Professional Documents

Culture Documents

PharmaEng CreamProduction PDF

PharmaEng CreamProduction PDF

Uploaded by

mailtorubal2573Copyright:

Available Formats

You might also like

- A Guide To Blend Uniformity: Overview of Blending Process and EquipmentDocument6 pagesA Guide To Blend Uniformity: Overview of Blending Process and Equipmentmailtorubal2573100% (1)

- Line Balancing Theory of ConstraintsDocument3 pagesLine Balancing Theory of Constraintsmonti_1234No ratings yet

- Design of Aseptic Process SimulationDocument5 pagesDesign of Aseptic Process SimulationFranck BureNo ratings yet

- Manufactura CelularDocument10 pagesManufactura CelularLizbeth Lima HanccoNo ratings yet

- Scale-Up of Chemical Engineering Process: Prof H R ShahDocument27 pagesScale-Up of Chemical Engineering Process: Prof H R Shahatgtegtrhrh100% (1)

- Main Index Installation, Operation and Maintenance Manual: 1.0 Index Reverse Osmosis SystemDocument142 pagesMain Index Installation, Operation and Maintenance Manual: 1.0 Index Reverse Osmosis SystemMile InriNo ratings yet

- Operations Research Perspectives: SciencedirectDocument10 pagesOperations Research Perspectives: Sciencedirectwilmervh.iNo ratings yet

- BioPharm - Scale Down - Upstream PDFDocument9 pagesBioPharm - Scale Down - Upstream PDFGeetanjali HubliNo ratings yet

- 2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesDocument8 pages2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesHubert BonamisNo ratings yet

- Simulation Model in LeanDocument12 pagesSimulation Model in Leandrrmm2sNo ratings yet

- A Study For Optimum Productivity Yield in 0.16 M Mixed of Wafer Fabrication FacilityDocument4 pagesA Study For Optimum Productivity Yield in 0.16 M Mixed of Wafer Fabrication FacilitykamaveriyanNo ratings yet

- Design and Optimization of A Large Scale Biopharmaceutical Facility Using Process Simulation and Scheduling ToolsDocument9 pagesDesign and Optimization of A Large Scale Biopharmaceutical Facility Using Process Simulation and Scheduling ToolsIRFAN AHANGERNo ratings yet

- Scale Down Biopharma - EIB 2013 PDFDocument17 pagesScale Down Biopharma - EIB 2013 PDFGeetanjali HubliNo ratings yet

- Virtual Cellular Manufacturing Configuring Routing FlexibilityDocument13 pagesVirtual Cellular Manufacturing Configuring Routing FlexibilityDrMohamed MansourNo ratings yet

- Coupling Simulation and Optimization For An Integrated Production and Maintenance Planning in Manufacturing SystemsDocument5 pagesCoupling Simulation and Optimization For An Integrated Production and Maintenance Planning in Manufacturing Systemswilmervh.iNo ratings yet

- Solid Dose: Sponsored byDocument25 pagesSolid Dose: Sponsored byAbou Tebba SamNo ratings yet

- Articulo Control de La CalidadDocument12 pagesArticulo Control de La CalidadCamilo EstradaNo ratings yet

- Pharmaceutical Pilot Scale UpDocument51 pagesPharmaceutical Pilot Scale UpDerejeNo ratings yet

- Industrial Flexibility New2 2021-2Document7 pagesIndustrial Flexibility New2 2021-2chermatisarahNo ratings yet

- Inventory Levels On Throughput: The Effect of Work-In-Process and Lead TimesDocument6 pagesInventory Levels On Throughput: The Effect of Work-In-Process and Lead TimesTino VelazquezNo ratings yet

- Pilot Plant Scale UpDocument7 pagesPilot Plant Scale UpDrx Rinku KunduNo ratings yet

- Kanikuła-Koch2010 Chapter MethodologyOfDesigningDisassemDocument8 pagesKanikuła-Koch2010 Chapter MethodologyOfDesigningDisassemAziz BenNo ratings yet

- RefineryWide Sim HEMag March PDFDocument3 pagesRefineryWide Sim HEMag March PDFnaraNJORNo ratings yet

- Operations Status and Bottleneck Analysis and Improvement of A Batch Process Manufacturing Line Using Discrete Event SimulationDocument12 pagesOperations Status and Bottleneck Analysis and Improvement of A Batch Process Manufacturing Line Using Discrete Event SimulationkinfegetaNo ratings yet

- Planning The Inflow of Products For Production LevellingDocument4 pagesPlanning The Inflow of Products For Production LevellingPratik PatilNo ratings yet

- Informe Final de ArtículosDocument10 pagesInforme Final de ArtículosAstri rivera Rivera ChiroqueNo ratings yet

- Strategies For Improving Capsule Filling EfficiencyDocument4 pagesStrategies For Improving Capsule Filling EfficiencySangram KendreNo ratings yet

- Tact Time StudyDocument10 pagesTact Time StudyAtul SharmaNo ratings yet

- 3 Job Shop Scheduling PDFDocument7 pages3 Job Shop Scheduling PDF123away123No ratings yet

- 1994c Apcom Slovenie Opti MoinhoDocument10 pages1994c Apcom Slovenie Opti MoinhoDirceu NascimentoNo ratings yet

- Cellular ManufacturingDocument10 pagesCellular ManufacturingjosicremaNo ratings yet

- GCP Sect8 Packaging PerformanceDocument10 pagesGCP Sect8 Packaging Performancelevanvui161No ratings yet

- Mixing Simulationtoolsin Process DevelopmentDocument4 pagesMixing Simulationtoolsin Process Developmentkumar_chemicalNo ratings yet

