Professional Documents

Culture Documents

Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85

Uploaded by

Miguel angel leon bautistaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85

Uploaded by

Miguel angel leon bautistaCopyright:

Available Formats

A-2

Unilet® Conduit Outlet Bodies:

FM7™, FM8®, Form 35® and Form 85™

For use with Rigid Steel, Rigid Aluminum, IMC, and EMT Conduit.

Applications

• Serve as pulling fittings.

• Make bends in conduit system.

• Provide openings for splicing.

• Connect and change direction of

conduit runs.

• Allow connections for branch runs.

• Permit access to conductors for main-

tenance.

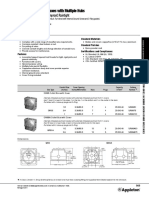

❶ FM7 Grayloy™-iron, 1" Type C ❷ FM7 Aluminum

Features: Unilet® conduit shown with cut-away body and Conduit Body with

outlet bodies cover to illustrate Wedge-Lok™ Cast Aluminum

• Roomy interiors: more wiring space. Clip Cover detail. Cover. 1" Type C

shown.

• Smooth, rounded integral bushings in

hubs protect conductor insulation.

• Accurately tapped, tapered threads for

tight, rigid joints and excellent ground

continuity.

Features: FM7™ Series

❶ FM7 Grayloy™-Iron Unilets: most eco-

nomical conduit bodies for use where

the special advantages of malleable iron ❸ FM8 Grayloy™-iron Conduit Body

or aluminum are not required. with cast cover, 1" Type C shown.

❷ FM7 Aluminum Unilets: same dimen-

sions and design features as FM7

Grayloy™-lron, plus light weight, high

corrosion resistance.

• Unique Wedge-Lok™ clip covers allow

easy removal. No retapping of corroded

body screw holes is necessary to re-

place cover.

• Completely interchangeable with

❺ Form 85 Aluminum Conduit

Crouse-Hinds Form 7* bodies, gaskets

and covers. Equivalent FM7 and Form ❹ Form 35 Malleable. Body with Stamped Aluminum

2" Type LB with rollers Cover. 2" Type C shown.

7* units have identical applications and

installation dimensions.

• Flat back design provides greater

• Pan-head cover screws secure cover • FM8 Grayloy™-iron with “FG” Series

cubic content for easier wire pulling and clips and provide superior screwdriver cast covers and gaskets are approved

more room for splicing. seating and torque. Cover screws and for use in wet locations.

• FM7 Grayloy™-Iron with “FG” Series clips are captive to prevent loss. • Stainless steel screws on stamped

cast covers and gaskets are approved

for use in wet locations. • Hub size, body style, and compliance and cast covers.

• Smooth hub bushings and cover

data molded into body in large, easy-

to-read form. Also maximum wire num-

• Smooth hub bushings and cover

openings protect conductor insulation.

openings protect conductor insulation. ber/size and cubic capacity. Smooth hub openings allow easy con-

Smooth hub openings allow easy con- duit joining.

duit joining. Features: FM8® Series

❸ Completely interchangeable with *Form 7 and Form 8 are products of Crouse-Hinds, a

member company of Cooper Industries.

Crouse-Hinds Form 8* bodies, gaskets

and covers. Equivalent FM8 and Form

A

8* units have identical applications and

installation dimensions.

• Flat back design provides greater

cubic content for easier wire pulling and

FM7

more room for splicing.

FM8

Effective October, 2001 7770 N. Frontage Road

Copyright 2001 Printed in U.S.A. Skokie, Illinois 60077

PAGE 2

A-3

Unilet® Conduit Outlet Bodies:

FM7™, FM8®, Form 35® and Form 85™

For use with Rigid Steel, Rigid Aluminum, IMC, and EMT Conduit.

Features: Form 35®

❹ Form 35 malleable iron Unilets: high • FM7 aluminum bodies: epoxy powder

coat.

tensile strength and ductility. High cor-

rosion-resistance, high impact and • FM7 and FM8 steel covers: zinc elec-

shock resistance. troplate.

• Exclusive built-in easy-pulling rollers • FM7 stamped aluminum covers: nat-

in type C (1-1/4" thru 4") and type LB ural finish.

(1-1/4" thru 4")– eliminate damage Form 85 • FM7 and FM8 Grayloy-iron covers:

when cable is pulled through hubs. triplecoat– (1) zinc electroplate, (2)

Standard Materials dichromate, and (3) epoxy powder coat.

