Professional Documents

Culture Documents

Model GPY: Technical Data Submittal Document

Uploaded by

Lwigy SaavedraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model GPY: Technical Data Submittal Document

Uploaded by

Lwigy SaavedraCopyright:

Available Formats

Project:

Customer:

Engineer:

Pump Manufacturer:

Technical Data

Submittal Document

Model GPY

Full Service Reduced Voltage

Wye-delta Open

Electric Fire Pump Controller

Contents:

Data Sheets

Dimensional Data

Wiring Schematics

Field Connections

Note: The drawings included in this package are for controllers

covered under our standard offering. Actual AS BUILT

drawings may differ from what is shown in this package.

February 2019

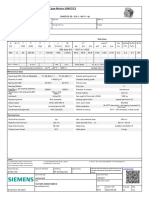

Technical Data

Model GPY Electric Fire Pump Controller

3L3 1M T3

From normal

3L2 T2

incoming power through

Disconnecting Means 3L1 T1

(IS/CB)*

M

CR4

1M 2M T5

CR5 1S T4

2M

T6

CR5 2M

3L1

1S

1S

3L2

Built to NFPA 20 (latest edition)

• UL218 - Fire Pump Controllers

Underwriters Laboratory (UL)

• CSA C22.2 No. 14 Industrial Control Equipment

Standard,

Listings, FM Global Class 1321/1323

Approvals and New York City Accepted for use in the City of New York by the Department of Buildings

Certifications Seismic Certification See page 7 for details

Optional

CE Mark Various EN, IEC & CEE directives and standards

Protection Rating

□ Standard: NEMA 2 (IP31)

Optional

□ NEMA 12 □ NEMA 4X-304 sst painted □ IP54

□ NEMA 3 □ NEMA 4X-304 sst brushed finish □ IP55

Enclosure □ NEMA 3R □ NEMA 4X-316 sst painted □ IP65

□ NEMA 4 □ NEMA 4X-316 sst brushed finish □ IP66

Accessories Paint Specifications

• Bottom entry gland plate • Red RAL3002

• Lifting Lugs • Powder coating

• Keylock handle • Glossy textured finish

Shortcircuit 200V to 208V 220V to 240V 380V to 416V 440V to 480V 575V to 600V

Withstand 60Hz 60Hz 50 Hz / 60Hz 60Hz 60Hz

Rating

HP (kw)

Standard 100kA

5-150 (3.7 - 110) 5-200 (3.7 - 147) 5-300 (3.7 - 220) 5-450 (3.7 - 335) n/a

Optional 150kA

Standard 50kA 200 (147) 250 (184) 350 - 450 (257 - 335) 500 (373) 5-500

Optional 100kA n/a n/a n/a n/a (3.7- 373)

*Please see Disconnecting Means details on page 3

This is a Marketing document. Please consult factory if additional information is required.

February 2019 2

Manufacturer reserves the right to modify this information without notice

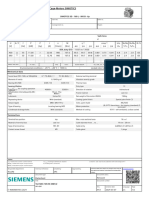

Technical Data

Model GPY Electric Fire Pump Controller

Ambient Standard: Optional:

Temperature

Rating

□ 4°C to 40°C / 39°F to 104°F □ 4°C to 55°C / 39°F to 131°F

Controllers built in Dubai, UAE (Tornatech FZE) are supplied standard with 55°C rating.

Surge

Surge arrestor rated to suppress surges above line voltage

Suppression

• Isolating switch and circuit breaker assembly:

- Door interlocked in the ON position

- Isolating switch rated not less than 115% of motor full load current

Disconnecting

- Circuit breaker continuous rating not less than 115% of motor full load current

Means

- Overcurrent sensing non-thermal type, magnetic only

- Instantaneous trip setting of not more than 20 times the motor full load current

• Common flange mounted operating handle

Service Entrance

Suitable as service entrance equipment

Rating

Emergency Start • Flange mounted • Integrated limit switch

Handle • Pull and latch activation • Across the line start (direct on line)

Locked Rotor • Operate shunt trip to open circuit breaker • Trip between 8 and 20 seconds

Protector • Factory set at 600% of motor full load current

Electrical • Voltage phase to phase (normal power)

Readings • Amperage of each phase when motor is running

Pressure • Continuous system pressure display

Readings • Cut-in and Cut-out pressure settings

• Pressure readings with date stamp

• Event recording with date stamp

Pressure and

• Under regular maintained operation, events are stored in memory for the life of the controller.

Event recorder

• Data viewable on operator interface display screen

• Downloadable by USB port to external memory device

• Pressure transducer and run test solenoid valve assembly for fresh water application

• Pressure sensing line connection 1/2” Female NPT

Pressure Sensing • Drain connection 3/8”

• Rated for 0-500PSI working pressure (standard display at 0-300PSI)

• Externally mounted with protective cover

This is a Marketing document. Please consult factory if additional information is required.

