Professional Documents

Culture Documents

Yet-Agru-Exe-Meb-000-Cmm-Prc-0001 Comm & Start Up Philosophy

Uploaded by

mohsin moinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yet-Agru-Exe-Meb-000-Cmm-Prc-0001 Comm & Start Up Philosophy

Uploaded by

mohsin moinCopyright:

Available Formats

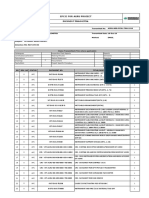

Doc No:

YET-AGRU-EXE-MEB-000-

CMM-PRC-0001

Revision: A

PROVISION OF ENGINEERING, PROCUREMENT, CONSTRUCTION,

INSTALLATION & COMMISSIONING (EPCIC) FOR YETAGUN ACID GAS Page: 1 of 6

REMOVAL UNIT (AGRU) PROJECT

PROJECT TITLE : PROVISION OF ENGINEERING,

PROCUREMENT, CONSTRUCTION,

INSTALLATION & COMMISSIONING

(EPCIC) FOR YETAGUN ACID GAS

REMOVAL UNIT (AGRU) PROJECT

OWNER : PETRONAS CARIGALI MYANMAR (HONG

KONG) LIMITED

CONTRACT NO. : A/PCML/C/18/004

DOCUMENT : COMMISSIONING & START UP

TITLE PHILOSOPHY

DOCUMENT

REVIEW : Z

CLASSFICATION

9 July

A Issued for Review RY RR

2019

Prep’d App’d Rev’d Endorsed App’d

Rev’d By

By By By By By

Rev Date Description

MEB PCML

© 2017 PETROLIAM NASIONAL BERHAD (PETRONAS). All rights reserved. No part of this document may be reproduced,

stored in a retrieval system or transmitted in any form or by any means (electronic, mechanical, photocopying, recording

or otherwise) without the permission of the copyright OWNER.

COMMISSIONING & START UP PHILOSOPHY

Doc No:

YET-AGRU-EXE-MEB-000-

CMM-PRC-0001

Revision: A

PROVISION OF ENGINEERING, PROCUREMENT, CONSTRUCTION,

INSTALLATION & COMMISSIONING (EPCIC) FOR YETAGUN ACID GAS Page: 2 of 6

REMOVAL UNIT (AGRU) PROJECT

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been approved.

Details must include revision number, description and indication of which pages and paragraphs

have been revised, date of revision approval, approvers’ title and signature.

Rev Description Date Approver Title Name

A Issued for Review 9-07-2019 Project Manager

Notes

:

(1) Document Holders to update Amendment Record as and when amendments/new

revisions are received.

(2) For description of amendment the Document Holder should indicate correction,

modification, and update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified with a

lower-case letter in the revision status line in the header.

COMMISSIONING & START UP PHILOSOPHY

Doc No:

YET-AGRU-EXE-MEB-000-

CMM-PRC-0001

Revision: A

PROVISION OF ENGINEERING, PROCUREMENT, CONSTRUCTION,

INSTALLATION & COMMISSIONING (EPCIC) FOR YETAGUN ACID GAS Page: 3 of 6

REMOVAL UNIT (AGRU) PROJECT

TABLE OF C0NTENT

1.0 INTRODUCTION.....................................................................................................4

1.1 PROJECT OVERVIEW..............................................................................................4

1.2 OBJECTIVE ...........................................................................................................5

2.0 SCOPE ...........................................................................................................5

3.0 DEFINITIONS........................................................................................................... 5

4.0 ABBREVIATIONS....................................................................................................6

5.0 APPENDIX ...........................................................................................................6

COMMISSIONING & START UP PHILOSOPHY

1.0 INTRODUCTION

1.1 PROJECT OVERVIEW

The Yetagun Field (Yetagun Main) is located in Andaman Sea, offshore of Myanmar in

Blocks M12, M13 and M14. PC Myanmar (Hong Kong) Limited (COMPANY) assumed

operatorship of the blocks on 12 September 2004. The participating interest in the

blocks is PCSB, MOGE, Nippon Oil and PTTEP.