• Sizes with flat-back design ideal

• Form 35 Unilet conduit outlet bodies:

where fitting is mounted flat against malleable iron. • FM7 cast aluminum covers: epoxy

surface. powder coat.

• Complete line of conduit bodies, cov- • Form 85 Unilet conduit outlet bodies:

Options

aluminum– copper-free (max. 4/10 of

ers and receptacles. 1%). 1/2" thru 2"– pressure cast. 2-1/2" • PVC Coating available upon request–

• Blank covers domed for extra wiring thru 4"– sand cast. consult factory.

space.

• FM7 Unilet conduit bodies: Grayloy- Compliances

iron or copper-free aluminum. • UL Standard 514A.

• FM8 Unilet conduit bodies: Grayloy- • Federal Spec. W-C-586B.

iron.

• Suitable for classified location use in

• Covers for Form 35 and 85: blank– Class I, Division 2 areas, if installed in

malleable iron, steel and aluminum. Du- compliance with NEC 501-4(b).

plex grounding receptacle– phenolic.

Lamp receptacle– porcelain. Wiring de-

• Appleton malleable iron products con-

Form 35 form to ASTM A47-77, Grade 32510,

vice and switch covers– aluminum. which has the following properties: ten-

Cover screws: stainless steel. sile strength, 50,000 psi; yield, 32,000

• Covers for FM7: stamped steel, psi; and elongation, 10%.

stamped aluminum, cast Grayloy-iron,

and cast aluminum; cover screws:

• Appleton aluminum products are pro-

duced from a high strength copper-free

stainless steel. (4/10 of 1% max.) alloy.

• Covers for FM8: cast Grayloy-iron, • Appleton Grayloy-iron products are a

stamped steel; cover screws: stainless gray iron alloy with tensile strength sim-

steel. ilar to ASTM-A48 Class 30A (30,000 psi

• Gaskets for Form 35 and Form 85: tensile), and with a Brinell hardness of

neoprene or composition fiber. approximately 180BH.

• Gaskets for FM7 and FM8: neoprene. Product Cross Reference

Standard Finishes • For explosionproof conduit outlet bod-

• Form 35 malleable iron bodies: triple- ies and boxes, see Cat. Section J.

Form 35 coat– (1) zinc electroplate, (2) dichro- • For Mogul Unilets®, see pages A-17

mate, and (3) epoxy powder coat. through A-24.

Features: Form 85™ • Form 35 Covers: steel: zinc electro-

❺ Form 85 aluminum Unilets: copper- plate. Malleable iron: triple-coat– (1)

free aluminum (max. 4/10 of 1% cop- zinc electroplate, (2) dichromate, and

per content). Lightweight, high corrosion (3) epoxy powder coat.

resistance. Self-oxidizing, self-renewing. • Form 85 aluminum bodies: epoxy

• Lightweight aluminum facilitates ship- powder coat.

ping, handling and installing. • Form 85 stamped aluminum covers:

• Sizes with flat-back design ideal where natural finish.

fitting is mounted flat against surface. • Form 85 cast aluminum covers:

A

• Complete line of conduit bodies, cov- epoxy powder coat.

ers and receptacles. • FM7 and FM8 Grayloy-iron bodies:

• Blank covers domed for extra wiring triplecoat– (1) zinc electroplate, (2)

dichromate, and (3) epoxy powder coat.

space.

Effective March, 2002 7770 N. Frontage Road

Copyright 2002 Printed in U.S.A. Skokie, Illinois 60077

PAGE 3

A-4

FM8® Grayloy™-Iron Conduit Bodies

and Covers; FM7™ Grayloy™-Iron and

Aluminum Unilet® Conduit Bodies:

Wedge-Lok™ Clip Covers

For use with Rigid Steel, Rigid Aluminum and IMC Conduit.

Freedom of Choice. With new FM8 series added to covers are available in Grayloy-iron. Covers can be used with-

Appleton’s full-line family of conduit bodies, you have a sin- out gaskets, or with a solid neoprene gasket. All Appleton

gle source for the right choice needed for every job– FM8 FM7 and FM8 bodies, covers and gaskets are interchange-

Grayloy-iron bodies and covers, FM7 Grayloy-iron or alu- able with Crouse-Hinds Form 7* and Form 8* bodies, cov-

minum threaded bodies and covers... malleable iron Form ers and gaskets.

