Professional Documents

Culture Documents

A320 Schematics 1597070006 PDF

A320 Schematics 1597070006 PDF

Uploaded by

Khairul Nazmi Zainol AriffinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A320 Schematics 1597070006 PDF

A320 Schematics 1597070006 PDF

Uploaded by

Khairul Nazmi Zainol AriffinCopyright:

Available Formats

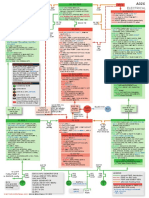

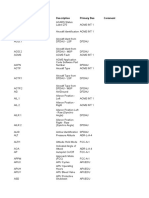

BLEED CAUTION, do not use AVIONICS VENTILATION CAUTION, do not use GND AIRCOND

HP GND air with APU bleed CONFIGURATIONS: AIRCOND air with air from PACK CTL

CLOSED, on GND (skin<9°-12°C), FLT(skin<32°-35°C)

if (skin>32°-35°C) then EXTRACT VLV partially opens

packs simultaneously Prim fail => flow not optimized

Sec fail => ECAM sgnal lost

Regulated pressure 44 +/- 4 psi OPEN, on GND (skin>9°-12°C) PACK 1

ZONE CTL Both fail => 15°C by a/ice vlv

Leak detection SMOKE CONFIG FLOW ZONE CTL

CH1 [AC1/DC1]

- single loop for APU and pylon ducts Air from avionics bay CONTROL Prim fail => 24°C by packs

CH2 [AC2/DC2] CABIN

- double loop for wing ducts SKIN EXCH VALVE Sec fail => no effect

SKIN HEAT AIR

OUTLET [DC ESS PACK 1 CTL Both fail => 20°C pack 1

Temperature control EXCHANGER SKIN

BYPASS VLV SHED] CH1 [AC1/DC1] 10°C pack 2

- HI TEMP if 290°C > 5sec or EXCH FILTER

270°C > 15sec or AEVC ISOL CH2 [AC2/DC2]

CAB FAN 1

257°C > 55sec [DC1] VLV [AC1]

- LO TEMP if < 150°C [DC ESS PACK

BLOWER COCKPIT EXTRACT 1 COCKPIT

Pressure control SHED]

ENG A/ICE VALVE FAN PANELS FAN SKIN AIR

- HI PRESS if > 60psi ENG 1 [DC1] SKIN AIR [AC1] [AC2] EXTRACT HOT AIR FLAP

- LO PRESS if < 4psi INLET VLV AVIONICS VLV

ENG 2 [DC2] PRESS VALVE

EQPMT TRIM

valve opens if unpowered REG VLV

AIR VALVES

FILTER FWD

AIRCOND SKIN CABIN

INLET MIXING

EXCH UNIT

VALVE INLET

FAN AIR VALVE EMER

ENG 1 [DC ESS SHED] 5th BYPASS

HP VLV VLV RAM AIR AIRCOND TRIM

ENG 2 [DC2] [DC ESS] GND

ENG 1 [DC ESS SHED] cargo AIR VALVES

regulates BLEED temp at 200°C 9th CONNECT

ENG 2 [DC2] under-floor PACK 2

(ENG 1 only) FLOW

CONTROL AFT

BLEED MONITORING BLEED VALVE CABIN

VALVE [DC2] PACK

COMPUTER ENG 1 [DC ESS SHED] pressure

BMC 1 [DC ESS SHED] ENG 2 [DC2] HYD WATER 2 CAB FAN 2

indication LOOP A

BMC 1 [DC2] RES TANK [AC2]

OVERPRESS LOOP B FILTER

PACK 2 CTL

VALVE (85psi) FF SATCOM

STARTER VLV CH1 [AC1/DC1]

FF CH2 [AC2/DC2] CABIN AIR

FF (85% recycle air)

temperature ZONE CTL

B1

indication X-BLEED VLV CH1 [AC1/DC1]

AUTOCTL [DC2] B2 CH2 [AC2/DC2]

HOT BLEED MANCTL [DC ESS SHED]

COLD FAN AIR

COLD AIR FROM PACK SAFETY

MIXED CONDITIONNED AIR VALVES MOT 1 CPC 1 PRESSURIZATION

WING ANTI ICE VLV [DC ESS] [DC ESS] - 2 safety valves (max 8.6psi or -.25psi)

