Professional Documents

Culture Documents

Specifying-VFDs-white-paper (Especificando Inversores)

Uploaded by

Gabriel SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifying-VFDs-white-paper (Especificando Inversores)

Uploaded by

Gabriel SilvaCopyright:

Available Formats

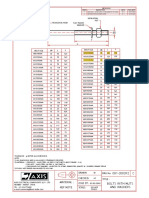

Top 10 Tips: Specifying VFDs: White Paper, Title Page

November 2013

WHITE PAPER

Top 10 Tips: Specifying VFDs

Variable frequency drives — or VFDs — can reduce

energy consumption, improve realtime control, and

lengthen motor life. Selecting the right one for your

application requires asking the correct questions.

Here are some expert tips to consider.

By Joe Kimbrell,

Product Manager, Drives, Motors, and Motion Control, AutomationDirect

November 2013

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 2

November 2013

Determine if a VFD is right for your application

The primary function of a variable frequency drive is to vary the speed of a three-phase

AC induction motor. VFDs also provide nonemergency start and stop control, accel-

eration and deceleration, and overload protection. In addition, VFDs can reduce the

amount of motor startup inrush current by accelerating the motor gradually. For these

reasons, VFDs are suitable for conveyors, fans, and pumps that benefit from reduced

WHITE PAPER

and controlled motor operating speed.

A VFD converts incoming AC power to DC, which is inverted back into three-phase

output power. Based on speed setpoints, the VFD directly varies the voltage and

frequency of the inverted output power to control motor speed. There is one caveat:

Converting AC power to a DC bus — and then back to a simulated AC sine wave —

can use up to 4% of the power that would be directly supplied to a motor if a VFD

were not used. For this reason, VFDs may not be cost-effective for motors run at full

speed in normal operation. That said, if a motor must output variable speed part of

the time, and full speed only sometimes, a bypass contactor used with a VFD can

maximize efficiency.

Consider your reasons for choosing a VFD

Typical reasons for considering VFDs include energy savings, controlled starting

current, adjustable operating speed and torque, controlled stopping, and reverse

operation. VFDs cut energy consumption, especially with centrifugal fan and pump

loads. Halving fan speed with a VFD lowers the required horsepower by a factor of

eight, as fan power is proportional to the cube of fan speed. Depending on motor size,

the energy savings could pay for the cost of the VFD in less than two years.

Starting an AC motor across the line requires starting current that can be more than

eight times the full load amps (FLA) of the motor. Depending on motor size, this could

place a significant drain on the power distribution system, and the resulting voltage dip

could affect sensitive equipment. Using a VFD can eliminate the voltage sag associated

with motor starting, and cut motor starting current to reduce utility demand charges.

Figure 1: In addition to varying speeds, conveyor

applications typically require frequent starting and

stopping. Here, VFDs substantially reduce starting

current to extend motor life.

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 3

November 2013

Controlling starting current can also extend motor life because across-the-line inrush

current shortens life expectancy of AC motors. Shortened life cycles are particularly

prominent in applications that require frequent starting and stopping. VFDs

substantially reduce starting current, which extends motor life, and minimizes the

necessity of motor rewinds.

The ability to vary operating speed allows optimization of controlled processes. Many

WHITE PAPER

VFDs allow remote speed adjustment using a potentiometer, keypad, programmable

logic controller (PLC), or a process loop controller. VFDs can also limit applied torque to

protect machinery and the final product from damage.

Controlled stopping minimizes product breakage or loss, as well as equipment wear

and tear. Because the output phases can be switched electronically, VFDs also eliminate

the need for a reversing starter.

Figure 2: Using VFDs to operate fans and pumps can significantly

reduce energy consumption, because they can tailor fan speed to

the application. Fan horsepower is proportional to the cube of fan

speed, so depending on motor size, energy savings can compensate

for the initial VFD purchase price in less than two years.

Select the proper size for the load

When specifying VFD size and power ratings, consider the operating profile of the load

it will drive. Will the loading be constant or variable? Will there be frequent starts and

stops, or will operation be continuous?

Consider both torque and peak current. Obtain the highest peak current under the

worst operating conditions. Check the motor FLA, which is located on the motor’s

nameplate. Note that if a motor has been rewound, its FLA may be higher than what’s

indicated on the nameplate.

Don’t size the VFD according to horsepower ratings. Instead, size the VFD to the motor

at its maximum current requirements at peak torque demand. The VFD must satisfy the

maximum demands placed on the motor.