35... aluminum Form 85... and malleable iron or aluminum Approved for wet locations. FM7 and FM8 Grayloy-iron

NEC Mogul 6x8x. bodies with the “FG” series cast covers and gasket are

Interchangeable. Appleton FM7 and FM8 bodies, covers approved for use in wet locations. (NEMA 3R)

and gaskets are completely interchangeable with equiva- Maximum corrosion protection. Appleton FM7 and FM8

lent Crouse-Hinds Form 7* and Form 8* bodies and cov- Grayloy-iron conduit bodies and cast covers have a triple-coat

ers. Applications and installation dimensions are also finish– (1) zinc electroplate, (2) dichromate, and (3) epoxy

interchangeable. powder coating. FM7 aluminum bodies and cast covers are

No wire damage. Appleton FM7 and FM8 bodies have a coated with epoxy powder coating. FM7 and FM8 blank steel

smooth, rounded, internal bushing in each hub and smooth covers have a zinc electroplate finish. Superior FM7 and FM8

cover openings to protect conductor insulation. finish gives greater corrosion protection in wet or harsh en-

Easy cover removal. Unique FM7 Wedge-Lok Clip-Cover vironments, assuring long, trouble-free service.

design allows easy removal at any later time, without dam- Grayloy-iron properties. Grayloy™ is an Appleton propri-

aging the conduit body. Because the cover is secured with etary cast graphite flake gray iron alloy with superior physi-

clips– not screws – no retapping of corroded body screw cal and mechanical properties offering strength, hardness,

holes is necessary to replace cover. fracture toughness, high vibration absorption and dimensional

Positive-seating cover screws. Pan-head cover screws, stability. Tensile strength is similar to ASTM-A48 Class 30A

which hold the clips, provide superior screwdriver seating (30,000 tensile), with Brinell hardness of approximately

and torque for easier cover installation or removal. Each cover 180BH.

screw and its attached locking clip are held captive in the Aluminum properties. Aluminum products are produced

cover to prevent loss. from a high strength copper-free (4/10 of 1% max.) alloy.

Full-line choice. Appleton FM7 and FM8 bodies are offered More wiring space. Appleton’s FM7 and FM8 flat-back de-

in a complete range of hub configurations and sizes. FM7 sign provides greater cubic content for easier wire pulling, and

covers are available in blank stamped steel or stamped alu- more room for splicing. FM7 and FM8 flat back fits flush and

minum, and also in cast Grayloy-iron or cast aluminum. FM8 snug against flat surfaces for more stable installation.

* Form 7 and Form 8 are products of Crouse-Hinds, a member company of

Cooper Industries.

Appleton Crouse-Hinds

FM7™ Form 7

Illustrated views are cut

away to demonstrate back

configurations.

LEFT

• Maximum wire number/size Appleton FM7 (C57, 1-1/2")

and cubic capacity 28 Cubic Inches Capacity

A

molded into body. Flat-Back Design

• Large size, style and RIGHT

compliance data Crouse-Hinds Form 7 (C57, 1-1/2")

molded into body. 26 Cubic Inches Capacity

Effective October, 2001 7770 N. Frontage Road

Copyright 2001 Printed in U.S.A. Skokie, Illinois 60077

PAGE 4

A-7

FM8® Grayloy™-Iron Unilet® Conduit

Bodies with Covers and Gaskets

For use with Rigid Steel and IMC Conduit.

These Appleton FM8 conduit bodies, covers and gaskets have the same applications and installation dimensions as Crouse-Hinds Form 8 fit-

tings. Equivalent FM8 and Form 8 items are interchangeable.