- Expert Systems With Applications: Joaquín Bautista, Rocío Alfaro-Pozo, Cristina Batalla-GarcíaDocument15 pagesExpert Systems With Applications: Joaquín Bautista, Rocío Alfaro-Pozo, Cristina Batalla-GarcíadedendjatiNo ratings yet

- Real-Time Bottleneck Detection and Prediction To Prioritize Fault Repair in Interlinked Production LinesDocument6 pagesReal-Time Bottleneck Detection and Prediction To Prioritize Fault Repair in Interlinked Production LinesDevlina PriliantiNo ratings yet

- Modelling An Ice Cream Factory For Debottlenecking (Technical Report)Document6 pagesModelling An Ice Cream Factory For Debottlenecking (Technical Report)pangregisterlang99No ratings yet

- Man Simulation 1Document13 pagesMan Simulation 1kushkimNo ratings yet

- Something About Unicorns and Majestic BeastsDocument9 pagesSomething About Unicorns and Majestic BeastsDanny JaliusNo ratings yet

- Heliyon: Okpala Charles Chikwendu, Anozie Stephen Chima, Mgbemena Chika EdithDocument9 pagesHeliyon: Okpala Charles Chikwendu, Anozie Stephen Chima, Mgbemena Chika EdithDIEGO FERNANDO HUAMANI TORRESNo ratings yet

- Jaureguibecker 2015Document4 pagesJaureguibecker 2015Murat AquaNo ratings yet

- 6 MaaloufDocument9 pages6 Maalouflechiquan2497No ratings yet

- Ideal Peptide PlantDocument4 pagesIdeal Peptide PlantjoesuhreNo ratings yet

- Case Study-Automation in ManufacturingDocument14 pagesCase Study-Automation in ManufacturingRohitNo ratings yet

- Synopsis of ProjectDocument6 pagesSynopsis of Projecthirak_buronNo ratings yet

- 1 s2.0 S0278612522000838 MainDocument18 pages1 s2.0 S0278612522000838 MainMann StrongNo ratings yet

- Poves Calderno2019Document5 pagesPoves Calderno2019wachoNo ratings yet

- Fill Finish March 2011Document10 pagesFill Finish March 2011Paulo Roberto Chiarolanza VilelaNo ratings yet

- Gev - Cor - 08 - 2004Document25 pagesGev - Cor - 08 - 2004Guilherme VieiraNo ratings yet

- Pilot Plant OperationDocument21 pagesPilot Plant Operationsandeep_waliaNo ratings yet

- Journal of Manufacturing Systems: Jun-Ho Lee, Cong Zhao, Jingshan Li, Chrissoleon T. PapadopoulosDocument13 pagesJournal of Manufacturing Systems: Jun-Ho Lee, Cong Zhao, Jingshan Li, Chrissoleon T. PapadopoulosDanny AucancelaNo ratings yet

- Multi-Product Production CyclingDocument9 pagesMulti-Product Production CyclingRicardo TrevinoNo ratings yet

- Molded Pulp Lot-Sizing and SchedulingDocument32 pagesMolded Pulp Lot-Sizing and SchedulingGuillermoNo ratings yet

- The Design and Operation of A Facility For Filling Hard Shell Gelatin CapsulesDocument28 pagesThe Design and Operation of A Facility For Filling Hard Shell Gelatin Capsulespharmashri5399100% (4)

- Five Best PracticesDocument10 pagesFive Best PracticesAntHony K-ianNo ratings yet

- Moshe Article PDFDocument16 pagesMoshe Article PDFicingrockNo ratings yet

- PSEAsia2013 99 PDFDocument6 pagesPSEAsia2013 99 PDFMostofa RubalNo ratings yet

- Application of Queuing Theory in Quality Control of Multi-Stage Flexible Flow ShopDocument8 pagesApplication of Queuing Theory in Quality Control of Multi-Stage Flexible Flow ShopsyafiraNo ratings yet

- An Investigation of Lead-Time e Ects in Manufacturing/ Remanufacturing Systems Under Simple PUSH and PULL Control StrategiesDocument20 pagesAn Investigation of Lead-Time e Ects in Manufacturing/ Remanufacturing Systems Under Simple PUSH and PULL Control StrategiesBunty EvolNo ratings yet

- Dynamic Operator Training Simulators For Sulphuric Acid, Phosphoric Acid, and DAP Production UnitsDocument10 pagesDynamic Operator Training Simulators For Sulphuric Acid, Phosphoric Acid, and DAP Production UnitsAdios ANo ratings yet

- Considerations For Estimating The Costs of Pilot-Scale FacilitiesDocument9 pagesConsiderations For Estimating The Costs of Pilot-Scale FacilitiesAlex100% (1)

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Critical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.From EverandCritical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.No ratings yet

- Excipient Risk AssessmentDocument6 pagesExcipient Risk Assessmentmailtorubal2573No ratings yet

- Terminal Sterilization of Pharmaceutical ProductsDocument8 pagesTerminal Sterilization of Pharmaceutical Productsmailtorubal2573No ratings yet

- Fda On Statistical ApproachesDocument33 pagesFda On Statistical Approachesmailtorubal2573No ratings yet

- Catalent Belgium, Brussels, Belgium 8.19.22 483Document10 pagesCatalent Belgium, Brussels, Belgium 8.19.22 483mailtorubal2573No ratings yet

- Water Vapor Transmission of Materials: Standard Test Methods ForDocument12 pagesWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573No ratings yet

- PI 045 1 PICS Guideline On Excipient GMP Risk AssessmentDocument7 pagesPI 045 1 PICS Guideline On Excipient GMP Risk Assessmentmailtorubal2573No ratings yet