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 4

November 2013

Consider the possibility that VFD oversizing may be necessary. Some applications

experience temporary overload conditions because of impact loading or starting

requirements. Motor performance is based on the amount of current the VFD can

produce. For example, a fully-loaded conveyor may require extra breakaway torque,

and consequently increased power from the VFD.

Many VFDs are designed to operate at 150% overload for 60 seconds. An application

WHITE PAPER

that requires an overload greater than 150%, or for longer than 60 seconds, requires

an oversized VFD.

Altitude also influences VFD sizing, because VFDs are air-cooled. Air thins at high

altitudes, which decreases its cooling properties. Most VFDs are designed to operate

at 100% capacity up to an altitude of 1,000 meters; beyond that, the drive must be

derated or oversized.

Be aware of braking requirements

With moderate inertia loads, overvoltage during deceleration typically won’t occur. For

applications with high-inertia loads, the VFD automatically extends deceleration time.

However, if a heavy load must be quickly decelerated, a dynamic braking resistor should

be used.

When motors decelerate, they act as generators, and dynamic braking allows the VFD

to produce additional braking or stopping torque. VFDs can typically produce between

15 and 20% braking torque without external components. When necessary, adding an

external braking resistor increases the VFD’s braking control torque — to quicken the

deceleration of large inertia loads and frequent start-stop cycles.

Determine I/O requirements

Most VFDs can integrate into control systems and processes. Motor speed can be

manually set by adjusting a potentiometer or via the keypad incorporated in some

VFDs. In addition, virtually every VFD has some I/O, and higher-end VFDs have multiple

I/Os and full-feature communications ports; these can be connected to controls to

automate motor speed commands.

Most VFDs include several discrete inputs and outputs, and at least one analog input

and one analog output. Discrete inputs interface the VFD with control devices such as

pushbuttons, selector switches, and PLC discrete output modules. These signals are

typically used for functions such as start/stop, forward/reverse, external fault, preset

speed selection, fault reset, and PID enable/disable.

Discrete outputs can be transistor, relay, or frequency pulse types. Typically, transistor

outputs drive interfaces to PLCs, motion controllers, pilot lights, and auxiliary relays.

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 5

November 2013

Relay outputs usually drive AC devices and other equipment with its own ground point,

as the relay contacts isolate the external equipment ground. The frequency output is

typically used to send a speed reference signal to a PLC’s analog input, or to another

VFD running in follower mode.

Typically, general-purpose outputs of most VFDs are transistors. Sometimes one or

more relay outputs are included for isolation of higher-current devices. Frequency pulse

WHITE PAPER

outputs are usually reserved for higher-end VFDs.

Analog inputs are used to interface the VFD with external 0 to 10 VDC or 4 to 20 mA sig-

nals. These signals can represent a speed setpoint and/or closed loop control feedback.

An analog output can be used as a feedforward to provide setpoints for other VFDs so

other equipment will follow the master VFD’s speed; otherwise, it can transmit speed,

torque, or current measurement signals back to a PLC or controller.

Select the proper control mode

VFD control mode choice greatly depends on the application. The three VFD control

modes are volts-per-Hertz (V/Hz), sensorless vector (sometimes called open-loop

vector), and closed-loop.

V/Hz-type VFDs use the ratio between voltage and frequency to develop the operating

flux to supply operating torque to the motor. Sensorless-vector VFDs have accurate

torque control over a wide speed range without having to use encoder feedback.

Closed-loop VFDs use encoder feedback to obtain motor speed and slip information.

Control mode comparison

Sensorless Closed

V/Hz

vector loop

Operating complexity Low Moderate High

Performance Good Good High

Starting torque (typical) 150 to 175% 200% 200%

Speed regulation (typical) ±2% ±1% ±0.2%

V/Hz control is adequate for many applications such as fans and pumps. However,

for applications that require greater degrees of speed regulation, sensorless vector

or closed-loop control types may be necessary. Applications such as paper mills, web

printing presses, or material converting require the added speed regulation that

closed-loop control provides.

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 6

November 2013

Understand your control profile requirements

Selecting the proper VFD control profiles is critical and depends greatly on the

application. Control profiles to consider include acceleration, deceleration, ramp

linearity, torque control, braking, and PID. Most of these parameters are available on

nearly every VFD type on the market, but PID may not be offered on very basic models.

WHITE PAPER

Figure 3: Web printing presses, paper mills, and mate-

rial converting applications require the precise speed

regulation of closed-loop control available in high-

er-end VFDs. Elsewhere, volts-per-Hertz (V/Hz) and

sensorless (or open-loop vector) modes are used.