Appleton FM8® Conduit Bodies NOTE: Refer to page A-15 for Wiring Capacity Table

Threaded Type C LB LL LR

Hub

Size (in.) Grayloy-Iron Grayloy-Iron Grayloy-Iron Grayloy-Iron

1/2 C18 LB18 LL18 LR18

3/4 C28 LB28 LL28 LR28

1 C38 LB38 LL38 LR38

1-1/4 C448 LB448 LL448 LR448

1-1/2 C58 LB58 LL58 LR58

2 C68 LB68 LL68 LR68

2-1/2 C78 LB78 LL78 LR78

3 C88 LB888 LL888 LR888

3-1/2 — LB98 — —

4 — LB108 — —

T TB X

Hub

Size (in.) Grayloy-Iron Grayloy-Iron Grayloy-Iron

1/2 T18 TB18 X18

3/4 T28 TB28 X28

1 T38 TB38 X38

1-1/4 T448 TB448 X448

1-1/2 T58 TB58 X58

2 T68 TB68 X68

2-1/2 T78 — —

3 T88 — —

®

Appleton FM8 Blank Covers and Gaskets (Covers furnished with stainless steel screws, 1-1/2"–4" covers provided with 4 screws)

Stamped Cover Cast Cover Solid Gasket Open Gasket

Steel Grayloy-Iron Neoprene Neoprene

FM8

Body

Size (in.)

1/2 180 180F GASK851N —

3/4 280 280F GASK852N —

1 380 380F GASK853N —

1-1/4 480 480F GASK854N —

1-1/2 580 580F — GASK805N

A

2 680 680F — GASK806N

2-1/2 880 880F — GASK808N

3 880 880F — GASK808N

3-1/2 980 980F — GASK809N

4 980 980F — GASK809N

Effective October, 2001 7770 N. Frontage Road

Copyright 2001 Printed in U.S.A. Skokie, Illinois 60077

PAGE 7

A-8

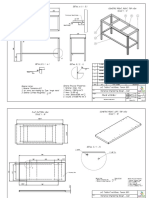

FM8® Conduit Body Dimensions

N N

N

F

P M B E

F

H

D

A J D

C K

L G R

TYPE C TYPES E, LB, LL, LR TYPES T, TB, X

Dimensions In Inches

Hub

Size A B C D E F G H J K L M N P R

1/2 4.22 1.47 1.47 5.94 3.13 2.31 2.28 4.38 5.09 1.78 0.63 1.25 3.28 1.00 2.59

3/4 4.81 1.66 1.69 6.56 3.31 2.50 2.50 4.91 5.75 2.00 0.75 1.50 3.94 1.19 2.81

1 5.59 1.84 1.97 7.56 3.72 2.78 2.91 5.72 6.63 2.28 0.88 1.75 4.53 1.38 3.22

1-1/4 6.56 2.19 2.38 8.44 4.06 3.13 3.31 6.41 7.50 2.63 1.09 2.19 5.31 1.75 3.56

1-1/2 7.88 2.78 2.78 10.38 5.28 4.03 4.03 7.75 9.13 2.78 1.38 2.44 6.50 2.09 4.03

2 9.75 3.88 3.56 12.38 6.38 5.13 4.81 9.19 11.13 3.56 1.88 3.00 8.63 3.00 4.81

2-1/2 12.25 5.00 4.44 15.63 — 6.69 6.13 11.44 13.94 4.44 2.50 3.50 10.88 4.25 —

3 12.25 5.00 4.81 15.63 — 6.69 6.50 11.44 13.94 4.81 2.50 4.25 10.88 4.25 —

3-1/2 15.00 6.25 5.69 — — — 7.56 13.75 16.88 — 3.13 4.75 13.44 5.44 —

4 15.00 6.25 5.94 — — — 7.81 13.75 16.88 — 3.13 5.25 13.44 5.44 —

Fraction/Decimal Equivalents (Inches)

Fraction Decimal Fraction Decimal Fraction Decimal Fraction Decimal

1/32 0.03 9/32 0.28 17/32 0.53 25/32 0.78

1/16 0.06 5/16 0.31 9/16 0.56 13/16 0.81

3/32 0.09 11/32 0.34 19/32 0.59 27/32 0.84

1/8 0.13 3/8 0.38 5/8 0.63 7/8 0.88

5/32 0.16 13/32 0.41 21/32 0.66 29/32 0.91

3/16 0.31 7/16 0.44 11/16 0.69 15/16 0.94

7/32 0.22 15/32 0.47 23/32 0.72 31/32 0.97

1/4 0.25 1/2 0.50 3/4 0.75 1 1.00

Effective September, 2002 7770 N. Frontage Road

Copyright 2002 Printed in U.S.A. Skokie, Illinois 60077

PAGE 8

A-15

Wiring Capacity: FM7™ and FM8®

Conduit Bodies and Covers

Combine Body and Cover Capacities for Total usable Capacity

per NEC 370-6(a)(1)