[AC ESS SHED] HP GND

CONNECT - if RAM AIR ON and ∂p<1psi, outflow vlv

Valve closes if unpowered MAN is 50% open (if not in MANUAL)

MAN V/S

MOT

SWITCH

[DC BAT] - EXCESS CAB ALT (>9550+/-350ft)

only SLATS 3,4 & 5

are heated OUTFLOW

VALVE MOT 2 CPC 2

[DC2] [DC2]

APU ELECTRONIC

FWD

CARGO

FIRE PROTECTION

APU

LIMITATIONS

RPM min 95%, max 107% (auto shut down)

CONTROL BOX

[BAT] BLEED

COMP

A321 only

SMOKE DETECT & CARGO VENT

VALVE CONTROL UNIT

running EGT max 682°C (5sec) or 700-742 OUTLET ISOL SMOKE DETECTORS

SDCU

start EGT max 900°C > 25'000ft VALVE SQUIBS

B CH1 [DC ESS SHED]

start EGT max 982°C < 25'000ft EXTRACT FAN B [DC BAT] F FIRE DETECTORS

APU FF CH2 [DC2]

LOW OIL LEVEL => 10 hrs APU ops [AC1]

start cycles: S 1min S 1min S 60min APU B FIREX BOTTLES

Enveloppe: STARTER AFT

START with AC pwr up to 39'000ft [BAT] CARGO

A321 only ELECTRICAL SUPPLY

START with EMER ELEC pwr up to 25'000ft COMP

APU LP VLV ENG 1 loop A [DC ESS], loop B [DC2]

BLEED ON 2packs max 15'000ft, 1 pack max 20'000ft [DC BAT]

BLEED ON for engine start max 20'000ft BULK ENG 2 loop A [DC2], loop B [DC ESS]

[HOT 1] APU loop A & B[DC BAT]

BLEED for WING A/ICE not permitted INLET CARGO

APU FUEL FLOW ~130 kg/hr APU PUMP ISOL ENG 1&2 BTL 1 squib A [HOT1] squib B [HOT2]

VENTILATION

[DC BAT] P VALVE ENG 1&2 BTL 2 squib A [DC2] squib B [DC2]

CONTROL

[AC ESS APU BTL squib A [HOT1] squib B [DC BAT]

SHED] CABIN APU auto extinguish [DC BAT]

AMBIENT

AIR

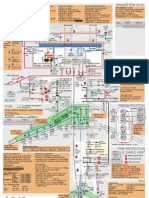

FUEL A319/A320 refueling / defueling lines

feeding lines

FUEL EIU ENG cool-down time 3'

or 1' if required by ops

NOZZLES ENG1 [DC BAT]

ENGINE

ENG2 [DC ESS] A319: CFM56-5B6/2 23'500lbs

TOTAL TANKS CAPACITY (den 0.80kg/l) A320: CFM56-5B4/2 27'000lbs

FF

19088kg CENTER TANK CENTER TANK A320E: CFM56-5B4/P 27'000lbs

HP VLV [DC ESS] A321: CFM56-5B1/2 30'000lbs

6600kg 6560kg

OUTER to INNER TRANSFER X-FEED FUEL METERING VLV N1 100% = 5000 rpm

- XFR valves open when INNER have ~750kg MOT 1 [DC ESS SHED] IDG OIL COOLER N2 100% = 14460 rpm

- T/O only with Outer TK full LP VALVE MOT 2 [DC1] IGNITION

MOT 1 [DC ESS] SERVO FUEL FADEC

- Automatic XFR after landing ENG ENG1&2 A [AC ESS]

MOT 2 [DC2] HEATER ENG1&2 CH A [DC ESS]

(to avoid, switch REFUEL panel PWR ON!) PMP or [AC STAT INV]

or transfer via DEFUEL/XFR valve jet pump FUEL/OIL HEAT ENG1 CHB [DC BAT]

1 ENG1 B [AC1]

see OMB vol.2 1.4 / 28.4 ENG2 CHB [DC2] ENG2 B [AC2]

DEFUEL LP VALVE

XFR MOT 1 [DC ESS]

FQI 1 2 1 2

XFR VALVES VLV MOT 2 [DC2]

CH1 [DC ESS SHED]