These parameters are programmable and can be selected using the operator

keypad, or by digital communications. Understanding these parameters (and how they

affect integration of the VFD into the process) is imperative; to this end, VFD user

manuals typically provide the information required to select and program the right

control profiles.

Know your communication options

Many VFDs have one or more built-in digital communication interfaces. Even the most

economical models typically include a serial interface such as Modbus RS-232/RS-485.

Ethernet and fieldbus communication are options offered with many VFDs.

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 7

November 2013

A digital communication interface can be used to connect the VFD to other devices that

can function as a master device such as a PLC or PC-based controller. The master device

can control the VFD with this interface instead of using the discrete and analog I/O. The

master can also use this interface to monitor the status of various VFD parameters such

as speed, current, and fault status.

An RS-232 connection is somewhat limited as the maximum RS-232 network cable

WHITE PAPER

length is 50 feet. Also, the RS-232 interface is one-to-one, allowing connection of only

one VFD to one controller. An RS-485 network cable can span up to 4,000 feet and al-

lows connection of multiple devices. Extra adapters may be required to make this type

of connection.

An Ethernet Interface provides a high-performance link between the control system

and multiple VFDs. Some VFD Ethernet interfaces are even available with a web server

that allows users to configure and control the VFD from any web browser. Ethernet pro-

tocols such as Modbus TCP/IP and EtherNet/IP take the guesswork out of VFD control

over Ethernet and make setup easy for non-IT users.

Don’t overlook installation and

operating requirements

VFDs generate a significant amount of heat. This heat can cause the internal

temperature of an enclosure to exceed the VFD’s thermal rating. Enclosure ventilation

or cooling may be necessary to keep enclosure temperature within specified limits.

Ambient temperature measurements and calculations should also be made to

determine the maximum expected temperature.

Operating precautions must also be considered. One should avoid running a standard

induction motor at low speed for an extended period of time, as this can cause the

motor temperature to exceed its rating due to limited airflow produced by the

motor’s fan.

When a standard motor operates at low speed, output load must be decreased. If 100%

output torque is desired at low speed, it may be necessary to use an inverter-duty

rated motor.

Don’t use a contactor or disconnect switch for run/stop control of the VFD and motor;

as this reduces VFD life. Cycling the input-power switching device while the VFD is

operating should be done only in emergency situations.

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

Top 10 Tips: Specifying VFDs: White Paper, pg. 8

November 2013

Beware of harmonics

Any non-linear load, which includes anything with rectifiers, generates harmonics

— including VFDs. If excessive, harmonics can overheat and damage equipment,

transformers, and even power distribution wiring.

Two types of filters can mitigate the harmonics associated with VFDs. Passive harmonic

WHITE PAPER

filters include AC line reactors and chokes. Reactors and chokes reduce VFD-related

harmonics and line notching, and are recommended for all installations. They also

protect the VFD from transient overvoltages, typically caused by utility capacitor

switching. Active harmonic filters sample the harmonic current waveform, invert

it, and feed the inverted waveform back to the line to counteract harmonics. Some

active filters also have dynamic braking circuits that allow motor deceleration to place

regenerative current back on the AC supply line.

Output line, or load, reactors protect motor and cable insulation from VFD short circuits

and insulated gate bipolar transistor (IGBT) reflective wave damage. They also allow

the motor to run cooler by smoothing the current waveform. Output line reactors are

recommended for operating non-inverter duty motors and applications in which

VFD-to-motor wiring exceeds 75 feet.

About AutomationDirect

In business since 1994, AutomationDirect is a distributor offering thousands of

industrial automation products for electrical control systems, including PLCs, operator

interfaces, AC drives, motors, stepper systems, sensors, motor control, enclosures and

more. Their prices are typically well below the list price of more traditional automation

companies because of their model and focus on efficiency and the majority of their

products are stocked for same-day shipping. Plus, get free two-day delivery on orders

over $49; some limitations apply. For more information, contact them at 800-633-0405

or visit www.automationdirect.com/drives

© 2013 AutomationDirect.com, Inc. All rights reserved. The #1 Value in Automation.™

You might also like

- Variable Frequency DrivesDocument46 pagesVariable Frequency DrivesCubix AutomationNo ratings yet

- Understanding Variable Speed Drives: Basic VFD TheoryDocument7 pagesUnderstanding Variable Speed Drives: Basic VFD TheorynikecerreroNo ratings yet

