Professional Documents

Culture Documents

Technical Workshop: The Progressive Levels of Optimisation

Uploaded by

Victor John PingkianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Workshop: The Progressive Levels of Optimisation

Uploaded by

Victor John PingkianCopyright:

Available Formats

TECHNICAL WORKSHOP

Makati Shangri-La, Manila, Philippines

20-22 June 2016

The Progressive Levels of Optimisation

In this three-day technical training workshop the progressive levels of cement manufacturing

process optimisation will be explored, beginning with the raw materials and their preparation,

moving on to the fuels for firing a cement kiln and the ventilation of the exhaust gases from

the process. An understanding of all these processes and how they interact is necessary to

control and optimise the process. The intention of this workshop is to provide and enhance that

understanding of the individual processes and their interaction.

Optimisation is a fundamental requirement for maximising the productivity and efficiency of the

cement manufacturing process. It is the way to minimise manufacturing costs, while maximising

product quality and the profitability of a cement factory and company. This Cemtech technical

training workshop will aim to explain how that can be achieved.

Outline Course Programme

Monday, 20 June 2016 Fuels and combustion continued...

Introduction & 1st Level of Optimisation: • Alternative fuel project methodologies

Raw materials • Alternative fuels best practice

• Review of core technologies and processes • Combustion air and oxygen requirements

• Best available technology • Exhaust gas volume

• Optimisation priorities of cement Wednesday, 22 June 2016

manufacturing

• The progressive levels of optimisation 3rd Level of Optimisation:

• Raw materials for cement manufacture Emissions and the exhaust gas flow path

• Raw mix design • Chloride cycles and bypass technology

• Converting the kiln feed raw mix into clinker • External cycles, sulphide inputs and

SO2 emissions

Tuesday, 21 June 2016 • Waste heat power generation

• Emissions mitigation

2nd Level of Optimisation:

• Preheater induced draught fans

Fuels and combustion

• Gas conditioning towers

• Fuels for firing the kiln and their combustion

• Drying in raw and coal mills

• Thermal energy cost minimisation

• Mill ventilation

For more information, see: www.Cemtech.com/Asia2016/Workshop

Tel: +44 (0) 1306 740 363 • Fax: +44 (0) 1306 740 660 • Email: info@Cemtech.com

Training Format

The format of these technical training workshops will be a series of lectures provided by course

tutor, Dr Clark, interspersed with exercises to illustrate and practice the concepts discussed in

the lectures. Open discussion forums will be encouraged following each lecture and exercise.

As the exercises will be largely Microsoft Excel based, participants should bring their laptop or

arrange to complete the exercises jointly with another participant.

The workshops will be of interest to both the technical and managerial staff of cement

companies. Guidance will be provided in the completion of the exercises which will be within the

compass of all delegates to Cemtech conferences.

Venue and Accommodation

The training course will take place at the Makati

Shangri-La. A specially discounted room rate from

PHP8000++ (USD174) per person per night will

be available to those wishing to stay in the Makati

Shangri-La. For other hotel recommendations at

different budget levels, please contact the organisers.

Registration Fee

• USD 1495 / EUR 1315 / GBP 995 per participant

• 10% discount for groups of three or more

Participants will be provided lunch and refreshments on each day of the training course.

FREE to participants: Technical Workshop Manual with Excel plant simulation models.

PLUS a complimentary copy of The Cement Plant Operations Handbook, 6th Edition,

published by International Cement Review.

For programme details and workshop registration, visit:

www.Cemtech.com/Asia2016/Workshop

Course Tutor Biography

Dr Michael Clark is a leading cement plant operations and technology specialist with over

40 years’ experience in the cement industry. His skills cover the whole process of cement

manufacturing from quarry planning, through clinker production, cement manufacture and

distribution. He is regarded as the leading international expert in problem identification,

efficiencies and improvements throughout the manufacturing process.

With a PhD in the manufacture of white cement, Dr Clark’s career highlights include senior

operational positions within Blue Circle Industries and ABB Linkman Systems Ltd, after

which he founded Whitehopleman (UK), an international consultancy specialising in the

cement industry. In addition, Dr Clark is Technical Consultant for International Cement

Review and Moderator of the CemNet.com e-Learning suite of training courses.