- Stage 6 Monograph 25 Feb 2011Document3 pagesStage 6 Monograph 25 Feb 2011mailtorubal2573No ratings yet

- Stratified Sampling of CapsuleDocument23 pagesStratified Sampling of Capsulemailtorubal2573No ratings yet

- Sample Sizes in Uniformity Measurements - The Role of USPDocument25 pagesSample Sizes in Uniformity Measurements - The Role of USPmailtorubal2573No ratings yet

- Method Development and Column Selection: How The Fluorophenyl Phase Provides The Power of Hilic and Reversed-Phase Modes in One ColumnDocument10 pagesMethod Development and Column Selection: How The Fluorophenyl Phase Provides The Power of Hilic and Reversed-Phase Modes in One Columnmailtorubal2573No ratings yet

- INN FileDocument14 pagesINN Filemailtorubal2573No ratings yet

- Uniformity of Dosage Units, Part 1: Acceptance Value: Peer-ReviewedDocument10 pagesUniformity of Dosage Units, Part 1: Acceptance Value: Peer-Reviewedmailtorubal2573No ratings yet

- Dissolution Rate Enhancement of Fenofibrate Using Liquisolid Tablet TechniqueDocument7 pagesDissolution Rate Enhancement of Fenofibrate Using Liquisolid Tablet Techniquemailtorubal2573No ratings yet

- Appendices A and B: API SpecificationDocument1 pageAppendices A and B: API Specificationmailtorubal2573No ratings yet

- Bisimilar Final Draft 23-01-2018 PDFDocument59 pagesBisimilar Final Draft 23-01-2018 PDFmailtorubal2573No ratings yet

- How To Make Hand Sanitiser GelDocument1 pageHow To Make Hand Sanitiser Gelmailtorubal2573No ratings yet

- PM2105 ComplianceDocument28 pagesPM2105 Compliancemailtorubal2573No ratings yet

- Gynomix: Soft Gelatin CapsuleDocument1 pageGynomix: Soft Gelatin Capsulemailtorubal2573No ratings yet

- Giz2012 0398en Eu Who GuidelinesDocument51 pagesGiz2012 0398en Eu Who Guidelinesmailtorubal2573No ratings yet

- ICH Q6 Decision Tree For Microbiology D PDFDocument1 pageICH Q6 Decision Tree For Microbiology D PDFmailtorubal2573No ratings yet

- EF15April29 2 MaryMurry AmwayDocument25 pagesEF15April29 2 MaryMurry Amwaymailtorubal2573No ratings yet

- Experiment 2: Water Flow Measurement WLF 922 Objectives: Process Control & Instrumentation Laboratory BKF3791Document5 pagesExperiment 2: Water Flow Measurement WLF 922 Objectives: Process Control & Instrumentation Laboratory BKF3791PMNo ratings yet

- Infusion Quiz 3Document6 pagesInfusion Quiz 3Dip Ayan MNo ratings yet

- JKLDocument9 pagesJKLanon_314301380No ratings yet

- Fuel Dispensing and Vapour Recovery ValvesDocument2 pagesFuel Dispensing and Vapour Recovery Valvesbr1404No ratings yet

- 3-1 Dynamic Light ScatteringDocument5 pages3-1 Dynamic Light ScatteringAmal PatelNo ratings yet

- Modulation Option On R90-160 Installation InstructionDocument23 pagesModulation Option On R90-160 Installation InstructionLiviu HogeaNo ratings yet

- Design of Pressure Vessel by Using ASME Sec-VIII Div-1Document6 pagesDesign of Pressure Vessel by Using ASME Sec-VIII Div-1jhaamit4No ratings yet

- Chapter-2 Energy Dissipation StructureDocument15 pagesChapter-2 Energy Dissipation StructureGoytom yigezuNo ratings yet

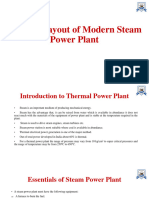

- General Layout of Modern Steam Power PlantDocument15 pagesGeneral Layout of Modern Steam Power PlanttabishkhanaligNo ratings yet

- Series: Innovative Split Case PumpsDocument3 pagesSeries: Innovative Split Case PumpssenaNo ratings yet

- Flashcards - Topic 2.3 Thermal Processes - CAIE Physics IGCSEDocument19 pagesFlashcards - Topic 2.3 Thermal Processes - CAIE Physics IGCSESaurabh.DeoNo ratings yet

- Fiberbond Fiberglass Piping Systems Series 20FR16-C: DescriptionDocument2 pagesFiberbond Fiberglass Piping Systems Series 20FR16-C: DescriptionANDERSON NERESNo ratings yet

- Nitric Oxide PFDDocument16 pagesNitric Oxide PFDPrashit JainNo ratings yet

- Ultrasonic Flowmeter Low Cost BrochureDocument3 pagesUltrasonic Flowmeter Low Cost BrochureCarlos Vilca JeriNo ratings yet

- Data Sheets FOR Pressure Safety ValvesDocument8 pagesData Sheets FOR Pressure Safety Valvessunildubey02No ratings yet

- Case Study On Rain Water Harvesting in NepalDocument12 pagesCase Study On Rain Water Harvesting in NepalArpeet NeupaneNo ratings yet

- New ReviewerDocument3 pagesNew ReviewerEun Ji KimNo ratings yet

- Aircraft Heat ExchangersDocument3 pagesAircraft Heat ExchangersDalibor Stevic100% (1)

- Nuclear Engineering and Design: Giorgio Besagni, Gaël R. Guédon, Fabio InzoliDocument16 pagesNuclear Engineering and Design: Giorgio Besagni, Gaël R. Guédon, Fabio InzoliRABIUL ISLAMNo ratings yet