Yetagun Main consists of 4 platforms namely, Yetagun A Wellhead platform, Yetagun

B Central Processing Platform and Living Quarters, Yetagun C Booster Compressor

Platform and Yetagun D Remote Wellhead Platform. Yetagun A, B and C is bridge-

linked. Sales gas is exported via 24-inch pipeline from Yetagun A to onshore Pipeline

Operating Centre (POC).

Stabilized Condensate is exported via 6-inch pipeline to Floating Offloading (FSO)

from Yetagun A. Full Well Stream (FWS) from Yetagun D is transported via 10-inch

pipeline to Yetagun C.

Yetagun Main is currently operating with Low Pressure (LP) Mode whereby limiting

the FWS from Yetagun-D to maximum 55 MMSCFD instead of 70 MMSCFD Pipeline

capacity due to high CO2 from Yetagun D.

The high CO2 gas with 34 mole% from Yetagun-D is blended with lean gas from

Yetagun Main to meet Gas Sales Agreement (GSA) requirement of less than 15 mole

% CO2 and GHV to be 950 - 1050 Btu/scf. However, Yetagun-A production has been

declining rapidly. This has resulted Yetagun-D gas production to be curtailed down in

order to meet the 15 mole% CO2, hence, lowering the potential of high Recovery

Factor (RF).

In order to maintain the overall production rate, COMPANY intends to install Acid Gas

Removal Unit (AGRU) at Yetagun-C to remove the CO2 from the Yetagun-D gas. The

product gas from AGRU (i.e. the Yetagun-D gas with CO2 content less than 15 mole

%) will be commingled with the low CO2 gas from Yetagun Main and send to gas

treating and conditioning system at Yetagun B prior to export.

As of June 2018, average production from Yetagun Main is 130 MMscfd whereas

Yetagun North is 30 MMscfd. Yetagun field is currently producing at average 160

MMscfd of gas and 3.3 kbd of condensate.

Field development activities which were executed at Yetagun facilities during the

different phases are described as below.

Phase 1: Installation of 20-slot wellhead platform (Yetagun-A), production platform

(Yetagun-B), and Floating Storage & Offtake (FSO) Vessel, with Daily Contract

Quantity (DCQ) of 200 MMSCFD of gas and 5400 BPD of associated condensate.

Phase 2: Capacity up gradation of the DCQ from 200 MMSCFD to 260 MMSCFD from

1st October 2002.

Phase 3: Facility Modifications to increase the production capacity to 400 MMSCFD

DCQ capacity from 1 April 2004.

Phase 4: Drilling of 4 new wells in 2008 and installation of Booster Compression

Platform in 2011/2012

Phase 5: Installation of 4- legged satellite wellhead platform (Yetagun-D) in

2014 with additional production of 70 MMSCFD.

Phase 6: Infill drilling of 3 new wells at Yetagun-A platform in 2015 and

upgrading of Yetagun-A with full SIPROD capability

Phase 7: Infill Drilling of 2 infill wells and 1 basement well at existing Yetagun-A

platform to increase production rate

Phase 8: Facility modification and Installation of Acid Gas Removal Unit, AGRU at

Yetagun- C Platform and tie-in at Yetagun-B platform

COMMISSIONING & START UP PHILOSOPHY

1.2 OBJECTIVE

The objective of this document is to provide the overall overview of the

commissioning and start up sequence based on specific system priority for the

Yetagun’s Acid Gas Removal Unit (AGRU) Project.

2.0 SCOPE

This document is applicable for Yetagun’s Acid Gas Removal Unit (AGRU) Project and

shall be referred in order to:

1. Identify the specific System and/or Equipment priority for the project

commissioning and start up;

2. To define the Commissioning and Start-Up flow/sequences to be followed by

CONTRACTOR in order to achieve smooth facility start up.

All works activities that required to be performed by CONTRACTOR during Testing,

Commissioning and Start Up executions are in accordance with CSP-20: Testing, Pre-

commissioning and Commissioning Guideline. Detailed activities such as scope of works,

vendor support and pre-commissioning and commissioning tasks shall be elaborated

further in each system detail procedure.

3.0 DEFINITIONS

COMPANY : PETRONAS CARIGALI MYANMAR (HONGKONG) LTD.

