easily retrofitted into the $0.07/kW-hr. Savings would be sig-

nificantly greater in high-cost locations

such as California ($0.136/kW-hr),

Germany ($0.155/kW-hr), and Italy

($0.26/kW-hr).

MTPV Power is deploying pilot-

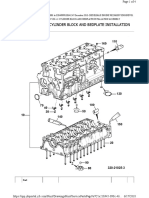

pu MTPV Power Corp.’s heat- scale systems to customers in prepara-

to-power system employs arrays tion for full commercial launch and is

of emitter and PV semiconductor developing strategic partnerships to

chips (red) to convert industrial-

penetrate initial markets, with a focus

scale waste heat into electricity.

In an industrial glass furnace on heat environments with temperatures

application, sets of 4 MTPV in the 600–1,400°C range generating

EBLADE Power Platform devices up to tens of MW of output. CEP

are deployed along the length

and through the walls of a flue This technology was funded through the NSF

conveying hot exhaust gases. Small Business Innovation Research Program.

This article was prepared by the National Science Foundation in partnership with CEP.

14 www.aiche.org/cep Month Year CEP

You might also like

- Chap 4 DC Biasing BJTDocument44 pagesChap 4 DC Biasing BJTUgeswran ThamalinggamNo ratings yet

- Yanmar Fault Codes ListDocument2 pagesYanmar Fault Codes ListJonas SvidinskasNo ratings yet

- Inverter Sizing of Grid-Connected Photovoltaic Systems in The Light of Local Solar Resource Distribution Characteristics and TemperatureDocument14 pagesInverter Sizing of Grid-Connected Photovoltaic Systems in The Light of Local Solar Resource Distribution Characteristics and TemperatureFrancisco José Murias DominguezNo ratings yet

- EE2451 EEGUC Hand WrittenDocument256 pagesEE2451 EEGUC Hand Writtensrivaas131985100% (1)

- Prima T2 Operation Manual PDFDocument34 pagesPrima T2 Operation Manual PDFsantiagocapera100% (1)

- Commissioning of Pipe and Flare Stack PDFDocument13 pagesCommissioning of Pipe and Flare Stack PDFABRAHAM ESTRADANo ratings yet

- 380engine Parts ManualDocument108 pages380engine Parts Manualkokila infraltdNo ratings yet

- Common Faults and DetectionDocument8 pagesCommon Faults and DetectionMohammad Jahid AlamNo ratings yet

- Compressed Earth Blocks - Open Source EcologyDocument7 pagesCompressed Earth Blocks - Open Source EcologyCristina BotezNo ratings yet

- Solar Gas Turbine SystemsDocument10 pagesSolar Gas Turbine SystemsARRI1100% (1)

- NEXTracker Support Services MKT 000040 Rev A.XDocument2 pagesNEXTracker Support Services MKT 000040 Rev A.XStenio ArcelinoNo ratings yet

- Philippine Distribution CodeDocument3 pagesPhilippine Distribution CodeMichael AnchetaNo ratings yet

- Wind Energy SystemsDocument16 pagesWind Energy SystemsMônica BuenoNo ratings yet

- 4JVP44 We 0111Document238 pages4JVP44 We 0111Elkin Martínez SilvaNo ratings yet

- Double Block and Bleed Ball ValvesDocument6 pagesDouble Block and Bleed Ball ValvesPalazzo345No ratings yet

- Micro Grid ConDocument43 pagesMicro Grid ConɌobeɌt CristianoNo ratings yet

- Optimisation Algorithm For Virtual Power Plant Operation: (DG) Size, ToDocument5 pagesOptimisation Algorithm For Virtual Power Plant Operation: (DG) Size, ToMichelle Maceas HenaoNo ratings yet

- Microgrids Distributed Power GenerationDocument4 pagesMicrogrids Distributed Power GenerationBasilNo ratings yet

- Celanovic11 PDFDocument12 pagesCelanovic11 PDFRadian FauziaNo ratings yet

- Navneet 1Document4 pagesNavneet 1Atul TanwarNo ratings yet

- Power Inverter Topologies For PhotovoltaDocument7 pagesPower Inverter Topologies For PhotovoltaÂn Bùi Hoàng ThiênNo ratings yet

- Sizing of Step-Up Transformers For PV Plants Through A Probabilistic ApproachDocument10 pagesSizing of Step-Up Transformers For PV Plants Through A Probabilistic ApproachAjay ChackoNo ratings yet

- Microgrid: A Conceptual Solution: Lasseter@engr - Wisc.eduDocument6 pagesMicrogrid: A Conceptual Solution: Lasseter@engr - Wisc.eduArijit Das AvroNo ratings yet

- Power ElectronicsDocument27 pagesPower ElectronicsAnand Pon KumarNo ratings yet