- Final Control ElementDocument16 pagesFinal Control ElementSanchit KhannaNo ratings yet

- System Saver Series Single Cartridge Air DryersDocument52 pagesSystem Saver Series Single Cartridge Air DryersModestasNo ratings yet

- Free Water PassageDocument46 pagesFree Water PassageAbiued EjigueNo ratings yet

- Design and Analysis of A Hypersonic Inlet WithDocument8 pagesDesign and Analysis of A Hypersonic Inlet WithArun G NairNo ratings yet

- BFD, PFD and PnidDocument9 pagesBFD, PFD and PnidKuatnNo ratings yet

- ANSYS FLUENT 12.0 User's Guide - 7.2 - PorousDocument13 pagesANSYS FLUENT 12.0 User's Guide - 7.2 - Porousabhya1987No ratings yet

- Refractory NotesDocument3 pagesRefractory NotesSarbajit Sanjat KumarNo ratings yet

- Reverse Osmosis Basics - Toray Reverse Osmosis Basics - Knowledge Base - Toray Membrane - TorayDocument2 pagesReverse Osmosis Basics - Toray Reverse Osmosis Basics - Knowledge Base - Toray Membrane - ToraySantosh Kumar SinghNo ratings yet

- Hydraulic of DozerDocument83 pagesHydraulic of DozerLinzaw OoNo ratings yet

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDocument11 pagesModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaNo ratings yet

PharmaEng CreamProduction PDF

PharmaEng CreamProduction PDF

Uploaded by

mailtorubal2573Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PharmaEng CreamProduction PDF

PharmaEng CreamProduction PDF

Uploaded by

mailtorubal2573Copyright:

Available Formats

Reprinted from

PHARMACEUTICAL ENGINEERING®

The Official Magazine of ISPE Batch Process Simulation

July/August 2006, Vol. 26 No. 4

This article

describes the Debottlenecking of a Batch

use of a batch

process Pharmaceutical Cream Production

simulator in the

modelling and

debottlenecking by Jully Tan, Dominic Chwan Yee Foo,

of an anti- Sivakumar Kumaresan, and Ramlan Abdul Aziz

allergic cream

production line

at an existing

pharmaceutical

facility.

C

Introduction the current production rate as the production

omputer Aided Process Design (CAPD) capacity was limited by the current operating

and simulation tools have been widely condition and equipment setup. Hence, a

used in the bulk and petrochemical debottlenecking study is needed for an increase

industries since the early 1960s. It in production. In addition, the debottlenecking

involves the use of computers to perform steady- study will assist the management team in fu-

state heat and mass balancing as well as sizing ture expansion plans.

and costing calculations for a process.1 How-

ever, the use of these CAPD and simulation Background Theory

tools has only emerged in pharmaceutical In order to increase production throughput,

manufacturing in the past decade.2-8 Compared process bottlenecks that limit the current pro-

to the readily available process simulators in duction need to be identified. Bottlenecks are

the bulk and petrochemical industries, there process limitations that are related to either

are only a limited number of simulators avail- equipment or resources (e.g., demand for vari-

able for pharmaceutical process modelling. This ous utilities, labor, and raw material). Hence,

situation is mainly due to the uncommon unit process debottlenecking can be defined as the

operations and the batch operation nature of identification and removal of obstacles in the

pharmaceutical processing. Due to its rela- attempt to increase the plant throughput.5 In

tively new emergence, more work needs to be batch manufacturing, two types of process

done in this sector. bottlenecks can be categorized. These are the

Due to the increasing customer demand of equipment capacity-related size bottleneck (an

the anti-allergic cream product, the pharma- equipment that is limited in size) as well as the

ceutical facility management team was looking scheduling bottleneck (due to the long occu-

for alternative expansion schemes to increase pancy of a piece of equipment during a process).

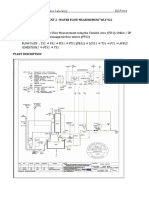

Figure 1. Base case

simulation flowsheet for

the production of anti-

allergic cream.

©Copyright ISPE 2006 JULY/AUGUST 2006 PHARMACEUTICAL ENGINEERING 1

Batch Process Simulation

The ability to identify and remove process bottlenecks that mum production. However, this is often not the case. All

create obstacles in a manufacturing process will increase process equipment will normally feature different utiliza-

plant throughput and fulfill customer needs. tion. The ability to raise utilization of the equipment will

A good tool to identify batch process bottleneck is via a help in raising process throughput. The processing step

throughput analysis study. Throughput analysis measures with the highest combined utilization is normally identi-

the equipment utilization in a batch process with two vari- fied as the first candidate for process debottlenecking.

ables, i.e., the capacity utilization and equipment uptime.5-6 Simulation tools that are capable of tracking capacity

Capacity utilization is defined as the percentage of the utilization and equipment uptime can facilitate the iden-

current operating load of a piece of equipment (e.g., vessel tification of process bottlenecks and the development of

volume for a reactor or filtering area of a filter) relative to its the scenarios for process debottlenecking. By using the

maximum load. For instance, a vessel with 100% capacity “what if” scenario, process alternatives can be simulated

utilization means that its current content has reached its via the use of simulation tools to reveal potential candi-

maximum level. dates for the debottlenecking study.