(PCML)

[The party who initiates the project and is ultimately

responsible for the funding of the project]

CONTRACTOR : MUHIBBAH ENGINEERING BHD. (MEB)

[The party who carries out EPCC for the project]

HUC SUB-CONTRACTOR : TRANSFAME SDN. BHD. (TRANSFAME)

[The party who sub-contracted by CONTRACTOR to

carry out the onshore pre-commissioning and offshore

HUC scope for the project]

VENDOR : Party who supplies and manufactures equipment/

materials or services specified and ordered by

CONTRACTOR

SUBCONTRACTOR : Party who providing subcontracting packages or

services specified and ordered by CONTRACTOR

4.0 ABBREVIATIONS

AGRU : Acid Gas Removal Unit

CMS : Completion Management System

CSP : Carigali Standard Procedure

DMCC : Discipline Mechanical Completion Certificate

FAT : Factory Acceptance Test

FSO : Floating, Storage & Offloading

HUC : Hoop-Up and Commissioning

HSSE : Health, Safety, Security and Environment

ITR : Inspection Test Record

JHA : Job Hazard Analysis

MEB : Muhibbah Engineering Berhad

PCML : Petronas Carigali Myanmar Ltd

PCSB : Petronas Carigali Sdn Bhd

PSV : Process Safety Valve

COMMISSIONING & START UP PHILOSOPHY

PTR : Performance Test Run

PTW : Permit to Work

RFC : Ready for Commissioning

SAT : Site Acceptance Test

5.0 APPENDIX

Appendix I: Commissioning and Start Up Sequence

COMMISSIONING & START UP PHILOSOPHY

You might also like

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0007-A Fuel Gas ProcedureDocument14 pagesYET-AGRU-EXE-MEB-000-PCMM-PRC-0007-A Fuel Gas Proceduremohsin moin100% (1)

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0002-0 General Testing Pre-Commissioning and Commissioning Procedure - Amended-signed-Code-3Document11 pagesYET-AGRU-EXE-MEB-000-PCMM-PRC-0002-0 General Testing Pre-Commissioning and Commissioning Procedure - Amended-signed-Code-3mohsin moin100% (1)

- Pipeline RepairsDocument44 pagesPipeline RepairsMohamad PizulNo ratings yet

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Document64 pagesMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATNo ratings yet

- Dep 30.48.40.31-Gen-Feb-2019 Thermally Sprayed Aluminium CoatingsDocument21 pagesDep 30.48.40.31-Gen-Feb-2019 Thermally Sprayed Aluminium CoatingsDevam RajNo ratings yet

- PEGS-12059-COR-053 - Control by Electrical Measurements of CathodicDocument19 pagesPEGS-12059-COR-053 - Control by Electrical Measurements of CathodicĐiệnBiênNhâmNo ratings yet

- De-oiling Pipelines CircularDocument2 pagesDe-oiling Pipelines Circularnice guyNo ratings yet

- Aug 2011Document10 pagesAug 2011c_nghia100% (2)

- Reference (Woodside - Standards)Document23 pagesReference (Woodside - Standards)shankarmech04@gmail.com100% (1)

- 34242631Document12 pages34242631allouche_abdNo ratings yet

- Pipeline Pigging Philosophy for Rumaila ProjectDocument15 pagesPipeline Pigging Philosophy for Rumaila ProjectfadhilNo ratings yet

- Hot Tap Form Proposed SignatoriesDocument43 pagesHot Tap Form Proposed SignatoriesSongAn BuiNo ratings yet

- PEGS-12059-COR-055 - Technical Assessment of Coating PlantsDocument26 pagesPEGS-12059-COR-055 - Technical Assessment of Coating PlantsĐiệnBiênNhâmNo ratings yet

- Materials System SpecificationDocument14 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- API 570 Piping Inspection Code GuideDocument43 pagesAPI 570 Piping Inspection Code Guideeduardo gonzalez100% (1)

- Welding HabitatDocument12 pagesWelding HabitatDesmond Chang100% (3)

- 350 - Tray Installation Manual - EngDocument36 pages350 - Tray Installation Manual - EngRashid MadathilNo ratings yet

- Petronas Technical Standards Health, Safety and Environment: 1 JUNE 2006 PTS 60.3203Document24 pagesPetronas Technical Standards Health, Safety and Environment: 1 JUNE 2006 PTS 60.3203enviroNo ratings yet

- Corrosion of Steels in Sour Gas EnvironmentDocument179 pagesCorrosion of Steels in Sour Gas Environmentaathittaya100% (1)