FM7™ Grayloy™-Iron Bodies and Covers: Threaded

Capacity in Cubic Inches

Hub LL Stamped Cast

Size (In.) C E LB LR L T TA TB X Cover Cover

1/2 4.0 4.0 4.0 4.0 5.0 6.0 6.0 6.0 6.0 0.3 0.4

3/4 7.0 7.0 7.0 7.0 9.0 10.0 10.0 10.0 10.0 0.5 0.8

1 11.0 11.0 11.0 11.0 13.5 15.5 15.5 15.5 15.5 1.3 1.3

1-1/4 20.0 — 20.0 20.0 22.5 20.0 20.0 20.0 20.0 1.8 2.0

1-1/2 28.0 — 28.0 28.0 31.0 28.0 28.0 28.0 28.0 2.3 3.0

2 50.0 — 50.0 50.0 55.0 50.0 50.0 50.0 50.0 2.8 4.8

2-1/2 102.0 — 102.0 102.0 — 102.0 — — — 9.8 9.7

3 133.0 — 133.0 133.0 — 133.0 — — — 9.8 9.7

3-1/2 — — 218.0 218.0 — 218.0 — — — 16.5 16.0

4 — — 244.0 244.0 — 244.0 — — — 16.5 16.0

FM7™ Aluminum Bodies and Covers: Threaded

Capacity in Cubic Inches

Hub LL Stamped Cast

Size (In.) C E LB LR L T TA TB X Cover Cover

1/2 4.0 4.0 4.0 4.0 — 6.0 — 6.0 6.0 0.3 0.4

3/4 7.0 7.0 7.0 7.0 — 10.0 — 10.0 10.0 0.5 0.8

1 11.0 11.0 11.0 11.0 — 15.5 — 15.5 15.5 1.3 1.3

1-1/4 20.0 — 20.0 20.0 — 20.0 — 20.0 20.0 1.8 2.0

1-1/2 28.0 — 28.0 28.0 — 28.0 — 28.0 28.0 2.3 3.0

2 50.0 — 50.0 50.0 — 50.0 — 50.0 50.0 2.8 4.8

2-1/2 102.0 — 102.0 102.0 — 102.0 — — — 9.8 9.7

3 133.0 — 133.0 133.0 — 133.0 — — — 9.8 9.7

3-1/2 — — 218.0 218.0 — 218.0 — — — 16.5 16.0

4 — — 244.0 244.0 — 244.0 — — — 16.5 16.0

FM8® Grayloy™-Iron Bodies and Covers: Threaded

Capacity in Cubic Inches

Hub LL Stamped Cast

Size (In.) C E LB LR L T TA TB X Cover Cover

1/2 5.0 — 5.0 5.0 — 6.0 — 6.0 6.0 0.5 0.3

3/4 8.0 — 8.0 8.0 — 10.0 — 10.0 10.0 0.8 0.8

1 13.0 — 13.0 13.0 — 15.0 — 15.0 15.0 1.0 1.0

1-1/4 24.0 — 24.0 24.0 — 25.0 — 25.0 25.0 1.5 1.5

1-1/2 42.5 — 42.5 42.5 — 44.0 — 44.0 44.0 1.8 7.5

2 105.0 — 105.0 105.0 — 105.0 — 105.0 105.0 4.5 12.5

2-1/2 200.0 — 200.0 200.0 — 200.0 — — — 12.3 34.5

3 217.0 — 217.0 217.0 — 217.0 — — — 12.3 34.5

A

3-1/2 — — 380.0 — — — — — — 24.0 65.3

4 — — 400.0 — — — — — — 24.0 65.3

Effective October, 2001 7770 N. Frontage Road

Copyright 2001 Printed in U.S.A. Skokie, Illinois 60077

PAGE 15

You might also like

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Miguel angel leon bautistaNo ratings yet

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Ciro LeonNo ratings yet

- Conduleta en TDocument6 pagesConduleta en TEd CalheNo ratings yet

- Form 8Document6 pagesForm 8deysydonaltNo ratings yet

- FS and FD Cast Device Boxes Malleable Iron, AlumuniumDocument26 pagesFS and FD Cast Device Boxes Malleable Iron, AlumuniumMuhamad PriyatnaNo ratings yet