Dr Clark has worked in over 30 countries around the world in Asia, Africa, Australia, the

Americas, eastern Europe and the Middle East.

For more information, see: www.Cemtech.com/Asia2016/Workshop

Tel: +44 (0) 1306 740 363 • Fax: +44 (0) 1306 740 660 • Email: info@Cemtech.com

You might also like

- Advanced Production OptimizationDocument4 pagesAdvanced Production OptimizationKhaled YassinNo ratings yet

- Boiler House Management Leaflet DSMDocument4 pagesBoiler House Management Leaflet DSMDebasish DewanNo ratings yet

- Efficiency & Green House Gases: CorrugatorsDocument2 pagesEfficiency & Green House Gases: Corrugatorsapi-207596187No ratings yet

- Urea TrainingDocument15 pagesUrea TrainingAkbar AliNo ratings yet

- Minor ProjectDocument18 pagesMinor ProjectPritam KumarNo ratings yet

- Recommendation 23Document33 pagesRecommendation 23mukul josephNo ratings yet

- Work Package 5 CHP Component IntegrationDocument14 pagesWork Package 5 CHP Component IntegrationaquinorickyNo ratings yet

- Cement Production Technology PapersDocument0 pagesCement Production Technology PapersBruno Vilas BoasNo ratings yet

- Electric Power Research Institute: AccomplishmentsDocument1 pageElectric Power Research Institute: AccomplishmentsPiyush AgarwalNo ratings yet

- DataDocument11 pagesDataRashida MajeedNo ratings yet

- Waste To Energy (WTE)Document51 pagesWaste To Energy (WTE)Santosh Gopal100% (1)

- Chem Eng May 2014Document84 pagesChem Eng May 2014Sandro GoisisNo ratings yet

- Chemical Engineering Magzanie May 2014Document84 pagesChemical Engineering Magzanie May 2014Ku BonNo ratings yet

- PC Pump Course - Engl - 3 DayDocument2 pagesPC Pump Course - Engl - 3 DayBrandonNo ratings yet

- 2019 North America Cement Production Seminar - Bethlehem PADocument2 pages2019 North America Cement Production Seminar - Bethlehem PAImad BoudjemadiNo ratings yet

- Biomass Conversion TechnologiesDocument196 pagesBiomass Conversion TechnologiescokavoliNo ratings yet

- PromaxDocument20 pagesPromaxehsan_sa405100% (1)

- Heat Exchanger Fouling Mitigation TechnologyDocument5 pagesHeat Exchanger Fouling Mitigation TechnologyKmt_AeNo ratings yet

- 2010-11-28 Fire Technology - Fire Suppression of Bus Engine Compartments PDFDocument51 pages2010-11-28 Fire Technology - Fire Suppression of Bus Engine Compartments PDFcesar_zarateNo ratings yet

- PC Pump CourseDocument2 pagesPC Pump CourseGerman AlvarezNo ratings yet

- On Mini ProjectDocument6 pagesOn Mini ProjectgirishchandraejjadaNo ratings yet

- Hydrocarbon Processing 03 2012Document117 pagesHydrocarbon Processing 03 2012Enrique CastañedaNo ratings yet

- Combustão - Controle de NOxDocument11 pagesCombustão - Controle de NOxTarso SantosNo ratings yet

- Refinery Operations GuideDocument295 pagesRefinery Operations Guideluv_y_kush357575% (8)

- Ball GrindingDocument10 pagesBall Grindingmahreza189No ratings yet

- EEP Automatic Plastic Rev.1.2 EnglishDocument16 pagesEEP Automatic Plastic Rev.1.2 EnglishMArwin NGNo ratings yet

- BMW - Group 4Document32 pagesBMW - Group 4Manav KhuranaNo ratings yet

- Additive ManufacturingDocument19 pagesAdditive ManufacturingRohit PatilNo ratings yet

- FINAL - Car - Park - Venilation - Systems - April - 14 - 2021 PORTUGUESDocument75 pagesFINAL - Car - Park - Venilation - Systems - April - 14 - 2021 PORTUGUESrestinhoNo ratings yet