CH2 [DC2] 1 [DC ESS SHED] INNER TANKS WING TANKS CENTER to WING TRANSFER

2 [DC2] 2 x 5540kg -Valve opens until wing tank is full then wait

2 x 6200kg until 250kg are used and re-opens

- Gravity transfer from CTR TK

OUTER TANKS only possible if >2000kg in

LH 1 LH 2 CTR1 CTR XFR RH 1 RH 2

REFUEL VALVE 2 x 704kg [AC1] [AC2] [AC1] VLV [AC1] [AC2] center tank these

[DC2] refueling on [DC1] [DC2] [DC1] L[DC1] [DC1] [DC2] are trapped

batteries with [DC ESS] R[DC2] [DC ESS]

[HOT1] CTR2

REFUEL [AC2] REFUEL REFUEL

COUPLING [DC2] COUPLING VALVE

FUEL IMBALANCE A319/A320 VENT TANK

INNER TK Full, max 1500kg ~50kg

INNER TK 4300kg, max 1600kg

TANK PUMPS WING PUMPS A321 FUEL

INNER TK 2250kg, max 2250kg A321 FUEL IMBALANCE

FUEL TEMPERATURE TOTAL CAPACITY

no limitations below 2250kg WING TK Full, max 1350kg

JET A1 min -43°C max +54°C

OUTER TK max 530kg, if OUTER+INNER same JET A min -36°C max +54°C (den 0.80kg/l) WING TK 4000kg, max 1500kg

or INNER of empty OUTER equal or higher (up to 3t) of WING TK 2350kg, max 2350kg

opposite INNER

JET B, JP-4, JP-5, JP-8, RT, TS-1 see OM B 1.1.1

18960kg no limitations below 2350kg

!!! NOT FOR OPERATIONAL USE !!! ©Pierre-Michel Gasser, 14.05.2007

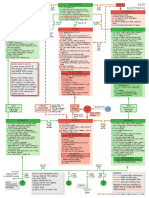

BATTERIES

2 x 28V 23 Ah, allow at

BAT 1 DC BAT BUS BAT 2 A320

least 20min in-flight PWR

BAT

CONT

COND CPC MAN CTL

FIRE APU LOOP A & B, AUTO EXT, BTL1

BAT

CONT

ELECTRICAL

HOT BUS 1 SQUIB B, FWD & AFT CARGO BOTTLES HOT BUS 2

FUEL APU PUMP, APU LP VLV

FIRE ENG 1&2 BTL 1 SQUIB A, APU BTL APU ECB SUPPLY, STARTER MOT (via BAT COM EXTERNAL HORN

SQUIB A only, available 3min with APU MASTER ON) FIRE ENG 1&2 BTL 1 SQUIB B

FLT CTL ELAC 1, SEC 1 DOORS DOORS & SLIDE CTL FLT CTL ELAC 2, PITCH TRIM MOT 1

FUEL APU LP VLV ENGINE ENG 1 FADEC CH B, ENG 1 EIU HYD RAT MAN CTL

HYD RAT AUTO CTL DC TIE NAV ADIRU 1 (back-up), ADIRU 2 (back-up

ESS DC TIE DC TIE

LDG GEAR PARK BRK CTL CONT 5min)

CONT

NAV ADIRU 3 (5min if on NORM or F/O) DOORS DOORS AND SLIDES CTL (stby)