- Olb y LBH AppletonDocument4 pagesOlb y LBH AppletonEDWARD VLADIMIR PIAMONTENo ratings yet

- Crouse Hinds Form7 Catalog PageDocument8 pagesCrouse Hinds Form7 Catalog PageFERNANDO RODRIGUEZNo ratings yet

- Steel Construction Presentation Sem 9THDocument22 pagesSteel Construction Presentation Sem 9THAr Shivali SinghNo ratings yet

- See Page 8 For Gaskets and Covers: Applications: Certifications and CompliancesDocument8 pagesSee Page 8 For Gaskets and Covers: Applications: Certifications and Compliancesxavos230509No ratings yet

- lb27_giDocument1 pagelb27_giluiszc2988No ratings yet

- FS and FD Cast Hub Device BoxesDocument14 pagesFS and FD Cast Hub Device BoxesRicardoNo ratings yet

- Accesorios Tuberia Eaton Crouse HindsDocument37 pagesAccesorios Tuberia Eaton Crouse HindsAlhexander ValegaNo ratings yet

- Catalog Appleton GR GRF Conduit Outlet Boxes en 1458690 2103Document5 pagesCatalog Appleton GR GRF Conduit Outlet Boxes en 1458690 2103Alexis Rodrigo Tapia EstrellaNo ratings yet

- Met EF EF1 EF2 TB ETDocument66 pagesMet EF EF1 EF2 TB ETĐức LêNo ratings yet

- Aggre GatorDocument4 pagesAggre GatorvandrorobertoNo ratings yet

- Unions, Sealing Fitting, Flexible CouplingDocument4 pagesUnions, Sealing Fitting, Flexible CouplingMuhamad PriyatnaNo ratings yet

- Meever India Brochure FinalDocument44 pagesMeever India Brochure FinalSrinu NaikNo ratings yet

- A1 Conduit Bodies and Boxes (Document41 pagesA1 Conduit Bodies and Boxes (Gustavo GaibarNo ratings yet

- TDS - FDDocument5 pagesTDS - FDNayif MuhammedNo ratings yet

- Tong Die DirectiveDocument4 pagesTong Die Directivemsm.ele2009No ratings yet

- Research Note On Aluminium Alloy Property PDFDocument80 pagesResearch Note On Aluminium Alloy Property PDFpenghzNo ratings yet

- Corrugated Aluminum Pipe For Sewers and DrainsDocument8 pagesCorrugated Aluminum Pipe For Sewers and DrainsFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Conventional Plaster Systems: 12 EditionDocument10 pagesConventional Plaster Systems: 12 EditionȄarlwin de los ReyesNo ratings yet

- TITAN Standard Pile Head Details PDFDocument48 pagesTITAN Standard Pile Head Details PDFJeffy DormareadiNo ratings yet

- DataSheet ZPurlinsDocument1 pageDataSheet ZPurlinshanna alemhuNo ratings yet

- L-2 Steel SectionsDocument23 pagesL-2 Steel SectionsRukhsar JoueNo ratings yet

- General Notes On Cable Trays PDFDocument18 pagesGeneral Notes On Cable Trays PDFswagata12345No ratings yet

- Guide to Cable Trays and AccessoriesDocument5 pagesGuide to Cable Trays and AccessoriesPeter AntonyNo ratings yet

- Appleton Cajas GRSSDocument1 pageAppleton Cajas GRSSArq. Giovanni LopezNo ratings yet

- Mogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TDocument8 pagesMogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TMiguel angel leon bautistaNo ratings yet

- Venti Lad orDocument11 pagesVenti Lad orjullNo ratings yet

- TP 08 LGSS SmallDocument8 pagesTP 08 LGSS SmallJnanjit ChalihaNo ratings yet

- Fairbanks End SuctionDocument16 pagesFairbanks End SuctionKitikhun VichanarksornsitNo ratings yet

- Sa Tun en 2Document4 pagesSa Tun en 2a_salehiNo ratings yet

- ProValve Knife Gate ValveDocument12 pagesProValve Knife Gate ValveHarry HonchoNo ratings yet

- SteelDocument41 pagesSteelmasoodNo ratings yet

- Esco BROCHUREDocument18 pagesEsco BROCHUREJohn GonzalezNo ratings yet

- World Refining-Rocket ScienceDocument3 pagesWorld Refining-Rocket ScienceIndunil WarnasooriyaNo ratings yet

