Professional Documents

Culture Documents

kc3012 en

Uploaded by

Tohir AhmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

kc3012 en

Uploaded by

Tohir AhmadCopyright:

Available Formats

Semi-F Series

&

FITLINK

Chains

Roller

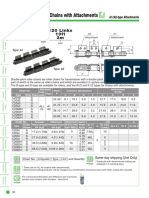

z Order No. Example Method 1 Method 2

3012H Body KC-3012 to KC-8022 Dedicated Cases KC-10020 to KC-12022 Dedicated Cases

Accessories

Chain

(Method with O-ring seals on both sides) (method where one side is fixed and the other is a Z-type oil seal)

(2 MB sprockets + 1 chain) 1 Set 3012L

3012C Case Coupling No.

Tensioners

A

Idlers

* You may order

just the chain if &

Coupling No. and Quantity B B required.

Sprockets

Order Method Dedicated Chain No. Dedicated Case No. Dedicated Case Dedicated Chain

Combinations and Quantity Dedicated Case Weight Dedicated Weight

A B ¥ ¥

No. (kg) Chain No. (kg)

Same-day shipping 3012C 69 63 0.3 3012L 0.1

4012C 77 72 0.3 4012L 0.2

Bushings

Oilless

Postage

4014C 84 75 0.4 4014L 0.2

MB3012 4016C 92 75 0.4 4016L 0.3

MB3012

3012L

=3012H

} 1 Set

5014C

5016C

101

111

85

85

0.5

0.6

5014L

5016L

0.4

0.5

Transmission

Guide

Accessories

3012C 5018C 122 85 0.8 5018L 0.6

• The body (H) consists of 2 sprockets (MB) and 1 6018C 142 106 1.2 6018L 1.0

chain (L). 6020C 158 105 1.6 6020L 1.2

• The body (H) and case (C) make up 1 set. 6022C 168 117 1.8 6022L 1.3

Conveyor Chains/

8018C 190 129 2.5 8018L 2.3

Sprockets

8020C 210 137 2.9 8020L 2.5

8022C 226 137 3.6 8022L 2.7

10020C 281 153 4.6 10020L 4.8

12018C 307 181 6.2 12018L 7.6

Couplings

Chain

* Content of the Body 12022C 357 181 8.0 12022L 9.3

A1 Multi-EP Grease No.2

For the lubricant agent, MBSG04 MBSG25

please use the dedicated Internal Capacity 400g Internal Capacity 2.5kg/16kg

Resin Rails

KANA standard coupling MBSG05

z Order No. Example grease. Internal Capacity 500g

MB 4012 See P345

Triple Speed/Carrier

(Transport) Chains

Type Model No.

Chain Coupling No. * An MB sprocket is on one side of the body (only 1 sprocket).

Body Dimensions Chain Coupling No. Prepared Shaft Hole Machining Limits Semi-F

Pulleys/Flanges

Timing Belts/

Weight kg ¥

BL BD Type Model No. Holes Minimum Maximum ¥

29.8 26.5 3012 12 14 16 0.2

36.0 36.0 4012 12 14 22 0.3

36.0 45.0 4014 12 14 30 0.5

Shaft Collars

40.0 51.0 4016 14.5 16 32 0.6

45.0 56.0 5014 14 16 35 0.9

45.0 63.0 MB 5016 16 18 40 1.1

45.0 73.0 Minimum Bore 5018 16 18 45 1.6

Pinions/Racks/

56.0 88.0 Shaft Hole 6018 20 22 55 2.6

Miter Gears

56.0 102.5 Non-machined 6020 20 22 60 3.6

56.0 115.0 6022 20 22 70 4.6

products

63.0 115.0 8018 20 22 80 5.2

65.0 125.0 Body Side 8020 20 22 85 7.0

Imperfect

Products

71.0 143.0 8022 20 22 100 8.8

80.0 162.0 10020 25 27 110 14.1

90.0 170.0 12018 35 37 125 19.7

100.0 210.0 12022 35 37 140 31.4

* Please refer to P24 to P33 for the Semi-F Series <Complete Product> order method. 379

Semi-F Series

&

PR

FITLINK

Chain Coupling Guide

Chains

Roller

Q. Which model do I need if I want to order chain couplings with cases?

Accessories

A. Models differ by shaft hole/key groove machining, NOT MACHINED <--> MACHINED

Chain

<Not Machined> * If you would like Coupling No. 5014

Model quantity

5014H x 1 5014H 5014C

Tensioners

Idlers

5014C x 1 (Body) (case)

&

Chain Coupling With Attached Case

Sprockets

<Inner Diameter Machined>

* Coupling No. 5014 If you would like inner diameter D20 and D30

Model Quantity

FBN5014D20 x 1

FBN5014D30 x 1

Bushings

For the body, 2 x MB sprockets (with no inner diameter

Oilless

5014C x 1 machining) and a chain are packed together as a set.