DC BUS 1 DC ESS DC BUS 2

COND PACK 1 PRIM, PACK 2 PRIM, ZONE COND RAM AIR INLET, CPC 1 COND PACK 1 SEC, PACK 2 SEC, ZONE CTL

STAT

CTL PRIM, AEVC AUTO FLT FCU 1 SEC, PACK 2 VLV CLOSURE, CPC 2

INV

COM VHF 3, SELCAL, 3rd ACP, COM VHF 1, RMP 1, CAPT & F/O ACP, FLT AUTO FLT FMGC 2, FCU 2

CONT

FUEL LEFT TK PUMP 1, RIGHT TK PUMP 1, INTERPHONE, CAPT LOUDSPEAKER, CIDS COM VHF 2, RMP 2, F/O LOUDSPEAKER

CTR TK PUMP 1 (A319/A320), LEFT XFR 1 & 2, DEU (A/B) FIRE ENG 1 LOOP B, ENG 2 LOOP A, ENG

VLV (A321) FIRE ENG 1 LOOP A, ENG 2 LOOP B 1&2 BTL 2 SQUIB A&B, SDCU CH 2

HYD ENG 1 PUMP CTL FLT CTL ELAC 1, SEC 1, PITCH TRIM MOT 2, FLT CTL ELAC 2, SEC 2 & 3, FAC 2, FCDC 2,

ICE ENG A/ICE CLOSURE VLV 1, WHC 1, RUD TRIM MOT 1, RUD TRAVEL LIM MOT 1, PITCH TRIM MOTOR 1 & 3, RUD TRIM MOT

STBY PHC, STBY & CAPT STATICS, CAPT SFCC 1 FLAPS & SLATS 2 & INDIC, RUD TRAV LIMIT MOT 2, SFCC 2

STAT

TAT, CAPT WIPER FUEL L&R TANK PUMP 1, ENG 1&2 LP VLV SLATS & FLAPS

INV

LDG GEAR BSCU CH1 MOT 1 FUEL FQI CH 2, LEFT TK PUMP 2, RIGHT TK

CONT

LIGHTS L CONSOLE, R MAIN INST PNL, HYD ENG 1&2 FIRE SHUT OFF VLV, B ELEC PUMP 2, CTR TK PUMP 2 (A319/A320),

SUPP READ, PEDESTRAL, L READ, L PUMP CTL XFEED VLV MOT 2, ENG 1&2 LP VLV MOT

BRIEF, L MAP, FLOOR ICE CAPT PHC, CAPT REPELLENT 2, XFR VLV L&R 2, REFUEL VLV, RIGHT

NAV GPS 1, CFDS EIS ECP(if bus lost, CLR & ALL still available) CTR XFR VLV (A321)

ENGINE ENG 1 OIL PRESS & QTY LDG GEAR LGCIU 1, SAFETY VLV, BRK HYD ENG 2 PUMP CTL, Y ELEC PUMP CTL,

PRESS INDIC PTU

LGT R DOME, L MAIN INST PANEL, STBY ICE ENG A/ICE CLOSURE VLV 2, WHC 2, F/O

COMPASS & AIRSPEED, some CABIN LGT PHC, F/O STATICS, F/O TAT, F/O WIPER,

EMER GEN CONFIG (stby) F/O REPELLENT

In case of loss of AC1 & NAV STBY HORIZON LDG GEAR BSCU CH 2, BRK FAN CTL

ENG ENG 1&2 FADEC CH A, ENG 1&2 EIU, LIGHTS R CONSOLE, R READ, R BRIEF, R

AC2 busses, RAT comes out FUEL HP & LP VLV MAP, ANNUNCIATOR LGT TEST/DIM, RWY

and EMER GEN comes DC ESS SHED TURN OFF CTL, TAXI & T/O CTL, LOGO

online after ~8 seconds available only with EMER GEN running CTL

NAV GPS 2, CFDS

COND PACK 1 VLV CLOSURE, AEVC BLEED BMC 2, ENG 2 HP & LP & FAN VLV

When LDG GEAR down AUTO FLT FMGC 1 ENG ENG 2 FADEC B & OIL PRESS & QTY

COM CVR CTL

(A320 only) or when the FIRE SDCU CH 1

DC FLT/GND

RAT stalls or on GND with can be powered via TR2 by EXT PWR

FLT CTL FAC 1, FCDC 1

COM CIDS 1 & 2, DEU (A/B)

speed<100kts(other types), FUEL FQI CH 1, XFEED VLV MOT 1, L&R

HYD LEAK MES VLV

XFR VLV 1

the EMER GEN is no longer LGT STBY & METER ALTIMETER LDG GEAR LGCIU 1 & 2, PARK BRK