- FM200 KiddeDocument37 pagesFM200 KiddeNguyen Van TuanNo ratings yet

- QP-018, Quality Manual Procedure For Coupon and Probes MonitoringDocument12 pagesQP-018, Quality Manual Procedure For Coupon and Probes MonitoringIksan Adityo MulyoNo ratings yet

- Tank Inspectiom ChecksheetDocument3 pagesTank Inspectiom Checksheetyskushwah16100% (1)

- Nitrogen Purging PDFDocument17 pagesNitrogen Purging PDFgshdavid100% (2)

- Psp-Koti-19 - Hot Tapping Procedure - Rev 0Document14 pagesPsp-Koti-19 - Hot Tapping Procedure - Rev 0cheehoong82No ratings yet

- Technical Authority FrameworkDocument22 pagesTechnical Authority Frameworkronelbarafaeldiego0% (1)

- PTS 60.3401 - Decommissioning, Remediation and Reclamation of On-Shore E and P Sites (Guideline)Document127 pagesPTS 60.3401 - Decommissioning, Remediation and Reclamation of On-Shore E and P Sites (Guideline)Norisham Mohamed AliNo ratings yet

- Corrosion Coupan Check ListDocument2 pagesCorrosion Coupan Check Listtrichysayee100% (1)

- Mercury PresentationDocument42 pagesMercury Presentationpejal5284100% (4)

- Turnaround workpack for exchanger 509-E-001GDocument91 pagesTurnaround workpack for exchanger 509-E-001GdwivedipramodkumarNo ratings yet

- Furnace Tube Pipeline PiggingDocument8 pagesFurnace Tube Pipeline PiggingPervez0% (1)

- Pigging Simulation For Horizontal Gas-Condensate Pipelines With Low-Liquid LoadingDocument9 pagesPigging Simulation For Horizontal Gas-Condensate Pipelines With Low-Liquid LoadingAnonymous aoNBPi2f1v100% (1)

- A4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Document20 pagesA4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Darrel Espino Aranas100% (1)

- 6.9 Pigging Philosophy PDFDocument10 pages6.9 Pigging Philosophy PDFDonald.KNo ratings yet

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Document70 pagesLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoNo ratings yet

- Multidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) ADocument4 pagesMultidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) AHOSAM HUSSEINNo ratings yet

- 029 Hot Tap Procedure 0011Document5 pages029 Hot Tap Procedure 0011Fadlul Akbar HerfiantoNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruNo ratings yet

- Pipeline DryingDocument2 pagesPipeline DryingAriel Anasco100% (2)

- ILI Pipeline CostDocument3 pagesILI Pipeline CostyogacruiseNo ratings yet

- Leak TestingDocument5 pagesLeak Testingogie_0513No ratings yet

- Installing and Operating a Thermal Relief ValveDocument12 pagesInstalling and Operating a Thermal Relief ValveHiren Panchal100% (1)

- Check List Oil PipelineDocument5 pagesCheck List Oil PipelineBalu Venkatesa PerumalNo ratings yet

- Pigging PresentationDocument42 pagesPigging PresentationAhmed AwwadNo ratings yet

- Off Brochure Petronas-Flng LR PDFDocument8 pagesOff Brochure Petronas-Flng LR PDFDak Kaiz100% (1)

- JOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentDocument7 pagesJOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentOrdu Henry Onyebuchukwu100% (1)

- 121205Document25 pages121205wdavid81No ratings yet

- Factors Contributing To Foarming Crude OilDocument11 pagesFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- Unpublished Asme B31.8 Interpretations To Be Published Within The Next EditionDocument7 pagesUnpublished Asme B31.8 Interpretations To Be Published Within The Next EditionMuhammad Zeeshan Wasi0% (1)

- SP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Document94 pagesSP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Rjeb mohamed100% (1)

- Introduction To Pipeline Risk AssessmentDocument33 pagesIntroduction To Pipeline Risk AssessmentLaila_Utari_Ratna100% (2)

- Coral FLNG SA Is The Special Purpose Entity Responsible To Develop and Operate Coral South Floating Platform (FLNG)Document4 pagesCoral FLNG SA Is The Special Purpose Entity Responsible To Develop and Operate Coral South Floating Platform (FLNG)MateusPauloNo ratings yet