- Variable Frequency Drive SelectionDocument6 pagesVariable Frequency Drive Selectionhasbi fadliNo ratings yet

- Buying Guide of Variable Frequency DrivesDocument5 pagesBuying Guide of Variable Frequency Drivesmfonseca31No ratings yet

- How To Select A Variable Frequency DriveDocument6 pagesHow To Select A Variable Frequency Drivedavid_diaz_sNo ratings yet

- Power Quality: M V S I o V F DDocument5 pagesPower Quality: M V S I o V F DHari Krishna.MNo ratings yet

- WATTS New Premium ContentDocument32 pagesWATTS New Premium ContentbaoHVLABNo ratings yet

- Guide To Variable Speed Drives (VSD) : Why Using A VSD Can Help You Save Money and The EnvironmentDocument20 pagesGuide To Variable Speed Drives (VSD) : Why Using A VSD Can Help You Save Money and The EnvironmentfelipeNo ratings yet

- Why Use Bypass in Variable Frequency Drive SystemDocument6 pagesWhy Use Bypass in Variable Frequency Drive Systemmani_208eeNo ratings yet

- Inverter Duty MotorDocument6 pagesInverter Duty Motorseshubabu_999No ratings yet

- Best VFD Applications For HVAC SystemsDocument4 pagesBest VFD Applications For HVAC SystemsjnikkoNo ratings yet

- Variable Speed DrivesDocument3 pagesVariable Speed DrivesmickygringoNo ratings yet

- Variable Frequency Drive BasicsDocument8 pagesVariable Frequency Drive Basicssrithu1008100% (2)

- Energy Savings of Variable Frequency DrivesDocument31 pagesEnergy Savings of Variable Frequency DrivesAnand AgrawalNo ratings yet

- Galco Tech Tips - Motor Control Selection GuideDocument2 pagesGalco Tech Tips - Motor Control Selection GuideGalco IndustrialNo ratings yet

- VFD For Centrifugal PumpsDocument11 pagesVFD For Centrifugal PumpsChem.EnggNo ratings yet

- Variable Frequency Drives For Centrifugal PumpsDocument11 pagesVariable Frequency Drives For Centrifugal PumpsOzkr_sgNo ratings yet

- WEG Vfds Vs Soft Starters White Paper Vfdsvssoftstarters Technical Article EnglishDocument5 pagesWEG Vfds Vs Soft Starters White Paper Vfdsvssoftstarters Technical Article EnglishcartarNo ratings yet

- Regarding Selection - WORD 97 FORMATDocument22 pagesRegarding Selection - WORD 97 FORMATSurya Prakash SinhaNo ratings yet

- Hydraulic Institute Knowledge Series: Motors & VFDS: Variable Frequency DrivesDocument32 pagesHydraulic Institute Knowledge Series: Motors & VFDS: Variable Frequency DrivesKarin GzaNo ratings yet

- Soft Starter Vs VFDDocument15 pagesSoft Starter Vs VFDMitesh GandhiNo ratings yet

- Figure No. 1 Variable Frequency DriveDocument38 pagesFigure No. 1 Variable Frequency DriveAshutosh SoniNo ratings yet

- Energy Answers For MotorsDocument4 pagesEnergy Answers For Motorsdetroit44No ratings yet

- VFD Applications For PumpDocument2 pagesVFD Applications For Pumpjhasunil00No ratings yet

- Yonis Hussain ReportDocument9 pagesYonis Hussain ReportENG.YONIS HUSSAINNo ratings yet

- Report On VFD For HT MotorDocument8 pagesReport On VFD For HT MotorDILEEPNo ratings yet

- Variable Frequency Control vs. Eddy Current ControlDocument3 pagesVariable Frequency Control vs. Eddy Current ControlA.YOGAGURUNo ratings yet

- Compatibility of Motor & VFDDocument3 pagesCompatibility of Motor & VFDorkwfdet sharklasersNo ratings yet

- VFD parameter setting guide for acceleration, torque & protectionDocument4 pagesVFD parameter setting guide for acceleration, torque & protectionykresna1631100% (1)

- MV & LV MotorDocument12 pagesMV & LV MotorSaber AbdelaalNo ratings yet

- Variable Frequency Drive (VFD)Document8 pagesVariable Frequency Drive (VFD)vishnurajpattambiNo ratings yet

- Figure No. 1 Variable Frequency DriveDocument38 pagesFigure No. 1 Variable Frequency Drivet_aditya2506No ratings yet