powered. BAT are feeding OXY CREW OXY CTL, PAX OXY CTL

LGT L DOME

DC&AC ESS without the AUTOCONTROL

WATER POTABLE WATER SYS,

BLEED BMC 1, ENG 1 LP & HP & FAN

SHED busses. VLV, X-BLEED MAN CTL 2 DRAINING, FLUSH CTL UNITS

DOORS CARGO DOORS

speed>50kts & on

TR 1 STATIC ESS TR TR 2

batteries only: BLUE HYD

converts AC 115V INVERTER STAT INV activates identical EMER converts AC 115V

into DC 28V RAT into DC 28V

max 200A

converts DC into AC regardless of BAT to TR1&2 GEN max 200A

switch position

5kVA 115V

failure of TR1

and/or TR2 or

400Hz

AC1

AC BUS 1 AC ESS AC BUS 2

COND PACK 1 PRIM, PACK 2 PRIM, ZONE AC ESS FLT CTL FAC 1 COND PACK 1 SEC, PACK 2 SEC, ZONE CTL

CTL PRIM, CABIN FAN 1, AVIONIC FAN ICE CAPT PITOT HEAT AC ESS SEC, CABIN FAN 2, AVIONIC FAN EXTRACT

FEED

BLOWER, AFT CRG VENT FAN EIS CAPT PFD, E/WD, DMC 1, DMC 3(if CAPT FEED AUTO FLT MCDU 2

(NORM)

COM HF1 (if installed),ACARS on 3), FWC 1, SDAC 1 (ALTN) EQPMT F/O SEAT

EQPMT CAPT SEAT, FOOT WARMER NAV ADIRU 1, AOA 1, ILS 1 or MMR 1 , VOR 1 FIRE LAV SMOKE SDCU CH 2

FUEL LEFT TK PUMP 1, RIGHT TK PUMP 1, ENGINE IGN A ENG 1 & 2 FLT CTL FAC 2

CTR TK PUMP 1 (A319/A320) AC ESS SHED FUEL LEFT TK PUMP 2, RIGHT TK PUMP 2,

HYD HYD BLUE ELEC PUMP PWR available only with EMER GEN running CTR TK PUMP 2 (A319/A320)

ICE WINDOW HEAT L PWR, STBY PITOT AUTO FLT MCDU 1 HYD YELLOW ELEC PUMP PWR

HEAT, STBY AOA HEAT, ICE DETECT 1 COM CVR ICE R WINDOW HEAT PWR, F/O PITOT HEAT,

EIS DMC 3, FDIU FUEL APU PUMP F/O AOA HEAT, ICE DETECT 2

LDG GEAR BSCU CHANNEL 1 ICE WING A/ICE SHUT OFF VLV L&R, EIS F/O PFD & ND, SD, DMC 2, FWC 2, SDAC 2

LIGHTS INST PNL INTEGRAL, some CAPT AOA HEAT LDG GEAR BSCU CHANNEL 2, BRK FANS

ANNUNCIATOR, L LDG, L RWY TURN OFF, L EIS CAPT ND LIGHTS some ANNUNCIATORS, R LDG, R RWY

TAXI & T/O, L LOGO, UPPER BCN, L WING, LDG GEAR INICATING PANEL TURN OFF, R TAXI & T/O, R LOGO, LOWER

some CABIN LGT NAV DME 1, ADF 1, ATC 1 BCN, STROBE, R WING, some CABIN LGT

NAV ADIRU 3, AOA RESOLVER 3, RA1, TCAS, OXY PAX OXY CTL ACTUATION NAV ADIRU 2, AOA RESOLVER 2, ILS 2 or MMR

WX RADAR, EGPWS 2 , VOR 2, DME 2, RA 2, ATC 2

ENGINE IGN B ENG 1, EVMU 1&2 AC STAT INV WATER HEATER, PRESS SYS

(only available on BAT) ENGINE IGN B ENG 2

LDG GEAR INDIC PANEL (GEN & AC FLT/GND

EMER GEN not running) can be powered direct by EXT PWR

LGT some ANNUNCIATORS LGT NAV, some CABIN LIGHTS

ENG IGN A

BUS TIE BUS TIE

CONT CONT

to L & R

FUEL PUMP 1 GEN ENG & APU GENERATORS APU EXT GEN LEGEND

in SMOKE config LINE 3-phase 90kVA 115V 400Hz LINE PWR LINE normal PWR distribution