- Chapter 1Document32 pagesChapter 1Muhammad ZulhilmiNo ratings yet

- Technology Paper Report CSI 31-03-09Document98 pagesTechnology Paper Report CSI 31-03-09jmpbarrosNo ratings yet

- Gas Conditioning & Processing - GLOMACSDocument5 pagesGas Conditioning & Processing - GLOMACSCHO ACHIRI HUMPHREYNo ratings yet

- Advanced-Heat Exchangers & BoilersDocument7 pagesAdvanced-Heat Exchangers & BoilersSaqib LaeeqNo ratings yet

- Sinter Plant ProcessDocument1 pageSinter Plant ProcessGaurav JaiswalNo ratings yet

- Cold Box Overview enDocument18 pagesCold Box Overview enSasa DjordjevicNo ratings yet

- 2014 PTQ q4Document156 pages2014 PTQ q4digeca100% (1)

- Advanced Materials For Construction and Repair of Concrete: EcomanDocument4 pagesAdvanced Materials For Construction and Repair of Concrete: EcomanLak ChauhanNo ratings yet

- FLSmidth ICPS 2020 PDFDocument4 pagesFLSmidth ICPS 2020 PDFDori MascarenhasNo ratings yet

- Tema-Htri by Bert BoxmaDocument5 pagesTema-Htri by Bert BoxmaKarthik AnandanNo ratings yet

- Capabilities & TechnologiesDocument3 pagesCapabilities & TechnologiesMFNo ratings yet

- 6.4 BenchmarksDocument6 pages6.4 BenchmarksYhaneNo ratings yet

- COEN 13116 Duct Burner Solutions LR WebDocument2 pagesCOEN 13116 Duct Burner Solutions LR WebscribdkhatnNo ratings yet

- Revista PetroleoDocument115 pagesRevista PetroleojesslpezNo ratings yet

- CMD: Italian diesel engine manufacturerDocument21 pagesCMD: Italian diesel engine manufacturerJavier Gaspar Lee RomeroNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- IIT Piping EnggDocument7 pagesIIT Piping EnggSikander GirgoukarNo ratings yet

- 1.4.3 Industrial Process Efficiency: Technology DescriptionDocument3 pages1.4.3 Industrial Process Efficiency: Technology DescriptionjuanNo ratings yet

- Oil-Gas Training Courses ListDocument101 pagesOil-Gas Training Courses ListMahesh100% (1)

- Deployment of CCS in The Cement IndustryDocument139 pagesDeployment of CCS in The Cement IndustryJonson CaoNo ratings yet

- CO Capture and Storage: Options and Challenges For The Cement IndustryDocument49 pagesCO Capture and Storage: Options and Challenges For The Cement IndustryMohamedRaahimNo ratings yet

- Schunk Sealing RingsDocument20 pagesSchunk Sealing Ringspeach5No ratings yet

- ProMax 3 BrochureDocument20 pagesProMax 3 BrochureNila Gama100% (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Engineered Ceramics: Current Status and Future ProspectsFrom EverandEngineered Ceramics: Current Status and Future ProspectsTatsuki OhjiNo ratings yet

- We Are Hiring: TRI PACIFIC Is Looking For ADocument1 pageWe Are Hiring: TRI PACIFIC Is Looking For AVictor John PingkianNo ratings yet

- JSA Welding and Cutting Metals Using Oxy AcetyleneDocument5 pagesJSA Welding and Cutting Metals Using Oxy AcetyleneVictor John PingkianNo ratings yet

- Job Safety Analysis for Gas WeldingDocument4 pagesJob Safety Analysis for Gas WeldingVictor John PingkianNo ratings yet

- Manufacturing Process & SystemDocument36 pagesManufacturing Process & SystemVictor John PingkianNo ratings yet

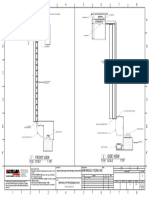

- 4 FRONT VIEW DETAILS MCC LayoutDocument1 page4 FRONT VIEW DETAILS MCC LayoutVictor John PingkianNo ratings yet

- 4 FRONT VIEW DETAILS MCC LayoutDocument1 page4 FRONT VIEW DETAILS MCC LayoutVictor John PingkianNo ratings yet