February 2019 Manufacturer reserves the right to modify this information without notice 3

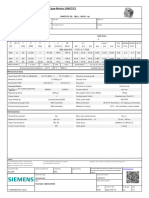

Technical Data

Model GPY Electric Fire Pump Controller

Audible Alarm 4” alarm bell - 85 dB at 10ft. (3m)

• Power available • Deluge valve start • Pump on demand/Automatic start

• Motor run • Remote automatic start • Pump room temperature (ºF or ºC)

Visual Indications

• Periodic test • Remote manual start • Lockout

• Manual start • Emergency start

Visual

• Control voltage not healthy • Overcurrent • Pump on demand

• Invalid cut-in • Overvoltage • Pump room alarm

• Lock rotor current • Phase loss L1 • Service required

• Loss of power • Phase loss L2 • Undercurrent

Visual & Audible • Phase loss L3 • Undervoltage

• Low ambient temperature

Alarms

• Low water level • Phase unbalanced • Check weekly test solenoid

• Motor trouble • Pressure transducer fault detected • Weekly test cut-in reached

• Phase reversal (normal power)

Audible and visual

• Fail to start

DPDT-8A-250V.AC

• Power available

• Phase reversal

• Motor run

• Common pump room alarm (field re-assignable)**

• Overvoltage

• Undervoltage

Remote Alarm • Phase unbalance

Contacts • Low pump room temperature

• High pump room temperature

• Common motor trouble (field re-assignable)**

• Overcurrent

• Fail to start

• Undercurrent

• Ground fault

• Free (field programmable)**

**Tornatech reserves the right to use any of these three alarm points for special specific application requirements.

This is a Marketing document. Please consult factory if additional information is required.

February 2019 4

Manufacturer reserves the right to modify this information without notice

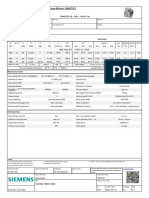

Technical Data

Model GPY Electric Fire Pump Controller

• Embedded microcomputer with software PLC logic

ViZiTouch V2 • 7.0” color touch screen (HMI technology)

Operator Interface • Upgradable software

• Multi-language

• Protocol: Modbus

Communication

• Connection type: Shielded female connector RJ45

Protocol

• Frame Format: TCP/IP

Capability

• Addresses: See bulletin MOD-GPx

• Start on pressure drop

Automatic Start • Remote start signal from automatic device

• Deluge valve start

• Start pushbutton

Manual Start • Run test pushbutton

• Remote start from manual device

• Manual with Stop pushbutton

Stopping

Operation • Automatic after expiration of minimum run timer ***

• Minimum run timer ***(off delay)

Field Adjustable &

Timers • Sequential start timer (on delay)

Visual Countdown

• Periodic test timer

• Pressure

Actuation

• Non-pressure

Visual Indication

• Automatic

Mode

• Non-automatic

***Can only be used if approved by the AHJ

This is a Marketing document. Please consult factory if additional information is required.

February 2019 Manufacturer reserves the right to modify this information without notice 5

Technical Data

Model GPY Electric Fire Pump Controller

Seismic

TRU Compliance, LLC

Certification TWEI Project No.: 15014

A Tobalski Watkins Affiliate

Company

Mounting

Rigid base and wall mounting

details

Seismic

Building Test Seismic AFLX-H ARIG-H AFLX-V ARIG-V

Certification

Code Criteria Parameters

SDS z/h IP

Seismic IBC

Information ICC- 2.0 1.0 1.5 3.20 2.40 1.33 0.53

2015, ASCE 7-10

ES

CBC Chapter 13

AC156 3.2 0.0 1.5 3.20 1.28 2.13 0.85

2016

RRS for Nonstructural Components Testing

10.0

Spectral Response Acceleration (g)

1.0

0.1

0.1 1.0 10.0

Frequency, f (Hz)

Horiz. Level 1 Vert. Level 1

Notes:

• Components are tested in accordance with ICC-ES AC156, IBC 2015 & CBC 2016.

• OSHPD Special Seismic Certification Preapproval (OSP)

This is a Marketing document. Please consult factory if additional information is required.

February 2019 6

Manufacturer reserves the right to modify this information without notice

Technical Data

Model GPY Electric Fire Pump Controller

A4 Flow switch provision High water reservoir level c/w visual indication

C18

and alarm contact (DPDT)

Foam pump application w/o pressure

A8

transducer and run test solenoid valve. C19 Emergency start alarm contact (DPDT)

A9 Low zone pump control function C20 Manual start alarm contact (DPDT)

A10 Middle zone pump control function C21 Deluge valve start alarm contact (DPDT)

A11 High zone pump control function C22 Remote automatic start alarm contact (DPDT)

Non-pressure actuated controller w/o pressure C23 Remote manual start alarm contact (DPDT)

A13

transducer and run test solenoid valve

High pump room temperature alarm contact

Lockout/interlock circuit from equipment C24

A16 (DPDT)

installed inside the pump room

Second set of standard alarm contacts (DPDT)

Built in alarm panel (120V.AC supervisory C25

(Typical for city of Los Angeles and Denver)

power) providing indication for:

• Audible alarm & silence pushbutton for motor Additional visual and alarm contact (Specify

B11 Cx

run, phase reversal, loss of phase. function) (DPDT)

• Pilot lights for loss of phase & supervisory Low suction pressure transducer for fresh

power available D1 water rated at 0-300PSI with visual indication

Built in alarm panel same as B11 but 220- and alarm contact

B11B

240VAC supervisory power Low suction pressure transducer for sea water

High motor temperature c/w thermoster relay D1A rated at 0-300PSI with visual indication and

B19A alarm contact

and alarm contacts (DPDT)

High motor temperature c/w PT100 relay and Pressure transducer and run test solenoid

