Professional Documents

Culture Documents

ME104 Crack Formation in Generator Connecting Rod Serrations

Uploaded by

Rani NoumanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME104 Crack Formation in Generator Connecting Rod Serrations

Uploaded by

Rani NoumanCopyright:

Available Formats

Return to TOC

ME104

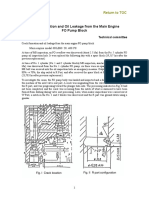

Crack Formation in Generator Connecting Rod Serrations

Technical committee

1. Outline of breakdown

While the ship was docked for Intermediate survey, overhaul inspection of generator diesel revealed

crack formation in all connecting rod serrations of the three generators aboard. The cracks were all

found at the upper section of the upper serration teeth.

All connecting rods (18) were replaced with new parts.

2. Cause

The following factors are considered as a possible cause.

1) Insufficient material strength

2) Insufficient processing accuracy

3) Decrease in tightening torque

For 1), test results revealed no problems. The surface roughness of the teeth was 18S for damaged

parts as against 6S in specification. The contact surface of the teeth was not even and indication of

strong contact was observed in certain local sections. Also, chamfering of the teeth was insufficient. In

addition, the measurement of a torque with which a damaged part was tightened to the index mark

showed that the torque had fallen to a range of 47 to 59 kg-m. (Specified torque was 60 to 65 kg-m.)

3. Countermeasure

<Ship Countermeasure>

1) To increase the rod bolt tightening torque.

To change it from 65 - 70 kg-m to 70 - 75kg-m.

2) Perform torque check in 3000 hours.

3) Perform serration collar check in 4000 hours.

4) Perform magnetic inspection of serrations after 4000 hours, on removal of piston.

<Maker Countermeasure>

1) Increase processing accuracy to improve tooth bearing (lapping)

2) Improve surface roughness (processing method)

3) Improve tooth root roughness (Roll processing at R section)

The parts will be replaced with improved parts as they are prepared.

You might also like

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Crack Formation in Generator Connecting Rod Serrations: ReturnDocument1 pageCrack Formation in Generator Connecting Rod Serrations: ReturnKišić SpasojeNo ratings yet

- Engineering Failure Analysis: Lucjan Witek, Micha Ł Sikora, Feliks Stachowicz, Tomasz TrzepiecinskiDocument10 pagesEngineering Failure Analysis: Lucjan Witek, Micha Ł Sikora, Feliks Stachowicz, Tomasz TrzepiecinskisobhanNo ratings yet

- Mining Gearbox ConditioningDocument6 pagesMining Gearbox Conditioningsam abusiNo ratings yet

- Diesel Generator Crank Shaft Balance Weight Mounting Bolt BreakageDocument2 pagesDiesel Generator Crank Shaft Balance Weight Mounting Bolt BreakageRani NoumanNo ratings yet

- Failure Analysis of A Helical GearDocument7 pagesFailure Analysis of A Helical Geartheerapat patkaewNo ratings yet

- Failure Analysis of A 40 Ton Crane Hook at A Hot Strip Mill: Souvik Das, Goutam Mukhopadhyay, Sandip BhattacharyyaDocument10 pagesFailure Analysis of A 40 Ton Crane Hook at A Hot Strip Mill: Souvik Das, Goutam Mukhopadhyay, Sandip BhattacharyyaSaifuddin SidikiNo ratings yet

- Engin Analysis of A Diesel Generator Crankshaft FailureDocument9 pagesEngin Analysis of A Diesel Generator Crankshaft FailureDarel DalmassoNo ratings yet

- Engineering Failure Analysis - DA1Document13 pagesEngineering Failure Analysis - DA1koushikNo ratings yet

- 1 25MWDocument33 pages1 25MWmadivala nagarajaNo ratings yet

- Generator TestingDocument11 pagesGenerator TestingYugandhara Chakravarthy Kancherla100% (1)

- Surface Grinding Characteristics of Ti-6Al-4V Alloy: Aritras Roy, Kanchan Maji, Sudin Kumar KunduDocument10 pagesSurface Grinding Characteristics of Ti-6Al-4V Alloy: Aritras Roy, Kanchan Maji, Sudin Kumar KunduSudin Kumar KunduNo ratings yet