5014L x 1 For the <Not Machined> case, you do not

Please select 2 sprockets which have been machined with need to order chains individually.

the shaft holes/keyways that you require.

Transmission

Accessories

FBN5014D20 FBN5014D30 5014L

See P376 to 377 (inner diameter D20) (inner diameter D30) (chain only)

Please use the Semi-F Series for non-standard products.

See P26 to 27

Conveyor Chains/

Sprockets

Ordering cases is the same as for <Not Machined>.

As chains must be ordered as single items, please take care.

Couplings

For chain couplings, we recommend that you include a case, and apply grease.

Chain

(1) When using at high rotational speed.

(2) When using it in a dusty/dirty environment, for example, or in a humid atmosphere.

(3) Scattering of the lubricant agent is prevented and also any intrusion of dust/dirt.

(4) The outer appearance looks smart while reducing danger.

Resin Rails

Lubrication significantly lengthens the life of the coupling.

For the lubricant agent, Grease

please use the dedicated Chain Chain

Grease Grease

KANA standard coupling Coupling Coupling

Weight kg Weight kg

Triple Speed/Carrier

(Transport) Chains

grease. No. No.

See P345 3012 0.05 6022 0.50

4012 0.09 8018 0.80

4014 0.10 8020 1.00

Pulleys/Flanges

Timing Belts/

A1 Multi-EP Grease No.2 4016 0.12 8022 1.00

MBSG04 MBSG25 5014 0.15 10020 1.70

Internal Capacity Internal Capacity 5016 0.18 12018 3.30

Shaft Collars

400g 2.5kg/16kg

MBSG05 5018 0.25 12022 4.30

Internal Capacity 6018 0.40 16018 8.30

500g

6020 0.50 16022 10.00

Pinions/Racks/

Miter Gears

Imperfect

Products

380

You might also like

- 06-MBN Installation, operation and maintenance instruction(英文)Document92 pages06-MBN Installation, operation and maintenance instruction(英文)Muchammad Shidieq Munadzar50% (2)

- Flail Mower Series-1Document54 pagesFlail Mower Series-1b43knsNo ratings yet

- 322C Excavator Electrical System: Area DDocument2 pages322C Excavator Electrical System: Area Dمهدي شقرونNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- kc3012 enDocument3 pageskc3012 enJazmine SalomonNo ratings yet

- UCPXDocument1 pageUCPXdAvId rObLeSNo ratings yet

- Cuplaje Flexibile - RoDocument2 pagesCuplaje Flexibile - Roioan cristian cotorobaiNo ratings yet

- Kana Chain Coupling PDFDocument3 pagesKana Chain Coupling PDFDjoko Dwi IrwantoNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- FYH ZK - EnglishDocument17 pagesFYH ZK - EnglishRicardo TurlaNo ratings yet

- Chainatta1 enDocument1 pageChainatta1 enArmor MachineryNo ratings yet

- Halfen Design PDFDocument5 pagesHalfen Design PDFNitin SharmaNo ratings yet

- JVC kw-v820bt, kw-v820btm Exploded View Parts ListDocument41 pagesJVC kw-v820bt, kw-v820btm Exploded View Parts Listsamasca_serbanNo ratings yet

- Chainc2040a1 enDocument1 pageChainc2040a1 enArmor MachineryNo ratings yet

- Brosur Nyaf 1 X 4 mm2 Biru 100 Meterrol JemboDocument1 pageBrosur Nyaf 1 X 4 mm2 Biru 100 Meterrol Jembom4l4ik4tny4w4No ratings yet

- LEAD SCREW - p1 - 785Document1 pageLEAD SCREW - p1 - 785wawandev7No ratings yet

- Telescopic CylinderDocument2 pagesTelescopic CylinderReference mapiyeNo ratings yet

- BROSUR JEMBO KabelDocument7 pagesBROSUR JEMBO KabelAde SaputraNo ratings yet

- Solenoid Valves - : Spare PartsDocument1 pageSolenoid Valves - : Spare PartsJhonny ChoquehuancaNo ratings yet

- Gantry Weights-Anchor bolts-33KV GANTRYDocument2 pagesGantry Weights-Anchor bolts-33KV GANTRYNewton AdhikariNo ratings yet

- L&T Construction Water & Effluent Treatment Ic Comparative StatementDocument5 pagesL&T Construction Water & Effluent Treatment Ic Comparative StatementRocket SinghNo ratings yet

- E1224b PDFDocument3 pagesE1224b PDFMai Thế ToanNo ratings yet

- Piher T-21Document6 pagesPiher T-21EanBombingNo ratings yet

- PuleyDocument7 pagesPuleyTrường PhạmNo ratings yet

- 223-6303 Bulldozer Ar-Pwr Angle & Tilt - With Adjustable PitchDocument2 pages223-6303 Bulldozer Ar-Pwr Angle & Tilt - With Adjustable PitchAnderson Oliveira SilvaNo ratings yet