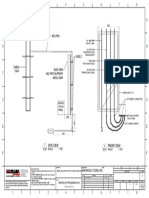

- 3 NEW ELECTRICAL LAYOUT Ladder Support PDFDocument1 page3 NEW ELECTRICAL LAYOUT Ladder Support PDFVictor John PingkianNo ratings yet

- 4 FRONT VIEW DETAILS MCC LayoutDocument1 page4 FRONT VIEW DETAILS MCC LayoutVictor John PingkianNo ratings yet

- Stock price analysis over timeDocument1 pageStock price analysis over timeVictor John PingkianNo ratings yet

- Re-Installation of Cable Tray Support 2'' X 2'' ANGLE BARCABLE TRAY 500 X 150 X 2400Document1 pageRe-Installation of Cable Tray Support 2'' X 2'' ANGLE BARCABLE TRAY 500 X 150 X 2400Victor John PingkianNo ratings yet

- 5 CABLE TRAY ACCESS HOLE MCC Layout PDFDocument1 page5 CABLE TRAY ACCESS HOLE MCC Layout PDFVictor John PingkianNo ratings yet

- 6 MACHINE ROOM S01 S05 ELECTRICAL SUPPORT LAYOUT MCC LayoutDocument1 page6 MACHINE ROOM S01 S05 ELECTRICAL SUPPORT LAYOUT MCC LayoutVictor John PingkianNo ratings yet

- AutoCAD Notes by Khalid Mahmud SirDocument87 pagesAutoCAD Notes by Khalid Mahmud SirBhashkarAbhishek100% (1)

- 5 CABLE TRAY ACCESS HOLE MCC LayoutDocument1 page5 CABLE TRAY ACCESS HOLE MCC LayoutVictor John PingkianNo ratings yet

- 3 NEW ELECTRICAL LAYOUT Ladder SupportDocument1 page3 NEW ELECTRICAL LAYOUT Ladder SupportVictor John PingkianNo ratings yet

- 4 FRONT VIEW DETAILS MCC LayoutDocument1 page4 FRONT VIEW DETAILS MCC LayoutVictor John PingkianNo ratings yet

- Perspective Front View: Scale 1:100 1 Scale 1:100 2Document1 pagePerspective Front View: Scale 1:100 1 Scale 1:100 2Victor John PingkianNo ratings yet

- 1037 ElementsDocument67 pages1037 ElementsVictor John PingkianNo ratings yet

- BoardDocument8 pagesBoardJerald ManlangitNo ratings yet

- Canned Goods Math Word ProblemDocument14 pagesCanned Goods Math Word ProblemAriel Mark Pilotin100% (3)

- Differential and Integral Calculus Formulas, Concepts, ExamplesDocument6 pagesDifferential and Integral Calculus Formulas, Concepts, ExamplesDayLe Ferrer AbapoNo ratings yet

- CNS 2Document14 pagesCNS 2Manoy BermeoNo ratings yet

- CNS 01Document14 pagesCNS 01Victor John PingkianNo ratings yet

- LINX REVIEW CENTER MATHEMATICS AND SCIENCES EXAMDocument10 pagesLINX REVIEW CENTER MATHEMATICS AND SCIENCES EXAMVictor John PingkianNo ratings yet

- PROBABILITY AND STATISTICS REVIEW FinalDocument56 pagesPROBABILITY AND STATISTICS REVIEW FinalVictor John Pingkian100% (1)

- Linx Review Center: Set ADocument11 pagesLinx Review Center: Set AWilssie SanchezNo ratings yet

- Convert 1 GJ to BTUDocument52 pagesConvert 1 GJ to BTUMarty Jablos0% (1)

- Ashrae D 90405 20100120 PDFDocument233 pagesAshrae D 90405 20100120 PDFrgopikrishna313No ratings yet

- Pipe 2019Document12 pagesPipe 2019Victor John Pingkian100% (1)

- BiomassDocument25 pagesBiomassMuhammadSami100% (1)