- PCSB Inspection and Maintenance Guidelines Volume 1Document124 pagesPCSB Inspection and Maintenance Guidelines Volume 1JaiNo ratings yet

- Inputs For Piping Stress AnalysisDocument1 pageInputs For Piping Stress AnalysisswapnavattemNo ratings yet

- Dec 09Document55 pagesDec 09c_nghia100% (1)

- STS Qac Sop 005 Joint Integrity ProcedureDocument32 pagesSTS Qac Sop 005 Joint Integrity Proceduremohd as shahiddin jafriNo ratings yet

- Pipeline Pig Launchers Recievers Design CodesDocument2 pagesPipeline Pig Launchers Recievers Design Codesankur2061No ratings yet

- Iraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectDocument8 pagesIraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectAhmedNo ratings yet

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0008-B Nitrogen (N2) System (Review & Check)Document14 pagesYET-AGRU-EXE-MEB-000-PCMM-PRC-0008-B Nitrogen (N2) System (Review & Check)mohsin moin100% (1)

- Provision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) ProjectDocument15 pagesProvision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) Projectmohsin moin100% (1)

- HAZOP STUDIES SCOPEDocument7 pagesHAZOP STUDIES SCOPEAlok KumarNo ratings yet

- Provision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) ProjectDocument15 pagesProvision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) Projectmohsin moin100% (1)

- YET-AGRU-EXE-MEB-000-PCMM-PRC-0008-B Nitrogen (N2) System (Review & Check)Document14 pagesYET-AGRU-EXE-MEB-000-PCMM-PRC-0008-B Nitrogen (N2) System (Review & Check)mohsin moin100% (1)

- EPCIC for AGRU Project DocumentsDocument4 pagesEPCIC for AGRU Project Documentsmohsin moinNo ratings yet

- 8yetc DWG PR 1010 21 - Rev - B0 PDFDocument10 pages8yetc DWG PR 1010 21 - Rev - B0 PDFmohsin moinNo ratings yet

- 8yetc DWG PR 1010 21 - Rev - B0 PDFDocument10 pages8yetc DWG PR 1010 21 - Rev - B0 PDFmohsin moinNo ratings yet

- FpmkeygffDocument1 pageFpmkeygfffodoreanflaviuNo ratings yet

- 8YETC LLS LL 1001 - 0Document6 pages8YETC LLS LL 1001 - 0mohsin moinNo ratings yet

- Instrucgtrrgrt IosDocument1 pageInstrucgtrrgrt IosfodoreanflaviuNo ratings yet

- Getting Off The Yellow Brick Road-Measurement and Definitonal Issues in PovertyDocument9 pagesGetting Off The Yellow Brick Road-Measurement and Definitonal Issues in Povertymohsin moinNo ratings yet

- 8yetc DWG PP XXXXDocument224 pages8yetc DWG PP XXXXmohsin moinNo ratings yet

- HT - Oral NarativeDocument38 pagesHT - Oral Narativemohsin moinNo ratings yet

- Read Me!Document2 pagesRead Me!dukkasrinivasflexNo ratings yet

- IaDocument7 pagesIamohsin moinNo ratings yet

- 01 Singapore (1824-1958) - This Is My Island in The Sun PDFDocument22 pages01 Singapore (1824-1958) - This Is My Island in The Sun PDFmohsin moinNo ratings yet

- Filipino Women in The Arts in The Context of Cultural DevelopmentDocument15 pagesFilipino Women in The Arts in The Context of Cultural Developmentmohsin moinNo ratings yet

- 04 Robert Kuok-Taipan Incorporated PDFDocument13 pages04 Robert Kuok-Taipan Incorporated PDFmohsin moinNo ratings yet

- Structural ExtensionDocument14 pagesStructural Extensionmohsin moinNo ratings yet

- IgDocument7 pagesIgmohsin moinNo ratings yet

- Yetagun AGRU - PipingDocument4 pagesYetagun AGRU - Pipingmohsin moin100% (1)

- Structural Deck Extension - AgruDocument19 pagesStructural Deck Extension - Agrumohsin moinNo ratings yet