B19B D5 valve for fresh water rated for 0-500PSI (for

alarm contacts (DPDT)

factory calibration purposes only)

Ground fault alarm detection c/w visual

B21 Pressure transducer and run test solenoid

indication and alarm contact (DPDT) D5D

valve for sea water rated for 0-500PSI

C1 Extra motor run alarm contact (DPDT)

D10 Omit mounting feet (when applicable)

C4 Periodic test alarm contact (DPDT)

High withstand rating for

C6 Low discharge pressure alarm contact (DPDT) D13 (normal power section)

• 208V to 480V = 150kA • 600V = 100kA

Low pump room temperature alarm contact

C7

(DPDT) D14 Anti-condensation heater & thermostat

Low water reservoir level alarm contact

C10 D14A Anti-condensation heater & humidistat

(DPDT)

High electric motor temperature alarm contact

C11 Anti-condensation heater & thermostat &

(DPDT) D14B

humidistat

High electric motor vibration c/w visual

C12

indication and alarm contact (DPDT) D15 Tropicalization

Pump on demand / automatic start alarm D18 CE Mark with factory certificate

C14

contact (DPDT)

Modbus with RTU frame format and RS485

C15 Pump fail to start alarm contact (DPDT) D26

connection

C16 Control voltage healthy alarm contact (DPDT) Motor heater connection (external single

D27

Flow meter valve loop open c/w visual phase power source and heater on/off contact)

C17

indication and alarm contact (DPDT) Motor heater connection (internal single phase

D27A

power source and heater on/off contact)

Note: Options chosen from this page are not electrically represented on the wiring schematics in this submittal package.

This is a Marketing document. Please consult factory if additional information is required.

February 2019 Manufacturer reserves the right to modify this information without notice 7

Technical Data

Model GPY Electric Fire Pump Controller

D28 Customized drawing set L01 Other language and English (bilingual)

Field programmable I/O board - L02 French

D34A

5 Input / 5 output

L03 Spanish

L04 German

L05 Italian

L06 Polish

L07 Romanian

L08 Hungarian

L09 Slovak

L10 Croatian

L11 Czech

L12 Portuguese

L13 Dutch

L14 Russian

L15 Turkish

L16 Swedish

L17 Bulgarian

L18 Thai

L19 Indonesian

L20 Slovenian

L21 Danish

L22 Greek

L23 Arabic

L24 Hebrew

L25 Chinese

Additional Options:

Note: Options chosen from this page are not electrically represented on the wiring schematics in this submittal package.

This is a Marketing document. Please consult factory if additional information is required.

February 2019 8

Manufacturer reserves the right to modify this information without notice

Technical Data

Model GPY Electric Fire Pump Controller

ViZiTouch V2 Operator Interface

PMS 295 PMS 361 Noir

Home

2 3

8

5 6 7

1 - Color touch screen 3 - Screen protector

2 - Onscreen menu 4 - Power LED (3 colors)

• HOME page 5 - START button

• ALARM page 6 - STOP button

• CONFIGURATION page 7 - RUN TEST button

• HISTORY page 8 - USB port

• SERVICE page

• MANUAL page

• LANGUAGES page

This is a Marketing document. Please consult factory if additional information is required.

February 2019 Manufacturer reserves the right to modify this information without notice 9

Electric Fire Pump Controller Model:GPA/GPP/GPY

Dimensions Built to the latest edition of the NFPA 20 standard

Sensing Line Connection - 1/2 " F.NPT

Drain - 3/8 " M.TUBE

Normal

Power and

Motor Leads

Entrance

Voltage / Power Table

Voltage Min HP Max HP

208 5 30 Notes:

220 - 240 5 30

- Standard NEMA: NEMA 2

- Standard paint : textured red RAL 3002.

380 - 400 - 415 5 60 - All dimensions are in inches [millimeters].

- Center of ViZiTouch screen: 29-5/8" [751] from bottom (no feet).

440 - 480 5 60 - Bottom conduit entrance through removable gland plate recommended.

- Use watertight conduit and connector only.

600 5 75 - Protect equipment against drilling chips.

- Door swing equal to door width.

- Seismic mounting to be rigid wall and base only.

Drawing for information only. Projection

Manufacturer reserves the right to modify this drawing without notice.

Contact manufacturer for "As Built" drawing.

REV. DESCRIPTION DD/MM/YY Drawing number

NYC 2. Revised logo 18/06/18

Dpt of Building

Approved

1. Valve Change 21/11/17 GPX-DI161 /E

0. First issue 16/11/16 CDL

Electric Fire Pump Controller

Reduced Voltage / Wye-Delta (Open Transition)