- 2Document21 pages2Anand Pon KumarNo ratings yet

- LG OLD Tech ProjectDocument39 pagesLG OLD Tech ProjectvishaliNo ratings yet

- Modified Algorithm For Drift Avoidance in PV System Using Neural NetworkDocument6 pagesModified Algorithm For Drift Avoidance in PV System Using Neural NetworkIIR indiaNo ratings yet

- Soft-Switching Converter With HF Transformer For Grid-Connected Photovoltaic SystemsDocument9 pagesSoft-Switching Converter With HF Transformer For Grid-Connected Photovoltaic SystemsVeeravasantharao BattulaNo ratings yet

- A High-Frequency Link Multilevel Cascade PDFDocument16 pagesA High-Frequency Link Multilevel Cascade PDFtcervera0No ratings yet

- Microgrid: A Conceptual Solution: Lasseter@engr - Wisc.eduDocument6 pagesMicrogrid: A Conceptual Solution: Lasseter@engr - Wisc.eduShiva KiranNo ratings yet

- Thermal Power PlantDocument15 pagesThermal Power Plantratantata545No ratings yet

- A Comprehensive Review On Distributed Power GenerationDocument5 pagesA Comprehensive Review On Distributed Power GenerationCésar Díaz LiberonaNo ratings yet

- Power-Management Strategies For A Grid-ConnectedDocument9 pagesPower-Management Strategies For A Grid-Connectedkhanh_ngaNo ratings yet

- 10 1016@j Solener 2019 03 037Document15 pages10 1016@j Solener 2019 03 037Farman AliNo ratings yet

- Mặt trờiDocument6 pagesMặt trờiDuy ThanhNo ratings yet

- Energy Trilemma Prosumer BuildingsDocument8 pagesEnergy Trilemma Prosumer BuildingsKaterinaNo ratings yet

- Micro Grids by LasseterDocument8 pagesMicro Grids by LasseterNikhil PerlaNo ratings yet

- Solar Based Induction CooktopDocument5 pagesSolar Based Induction CooktopSunil MåüřÿäNo ratings yet

- Impact The Expansion of The Production of Generation of Solar Power On The Low Voltage Network in EgyptDocument4 pagesImpact The Expansion of The Production of Generation of Solar Power On The Low Voltage Network in EgyptJoelson PaixãoNo ratings yet

- Wind ProjectDocument11 pagesWind ProjectjyotiblossomsNo ratings yet

- A Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsDocument10 pagesA Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsMIKS DARKNo ratings yet

- Voltage Regulation By: Grid Using PV PlantDocument19 pagesVoltage Regulation By: Grid Using PV PlantUdgam TiwariNo ratings yet

- A Modified Sepic Converter With High Static Gain For Renewable ApplicationsDocument12 pagesA Modified Sepic Converter With High Static Gain For Renewable Applicationsmylaptop VJethoseNo ratings yet

- Whitepaper: Centralized System Layout - Decentralized Inverter ConceptDocument4 pagesWhitepaper: Centralized System Layout - Decentralized Inverter ConceptBrahadeesh Perinkolam MuraliNo ratings yet

- The Gas Turbine ElectricalDocument32 pagesThe Gas Turbine Electricaldavid.menendez77No ratings yet

- Smart Power Generation by Wasted HeatDocument5 pagesSmart Power Generation by Wasted HeatVedant ChoudharyNo ratings yet

- Micro GeneratorDocument8 pagesMicro GeneratorDhya AffNo ratings yet

- Islanding Operation of Captive Power Plant: Ranjan BandyopadhyayDocument3 pagesIslanding Operation of Captive Power Plant: Ranjan BandyopadhyayBhavik Prajapati100% (1)

- Short-Circuit Modeling of A Wind Power PlantDocument9 pagesShort-Circuit Modeling of A Wind Power Plantamir yazdanNo ratings yet

- Energy Efficiency Improvement in Thermal PowerDocument6 pagesEnergy Efficiency Improvement in Thermal Powerabbaz ajiNo ratings yet

- Lacerda 2017Document7 pagesLacerda 2017bawapranith1No ratings yet

- 1 s2.0 S0306261919320677 MainDocument14 pages1 s2.0 S0306261919320677 MainAhmedAdrarNo ratings yet

- 70% Decrease of HotspottedDocument5 pages70% Decrease of HotspottedjarolNo ratings yet

- Comparison Solar Tower Parabolic Trough 2015Document9 pagesComparison Solar Tower Parabolic Trough 2015ZaidNo ratings yet

- A New Golden Section Method Based Maximum Power Point 2016 Energy ConversionDocument12 pagesA New Golden Section Method Based Maximum Power Point 2016 Energy ConversionsegacdfanNo ratings yet

- Concentrated Solar Power in India: Current Status, Challenges and Future OutlookDocument6 pagesConcentrated Solar Power in India: Current Status, Challenges and Future Outlook11751175No ratings yet