- IJE Volume 31 Issue 3 Pages 473-479Document7 pagesIJE Volume 31 Issue 3 Pages 473-479Juan AsarcadoNo ratings yet

- Failure Analysis: Integrally Geared Compressor Cracked ImpellerDocument35 pagesFailure Analysis: Integrally Geared Compressor Cracked ImpellerAbdulrahman AlkhowaiterNo ratings yet

- Failure Analysis of Air Cooled Conden 2014 Case Studies in Engineering FailuDocument7 pagesFailure Analysis of Air Cooled Conden 2014 Case Studies in Engineering FailuMeccbellNo ratings yet

- SM490A Repair 따른 물성변화Document22 pagesSM490A Repair 따른 물성변화Nix LeeNo ratings yet

- Engineering Failure Analysis: Warwick Payten, Damien Charman, Andrew Chapman, Kourosh Bashiri, Phillip BendeichDocument13 pagesEngineering Failure Analysis: Warwick Payten, Damien Charman, Andrew Chapman, Kourosh Bashiri, Phillip BendeichFlo RenceNo ratings yet

- Steam Turbine Rotor Discs Repair - RevDocument39 pagesSteam Turbine Rotor Discs Repair - Revalfattah25No ratings yet

- 1978-06 Successful Applications of NDT Techniques To Mining Equipment Maintenance - Sutcliffe, Cottier (#MNG)Document3 pages1978-06 Successful Applications of NDT Techniques To Mining Equipment Maintenance - Sutcliffe, Cottier (#MNG)rhinemine100% (1)

- Influence of Gear Surface Roughness On The Pitting and Micropitting LifeDocument9 pagesInfluence of Gear Surface Roughness On The Pitting and Micropitting LifeGogyNo ratings yet

- 27 MW Steam Turbine Blade Failure Case HistoryDocument23 pages27 MW Steam Turbine Blade Failure Case HistoryPablo Scott100% (1)

- Fatigue Analysis of Girth Gear of A Rotary DryerDocument16 pagesFatigue Analysis of Girth Gear of A Rotary DryertaghdirimNo ratings yet

- 4-Spalling Investigation of Connecting RodDocument10 pages4-Spalling Investigation of Connecting RodHakimNo ratings yet

- 01 - Failure Analysis of A Sugracane Loader Rear Shaft (Brazil-2020)Document8 pages01 - Failure Analysis of A Sugracane Loader Rear Shaft (Brazil-2020)Jose Martin ChaconNo ratings yet

- 2014 Mill and Kiln Gear InspectionsDocument28 pages2014 Mill and Kiln Gear InspectionsFernando Erices100% (1)

- MotocycleEngine Bari2017Document14 pagesMotocycleEngine Bari2017Rodrigo ConciNo ratings yet

- Steam Turbine BasicsDocument22 pagesSteam Turbine BasicsSumit ChaurasiaNo ratings yet

- Abrasion of The Shaft Supporting The Cam Shaft Drive Chain UnitDocument3 pagesAbrasion of The Shaft Supporting The Cam Shaft Drive Chain UnitRani NoumanNo ratings yet

- Sliding Wear Behavior of Tac-Containing Ti (CN) - Wc-Ni/Co CermetsDocument10 pagesSliding Wear Behavior of Tac-Containing Ti (CN) - Wc-Ni/Co CermetsVikas VermaNo ratings yet

- 2-Failure Analysis of A Petrochemical Plant Reducing GearDocument6 pages2-Failure Analysis of A Petrochemical Plant Reducing GearFathur RahmanNo ratings yet

- Improving Wear Resistance Via Hardfacing of Cultivator ShovelDocument9 pagesImproving Wear Resistance Via Hardfacing of Cultivator ShovelALDO ROGERNo ratings yet

- Engineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunDocument10 pagesEngineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunBima SorayaNo ratings yet

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Document8 pagesIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNo ratings yet

- Coupled Mechanical, Metallurgical and FEM Based Failure Investigation ofDocument27 pagesCoupled Mechanical, Metallurgical and FEM Based Failure Investigation ofpoojaNo ratings yet

- Ladle Tilting MachineDocument17 pagesLadle Tilting Machinenailulfalah17No ratings yet

- Pourmohammad 2019Document11 pagesPourmohammad 2019CHONKARN CHIABLAMNo ratings yet