Model: GPY

Wiring schematic Built to the latest edition of the NFPA 20 standard

1L3 3L3

1L2 3L2

1L1 3L1

White

White

White

Black

Black

Black

17

3L3 64 66 68

3L2 65 67 69

18 20 3L1

4 2 3L1 19 21

To J2-J3-J4 To J76

2

1

3L2

NO NO +

C J40 J14 AI4

Motor Run C

TB1

NC NC -

2

1

NO NO +

C J42 J15 AI3

Power Available C

TB2

NC NC -

2

1

NO NO +

C J37 J16 AI2

Phase Reversal C

TB3

NC NC -

2

1

Red

NO NO +

C J39 J17 AI1

White

Pump Room Alarm C

TB4 Black

NC NC -

2

1

NO

NO LS1-1

C J41 LS1

Motor Trouble C

TB5 J54 LS1-2

NC NC

2

1

NO J20 UP

NO

C J55

(Field Programmable) C

TB6

NC NC J8 DOWN

Black - +

J46 Red

AB

Remote Manual Start IN1

SV1-1 Brown

SV

Lockout IN2 J43 SV1-2 Blue

Remote Automatic Start J1* IN3

4

Deluge Valve J45

J2* IN4 ST 2

J25

Water Reservoir Low IN5

J44 24V in

IN6 24V out 3L2

X1 H2

1

IN7 J47 24VAC 3 X2 H1

3L1

IN8

NC

J36 CR4-1

C

CR4 CR4-2

NO

NC

J38 CR5-1

C

CR5 CR5-2

NO

GF

69

L3 68

J76 67

L2 66 To CT1-CT2-CT3 Legend

65 1M-2M Contactors

1S Contactor

L1 64

AB Alarm Bell

CB Circuit Breaker

CR Control Relay

J53 CT Current Transformer

EB Electric I/O Board

IS Isolating Switch

J Jumper

J4 L3 3L3 LS Limit Switch

PT Pressure Transducer

SA Surge Arrester

J3 ST Shunt Trip

L2 3L2 To 3L1-3L2-3L3

SV Solenoid Valve

VMB ViZiTouch Main Board

XTR Transformer

J2 L1 3L1

Drawing for information only.

* Remove jumper to use this feature Manufacturer reserves the right to modify this drawing without notice.

** Contact closes when emergency start is in "ON" position Contact manufacturer for "As Built" drawing.

REV. DESCRIPTION DD/MM/YY Drawing number

NYC 2 Update Logo 23/04/18

Dpt of Building

Approved

1 Removed (fail safe) text from Power Available relay 20/02/17 GPY-WS600 /E

0 First issue 10/11/16 CDL

Electric Fire Pump Controller Model: GPX

Terminal Diagram and Sizing for Isolating Switch Built to the latest edition of the NFPA 20 standard

Power Terminals

3 Phases Notes:

Bonding Incoming Power 1 - For proper wire sizing, refer to NFPA70 and NEC (USA) or CEC (Canada) or local code.

Ground 2 - Controller suitable for service entrance in USA.

3 - For more accurate motor connections refer to motor manufacturer or motor nameplate.

4 - Controller is phase sensitive. Incoming lines must be connected in ABC sequence.

L1 L2 L3

IS1

COPPER CONDUCTORS for Isolating Switch (IS1).

Field Wiring According to Bending Space (AWG or MCM). Terminals L1 - L2 - L3

Bending

5 " (127 mm) 8 " (203 mm)

Space

HP

5 7.5 10 15 20 25 30 40 50 60

Voltage

208 1x (10 to 1/0) 1x (8 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (3 to 1/0) 1x (2 to 1/0) 1x (1/0 to 250) 1x (3/0 to 250) 1x (4/0 to 250)

220 to 240 1x (10 to 1/0) 1x (10 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (4 to 1/0) 1x (3 to 1/0) 1x (1 to 250) 1x (2/0 to 250) 1x (3/0 to 250)

380 to 416 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (8 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (3 to 1/0) 1x (3 to 1/0)

440 to 480 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (8 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (3 to 1/0)

600 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (8 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0)

Bending

Space 12 " (305 mm) 16 " (406 mm)

HP

75 100 125 150 200 250 300 350 400 450 500

Voltage

208 1x (300 to 500) 1x (500) 2x (4/0 to 500) 2x (250 to 500) 2x (400 to 600) -------- -------- -------- -------- -------- --------

220 to 240 1x (250 to 500) 1x (350 to 500) 2x (3/0 to 500) 2x (4/0 to 500) 2x (350 to 500) 2x (500 to 600) -------- -------- -------- -------- --------

2x (400 to 600)

380 to 416 1x (1/0 to 250) 1x (3/0 to 250) 1x (250) 1x (300 to 500) 2x (3/0 to 250) 2x (4/0 to 500) 2x (300 to 500) 2x (500 to 600) 2x (600) --------

2x (400 to 500)

440 to 480 1x (1 to 250) 1x (2/0 to 250) 1x (3/0 to 250) 1x (4/0 to 250) 1x (350 to 500) 2x (3/0 to 250) 2x (4/0 to 500) 2x (300 to 500) 2x (350 to 500) 2x (400 to 600) 2x (500 to 600)

600 1x (3 to 1/0) 1x (1 to 250) 1x (2/0 to 250) 1x (3/0 to 250) 1x (250 to 500) 1x (350 to 500) 2x (3/0 to 250) 2x (4/0 to 500) 2x (250 to 500) 2x (300 to 500) 2x (350 to 500)

Bending

Space 5 " (127 mm) 8 " (203 mm) 12 " (305 mm)

ALUMINUM CONDUCTORS for Isolating Switch (IS1).