- THINK GAS WITNESS REPORT - Vishal PipesDocument10 pagesTHINK GAS WITNESS REPORT - Vishal PipesGururaj P KundapurNo ratings yet

- GA-150027-1 (003) Ffetbigbore1750 PDFDocument1 pageGA-150027-1 (003) Ffetbigbore1750 PDFriinNo ratings yet

- Katalog NYMHYDocument1 pageKatalog NYMHYpusdatin kemhanNo ratings yet

- Nymhy 2436Document1 pageNymhy 2436MUHAMMAD NAUVALNo ratings yet

- Cutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdureDocument6 pagesCutting G Off of Turboc Charger (Temp Porary) : Ro Tor Locking Proce EdurepcatruongNo ratings yet

- BOQ5Document2 pagesBOQ5md. shaju ahamedNo ratings yet

- Nym 1039 PDFDocument2 pagesNym 1039 PDFSaor PakpahanNo ratings yet

- Indoor Cable Indoor Cable: (Copper Conductor, PVC Insulated and PVC Sheathed)Document2 pagesIndoor Cable Indoor Cable: (Copper Conductor, PVC Insulated and PVC Sheathed)Saor PakpahanNo ratings yet

- Nym 1039Document2 pagesNym 1039Riri AuliaNo ratings yet

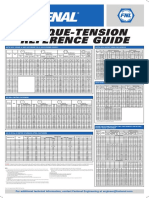

- Torque-Tension Reference GuideDocument1 pageTorque-Tension Reference GuidemaxNo ratings yet

- CLS-10K-WHS Master-26-05-2023Document7 pagesCLS-10K-WHS Master-26-05-2023shajahan hameedNo ratings yet

- INTERCONTEC - Connectors Series B - Standard INTERCONTEC - Connectors Series B - SpeedtecDocument1 pageINTERCONTEC - Connectors Series B - Standard INTERCONTEC - Connectors Series B - SpeedtecLuis Pinto RojasNo ratings yet

- Automotive Differential HousingDocument5 pagesAutomotive Differential Housingfileuse.fNo ratings yet

- CB 534 D Sistema Electrico PDFDocument6 pagesCB 534 D Sistema Electrico PDFCarlos IrabedraNo ratings yet

- Cuplaje Rigide - RoDocument2 pagesCuplaje Rigide - Roioan cristian cotorobaiNo ratings yet

- Ahw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Document6 pagesAhw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Parag Lalit SoniNo ratings yet

- PiherDocument5 pagesPiherElvir ModricNo ratings yet

- BT ManualDocument6 pagesBT Manualpatrickmen_86No ratings yet

- LT - Power - Cable Schedule For Garret Line (Danieli)Document3 pagesLT - Power - Cable Schedule For Garret Line (Danieli)zibraltan1No ratings yet

- Bill of Materials: Notes: 1) - Impact Testing Is Required 2) - Insulation Cleats To Be ProvidedDocument3 pagesBill of Materials: Notes: 1) - Impact Testing Is Required 2) - Insulation Cleats To Be ProvidedSubrata DasNo ratings yet

- Drylin® 20SHT 08Document1 pageDrylin® 20SHT 08juanibirisNo ratings yet

- 980G Wheel Loader Electrical System: Machine Harness Connector and Component LocationsDocument2 pages980G Wheel Loader Electrical System: Machine Harness Connector and Component LocationsRafa GarciaNo ratings yet

- IBR Valves Schedule: Thermax LTD., PuneDocument3 pagesIBR Valves Schedule: Thermax LTD., PuneGuitarist Ratan DebnathNo ratings yet

- RENR81260001Document4 pagesRENR81260001dardar21918No ratings yet

- UH06Document1 pageUH06deprianto MNo ratings yet

- Acople 5R10Document1 pageAcople 5R10Jose Emilio Carrero AngaritaNo ratings yet

- Lead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsDocument1 pageLead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsMyint Myat NaingNo ratings yet

- Parts: N1 To N8Document10 pagesParts: N1 To N8Encep Rustandi100% (1)

- Cable Assembly: Technical Data SheetDocument2 pagesCable Assembly: Technical Data SheetrizkyNo ratings yet

- Components and Descriptions Components and Descriptions: RTD Assemblies RTD AssembliesDocument7 pagesComponents and Descriptions Components and Descriptions: RTD Assemblies RTD AssembliesVinicio VillarruelNo ratings yet

- Winch Ga DrawingDocument1 pageWinch Ga DrawingrituNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Gre Eec D 99 CL P 11871 08 001 02Document7 pagesGre Eec D 99 CL P 11871 08 001 02Greddy FerrerNo ratings yet