Equipment uptime measures the effectiveness of a piece of The Cost Benefit Ratio (CBR) is among the criteria that

equipment that is utilized in time. It is given as the percent- can be used to evaluate the economic performance of

age of the equipment utilization time over the plant cycle debottlenecking alternatives. As the name suggests, CBR is

time. For example, a reactor that operates for five hours a measure based on the ratio of benefits obtained for a given

within a plant with a cycle time of 10 hours has an uptime of expansion cost.9 The first step in CBR analysis is to deter-

50%. The product of equipment capacity utilization and its mine the beneficial elements, disbenefits, and expansion cost

uptime defines the combined utilization of the respective for a project. For the case of pharmaceutical process debottle-

equipment.5-6 necking, CBR formulation can be defined as shown in the

In an ideal situation, a plant should have all equipment following equation:

running at 100% combined utilization to achieve maxi-

Figure 2. Operation Gantt Chart for the base case simulation.

2 PHARMACEUTICAL ENGINEERING JULY/AUGUST 2006 ©Copyright ISPE 2006

Batch Process Simulation

Revenue of

Revenue of – current

alternative operation

CBR = __________________________________________ (1)

Investment Operating Operating

cost of + cost of – cost of

alternative alternative current

operations

Model Development –

Antiallergic Cream Production

Figure 1 shows the base case simulation flowsheet for the

production of anti-allergic cream modelled in a process simu-

lator.10 The base case simulation model was developed to

Figure 3. Capacity, time and combined utilization for unit

reflect the actual operating condition in the existing pharma-

procedures in base case simulation.

ceutical manufacturing facility that is operated in batch

processing mode. This modelling environment, involves the blended product is next transferred to Filler P-5/FL-101 in

modelling of a few operations that take place sequentially in the Packaging Section where it is filled into the tubes of 15 g

a single unit procedure.10 For instance, the Jacketed Heater each. The existing filling machine is operated at a speed of 30

procedure P-1 in the Pre-Mixing section - Figure 1 was used tubes/min. The tubes are then sent to the cartoning packag-

to model the sequential operations of raw material charges, ing procedure P-7 (using a belt conveyer P-6/BC-101) where

material heating (for melting purpose), agitation processes, the anti-allergic cream in tubes are packed manually by two

as well as product discharge. All these individual operations operators into the tube cartons, each at a speed of 20 cartons/

took place in the single vessel of V-101. The modelling of these min. Next, 12 cartons of anti-allergic cream are packed into

single operations is described next. one wrapper in the Shrink Wrapper (P-8/GBX-101) with a

In the base case process, there are nine major processing speed of five wrappers/min. Finally, six wrappers are packed

steps in three different sub-sections. This includes raw into each of the pallet boxes in Packing Machine P-9/BX-102

material melting in the Pre-Mixing Section, deionized (DI) (equivalent to 72 tubes/pallet box) before they are sent to the

water heating, and material blending in the Main Blending warehouse. Approximately six sealed pallet boxes are packed

Section, as well as filling, conveying, cartoning, shrink wrap- per minute by the operator manually.

ping, and shipment packaging in the Packaging sections. Due As the manufacturing process is carried out in a batch

to the capacity limitation of the pre-mixing vessel, the raw operation mode, efforts have been made to document the

material is divided into two sub-mix batches in the Pre- scheduling details of each processing step. The Operation

Mixing Section. Two batches of Emulsifying Wax (ESW) and Gantt Chart for the complete recipe of a single batch opera-

Foam Stabilizer (FS) are independently heated in the heating tion is shown in Figure 2. It also should be noted that the

procedures P-1 (carried out in Jacketed Heater V-101) and P- process time for certain operations are dependant upon other

2 (in Jacketed Heater V-102) to approximately 100ºC before operations of other procedure (e.g., transfer-out operation in

the emulsifier (EMUL) and ointment (OIN) are added. The P-4 is set equal to the filling duration of P-5). Hence, the

emulsifier and ointment are originally in wax form and need duration of this slave operation is set to follow to the duration

to be melted for uniform mixing. All raw materials are of the master operation using the Master-Slave Relationship

charged at room temperature. function.10 The customer demand for this anti-allergic cream

DI water is heated in the electric heater EH-101 (proce- product is expected to rise another 150% of the current

dure P-3) before being transferred into the Main Blending production capacity in upcoming years. However, the process

Tank, V-103 (P-4) in the Main Blending Section. An Antimi- is currently running at its maximum capacity and any at-

crobial Agent (AM) is next added into the hot DI water, tempt to increase production is not possible due to the process

followed by agitation for 10 minutes. The mixture in the bottleneck. This calls for a systematic procedure to analyze

jacketed heater V-101 and V-102 is then transferred into V- the current production facilities and next to debottleneck the

103. The mixture of all ingredients in V-103 is blended once process. Apart from debottlenecking the current production,

more for 15 minutes in order to produce a uniform composi- the debottlenecking study also will develop solutions for

tion. The mixture is then left in an air-conditioned dispensing future expansion.

room to be naturally cooled to room temperature. This cooling

operation took approximately 19 hours to accomplish due to Bottleneck Identification Strategies

the slow rate of natural cooling. Upon the completion of the In the current operation, the annual operating time for the

cooling operation, the Active Ingredient (AI) of the anti- anti-allergic cream manufacturing is taken as 2080 hours,

allergic cream is finally added. The products are once again which is based on 52 operation weeks, five days a week and

blended for 15 minutes to obtain uniform composition before eight hours operation per day. From the base case simulation,

the product mixture is sent to the Packaging Section. a complete batch of pharmaceutical cream production is

Upon the completion of the Main Blending Procedure, the found to have a process batch time of 40.2 hrs and a minimum