Field Wiring According to Bending Space (AWG or MCM). Terminals L1 - L2 - L3

Bending

Space 5 " (127 mm) 8 " (203 mm) 10 " (254 mm)

HP

5 7.5 10 15 20 25 30 40 50 60

Voltage

1x (300) ** or

208 1x (10 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (3 to 1/0) 1x (1 to 1/0) 1x (1/0) 1x (3/0 to 250) 1x (4/0 to 250)

1x (250) 90°C *

220 to 240 1x (10 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (3 to 1/0) 1x (2 to 1/0) 1x (1 to 1/0) 1x (2/0 to 250) 1x (4/0 to 250) 1x (250)

380 to 416 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (4 to 1/0) 1x (2 to 1/0) 1x (1 to 1/0) 1x (1/0)

440 to 480 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (2 to 1/0) 1x (1 to 1/0)

600 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (10 to 1/0) 1x (8 to 1/0) 1x (6 to 1/0) 1x (6 to 1/0) 1x (4 to 1/0) 1x (4 to 1/0) 1x (2 to 1/0)

Bending

Space 12 " (305 mm) 16 " (406 mm)

HP

75 100 125 150 200 250 300 350 400 450 500

Voltage

1x(500) 90°C or

208 1x (400 to 500) 2x (300 to 500) 2x (350 to 500) 2x (600) -------- -------- -------- -------- -------- --------

2x(4/0 to 250) **

220 to 240 1x (350 to 500) 1x (500) 2x (250 to 500) 2x (300 to 500) 2x (500) 2x (600) 90°C * -------- -------- -------- -------- --------

1x (350) ** 2x (500 to 600)

380 to 416 1x (3/0 to 250) 1x (250) 1x (400 to 500) 2x (4/0 to 250) 2x (300 to 500) 2x (400 to 500) 2x (600) 90°C * 2x (600) 90°C * --------

N/A ** 2x (500)

1x (300) ** or

440 to 480 1x (1/0 to 250) 1x (3/0 to 250) 1x (250) 1x (500) 2x (250) 2x (300 to 500) 2x (400 to 500) 2x (500) 2x (600) 2x (600) 90°C *

1x (250) 90°C *

600 1x (1 to 1/0) 1x (2/0 to 250) 1x (3/0 to 250) 1x (4/0 to 250) 1x (350 to 500) 1x (500) 2x (4/0 to 250) 2x (300 to 500) 2x (350 to 500) 2x (400 to 500) 2x (500)

Bending

Space 5 " (127 mm) 8 " (203 mm) 12 " (305 mm)

* For standard enclosure, use 90°C aluminium wire. Consult Factory for Use of Conductors Rated Lower than 90°C. Drawing for information only.

Manufacturer reserves the right to modify this drawing without notice.

** Consult Factory Contact manufacturer for "As Built" drawing.

REV. DESCRIPTION DD/MM/YY Drawing number

NYC

Dpt of Building

2 Revised logo 18/06/18

Approved

1 General Revision (added AL coverage) 10/07/17 GPX-TD602 1/2 /E

0 First issue 16/03/17 CDL

Electric Fire Pump Controller Model: GPX

Terminal Diagram and Sizing For GPP,GPY & GPW Built to the latest edition of the NFPA 20 standard

Notes:

Motor Terminals 1 - For proper wire sizing, refer to NFPA70 and NEC (USA) or CEC (Canada) or local code.

2 - Controller suitable for service entrance in USA.

3 - For more accurate motor connections refer to motor manufacturer or motor nameplate.

2M 1M 2M 1M 4 - Controller is phase sensitive. Incoming lines must be connected in ABC sequence.

T7 T8 T9 T1 T2 T3 T6 T4 T5 T1 T2 T3

M M

Model : GPP Models : GPW & GPY

COPPER CONDUCTORS for Motor Connection (1M-2M).

Field Wiring According to Bending Space (AWG or MCM). Terminals T1-T2-T3-T4-T5-T6-T7-T8-T9

HP

5 7.5 10 15 20 25 30 40 50 60

Voltage

208 1x (14 to 10) 1x (12 to 10) 1x (10) 1x (8 to 2) 1x (8 to 2) 1x (6 to 2) 1x (6 to 1/0) 1x (4 to 2/0) 1x (2 to 3/0) 1x (1 to 2/0)

220 to 240 1x (14 to 10) 1x (12 to 10) 1x (10) 1x (8 to 2) 1x (8 to 2) 1x (6 to 2) 1x (6 to 1/0) 1x (4 to 2/0) 1x (3 to 2/0) 1x (2 to 2/0)

380 to 416 1x (14 to 10) 1x (14 to 10) 1x (14 to 10) 1x (12 to 10) 1x (10) 1x (10) 1x (8 to 2) 1x (6 to 2) 1x (6 to 2) 1x (4 to 1/0)

440 to 480 1x (14 to 10) 1x (14 to 10) 1x (14 to 10) 1x (12 to 10) 1x (12 to 10) 1x (10) 1x (10 to 2) 1x (8 to 2) 1x (6 to 2) 1x (6 to 2)

600 1x (14 to 10) 1x (14 to 10) 1x (14 to 10) 1x (14 to 10) 1x (12 to 10) 1x (12 to 10) 1x (10) 1x (10 to 2) 1x (8 to 2) 1x (8 to 2)

HP

75 100 125 150 200 250 300 350 400 450 500

Voltage

208 1x (2/0 to 3/0) 1x (3/0 to 300) 1x (250 to 300) 2x (1/0 to 300) 2x (3/0 to 350) -------- -------- -------- -------- -------- --------