CONT CONT CONT CONT PWR on BAT only

max load 100%

PWR with EMER GEN

EMER GENERATOR

GCU GEN APU GEN alternate feeding lines

3-phase 5kVA 115V 400Hz

(1 per generator) 1 GEN 2 Busses in red are available in

controls frequency SOURCE PRIORITY GPCU

and voltage 1) ENG GEN EMER ELEC config with EMER

2) APU or EXT if switch ON GEN running

EXT

PWR

!!! NOT FOR OPERATIONAL USE !!! ©Pierre-Michel Gasser, 31.1.2005

You might also like

- Memory Jogger A320Document157 pagesMemory Jogger A320Vikram Kailthya96% (49)

- A320 For DummiesDocument223 pagesA320 For DummiesEmmanuel Adell82% (11)

- A320 SystemsDocument4 pagesA320 SystemsHarshenDesai100% (8)

- A320 Air PDFDocument1 pageA320 Air PDFStephanie Johnson100% (1)

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- A320 To PanelDocument1 pageA320 To PanelAzral Abu Bakar100% (2)

- A320 Alpha Call Up N CB LocationDocument20 pagesA320 Alpha Call Up N CB LocationReksa Karisma YogasmaraNo ratings yet

- Panel Ejets PDFDocument3 pagesPanel Ejets PDFEdd PO100% (1)

- Alpha Call-Ups A330Document18 pagesAlpha Call-Ups A330János Rédei100% (4)

- A320 Debrief SchematicsDocument26 pagesA320 Debrief Schematicsflyjeetu100% (8)

- PFD & ND A320 A330Document8 pagesPFD & ND A320 A330Amit Saha90% (21)

- Instructor Support A320Document208 pagesInstructor Support A320Nik Martin100% (27)

- A320Document1 pageA320Heber CastroNo ratings yet

- Airbus Flight Control Laws: The Reconfiguration LawsFrom EverandAirbus Flight Control Laws: The Reconfiguration LawsRating: 4.5 out of 5 stars4.5/5 (16)

- A320 FMGS Codes BragaDocument25 pagesA320 FMGS Codes BragaMarcos Braga92% (13)

- BarmanDocument54 pagesBarmangene roy hernandez100% (1)

- Airbus A320 SystemsDocument41 pagesAirbus A320 SystemsmonawarNo ratings yet

- A320 Elec PDFDocument1 pageA320 Elec PDFStephanie Johnson100% (1)

- A320 CB-PanelsDocument95 pagesA320 CB-Panelsyazan999No ratings yet

- Cat - Dcs.sis - Controller 3412 XDocument2 pagesCat - Dcs.sis - Controller 3412 XKariem R Noweer67% (3)

- A320 EACM Message RESET CB PDFDocument44 pagesA320 EACM Message RESET CB PDFbluesky_1976100% (5)

- E 170 Interactive Cockpit GuideDocument90 pagesE 170 Interactive Cockpit Guideaivanov3100% (14)

- HP GND Air With APU Bleed: CAUTION, Do Not UseDocument1 pageHP GND Air With APU Bleed: CAUTION, Do Not UseElias Iruela100% (1)

- g550 Notes Feb16Document18 pagesg550 Notes Feb16christosNo ratings yet

- A320 Hyd PDFDocument1 pageA320 Hyd PDFStephanie Johnson100% (1)

- Design of TransformerDocument47 pagesDesign of TransformerhamzaNo ratings yet

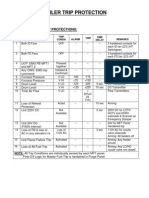

- Boiler Trip Protection: Master Fuel Trip ProtectionsDocument2 pagesBoiler Trip Protection: Master Fuel Trip ProtectionsKuntal Satpathi100% (3)

- A320 CB PanelsDocument67 pagesA320 CB PanelsMiklós Meixner100% (4)

- Test Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDocument24 pagesTest Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDavidLarsonDDSfgaq100% (42)

- A320 - A330 QRH Abnormal and Emergency Procedures SummaryDocument8 pagesA320 - A330 QRH Abnormal and Emergency Procedures SummaryAlexander Sturm50% (2)

- Reset TipsDocument66 pagesReset TipsJoe Ho100% (3)

- A320 AirDocument1 pageA320 AirEnrique Barberan100% (1)

- A320 FlowsDocument11 pagesA320 FlowsCarlos Andrés Valencia G100% (2)

- Airbus A320 Flight Controls LawsDocument74 pagesAirbus A320 Flight Controls LawsMoHd MacKi0% (1)

- V Lift Presentation JBPDocument9 pagesV Lift Presentation JBPrekyhoffman0% (1)