- Alluminio TeoriaDocument91 pagesAlluminio TeoriaxypangioNo ratings yet

- Rolled Steel Sections GuideDocument38 pagesRolled Steel Sections GuideragulNo ratings yet

- Steel and AluminiumDocument15 pagesSteel and Aluminiumvipanchika mmNo ratings yet

- Nema Ve1 PDFDocument27 pagesNema Ve1 PDFAlif Anshar100% (1)

- Aluminium Honeycomb Ventilation Panels EMI/RFI ShieldingDocument5 pagesAluminium Honeycomb Ventilation Panels EMI/RFI Shieldingbadmike71No ratings yet

- Stay Cable Curved Bridge: G. Machinchang, Langkawi, Malaysia LIM Chin-BengDocument80 pagesStay Cable Curved Bridge: G. Machinchang, Langkawi, Malaysia LIM Chin-BengTigercb Lim100% (2)

- Expamet Plastering AccessoriesDocument20 pagesExpamet Plastering Accessoriesapi-27549425100% (3)

- Cabillas Convencionales PDFDocument12 pagesCabillas Convencionales PDFgenesisNo ratings yet

- CG3334 IBR Brochure - 1Document2 pagesCG3334 IBR Brochure - 1jitendra.jangidNo ratings yet

- Katalog Ogranicznikow Przepiec Serii 3hsrDocument20 pagesKatalog Ogranicznikow Przepiec Serii 3hsrakhilNo ratings yet

- ERSS-Lecture 8 (ChiewSP 6mar20)Document41 pagesERSS-Lecture 8 (ChiewSP 6mar20)sunilarunaNo ratings yet

- Invicta Penstock BrochureDocument8 pagesInvicta Penstock Brochurekad-7No ratings yet

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- 2016 GME Steel ProductsDocument16 pages2016 GME Steel ProductsMarco Dos Santos NevesNo ratings yet

- Tube of Different SizesDocument20 pagesTube of Different SizesGajraj ChauhanNo ratings yet

- Technical Information ASSET DOC LOC 1543414Document24 pagesTechnical Information ASSET DOC LOC 1543414number_25No ratings yet

- 8.4 Spherical Roller BearingsDocument68 pages8.4 Spherical Roller Bearingsrrobles011No ratings yet

- Modelling a Tiger I s.SS.PZ.Abt.101, Normandy 1944: In 1/35 scaleFrom EverandModelling a Tiger I s.SS.PZ.Abt.101, Normandy 1944: In 1/35 scaleNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Miguel angel leon bautistaNo ratings yet

- Unilet Conduit Outlet Bodies: LBD and LBDN. Conduit Outlet Boxes: JB, GS and SEHDocument7 pagesUnilet Conduit Outlet Bodies: LBD and LBDN. Conduit Outlet Boxes: JB, GS and SEHMiguel angel leon bautistaNo ratings yet

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Miguel angel leon bautistaNo ratings yet

- Mogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TDocument8 pagesMogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TMiguel angel leon bautistaNo ratings yet

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Miguel angel leon bautistaNo ratings yet

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Miguel angel leon bautistaNo ratings yet

- Unilet Conduit Outlet Bodies: LBD and LBDN. Conduit Outlet Boxes: JB, GS and SEHDocument7 pagesUnilet Conduit Outlet Bodies: LBD and LBDN. Conduit Outlet Boxes: JB, GS and SEHMiguel angel leon bautistaNo ratings yet

- Mogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TDocument8 pagesMogul Unilet Conduit Outlet Bodies: NEC 6x8x Series (C, LB and UB) and Types LL, LR and TMiguel angel leon bautistaNo ratings yet

- DC Electrical Training Manual PDFDocument382 pagesDC Electrical Training Manual PDFMiguel angel leon bautista100% (3)

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Miguel angel leon bautistaNo ratings yet

- Catalog CONDORDocument138 pagesCatalog CONDORCostel Sentes100% (1)

- Catalog CONDORDocument138 pagesCatalog CONDORCostel Sentes100% (1)

- DC Electrical Training Manual PDFDocument382 pagesDC Electrical Training Manual PDFMiguel angel leon bautista100% (3)

- Torque RotariaDocument41 pagesTorque RotariaMiguel angel leon bautistaNo ratings yet