- Motor CatalogDocument1 pageMotor CatalogKingsley InbasinghNo ratings yet

- Overspeed Motors May 2020 - Technical Bulletin - 508Document1 pageOverspeed Motors May 2020 - Technical Bulletin - 508Simtom8585No ratings yet

- Overspeed Motors May 2020 - Technical Bulletin - 508Document1 pageOverspeed Motors May 2020 - Technical Bulletin - 508Tamnava22No ratings yet

- How To Select A Variable Frequency DriveDocument2 pagesHow To Select A Variable Frequency Drivehasbi fadli100% (1)

- 11 VSD& Harmonics PDFDocument100 pages11 VSD& Harmonics PDFsiruslara6491No ratings yet

- VFDDocument2 pagesVFDabuzar12533No ratings yet

- Benefits of VSD SystemsDocument7 pagesBenefits of VSD Systemsalx 100No ratings yet

- NIDECDocument18 pagesNIDECroyert8No ratings yet

- Variable Speed DriveDocument1 pageVariable Speed DriveKenneth LewisNo ratings yet

- VFD-types, working, soft-starter, market scope overviewDocument11 pagesVFD-types, working, soft-starter, market scope overviewdharnishNo ratings yet

- How To Read A Motor NameplateDocument8 pagesHow To Read A Motor Nameplateabdulyunus_amirNo ratings yet

- A Report ON: Reduction of The Failure Rate in Variable Frequency DrivesDocument29 pagesA Report ON: Reduction of The Failure Rate in Variable Frequency Drivesoh yayNo ratings yet

- F05 Fault On An Allen BradleyDocument12 pagesF05 Fault On An Allen Bradleymextico06No ratings yet

- Variable frequency drive overview and benefitsDocument12 pagesVariable frequency drive overview and benefitsDev KumarNo ratings yet

- VFD Maintenance Tips: Restarting Your Electrical Equipment After A Long ShutdownDocument3 pagesVFD Maintenance Tips: Restarting Your Electrical Equipment After A Long Shutdownashumishra007No ratings yet

- Variable Frequency DriveDocument9 pagesVariable Frequency DriveOsama SalemNo ratings yet

- Are VFD and VSD The Same - Empowering Pumps and EquipmentDocument5 pagesAre VFD and VSD The Same - Empowering Pumps and EquipmentHavandinhNo ratings yet

- Ac & Servo DrivesDocument11 pagesAc & Servo DrivesSPD SMS2 ElectricalNo ratings yet

- Turn Green With Variable-Frequency Drives: Hydraulic PressesDocument3 pagesTurn Green With Variable-Frequency Drives: Hydraulic PressesabhisdestinyNo ratings yet

- How VFDs Can Help Reduce Maintenance CostsDocument3 pagesHow VFDs Can Help Reduce Maintenance CostsMenaNo ratings yet

- Application of VFD in Power PlantDocument62 pagesApplication of VFD in Power PlantSakthi MuruganNo ratings yet

- Avoid Over-Specifying Inverter-Duty MotorsDocument9 pagesAvoid Over-Specifying Inverter-Duty MotorsCesar HernandezNo ratings yet

- VSD Advantages, Disadvantages, Selection Criteria and Installation Tips and TricksDocument18 pagesVSD Advantages, Disadvantages, Selection Criteria and Installation Tips and TricksMike CerreroNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Siemens Modbus and Ion TechnologyDocument21 pagesSiemens Modbus and Ion TechnologyGabriel SilvaNo ratings yet

- Modbus TCP Wizard DOKU V13 eDocument29 pagesModbus TCP Wizard DOKU V13 egabrielangelosilvaNo ratings yet

- Ion Enterprise 5.0 Administrator GuideDocument191 pagesIon Enterprise 5.0 Administrator GuidegabrielangelosilvaNo ratings yet

- EBX200 Product Data SheetDocument2 pagesEBX200 Product Data SheetGabriel SilvaNo ratings yet

- Industrial Ground Fault Sensing and Protection Application NoteDocument8 pagesIndustrial Ground Fault Sensing and Protection Application NoteGabriel Silva100% (1)

- 7UT6 Catalogue 2006 enDocument48 pages7UT6 Catalogue 2006 enGabriel SilvaNo ratings yet

- Info Iec60870-5-104 (Ed2.0) en DDocument10 pagesInfo Iec60870-5-104 (Ed2.0) en DEdison Javier Duque GarciaNo ratings yet