- Aiche-36-011Failure of Cooling Water CirculatingDocument10 pagesAiche-36-011Failure of Cooling Water CirculatingHsein WangNo ratings yet

- Weld Cracks in An Ammonia Converter: James D. CampbellDocument6 pagesWeld Cracks in An Ammonia Converter: James D. Campbellvaratharajan g rNo ratings yet

- Integrity Inspection of A Steam Turbine Rotor in A Geothermal Power PlantDocument3 pagesIntegrity Inspection of A Steam Turbine Rotor in A Geothermal Power PlantKiranNo ratings yet

- Pipe Strain: 50 OrbitDocument11 pagesPipe Strain: 50 Orbitsaadbakhtyar2065No ratings yet

- Advanced Vibration Analysis On Gear Box TrainDocument25 pagesAdvanced Vibration Analysis On Gear Box TrainmitrachintuNo ratings yet

- L&T (ECC) Placement Paper Pattern: Section-1Document8 pagesL&T (ECC) Placement Paper Pattern: Section-1Anees SheikhNo ratings yet

- QE White Paper - How To Improve Asset LifespanDocument16 pagesQE White Paper - How To Improve Asset LifespanArturo PintoNo ratings yet

- Effect of Pouring Temperature and Stirring Speed OnDocument6 pagesEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cswip Question and Answers: ResponsibilitiesDocument11 pagesCswip Question and Answers: Responsibilitiesfery0% (1)

- Experimental Investigation of Crank Shaft With Crack of A Diesel EngineDocument6 pagesExperimental Investigation of Crank Shaft With Crack of A Diesel EngineTJPRC PublicationsNo ratings yet

- May 2022 MonthDocument5 pagesMay 2022 MonthJNo ratings yet

- Brittle Fracture of Turbine Rotor in Nagasaki: Instructor: Dr. Norlaili BT Amir MDB3023: Engineering MaterialsDocument6 pagesBrittle Fracture of Turbine Rotor in Nagasaki: Instructor: Dr. Norlaili BT Amir MDB3023: Engineering MaterialspedoqpopNo ratings yet

- Remanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingDocument9 pagesRemanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingSujay NahaldeNo ratings yet

- Re-Rate Case StudyDocument4 pagesRe-Rate Case StudyA_MosbahNo ratings yet

- Method Statement For Concrete Core CuttingDocument5 pagesMethod Statement For Concrete Core CuttingSimon GikonyoNo ratings yet

- Analysis of An Unusual Crankshaft Failure PDFDocument9 pagesAnalysis of An Unusual Crankshaft Failure PDFHector CastelblancoNo ratings yet

- 1 Exemplary Technical Report 2012 PDFDocument99 pages1 Exemplary Technical Report 2012 PDFMKPashaPashaNo ratings yet

- 1 Exemplary Technical Report 2012Document99 pages1 Exemplary Technical Report 2012MKPashaPashaNo ratings yet

- Failure Analysis of Bridge ShaftDocument19 pagesFailure Analysis of Bridge ShaftAhmad Abdul GhaniNo ratings yet

- Cowes Condition AssessDocument17 pagesCowes Condition AssessMuhammad Imran NasirNo ratings yet

- Failure Analysis of Coal Pulverizer Mill PDFDocument12 pagesFailure Analysis of Coal Pulverizer Mill PDFHendraNo ratings yet

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Encl-Regulation On Templates (OJ - L - 202302449)Document31 pagesEncl-Regulation On Templates (OJ - L - 202302449)Rani NoumanNo ratings yet

- ME128 Blockage of The Fuel Oil Auto Back Wash StrainerDocument1 pageME128 Blockage of The Fuel Oil Auto Back Wash StrainerRani Nouman0% (1)

- ME129 Pitting of FO Purifier Main CylinderDocument1 pageME129 Pitting of FO Purifier Main CylinderRani NoumanNo ratings yet

- ME132 Wrapping of The AB Soot Blower Lange TubeDocument2 pagesME132 Wrapping of The AB Soot Blower Lange TubeRani NoumanNo ratings yet

- Economizer Soot FireDocument2 pagesEconomizer Soot Fireadam shaneNo ratings yet

- ME127 Crack Formation and Oil Leakage From The ME FO Pump BlockDocument1 pageME127 Crack Formation and Oil Leakage From The ME FO Pump BlockRani NoumanNo ratings yet