- E&I Tie-InDocument7 pagesE&I Tie-Inmohsin moinNo ratings yet

- DCSDocument34 pagesDCSmohsin moinNo ratings yet

- Athus Souza - ResumeDocument2 pagesAthus Souza - ResumeArielBen-ShalomBarbosaNo ratings yet

- r6 - SCV - PV - 2012 June MarkB PDFDocument32 pagesr6 - SCV - PV - 2012 June MarkB PDFsanjiivNo ratings yet

- DataSheet ULCAB300Document2 pagesDataSheet ULCAB300Yuri OliveiraNo ratings yet

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet

- Challenging Cognitive Distortions HealthyPsych - ComDocument1 pageChallenging Cognitive Distortions HealthyPsych - ComLeila MargaridaNo ratings yet

- Connection StringsDocument18 pagesConnection Stringsapi-3808731100% (4)

- SPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsDocument9 pagesSPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsTHiago LOpesNo ratings yet

- Handbook of Research On Emerging Pedagogies For The Future of Education, Trauma-Informed, Care, and Pandemic Pedagogy Aras BozkurtDocument535 pagesHandbook of Research On Emerging Pedagogies For The Future of Education, Trauma-Informed, Care, and Pandemic Pedagogy Aras BozkurtBrenda MoysénNo ratings yet

- How To Recover An XP Encrypted FileDocument2 pagesHow To Recover An XP Encrypted FileratnajitorgNo ratings yet

- JohnsonJohnson 2006 PDFDocument84 pagesJohnsonJohnson 2006 PDFakfar b417No ratings yet

- The 4 PsDocument7 pagesThe 4 PsJuan Camilo Giorgi MartinezNo ratings yet

- CHEM F313: Instrumental Methods of AnalysisDocument12 pagesCHEM F313: Instrumental Methods of AnalysisAYUSH SHARMANo ratings yet

- Indexed Addressing & Flow Rate AveragingDocument5 pagesIndexed Addressing & Flow Rate AveragingMestrecal MeloNo ratings yet

- Operating Instructions MA 42 - Maico Diagnostics PDFDocument28 pagesOperating Instructions MA 42 - Maico Diagnostics PDFJuan PáezNo ratings yet

- Trains-Dutch-East-Indies - Dirk TeweuenDocument30 pagesTrains-Dutch-East-Indies - Dirk TeweuenMohamad AliwafaNo ratings yet

- Sample Administrative Disicplinary CasesDocument13 pagesSample Administrative Disicplinary CasesWen DyNo ratings yet

- Fin4010 Assignment 3Document3 pagesFin4010 Assignment 3Grace AtteNo ratings yet

- Experienced Welder Seeks New OpportunityDocument2 pagesExperienced Welder Seeks New OpportunityLen HebronNo ratings yet

- Nevada Reports 1882-1883 (17 Nev.) PDFDocument334 pagesNevada Reports 1882-1883 (17 Nev.) PDFthadzigsNo ratings yet

- Decolonising The FutureDocument20 pagesDecolonising The Futurebybee7207No ratings yet

- 266DSH Differential Pressure TransmittersDocument36 pages266DSH Differential Pressure TransmittersSibabrata ChoudhuryNo ratings yet

- Describe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementDocument3 pagesDescribe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementAlemayehu Demeke80% (5)

- COVID-19 Impact on Philippine ExportsDocument5 pagesCOVID-19 Impact on Philippine ExportsHazel BorboNo ratings yet

- Bloodborne Pathogens Program: Western Oklahoma State College Employee Training HandbookDocument35 pagesBloodborne Pathogens Program: Western Oklahoma State College Employee Training HandbookKashaNo ratings yet

- Metsec Purlin Technical ManualDocument88 pagesMetsec Purlin Technical ManualAnbalaganV100% (2)

- Indian Standard: Specification For Reels and Drums For Bare ConductorsDocument13 pagesIndian Standard: Specification For Reels and Drums For Bare ConductorsUppala Krishna ChaitanyaNo ratings yet

- KEB GM 2014 3 - enDocument109 pagesKEB GM 2014 3 - envankarpNo ratings yet

- Response of Hollow-Core Slab Floors To Concentrated LoadsDocument16 pagesResponse of Hollow-Core Slab Floors To Concentrated LoadsJuan Carlos GonzálezNo ratings yet

- Arpit Y2Document7 pagesArpit Y2swapnil jainNo ratings yet