©Copyright ISPE 2006 JULY/AUGUST 2006 PHARMACEUTICAL ENGINEERING 3

Batch Process Simulation

Economic Parameters Base Case Scheme 1 Scheme 2 Scheme 3 Scheme 4 Scheme 5

Batch Production (tubes/batch) 13,333 13,333 13,333 13,333 13,333 13,333

Plant Batch Time (hour) 40.2 41.7 26.2 23.3 27.7 24.8

Minimum Cycle Time (hour) 29.0 21.6 15.0 12.0 9.9 7.6

Number of Batches/year 66 87 121 147 173 215

Annual Production (tube/yr) 880,000 1,160,000 1,613,300 1,960,000 2,306,600 2,866,600

Cost of Investment ($) - 10,000 255,000 555,000 265,000 565,000

Annual Operating Cost ($) 947,200 1,310,000 1,432,700 1,536,000 2,167,200 2,393,500

Unit Production Cost ($/tube) 2.30 1.13 0.89 0.78 0.94 0.83

Annual Revenue ($) 2,200,000 2,900,000 4,033,000 4,900,000 5,766,700 7,166,700

Gross Margin 57.0 54.9 64.5 68.7 62.7 66.6

Cost Benefit Ratio (CBR) - 1.88 2.47 2.36 2.40 2.47

Table A. Throughput and economic evaluation of base case study and various debottlenecking schemes.

cycle time of 29 hrs - Figure 2. The minimum cycle time of the option at the present moment. Hence, debottlenecking options

process is defined as the minimum time possible between the will only focus on the reduction of equipment uptime of P-4/V-

start of two consecutive batches. It is equal to the longest 103. This is described in the next section.

occupation time among all pieces of equipment involved in

this process.10 In the case of anti-allergic cream manufactur- Debottlenecking Schemes

ing; the minimum cycle time corresponds to the prolonged After identifying the candidate for process debottlenecking,

cooling operation in the Main Blending procedure P-4. With the feasibility of various debottlenecking schemes were evalu-

an interval of two hours for tank cleaning between batches, ated. Five debottlenecking schemes were analyzed in which

this sets the plant annual production at 66 batches. The all schemes were applied focusing on reducing the equipment

throughput of the base case is summarized in Table A (col- uptime of P-4/V-103 as the process time bottleneck.

umn 2). The simplest option to increase the process through-

put by increasing daily operating duration is determined to Alternative Debottlenecking Schemes

be uneconomical due to the high operating cost in hiring Figure 4 shows the simulation flowsheet for debottlenecking

additional staff. This leads us to explore the use of combined Scheme 1. As shown, a new intermediate tank V-104 is

utilization concept as has been discussed earlier. installed after the Main Blending vessel. The main rationale

Figure 3 displays the capacity, time, and combined utiliza- underlying this scheme is to reduce the equipment uptime of

tion of all the procedure/equipment pairs in the base case Main Blending vessel (P-4/V-103), by spending a minimal

simulation. As shown, the Main Blending Procedure P-4 (V- investment cost of US $10,000 (purchase cost for V-104). By

103) with an equipment capacity utilization of 89.9% and the adding the intermediate tank V-104, the two subsequent

equipment uptime of 93.6% has a much higher combined procedures P-4/V-103 and P-5/FL-101 are disconnected. The

utilization percentage of 84.1% as compared to other proce- Transfer-Out operation in P-4/V-103 is no longer constrained

dures. The high equipment uptime of this procedure is mainly by the slow filling operation in Filler P-5/FL-101. Upon the

due to the long cooling operation (19 hours) and Transfer-Out completion on the blending operations in P-4/V-103, the

operation (8.4 hours). This also makes P-4/V-103 the sched- product mixture is transferred into the newly added V-104 for

uling bottleneck of the process, i.e., process with longest temporary storage while waiting for the filling operation to

operating duration (see Operation Gantt Chart in Figure 2). complete. The main blending procedure can then be carried

Note that certain procedures (e.g. Filler P5/FL-101, Belt out for a subsequent operation. Simulation results showed

Conveyer P-6/BC-101, etc.) are not considered as size bottle- that the annual production for this scheme has increased to

necks even though they have 100% size utilization, as the 87 batches due to the reduction of minimum cycle time that

operation speed of this equipment can be adjusted according limits the number of annual production from 29 hrs (in the

to the operational needs.5 base case simulation) to 21.6 hrs (shown in the third column

After identifying the Main Blending Procedure P-4 (V-103) in Table A). This corresponds to an increase of annual

as the first process bottlenecking candidate, debottlenecking production rate of 32%, but is insufficient to fulfill the

strategies will next be focused on reducing either the size or projected customer demand.

time utilization of this procedure/equipment. However, since Scheme 2 for process debottlenecking is shown in Figure 5.

there are two pre-mixing tanks that serve as the mixture It focuses on the reduction of cooling operation of P-4/V-103

preparation proceeding to P-4/V-103, any attempt of changing instead. A multifunctional blending tank with a cooling

a larger Main Blending vessel will lead to the replacement of system (purchase cost of US $255,000) is installed to replace

the two pre-mixing tanks V-101 and V-102. This has been the main blending tank. This reduces the cooling time of the

determined by the management team to be an infeasible product mixture from the current 19 hours to five hours.

4 PHARMACEUTICAL ENGINEERING JULY/AUGUST 2006 ©Copyright ISPE 2006

Batch Process Simulation

Figure 4. Debottlenecking Scheme 1 with the installation of an intermediate tank.