220 to 240 1x (1/0 to 2/0) 1x (3/0) 1x (4/0 to 300) 1x (300) 2x (2/0 to 300) 2x (4/0 to 350) -------- -------- -------- -------- --------

380 to 416 1x (4 to 2/0) 1x (2 to 2/0) 1x (1/0 to 2/0) 1x (2/0 to 3/0) 1x (4/0 to 300) 1x (300) 2x (2/0 to 300) 2x (3/0 to 300) 2x (4/0 to 350) 2x (4/0 to 350) --------

440 to 480 1x (4 to 2/0) 1x (3 to 2/0) 1x (2 to 2/0) 1x (1/0 to 3/0) 1x (2/0 to 3/0) 1x (4/0 to 300) 1x (300) 2x (1/0 to 300) 2x (2/0 to 300) 2x (3/0 to 350) 2x (4/0 to 350)

600 1x (6 to 2) 1x (4 to 2/0) 1x (3 to 2/0) 1x (2 to 3/0) 1x (1/0 to 3/0) 1x (2/0 to 3/0) 1x (4/0 to 300) 1x (250 to 300) 1x (300) 2x (1/0 to 300) 2x (2/0 to 300)

ALUMINUM CONDUCTORS for Contactor (1M-2M).

Field Wiring According to Bending Space (AWG or MCM). Terminals T1-T2-T3-T4-T5-T6-T7-T8-T9

HP

5 7.5 10 15 20 25 30 40 50 60

Voltage

208 1x (12 to 10) 1x (10) 1x (10) 1x (8 to 2) 1x (6 to 2) 1x (4 to 2) 1x (4 to 1/0) 1x (2 to 2/0) 1x (1/0 to 3/0) 1x (2/0)

220 to 240 1x (12 to 10) 1x (10) 1x (10) 1x (8 to 2) 1x (8 to 2) 1x (6 to 2) 1x (4 to 1/0) 1x (2 to 2/0) 1x (1 to 2/0) 1x (1/0 to 2/0)

380 to 416 1x (12 to 10) 1x (12 to 10) 1x (12 to 10) 1x (10) 1x (10) 1x (8 to 2) 1x (8 to 2) 1x (6 to 2) 1x (4 to 2) 1x (3 to 1/0)

440 to 480 1x (12 to 10) 1x (12 to 10) 1x (12 to 10) 1x (12 to 10) 1x (10) 1x (10) 1x (8 to 2) 1x (8 to 2) 1x (6 to 2) 1x (4 to 2)

600 1x (12 to 10) 1x (12 to 10) 1x (12 to 10) 1x (12 to 10) 1x (10) 1x (10) 1x (10) 1x (8 to 2) 1x (8 to 2) 1x (6 to 2)

HP

75 100 125 150 200 250 300 350 400 450 500

Voltage

208 1x (3/0) Consult Factory 1x (300) 90°C * 2x (3/0 to 300) 2x (250 to 350) -------- -------- -------- -------- -------- --------

220 to 240 1x (2/0) 90°C * Consult Factory 1x (300) 1x (300) 90°C * 2x (4/0 to 300) 2x (300 to 350) -------- -------- -------- -------- --------

380 to 416 1x (2 to 2/0) 1x (1/0 to 2/0) 1x (1/0 to 2/0) 1x (3/0) 90°C * 1x (300) 1x (300) 90°C * 2x (4/0 to 300) 2x (250 to 300) 2x (300 to 350) 2x (300 to 350) --------

440 to 480 1x (3 to 2/0) 1x (2 to 2/0) 1x (2/0) 90°C * 1x (2/0 to 3/0) 1x (3/0) 90°C * 1x (300) 1x (300) 90°C * 2x (3/0 to 300) 2x (4/0 to 300) 2x (250 to 350) 2x (300 to 350)

600 1x (4 to 2) 1x (3 to 2/0) 1x (2 to 2/0) 1x (1/0 to 3/0) 1x (3/0) 1x (3/0) 90°C * 1x (300) 1x (300) 90°C * Consult Factory 2x (3/0 to 300) 2x (4/0 to 300)

* For standard enclosure, use 90°C aluminium wire. Consult Factory for Use of Conductors Rated Lower than 90°C.

Drawing for information only.

Manufacturer reserves the right to modify this drawing without notice.

Contact manufacturer for "As Built" drawing.

REV. DESCRIPTION DD/MM/YY Drawing number

NYC

Dpt of Building

2 Revised logo 18/06/18

Approved

1 General Revision (added AL coverage) 10/07/17 GPX-TD602 2/2 /E

0 First issue 16/03/17 CDL

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Inbuilt ATS PanelDocument17 pagesInbuilt ATS Panelbhima irabattiNo ratings yet

- Electric Pump Ffu Gpy-Sv3673-EDocument13 pagesElectric Pump Ffu Gpy-Sv3673-EPLTMG MPP JAYAPURA 50MWNo ratings yet

- Technical Data: Model GPY Electric Fire Pump ControllerDocument1 pageTechnical Data: Model GPY Electric Fire Pump Controllerneng hengNo ratings yet

- Tornatech Controller Data Sheet For EFP-WDO PDFDocument13 pagesTornatech Controller Data Sheet For EFP-WDO PDFViệt Đặng XuânNo ratings yet