- Airbus A320 Systems A4 FormatDocument48 pagesAirbus A320 Systems A4 FormatLogan Doe100% (28)

- A320 Performance Training ManualDocument154 pagesA320 Performance Training ManualJulioallende85% (13)

- A320 Automation PDFDocument1 pageA320 Automation PDFAlina Costica100% (13)

- A320 Automation PDFDocument1 pageA320 Automation PDFAlina Costica100% (13)

- A320 FLT CTRL Laws and ProtectionsDocument37 pagesA320 FLT CTRL Laws and Protectionsbojan6593% (15)

- A333 Elec PDFDocument1 pageA333 Elec PDFStephanie JohnsonNo ratings yet

- Power Plant EmergencyDocument22 pagesPower Plant Emergencysekhar_ntpc75% (4)

- Guidance For Preflight Walk-Around REV02 PDFDocument60 pagesGuidance For Preflight Walk-Around REV02 PDFAlina Costica100% (4)

- A330 HydDocument1 pageA330 HydElias Iruela100% (7)

- Airbus A320 Flight Controls LawsDocument74 pagesAirbus A320 Flight Controls Lawspontoo97% (79)

- A320 Eletrical SystemDocument1 pageA320 Eletrical SystemEduardo Almeida SilvaNo ratings yet

- Cold Weather Operations Manual REV0-05.2012 PDFDocument119 pagesCold Weather Operations Manual REV0-05.2012 PDFAlina Costica100% (2)

- A320 TestDocument1 pageA320 Testcaptmon351100% (2)

- A320 ElecDocument1 pageA320 ElecEnrique Barberan100% (1)

- A320 - Ecam - Pages PDFDocument1 pageA320 - Ecam - Pages PDFRaja17450% (2)

- Smartcockpit Questions Answers For Airbus A 320Document78 pagesSmartcockpit Questions Answers For Airbus A 320Alina Costica100% (17)

- Smartcockpit Questions Answers For Airbus A 320Document78 pagesSmartcockpit Questions Answers For Airbus A 320Alina Costica100% (17)

- A320Document95 pagesA320ccoyureNo ratings yet

- ND A320Document11 pagesND A320puneetkhokhar4504No ratings yet

- ATR CB Location 72-600Document19 pagesATR CB Location 72-600KitKat ShArry100% (3)

- Renr2477renr2477-02 SisDocument4 pagesRenr2477renr2477-02 SisNanda PutriNo ratings yet

- LPPEH Standard GuidelinesDocument27 pagesLPPEH Standard GuidelinesEncik Syafix57% (7)

- A320 Overhead PanelDocument1 pageA320 Overhead PanelMartha B. de Lima100% (4)

- Airbus A330 PanelsDocument1 pageAirbus A330 PanelsLbrito0175% (4)

- Airbus A320 Family CB List and ResetsDocument30 pagesAirbus A320 Family CB List and ResetsZbor ZborNo ratings yet

- Tech NotesDocument20 pagesTech NotesMuvinda JayasingheNo ratings yet

- Circuit BreakersDocument3 pagesCircuit BreakersSuratman Bin SuparmanNo ratings yet

- Airbus Aids CodesDocument1 pageAirbus Aids CodesARJIT GUPTANo ratings yet

- 737ng Acms CodesDocument13 pages737ng Acms CodesSamitha Ruwan Kumara100% (2)

- Airbus A320 Family CB List and ResetsDocument30 pagesAirbus A320 Family CB List and Resetsaeozbay94% (17)

- Brand Life Cycle Theoretical DiscoursesDocument7 pagesBrand Life Cycle Theoretical DiscoursessolahaiNo ratings yet

- Toyota Mil CodeDocument3 pagesToyota Mil CodeinayyerNo ratings yet

- Airbus A320 No-Go Items AtaDocument1 pageAirbus A320 No-Go Items Ata57tnd7czznNo ratings yet

- STS1Document12 pagesSTS1Kom WongsawatNo ratings yet

- 48 50a-3wDocument28 pages48 50a-3wtecairNo ratings yet

- Chapter 29 Embraer DescriptionDocument3 pagesChapter 29 Embraer Descriptionaerologik_347746151No ratings yet