- Modbus TCP PN CPU ManualDocument64 pagesModbus TCP PN CPU ManualShobeir TabasiNo ratings yet

- Modbus TCP PN CPU ManualDocument64 pagesModbus TCP PN CPU ManualShobeir TabasiNo ratings yet

- 1769-Td008-Compact LogixPower Supplies SPCDocument12 pages1769-Td008-Compact LogixPower Supplies SPCpablo484No ratings yet

- Inspection & Testing of Elastic Rail Clips PDFDocument5 pagesInspection & Testing of Elastic Rail Clips PDFfiemsabyasachi0% (1)

- New Product Introduction Process: August 16, 2016Document30 pagesNew Product Introduction Process: August 16, 2016JuliaChenNo ratings yet

- OM B - Basic PDFDocument114 pagesOM B - Basic PDFTodor ToshkovNo ratings yet

- Ari Globe Valve SupraDocument26 pagesAri Globe Valve SupraAi-samaNo ratings yet

- Rate of Grease Penetration of Flexible Barrier Materials (Rapid Method)Document3 pagesRate of Grease Penetration of Flexible Barrier Materials (Rapid Method)DanZel Dan100% (1)

- Coal Petroleum: Crude OilDocument25 pagesCoal Petroleum: Crude Oiljojo basenNo ratings yet

- Ssnt Question BankDocument32 pagesSsnt Question Bankhowise9476No ratings yet

- MCQ (Trigo)Document10 pagesMCQ (Trigo)RaghavNo ratings yet

- How To Sell Hillstone 306. Cloudhive v2.8Document98 pagesHow To Sell Hillstone 306. Cloudhive v2.8Emmanuel CoriaNo ratings yet

- An SAP Consultant - ABAP - ALV Blocked List1Document3 pagesAn SAP Consultant - ABAP - ALV Blocked List1Shikhar AgarwalNo ratings yet

- 1081 Camid Vs Op DigestDocument2 pages1081 Camid Vs Op DigestLennart Reyes67% (3)

- Kirkpatricks ModelDocument2 pagesKirkpatricks Modelnazia_ahmed_10No ratings yet

- Juno Gi BrochureDocument2 pagesJuno Gi BrochureJerry VagilidadNo ratings yet

- Soc 1 Report Salesforce Services - 5EwWEDocument75 pagesSoc 1 Report Salesforce Services - 5EwWEArif IqbalNo ratings yet

- Toshiba X-Ray Tube Product InfoDocument10 pagesToshiba X-Ray Tube Product InfoJairo ManzanedaNo ratings yet

- Sjzl20061019-ZXC10 BSCB (V8.16) Hardware ManualDocument69 pagesSjzl20061019-ZXC10 BSCB (V8.16) Hardware ManualAhmadArwani88No ratings yet

- Lista Carti Audio Dezvoltare PersonalaDocument4 pagesLista Carti Audio Dezvoltare PersonalaNicu Osan50% (2)

- HW1Document1 pageHW1mohsenanNo ratings yet

- SQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsDocument6 pagesSQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsAchamyeleh TamiruNo ratings yet

- Capital Harness XC LaunchDocument36 pagesCapital Harness XC LaunchnizarfebNo ratings yet

- OCP - SQL&PL - SQL (Vol1)Document322 pagesOCP - SQL&PL - SQL (Vol1)api-3814149100% (1)

- 4 Way Test of The Things We Think, Say or DoDocument5 pages4 Way Test of The Things We Think, Say or DoObakoma JosiahNo ratings yet

- Abdulbasit MohammedDocument170 pagesAbdulbasit MohammedGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Operating Instructions MA 42 - Maico Diagnostics PDFDocument28 pagesOperating Instructions MA 42 - Maico Diagnostics PDFJuan PáezNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Business Plan For Mobile Food CourtDocument13 pagesBusiness Plan For Mobile Food CourtMd. Al- AminNo ratings yet

- TerrSet TutorialDocument470 pagesTerrSet TutorialMoises Gamaliel Lopez Arias100% (1)

- Bec Vantage Practice TestsDocument35 pagesBec Vantage Practice TestsHilda FlorNo ratings yet

- Monographie BtttyrtIPM-5 Tables Vol7Document246 pagesMonographie BtttyrtIPM-5 Tables Vol7arengifoipenNo ratings yet

- Column:C2 900X900: Basic Design ParametersDocument2 pagesColumn:C2 900X900: Basic Design ParametersAnonymous tBhJoH5wgMNo ratings yet