- 938G Series II Wheel Loader Electrical System IT38G Series II Integrated ToolcarrierDocument4 pages938G Series II Wheel Loader Electrical System IT38G Series II Integrated ToolcarrierGlenn DiazNo ratings yet

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- Captura de Pantalla 2022-04-14 A La(s) 2.46.12 P. M.Document210 pagesCaptura de Pantalla 2022-04-14 A La(s) 2.46.12 P. M.Oscar GomezNo ratings yet

- Everest Blower Troble Shooting ManualDocument10 pagesEverest Blower Troble Shooting Manualdumb2471817100% (1)

- 08 Polycom InspectionDocument33 pages08 Polycom InspectionAnita Fernandez C.100% (3)

- Operation Manual: TQ340/35Y Power Casing TongDocument20 pagesOperation Manual: TQ340/35Y Power Casing TongNgwe Min TheinNo ratings yet

- Lubrication School: Training and Capability DevelopmentDocument20 pagesLubrication School: Training and Capability DevelopmentFraz AhmadNo ratings yet

- 25 Ton Rod Spinner Operators Manual: ContentDocument6 pages25 Ton Rod Spinner Operators Manual: ContentMateo PorrasNo ratings yet

- Installation, Operation and Maintenance Instructions: Vibrating Feeders & ConveyorsDocument8 pagesInstallation, Operation and Maintenance Instructions: Vibrating Feeders & ConveyorsKarin AndersonNo ratings yet

- RTB 1 09c Bogie Subsystems Flange LubricationDocument8 pagesRTB 1 09c Bogie Subsystems Flange Lubricationsagger09No ratings yet

- Luneta L300 SMW-X 3.2-ZSDocument2 pagesLuneta L300 SMW-X 3.2-ZSMartín CórdobaNo ratings yet

- Manual CycloBlower T5CDL, 37-2-600 V5 12-05Document48 pagesManual CycloBlower T5CDL, 37-2-600 V5 12-05Jorge Antonio Quant Jo100% (1)

- 2017 Mini Hydraulic Excavator Parts Reference GuideDocument9 pages2017 Mini Hydraulic Excavator Parts Reference GuideLeszek GrabiecNo ratings yet

- Manufacturing Instructions SN 200-7: Important ! Please Note The Corresponding Correction/revision !Document9 pagesManufacturing Instructions SN 200-7: Important ! Please Note The Corresponding Correction/revision !RaviTeja BhamidiNo ratings yet

- Tesco: Synthetic Blend Grease NLGI #1 - Cold WeatherDocument2 pagesTesco: Synthetic Blend Grease NLGI #1 - Cold Weatherlucas ronaldo coronel mendozaNo ratings yet

- Manual Lubricating PumpDocument56 pagesManual Lubricating PumpfrancoemanuelNo ratings yet

- AMSOIL SemiFluid 00 Synthetic EP Grease (GSF)Document2 pagesAMSOIL SemiFluid 00 Synthetic EP Grease (GSF)amsoildealerNo ratings yet

- Difficult To Lubricate AreasDocument12 pagesDifficult To Lubricate AreasBhushan MalsheNo ratings yet

- J IndexDocument4 pagesJ Indexapi-3820466No ratings yet

- AAR - Manual-Of-Standards-And-Recommended-PracticesDocument18 pagesAAR - Manual-Of-Standards-And-Recommended-PracticesAndres SalcedoNo ratings yet

- Calculating Grease Quantity, FrequencyDocument5 pagesCalculating Grease Quantity, Frequencymans2014No ratings yet

- S04 MaintenanceDocument4 pagesS04 MaintenanceJacquelineNo ratings yet

- ZF Transmition OilDocument16 pagesZF Transmition OilSamwelNo ratings yet

- 013.0 - Cat-6030 - CAMP - Greasing System - AttachmentDocument46 pages013.0 - Cat-6030 - CAMP - Greasing System - Attachmentmogomotsi maganoNo ratings yet

- Instruction Manual GPS GWIM01-10 Amd 02Document8 pagesInstruction Manual GPS GWIM01-10 Amd 02Suelen BarbosaNo ratings yet

- Grayhound Wear Check Guide Book 21085Document36 pagesGrayhound Wear Check Guide Book 21085julianmata100% (1)

- Fuchs Cassida Product-OverviewDocument4 pagesFuchs Cassida Product-OverviewRafael Nakazato RecioNo ratings yet

- Supplementary Service ManualDocument37 pagesSupplementary Service ManualarifinNo ratings yet

- International Price List 90.3Document36 pagesInternational Price List 90.3Salem IereebiNo ratings yet

- ZF Transmission Oil Lubrication GuideDocument14 pagesZF Transmission Oil Lubrication GuidePrudz100% (1)