- Model GPY: Technical Data Submittal DocumentsDocument14 pagesModel GPY: Technical Data Submittal Documentsbhima irabattiNo ratings yet

- NEMA Motor Data: 1LE2221-2AB11-4AA3 MLFB-Ordering DataDocument1 pageNEMA Motor Data: 1LE2221-2AB11-4AA3 MLFB-Ordering DataAlejandro VazNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- Gfy SV502 e PDFDocument9 pagesGfy SV502 e PDFedward baskaraNo ratings yet

- Catalog Đ NG Cơ Qu T Tăng Áp 90KW, 2975rpm YBX3-280M-2 ChinaDocument7 pagesCatalog Đ NG Cơ Qu T Tăng Áp 90KW, 2975rpm YBX3-280M-2 ChinaPhạm Hoài AnhNo ratings yet

- 1LE1604-3AB59-0GB4-Z B91+D30+D31+M1L Datasheet enDocument2 pages1LE1604-3AB59-0GB4-Z B91+D30+D31+M1L Datasheet enSergio FerrariNo ratings yet

- Siemens Motor 2HP - 1800 Rpm1MB2121-1AB41-6AG3Document6 pagesSiemens Motor 2HP - 1800 Rpm1MB2121-1AB41-6AG3marco antonio ramos melendezNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PToko DownloadNo ratings yet

- STF24N60M2, Stfi24n60m2, STFW24N60M2Document18 pagesSTF24N60M2, Stfi24n60m2, STFW24N60M2DalasteriskNo ratings yet

- Product Information PacketDocument7 pagesProduct Information PacketYanci JhoeNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- 1LE1623-3AB53-5GB4 Datasheet enDocument1 page1LE1623-3AB53-5GB4 Datasheet enSergio FerrariNo ratings yet

- 1LE1603-1DC43-4AB4-Z H01+Q01 Datasheet enDocument2 pages1LE1603-1DC43-4AB4-Z H01+Q01 Datasheet ennarminaNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- 1LE1501-3AB53-4AB4 Datasheet enDocument1 page1LE1501-3AB53-4AB4 Datasheet enfarid.chira2No ratings yet

- 1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enDocument2 pages1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enTien NguyenNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- 02.ex EnclosuresDocument52 pages02.ex EnclosuresJavier Enrrique Iglesias PelcastreNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZOmair FarooqNo ratings yet

- Type Series Booklet: Submersible MotorDocument40 pagesType Series Booklet: Submersible MotorJoao PauloNo ratings yet

- 1le1503 2DC03 4ab4Document2 pages1le1503 2DC03 4ab4faisal kingNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- 1le1523 1eb43 4ab4Document2 pages1le1523 1eb43 4ab4pmf engineering limitedNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PTio SNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- 1le1502 2BB03 4aa4Document3 pages1le1502 2BB03 4aa4Atlanta Bolivia100% (1)

- 1LE1503-1EA23-4AB4 Datasheet enDocument1 page1LE1503-1EA23-4AB4 Datasheet enpatilshailesh123No ratings yet

- 1LE1503-2BB03-4AA4 Datasheet enDocument1 page1LE1503-2BB03-4AA4 Datasheet enAnil Kumar KnNo ratings yet

- Catalog Đ NG Cơ Qu T Tăng Áp 110KW, 2984rpm YB3-315S-2 ChinaDocument7 pagesCatalog Đ NG Cơ Qu T Tăng Áp 110KW, 2984rpm YB3-315S-2 ChinaPhạm Hoài AnhNo ratings yet

- Siemens Motors DatasheetDocument2 pagesSiemens Motors DatasheetFar DesignNo ratings yet

- LEDchip-M500415 M500416 M500417 CLU028-1202C4 - 0140P - 201801 - 180423Document15 pagesLEDchip-M500415 M500416 M500417 CLU028-1202C4 - 0140P - 201801 - 180423Ramez FaroukNo ratings yet

- Article 365TSTGS16503 DataPack 9Document8 pagesArticle 365TSTGS16503 DataPack 9Macoflusa SA de CVNo ratings yet

- 30HP 286T 1LE2221-2CB29-0AA3-Z DatasheetDocument1 page30HP 286T 1LE2221-2CB29-0AA3-Z DatasheetJonathan Lepe NovoaNo ratings yet

- 1le1002 1ca13 4aa4Document3 pages1le1002 1ca13 4aa4Atlanta BoliviaNo ratings yet

- 1MB1553 2DB03 4JB4 Z B02 Datasheet enDocument2 pages1MB1553 2DB03 4JB4 Z B02 Datasheet enadriansya7No ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- 1LE2321-3CB11-2AA3 Datasheet en PDFDocument1 page1LE2321-3CB11-2AA3 Datasheet en PDFJolito RamosNo ratings yet

- TinyTrak4 Hardware Manual v0.6Document9 pagesTinyTrak4 Hardware Manual v0.6Scott Gillis100% (1)

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- 1le5584 3aa03 4ab4Document2 pages1le5584 3aa03 4ab4Dharmesh ChanawalaNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- 1LE1523-1EB43-4AA4 Datasheet enDocument1 page1LE1523-1EB43-4AA4 Datasheet enmuhammad nazmiNo ratings yet

- 1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enDocument1 page1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enopplusNo ratings yet

- 3 - 22KV Transformers - Tech - Speci PDFDocument44 pages3 - 22KV Transformers - Tech - Speci PDFHung NguyenNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZAtiqah Putri Sari100% (1)