- Wireline Anchor Weight Indicator Systems Illustrated Parts BreakdownDocument118 pagesWireline Anchor Weight Indicator Systems Illustrated Parts BreakdownMiguel angel leon bautistaNo ratings yet

- Door StopsDocument6 pagesDoor StopsDavid GravesNo ratings yet

- Try These Funny Hindi Rhymes To Memorize That Tricky Periodic Table - KshitijDocument12 pagesTry These Funny Hindi Rhymes To Memorize That Tricky Periodic Table - KshitijabhijeetNo ratings yet

- Advanced Tool MaterialsDocument8 pagesAdvanced Tool MaterialsSry Putri AbdullahNo ratings yet

- IMYP Lab Work Redox and Electrochemical CellsDocument6 pagesIMYP Lab Work Redox and Electrochemical CellsVaida MatulevičiūtėNo ratings yet

- AMS5662Document11 pagesAMS566213421301508No ratings yet

- Practical 1 SheetmetalDocument7 pagesPractical 1 SheetmetalSyamira ZakariaNo ratings yet

- Din 22261-2 2006-12Document130 pagesDin 22261-2 2006-12ivan8113No ratings yet

- Nedal Alloy Datasheet EN AW 7003 PDFDocument1 pageNedal Alloy Datasheet EN AW 7003 PDFSinan YıldızNo ratings yet

- Hes D2016Document15 pagesHes D2016PPC100% (1)

- Dormer Pramet Drill TroubleshootingDocument4 pagesDormer Pramet Drill TroubleshootingOmkar KshirsagarNo ratings yet

- Atomic Structure of STAINLESS STEEL E316Document8 pagesAtomic Structure of STAINLESS STEEL E316Parikshit UjoodhaNo ratings yet

- Din Iso 4381Document8 pagesDin Iso 4381rajeskumarNo ratings yet

- Rack Conveyor Assembly and Detail DrawingDocument3 pagesRack Conveyor Assembly and Detail DrawingShandy Dwi PrayogaNo ratings yet

- Australian Mineral ExplorationDocument18 pagesAustralian Mineral Explorationtherockhound99No ratings yet

- Materials Science & Engineering ADocument13 pagesMaterials Science & Engineering ADaniel NavarroNo ratings yet

- Asme Marking-And-Mechanical-Properties-Of-Steel-FastenersDocument3 pagesAsme Marking-And-Mechanical-Properties-Of-Steel-Fastenersjyoti prakash singhNo ratings yet

- TurningDocument766 pagesTurningDavid BahenaNo ratings yet

- Information # 1Document1 pageInformation # 1Mantenimiento MelgarNo ratings yet

- Pinnacle Alloys E6013Document2 pagesPinnacle Alloys E6013rahulNo ratings yet

- Extreme Steel Wastage From WTC 1 or 2 and WTC 7Document11 pagesExtreme Steel Wastage From WTC 1 or 2 and WTC 7sirisfiNo ratings yet

- Universal Impact TestingDocument1 pageUniversal Impact TestingSHRI GANAPATHY INDUSTRIESNo ratings yet

- Po31510 Fres36x20 SF48410Document1 pagePo31510 Fres36x20 SF48410Keshia Murillo PinnockNo ratings yet

- Tabel Aisc LRFDDocument334 pagesTabel Aisc LRFDBustamin SipilNo ratings yet

- General Welding GuidelinesDocument13 pagesGeneral Welding GuidelinesSamir669No ratings yet

- Chloride Metallurgy - Process Technology Development - : Edgar PeekDocument39 pagesChloride Metallurgy - Process Technology Development - : Edgar PeekMauricioTeranAguilarNo ratings yet

- Total Solutions: Product GuideDocument8 pagesTotal Solutions: Product Guideanlei933No ratings yet

- Sa 325 PDFDocument12 pagesSa 325 PDFMo'men Abu-SmaihaNo ratings yet

- Connection Design-VijayDocument278 pagesConnection Design-VijayPrabhumk07No ratings yet

- Selection For Welding Consumables: A 479 Gr.316LDocument2 pagesSelection For Welding Consumables: A 479 Gr.316LanandmlNo ratings yet

- Alloy 5356 Welding Data SheetDocument2 pagesAlloy 5356 Welding Data SheetGeLoRa66No ratings yet