- Electrification of Industrial Processes and Application of Hybrid Generation Management by Shailesh - CHETTY - PAPERDocument19 pagesElectrification of Industrial Processes and Application of Hybrid Generation Management by Shailesh - CHETTY - PAPERSundar SahooNo ratings yet

- Sdarticle 15Document12 pagesSdarticle 15Desu MihretuNo ratings yet

- Implementation of Multi Level Inverter For SEPIC Converter With Grid Connected PV SystemDocument9 pagesImplementation of Multi Level Inverter For SEPIC Converter With Grid Connected PV SystemAl MahdaliNo ratings yet

- Ijaerv13n24 38Document9 pagesIjaerv13n24 38tran duyNo ratings yet

- The Performance of Both PHC Absorbers/Emitters and OverallDocument5 pagesThe Performance of Both PHC Absorbers/Emitters and Overallkalu chimdiNo ratings yet

- 2 Renewable Energy Technologies and Applications: 2.1 Concentrating Solar Thermal Power TechnologiesDocument15 pages2 Renewable Energy Technologies and Applications: 2.1 Concentrating Solar Thermal Power TechnologiesRameshNo ratings yet

- Understanding KWH/KWP by Comparing Measured Data With Modelling Predictions and Performance ClaimsDocument6 pagesUnderstanding KWH/KWP by Comparing Measured Data With Modelling Predictions and Performance ClaimsRizkiWiraPratamaNo ratings yet

- Case Studies On The Use of Solar Irradiance Forecast For Optimized Operation Strategies of Solar Thermal Power PlantsDocument10 pagesCase Studies On The Use of Solar Irradiance Forecast For Optimized Operation Strategies of Solar Thermal Power PlantsNancyNo ratings yet

- ARPA E Project Selections - TECHNICAL DESCRIPTIONSDocument15 pagesARPA E Project Selections - TECHNICAL DESCRIPTIONSChristopher DorobekNo ratings yet

- CO-Generation: 2 Need of CogenerationDocument7 pagesCO-Generation: 2 Need of Cogenerationajay kumar royNo ratings yet

- Major ProjectDocument4 pagesMajor ProjectSaroj kumar BiswasNo ratings yet

- Lallart 2008Document9 pagesLallart 2008Minh Le VanNo ratings yet

- 2015 02 Beacon SDocument1 page2015 02 Beacon SÅdnAn MehmOodNo ratings yet

- Root Cause AnalysisDocument56 pagesRoot Cause AnalysisÅdnAn MehmOodNo ratings yet

- 10.37 Spring 2007 Homework 1 Due Wednesday, Feb. 14Document6 pages10.37 Spring 2007 Homework 1 Due Wednesday, Feb. 14ÅdnAn MehmOodNo ratings yet

- Skill Learning Websites For FreelancersDocument94 pagesSkill Learning Websites For FreelancersÅdnAn MehmOodNo ratings yet

- Market Res Testing SteelscrDocument23 pagesMarket Res Testing SteelscrÅdnAn MehmOodNo ratings yet

- Steelscreen A Secure PortalDocument6 pagesSteelscreen A Secure PortalÅdnAn MehmOodNo ratings yet

- 15.566 Information Technology As An Integrating Force in ManufacturingDocument15 pages15.566 Information Technology As An Integrating Force in ManufacturingÅdnAn MehmOodNo ratings yet

- Did You Know: It'S Not The Heat, It'S The Humidity', Is More Than A Cliché, It'S A Danger SignalDocument1 pageDid You Know: It'S Not The Heat, It'S The Humidity', Is More Than A Cliché, It'S A Danger SignalÅdnAn MehmOodNo ratings yet

- 10.37 Spring 2007 Homework 1 Due Noon Wednesday, Feb. 14Document4 pages10.37 Spring 2007 Homework 1 Due Noon Wednesday, Feb. 14ÅdnAn MehmOodNo ratings yet

- Integrating Systems in The B2B Value ChainDocument11 pagesIntegrating Systems in The B2B Value ChainÅdnAn MehmOodNo ratings yet

- What Is A DatabaseDocument12 pagesWhat Is A DatabaseÅdnAn MehmOodNo ratings yet

- MIT15 031JS12 Lec9 PDFDocument18 pagesMIT15 031JS12 Lec9 PDFÅdnAn MehmOodNo ratings yet

- 15.566 Information Technology As An Integrating Force in ManufacturingDocument4 pages15.566 Information Technology As An Integrating Force in ManufacturingÅdnAn MehmOodNo ratings yet

- Comfort Science Solutions For Flexible Foam, Flooring and Footwear ApplicationsDocument4 pagesComfort Science Solutions For Flexible Foam, Flooring and Footwear ApplicationsÅdnAn MehmOod100% (1)