- ME126 Fracture of The ME Tie RodDocument2 pagesME126 Fracture of The ME Tie RodRani NoumanNo ratings yet

- Air Compressor Damage: 1. TypeDocument2 pagesAir Compressor Damage: 1. TypeRani NoumanNo ratings yet

- Main Engine Turbocharger Damage: 1. ModelDocument2 pagesMain Engine Turbocharger Damage: 1. ModelRani NoumanNo ratings yet

- ME125 HFO Purifier Upper BearingDocument2 pagesME125 HFO Purifier Upper BearingRani NoumanNo ratings yet

- Diesel Generator Damage: 1. Trouble MachineryDocument2 pagesDiesel Generator Damage: 1. Trouble MachineryRani NoumanNo ratings yet

- Damage To The Main Engine Auxiliary Blower Non-Return ValveDocument2 pagesDamage To The Main Engine Auxiliary Blower Non-Return ValveRani NoumanNo ratings yet

- Crack of The Main Boiler (P) Superheated Steam Pipe: 1. Device SummaryDocument2 pagesCrack of The Main Boiler (P) Superheated Steam Pipe: 1. Device SummaryRani NoumanNo ratings yet

- ME129 Pitting of FO Purifier Main CylinderDocument1 pageME129 Pitting of FO Purifier Main CylinderRani NoumanNo ratings yet

- ME129 Pitting of FO Purifier Main CylinderDocument1 pageME129 Pitting of FO Purifier Main CylinderRani NoumanNo ratings yet

- Crack in The Main Engine Piston Crown: Return To TOCDocument3 pagesCrack in The Main Engine Piston Crown: Return To TOCRani NoumanNo ratings yet

- Main Engine Governor Operation Failure: Return To TOCDocument2 pagesMain Engine Governor Operation Failure: Return To TOCRani NoumanNo ratings yet

- Main Engine Startup Failure: Return To TOCDocument4 pagesMain Engine Startup Failure: Return To TOCRani NoumanNo ratings yet

- Cargo Oil Pump Turbine Condenser Damage: Return To TOCDocument4 pagesCargo Oil Pump Turbine Condenser Damage: Return To TOCRani NoumanNo ratings yet

- Damage To Idle Gear of Drive LO Pump For Diesel GeneratorDocument2 pagesDamage To Idle Gear of Drive LO Pump For Diesel GeneratorRani NoumanNo ratings yet

- Generator Engine Suction Valve Rod Severance: Return To TOCDocument3 pagesGenerator Engine Suction Valve Rod Severance: Return To TOCRani NoumanNo ratings yet

- Damage of The Main Engine No. 1 Cylinder Exhaust Valve Driving UnitDocument2 pagesDamage of The Main Engine No. 1 Cylinder Exhaust Valve Driving UnitRani NoumanNo ratings yet

- Burnout of ACB of Main Switchboard: Return To TOCDocument2 pagesBurnout of ACB of Main Switchboard: Return To TOCRani Nouman100% (1)

- Main Engine Cross Head Guide Shoe White Metal Peeling: Return To TOCDocument2 pagesMain Engine Cross Head Guide Shoe White Metal Peeling: Return To TOCRani NoumanNo ratings yet

- Open Failure of ACB of Turbo Generator: Return To TOCDocument2 pagesOpen Failure of ACB of Turbo Generator: Return To TOCRani NoumanNo ratings yet

- Main Engine Turbocharger Damage: Return To TOCDocument2 pagesMain Engine Turbocharger Damage: Return To TOCRani NoumanNo ratings yet

- Auxiliary Air Compressor Damage Incident: Return To TOCDocument2 pagesAuxiliary Air Compressor Damage Incident: Return To TOCRani NoumanNo ratings yet

- Inappropriate Boiler Water Circulation Ratio of High Pressure Boiler Circulation Water PumpDocument2 pagesInappropriate Boiler Water Circulation Ratio of High Pressure Boiler Circulation Water PumpRani NoumanNo ratings yet

- Breakage of Generator Connecting Rod: Return To TOCDocument3 pagesBreakage of Generator Connecting Rod: Return To TOCRani NoumanNo ratings yet

- Diesel Generator Frame Block Damage: Return To TOCDocument2 pagesDiesel Generator Frame Block Damage: Return To TOCRani NoumanNo ratings yet