- Produçao de Briquetes A Partir Da Casca Do Fruto de Licuri (Syagrus Coronata) e Palha de Cana-de-AçúcarDocument9 pagesProduçao de Briquetes A Partir Da Casca Do Fruto de Licuri (Syagrus Coronata) e Palha de Cana-de-AçúcarRenan Guilherme de Oliveira GuihNo ratings yet

- 30M - ConocoPhillips Optimized Cascade PDFDocument11 pages30M - ConocoPhillips Optimized Cascade PDFPutu Indra MahatrisnaNo ratings yet

- BME lecture week semester finalDocument20 pagesBME lecture week semester finalarthey FriendNo ratings yet

- UntitledDocument2 pagesUntitledMarc Gabriel ReyesNo ratings yet

- Biochar by Design: Nature Geoscience April 2014Document3 pagesBiochar by Design: Nature Geoscience April 2014Anna Carolina MachadoNo ratings yet

- FWEmap 2023 OnlineDocument1 pageFWEmap 2023 OnlineShawanda FlynnNo ratings yet

- GT Load Effect On HRSGDocument3 pagesGT Load Effect On HRSGsatishchemeng100% (1)

- Natural Gas Processing LectureDocument19 pagesNatural Gas Processing LectureManepalli Narasimha Murthy50% (2)

- UK Carbon Reduction PlanDocument7 pagesUK Carbon Reduction PlanAnkit DiwakarNo ratings yet

- Asco Co By-Product Recovery SystemsDocument2 pagesAsco Co By-Product Recovery Systemssemarasik_651536604No ratings yet

- Biodegradable Waste: SourcesDocument3 pagesBiodegradable Waste: SourcesRockyNo ratings yet

- t3369 Francis Turbine ScreenDocument8 pagest3369 Francis Turbine ScreenluizbarbieriNo ratings yet

- A Pilot Power Plant Based On Concentrating Solar and Energy Storage Technologies For Improving Electricity DispatchDocument8 pagesA Pilot Power Plant Based On Concentrating Solar and Energy Storage Technologies For Improving Electricity Dispatchayupermata2106No ratings yet

- CroDocument2 pagesCroParash Mani TimilsinaNo ratings yet

- Index to Co-Generator Gas Turbine Cause Code TablesDocument59 pagesIndex to Co-Generator Gas Turbine Cause Code TablessamsNo ratings yet

- Biomass EnergyDocument12 pagesBiomass Energydgagan22No ratings yet

- Gujarat Pellet SuppliersDocument1 pageGujarat Pellet SuppliersmanojNo ratings yet

- Optimization of a Thermal Cracker Operation via Linear ProgrammingDocument1 pageOptimization of a Thermal Cracker Operation via Linear ProgrammingCharly JiménezNo ratings yet

- Optimization of PV SystemsDocument13 pagesOptimization of PV SystemsStanleyNo ratings yet

- Business Cases - Hydrogen Into Gas GridDocument18 pagesBusiness Cases - Hydrogen Into Gas GridLeidy Johanna Cardenas SolanoNo ratings yet

- RRS&RRLDocument15 pagesRRS&RRLJohnCris B. FornilosNo ratings yet

- EAP Skillful Book 9Document120 pagesEAP Skillful Book 9paulaNo ratings yet

- BioPort Rotterdam Gateway to Renewables for EuropeDocument16 pagesBioPort Rotterdam Gateway to Renewables for EuropekrenariNo ratings yet

- Datasheet IMEON Battery EN BA V4EDocument2 pagesDatasheet IMEON Battery EN BA V4EStellinaNo ratings yet

- SLXRB Streamline X ReGen BrochureDocument2 pagesSLXRB Streamline X ReGen BrochureAlexandr SorokaNo ratings yet

- Power-to-Gas: Linking Electricity and GasDocument17 pagesPower-to-Gas: Linking Electricity and GasAminos MaNo ratings yet

- Waste to Energy Conversion CourseDocument2 pagesWaste to Energy Conversion Courserama deviNo ratings yet

- Steam Generation - Distribution 2023Document64 pagesSteam Generation - Distribution 2023Aaqil cassimNo ratings yet

- Oschatz Group Company PresentationDocument25 pagesOschatz Group Company PresentationKwangsuKimNo ratings yet