- 15.566 Information Technology As An Integrating Force in ManufacturingDocument7 pages15.566 Information Technology As An Integrating Force in ManufacturingÅdnAn MehmOodNo ratings yet

- 15.566 Information Technology As An Integrating Force in ManufacturingDocument7 pages15.566 Information Technology As An Integrating Force in ManufacturingÅdnAn MehmOodNo ratings yet

- 15.566 Information Technology As An Integrating Force in ManufacturingDocument5 pages15.566 Information Technology As An Integrating Force in ManufacturingÅdnAn MehmOodNo ratings yet

- Crosslinking and BranchingDocument5 pagesCrosslinking and BranchingÅdnAn MehmOodNo ratings yet

- Other Polymers oDocument5 pagesOther Polymers oÅdnAn MehmOodNo ratings yet

- Aromatic Substitutions: Lecture 29: Functionalization Case Studies: Biomaterials Systems, LC PolymersDocument5 pagesAromatic Substitutions: Lecture 29: Functionalization Case Studies: Biomaterials Systems, LC PolymersÅdnAn MehmOodNo ratings yet

- What Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?Document3 pagesWhat Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?ÅdnAn MehmOodNo ratings yet

- Metallocene Chemistry21Document5 pagesMetallocene Chemistry21ÅdnAn MehmOodNo ratings yet

- What Are ARV or ARC Valves? When To Use Automatic Recirculation Valve?Document4 pagesWhat Are ARV or ARC Valves? When To Use Automatic Recirculation Valve?ÅdnAn MehmOodNo ratings yet

- Basic Motors: 3. Speed of Rotation: Synchronous SpeedDocument2 pagesBasic Motors: 3. Speed of Rotation: Synchronous SpeedNabil RamehNo ratings yet

- Basic Wire Line and Petro Physics R LeveridgeDocument37 pagesBasic Wire Line and Petro Physics R LeveridgeTg TarroNo ratings yet

- B.Tech Mech 2018R PDFDocument247 pagesB.Tech Mech 2018R PDFKKNo ratings yet

- FLS Kiln Probe and gas analysersDocument8 pagesFLS Kiln Probe and gas analysersFran jimenezNo ratings yet

- 10 EM Spectrum of Light Compiled Questions v2Document4 pages10 EM Spectrum of Light Compiled Questions v2Hafez MurtzaNo ratings yet

- Recyclage Sédiment Flash Calciné 2021Document15 pagesRecyclage Sédiment Flash Calciné 2021AliNo ratings yet

- Nanocatalytic Materials For Energy-Related Small-Molecules Conversions: Active Site Design, Identification and Structure Performance Relationship DiscoveryDocument11 pagesNanocatalytic Materials For Energy-Related Small-Molecules Conversions: Active Site Design, Identification and Structure Performance Relationship DiscoveryJohnNo ratings yet

- Specification Sheet: Specifications TV2000, TV4000, TV7000DCDocument6 pagesSpecification Sheet: Specifications TV2000, TV4000, TV7000DCAatir AhmedNo ratings yet

- Curva Bomba Fristam Tipo FPX1732Document1 pageCurva Bomba Fristam Tipo FPX1732Fernando Pulgar BarillasNo ratings yet

- Biocarbon Production From Hungarian Sunflower ShellsDocument5 pagesBiocarbon Production From Hungarian Sunflower ShellsMuhamad SuharNo ratings yet

- Eaton VICKERS Filtration Master CatalogDocument56 pagesEaton VICKERS Filtration Master CatalogDanielEscobarMontecinosNo ratings yet

- ATB Produktfolder EnglischDocument12 pagesATB Produktfolder EnglischonlineshaddowNo ratings yet

- 3rd HarmonicsDocument6 pages3rd HarmonicsAmal P RaviNo ratings yet

- A Proposed Lifestyle Shopping MallDocument47 pagesA Proposed Lifestyle Shopping MallBeatriz PasajolNo ratings yet

- E E E Zn:1.07 E ZN Error × 100 153.9: CHUA, JOHN JOSEPH - 2014-30936 Chem 26.1Document3 pagesE E E Zn:1.07 E ZN Error × 100 153.9: CHUA, JOHN JOSEPH - 2014-30936 Chem 26.1Jj ChuaNo ratings yet

- CHEM 14 Problem Set 3, Ma'am Fatsy CruzDocument2 pagesCHEM 14 Problem Set 3, Ma'am Fatsy CruzDoroteo Jose StationNo ratings yet

- Boomer S1 L-M PDFDocument4 pagesBoomer S1 L-M PDFArturo Pedro Salgado MedinaNo ratings yet

- CVR Technique App Guide For Smarter GridDocument31 pagesCVR Technique App Guide For Smarter GridJuan Felipe Reyes M.No ratings yet

- Bernoullis EquationDocument45 pagesBernoullis EquationEuniceNo ratings yet