Chilled water is used as cooling agent to cool the mixture from purchase cost of $300,000) is installed in addition to the new

85ºC to room temperature. This leads to the reduction of multifunctional blending tank in Scheme 2 to accelerate the

minimum cycle time to 15 hrs. Hence, an increase of 83.3% is filling rate. Simulation results showed that with the reduc-

achieved for annual production as compared to the base case, tion of Transfer-out duration in P-4/V-103, combined utiliza-

i.e., from 66 to 121 batches (fourth column in Table C). From tion values of P-4/V-103, P-5/FL-101 and P-6/BC-101 have

Table B, it is shown that even although P-4/V-103 remains as been reduced slightly, while other unit procedures increase in

the overall process bottleneck, its combined utilization value their combined utilization values - Table B. The net result is

has actually been reduced from 84.2% in the base case the reduction of minimum cycle time to 12 hrs and an increase

simulation to 79.3%, due to the reduction of its uptime. On the annual production rate of 147 batches, i.e., 122.7% compared

other hand, combined utilization of other unit procedures to the base case (fifth column in Table A).

have increased significantly. This leads to an overall increase Another debottlenecking alternative focusing on reducing

of process throughput. Further debottlenecking can only be the overall uptime of P-4/V-103 is presented in Scheme 4 -

achieved if the long duration of the Transfer-out operation in Figure 7. Instead of installing a new filling machine as in

P-4/V-103 (to filler P-5/FL-101) can be reduced. Scheme 3, an intermediate storage tank (V-104; purchase

Figure 6 shows the simulation flowsheet of Scheme 3 that cost of US $10,000) is added in addition to the installation of

explores the reduction of P-4/V-103 uptime from a different a new Blending Tank (P-4/V-103). This scheme exhibits the

perspective. As the Transfer-Out duration of P-4/V-103 is same characteristics as the combination of Scheme 1 and

dependent upon the filling rate in P-5/FL-10, one alternative Scheme 2. Simulation results showed that the annual pro-

to reduce the duration of Transfer-Out operation in P-4/V-103 duction for this scheme is 173 batches with a minimum cycle

is to install a high speed filler to shorten the filling duration time reduced to 9.9 hrs (sixth column in Table A). This

in P-5/FL-10, and hence the Transfer-out duration in P-4/V- corresponds to an increase of annual production rate of 162%,

103. As shown in Figure 6, a new filler (50 tubes/min; fulfilling the future market demand. It also should be noted

Equipment Tag Procedure Name Base Case Scheme 1 Scheme 2 Scheme 3 Scheme 4 Scheme 5

V-102 P-2 Jacketed Heater 2 4.71 6.19 8.59 10.41 12.26 16.00

V-101 P-1 Jacketed Heater 1 8.04 10.56 14.66 17.76 20.92 27.30

V-103 P-4 Main Blending Tank 84.12 82.30 79.34 77.11 57.27 79.13

FL-101 P-5 Filler 27.13 35.65 49.48 38.81 70.61 56.81

BC-101 P-6 Belt Conveyor 23.90 31.41 43.60 31.68 62.21 46.38

BX-101 P-7 Manual Cartoning 17.93 23.56 32.70 39.60 46.66 57.97

GBX-101 P-8 Shrink Wrapping 11.95 15.70 21.80 26.40 31.10 38.65

BX-102 P-9 Manual Pallet Packaging 1.66 2.18 3.03 3.67 4.32 5.37

Table B. Combined utilization for different debottlenecking schemes.

©Copyright ISPE 2006 JULY/AUGUST 2006 PHARMACEUTICAL ENGINEERING 5

Batch Process Simulation

Raw Material Symbol Price ($/kg) Unit/Batch Cost/Batch ($) Annual Cost ($) % Contribution

Emulsifier EMUL 15.50 30.00 kg 465.00 30,690.00 11.15

Emulsifying Wax ESW 5.05 3.60 kg 18.18 1,200.00 0.44

Foam Stable FS 3.00 14.40 kg 43.20 2,851.00 1.04

Antimicrobial Agent AM 4.00 0.24 kg 0.96 63.00 0.02

Active Ingredient AI 650.00 2.00 kg 1,300.00 85,800.00 31.17

Emulsifying Ointment OIN 15.00 12.00 kg 180.00 11,880.00 4.32

Deionized Water DI water 0.50 137.76 kg 68.88 4,546.00 1.65

Water Water 0.03 69.63 kg 2.09 138.00 0.05

Tube Tube 0.10 13,333.00 1,333.30 88,000.00 31.97

Carton Box Small box 0.05 13,333.00 666.65 44,000.00 15.98

Pallet Box Big box 0.50 185.00 92.50 6,110.00 2.22

TOTAL COST 3,635.44 239,939.06 100.00

Table C. Cost of raw material for base case simulation.

that after the installation of intermediate storage tank V- the presence of the additional intermediate tank and the high

101, filler P-5/FL-101 has became the unit procedure with the speed filling machine, the production increases to 215 batches

highest combined utilization value. As shown in Table B, all per annum, i.e., an increase of 225% with minimum cycle time

unit procedures experienced an increase in their combined reduced to 7.6 hr (seventh column in Table C). The capital

utilization values except that of P-4/V103. This is consistent investment needed in this scheme is calculated as the sum-

with the finding of Koulouris et al,5 where new bottleneck mary of individual equipment in the previous schemes, i.e.

equipment will emerge after the current bottleneck is over- $565,000.

come. Debottlenecking efforts are stopped at this scheme as All the proposed debottlenecking schemes have demon-

the debottlenecking objective is reached, i.e., achieving the strated significant improvement on the annual production

150% increase in production as compared to current produc- throughput. This is mainly due to the reduction of minimum

tion. However, to cater for future expansion plan as re- cycle time associated with main blending tank procedures. As

quested by the management team, the replacement of a new previously mentioned, Scheme 4 serves as the debottlenecking

P-5/FL-101 is studied in the next debottlenecking scheme. scheme for current increase of production; while Scheme 5

Figure 8 shows the simulation flowsheet for Scheme 5, with the highest process throughput is reserved for future

which includes filler P-5/FL-101 for debottlenecking. With expansion plans.