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- 1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enDocument1 page1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enaminullahsharifNo ratings yet

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- 3 Weg Motores Expjmieee 841crusheriecDocument43 pages3 Weg Motores Expjmieee 841crusheriecJaime Olazo MolloNo ratings yet

- Citizen Led CLU048-1212C4Document15 pagesCitizen Led CLU048-1212C4lucas786No ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- 1LE1001-0EB42-2FB4 Datasheet enDocument1 page1LE1001-0EB42-2FB4 Datasheet enAde FaisalNo ratings yet

- Red Hat Enterprise Linux-8-Performing An Advanced RHEL installation-en-USDocument166 pagesRed Hat Enterprise Linux-8-Performing An Advanced RHEL installation-en-USDavidNo ratings yet

- 26.2.2 Packet Tracer - Configure Extended IPv4 ACLs - Scenario 2 - ILMDocument4 pages26.2.2 Packet Tracer - Configure Extended IPv4 ACLs - Scenario 2 - ILMTRYST CHAMANo ratings yet

- Memory ManagementDocument63 pagesMemory ManagementTheSpeedDealNo ratings yet

- Client 4 - ARM Tech Symposia Trustonic 01112023 - John Dent (Trustonic)Document31 pagesClient 4 - ARM Tech Symposia Trustonic 01112023 - John Dent (Trustonic)Andy WuNo ratings yet

- Error Detection and Correction IntroDocument38 pagesError Detection and Correction IntroUjjwalNo ratings yet

- Assignment 2 - EnCase ForensicsDocument2 pagesAssignment 2 - EnCase ForensicsAshley CastroNo ratings yet

- PM Debug InfoDocument33 pagesPM Debug Infomarcoscastellanos986No ratings yet

- Ch3 ExerciseDocument2 pagesCh3 ExerciseToqa HayajnehNo ratings yet

- Section 10.1: Boolean FunctionsDocument23 pagesSection 10.1: Boolean FunctionsOsamah AzamNo ratings yet

- Build A Todo List Mobile App - Hands-On ExerciseDocument36 pagesBuild A Todo List Mobile App - Hands-On ExerciseVanshaj GuptaNo ratings yet

- Project ReportDocument56 pagesProject ReportAstha MishraNo ratings yet

- Visvesvaraya Technological University: Computer Graphics and Visualization Lab (10CSL67)Document58 pagesVisvesvaraya Technological University: Computer Graphics and Visualization Lab (10CSL67)Rifat IqbalNo ratings yet

- Practical File Cyber Laws and IPR Lab (BTIT513-18) : Bachelor of Technology IN Information TechnologyDocument12 pagesPractical File Cyber Laws and IPR Lab (BTIT513-18) : Bachelor of Technology IN Information TechnologyAnmol SharmaNo ratings yet

- 09 QoSDocument55 pages09 QoSashwinlamroiaNo ratings yet

- Case Mode Period UX UY UZ Sum UX Sum UY Sum UZ SecDocument4 pagesCase Mode Period UX UY UZ Sum UX Sum UY Sum UZ SecSudip ShresthaNo ratings yet

- Veergatha3 0Document35 pagesVeergatha3 0Gtx SibbuNo ratings yet

- SAP Installations Using Shared Oracle HomesDocument6 pagesSAP Installations Using Shared Oracle HomesvikramdasNo ratings yet

- OtpDocument9 pagesOtpDenisElonNo ratings yet

- 01 MS-17L1 MS-17L2 MS-1581 MS-1582 v1.0 EnglishDocument58 pages01 MS-17L1 MS-17L2 MS-1581 MS-1582 v1.0 EnglishDavidNo ratings yet

- Manage Microsoft Sentinel Analytics Rules SlidesDocument24 pagesManage Microsoft Sentinel Analytics Rules SlidesJesse OliveiraNo ratings yet

- DevOps and Kubernetes Fundamentals - Infrastructure As Code With TerraformDocument48 pagesDevOps and Kubernetes Fundamentals - Infrastructure As Code With TerraformJamesNo ratings yet

- Case Study Why Nokia FailedDocument3 pagesCase Study Why Nokia FailedMD. ISRAFIL PALASH67% (3)

- Manual of Self Hypnosis Engineering Studio ProDocument11 pagesManual of Self Hypnosis Engineering Studio ProArq Francisco Melgar FlNo ratings yet

- Smart Safe City Project SolutionDocument32 pagesSmart Safe City Project Solutionalfimuhammad47100% (1)

- IRZ TEK Catalog 2015 ENDocument47 pagesIRZ TEK Catalog 2015 ENCesar VellorinNo ratings yet

- Emcp TrianingDocument31 pagesEmcp TrianingMr.Thawatchai hansuwan100% (1)

- EMV Payments CHIP Terms Definitions and Explanations - NeapayDocument18 pagesEMV Payments CHIP Terms Definitions and Explanations - Neapaysajad salehiNo ratings yet

- Dice Resume CV Yamini VakulaDocument5 pagesDice Resume CV Yamini VakulaharshNo ratings yet

- Matrix Det 1Document16 pagesMatrix Det 1QwertyNo ratings yet

- Chapter 3 - REDocument12 pagesChapter 3 - REtamerkobba12No ratings yet