- The-Problematics-Of-Grammatical-Homonymy-The-Subject-And-Object-Complements - Content File PDFDocument6 pagesThe-Problematics-Of-Grammatical-Homonymy-The-Subject-And-Object-Complements - Content File PDFAlina CosticaNo ratings yet

- Agricolor 2019. En.Document32 pagesAgricolor 2019. En.Alina CosticaNo ratings yet

- Dramaturgy and Performance - Review BookDocument2 pagesDramaturgy and Performance - Review BookKamal TidulNo ratings yet

- LG Membranes Technical ManualDocument46 pagesLG Membranes Technical Manualfarhadzaker0% (1)

- Stages of The Venture Life CycleDocument8 pagesStages of The Venture Life CycleOckouri BarnesNo ratings yet

- 2000 - The Genetics of Mental IllnessDocument9 pages2000 - The Genetics of Mental Illnesssiempreviva84No ratings yet

- Copper-Alloy Plate and Sheet For Pressure Vessels, Condensers, and Heat ExchangersDocument7 pagesCopper-Alloy Plate and Sheet For Pressure Vessels, Condensers, and Heat ExchangersSharad KokateNo ratings yet

- MEC 309 OutlineDocument4 pagesMEC 309 OutlineBob jonesNo ratings yet

- Est Siga-Cr PDFDocument6 pagesEst Siga-Cr PDFjhon bayonaNo ratings yet

- Jurnal Prosedur SEM-EDXDocument105 pagesJurnal Prosedur SEM-EDXRiskaNo ratings yet

- Reducing The Braking Distance of An SQL Query Engine: Carey@almaden. Ibm. Corn Kossmann@db, Fmi - Uni-Passau - deDocument12 pagesReducing The Braking Distance of An SQL Query Engine: Carey@almaden. Ibm. Corn Kossmann@db, Fmi - Uni-Passau - dedavidrajhivcNo ratings yet

- Zhob Adda ProjectDocument32 pagesZhob Adda ProjectKalim UllahNo ratings yet

- Success Stories of Women Entrepreneur: March 2012Document13 pagesSuccess Stories of Women Entrepreneur: March 2012Sachin KumarNo ratings yet

- Food ProductionDocument2 pagesFood ProductionchrizzdM100% (1)

- Hammarby SjojstadDocument14 pagesHammarby SjojstadAshim MannaNo ratings yet

- Ebook Chem 2 Chemistry in Your World 2Nd Edition Hogg Test Bank Full Chapter PDFDocument28 pagesEbook Chem 2 Chemistry in Your World 2Nd Edition Hogg Test Bank Full Chapter PDFalankiet45olsq100% (13)

- Lovair - L-990 (991 992) Sensor Tap - Parts ListDocument1 pageLovair - L-990 (991 992) Sensor Tap - Parts ListNguyên Trịnh CaoNo ratings yet

- The Physical and Psychophysical Effects of Umami and Kokumi Compounds On The Actual and Perceived Thcikness of Model Liquid FoodsDocument44 pagesThe Physical and Psychophysical Effects of Umami and Kokumi Compounds On The Actual and Perceived Thcikness of Model Liquid FoodsOscar HooglandNo ratings yet

- Emerson, Society and SolitudeDocument317 pagesEmerson, Society and SolitudeAlessandro LattuadaNo ratings yet

- Possession Saxon Genitive S 41798Document2 pagesPossession Saxon Genitive S 41798izabelaNo ratings yet

- Chapter Two: Introduction To GrammarsDocument21 pagesChapter Two: Introduction To GrammarsEbisa KebedeNo ratings yet

- Just Good Friends by Jeffrey ArcherDocument2 pagesJust Good Friends by Jeffrey ArcherCristian Colucci100% (1)

- Tool BoxDocument6 pagesTool BoxSinar GemilangNo ratings yet

- Fresh Frozen Plasma (FFP) and Cryoprecipitate: Patient InformationDocument6 pagesFresh Frozen Plasma (FFP) and Cryoprecipitate: Patient InformationAgus LastyaNo ratings yet

- EEC 242 Syllabus Fall 2020Document5 pagesEEC 242 Syllabus Fall 2020Faheem ParachaNo ratings yet

- Transcribing Activity For MS WardDocument23 pagesTranscribing Activity For MS WardJasmin B. ERMITANo ratings yet