Figure 5. Debottlenecking Scheme 2 with the installation of new multifunctional blending tank.

6 PHARMACEUTICAL ENGINEERING JULY/AUGUST 2006 ©Copyright ISPE 2006

Batch Process Simulation

Figure 6. Debottlenecking Scheme 3 with the installation of new multifunctional blending tank and new filler.

Economic Evaluation dominate the raw material cost, each contributing 31% of the

Preliminary economic evaluations are next carried out for the overall production cost. Note that the distribution of raw

base case simulation and each of the debottlenecking schemes. material costs remains the same for all schemes as shown in

This is done via the economic evaluation function of the Table C, only differing by total annual cost for each scheme

simulation software.10 In order to regenerate a realistic cost due to the different annual throughput.

estimate, raw material costs and equipment purchase costs The economic evaluation comparing the various

are obtained from local industrial suppliers. Table C shows debottlenecking schemes with respect to the base case study

the cost of the raw material for the production of anti-allergic is shown in Table A. The Cost Benefit Ratio (CBR) is used as

cream and their contribution to the overall production cost in a tool in comparing the alternative schemes. As shown,

the base case simulation. The active ingredient for the anti- except for Scheme 1, all other debottlenecking schemes are

allergic cream and the tube (where 15 g of cream is filled) having similar CBR values with Scheme 2 and Scheme 5

Figure 7. Debottlenecking Scheme 4 with the installation of intermediate tank and new multifunctional blending tank.

©Copyright ISPE 2006 JULY/AUGUST 2006 PHARMACEUTICAL ENGINEERING 7

Batch Process Simulation

Figure 8. Debottlenecking Scheme 5 for future plant expansion.

having the highest value of 2.47. This indicates that except 4. Ernst, S., Garro, O. A., Winkler, S., Venkataraman, G.,

for Scheme 1 all debottlenecking schemes have equal value Langer R., Cooney, C. L., and Sasisekharan, R., “Process

for investment. Simulation for Recombinant Protein Production: Cost

In the previous debottlenecking section, it is shown that Estimation and Sensitivity Analysis for Heparinase I

Scheme 4 was selected to be the debottlenecking scheme due to Expressed in Escherichia coli,” Biotechnology and Bioengi-

its fulfillment to future customer demand, i.e., by producing neering, Vol. 53, No. 6, 1997, pp. 575-582.

more than 150% of the current production. On the other hand, 5. Koulouris, A., Calandranis, J., and Petrides, D. P.,

Scheme 5 that has been identified to be the future debottlenecking “Throughput Analysis and Debottlenecking of Integrated

scheme also shows a promising CBR value of 2.47. Batch Chemical Processes,” Computers and Chemical

Engineering, Vol. 24, 2000, pp. 1387-1394.

Conclusion 6. Petrides, D. P., Koulouris, A., and Siletti, C., “Throughput

In this work, Computer-Aided Process Design (CAPD) and Analysis and Debottlenecking of Biomanufacturing Fa-

simulation tools are used in the systematic identification of the cilities: A Job for Process Simulators,” BioPharm, August

process bottleneck and a debottlenecking study. An operational 2002, pp.2-7.

pharmaceutical case study of anti-allergic cream production is 7. Petrides, D. P., Koulouris, A., and Siletti, C., “The Role of

used to demonstrate the effectiveness of the tools. The base case Process Simulation in Pharmaceutical Process Develop-

and four debottlenecking schemes are simulated using SuperPro ment and Product Commercialization,” Pharmaceutical

Designer. The annual process throughput is increased signifi- Engineering, Vol. 22, No. 1, 2002, pp. 56-65.

cantly with the reduction of equipment uptime of the process 8. Oh, S. K. W., Kuek, K. H., and Wong, V. V. T., “Design,

time bottleneck. The study produced a debottlenecking scheme Simulation and Optimisation of A Large Scale Monoclonal

that achieves the current production needs, with a scheme that Antibody Production Plant: Upstream Design,” Pharma-

will cater for a future expansion plan. ceutical Engineering, Vol. 24, No. 6, 2004, pp. 42-60.

9. Blank, L. T. and Tarquin A. J., Engineering Economy,

References New York: McGraw-Hill, 2003.

1. Westerberg, A. W., Hutchison, H. P., Motard, R. L., and

10. Intelligen, Inc., SuperPro Designer User’s Guide, Scotch

Winter, P., Process Flowsheeting, Cambridge: Cambridge

Plains: Intelligen, Inc., 2005.

University Press, 1979.

2. Petrides, D., Sapidou, E., and Calandranis, J., “Com-

puter-Aided Process Analysis and Economic Evaluation

Acknowledgement

The authors would like to thank Dr. Alexandros Koulouris,

for Biosynthetic Human Insulin Production – A Case

the Managing Director of Intelligen Europe, for his construc-

Study,” Biotechnology and Bioengineering, 48, 1995, pp.

tive feedback with this project.

529-541.

3. Hwang, F., “Batch Pharmaceutical Process Design and

Simulation,” Pharmaceutical Engineering, January/Feb-

ruary 1997, pp. 28-43.

8 PHARMACEUTICAL ENGINEERING JULY/AUGUST 2006 ©Copyright ISPE 2006

Batch Process Simulation

About the Authors Sivakumar Kumaresan is a lecturer in

Jully Tan is a research student at the Chemi- chemical engineering at the Universiti Ma-

cal Engineering Pilot Plant, Universiti laysia Sabah. He has a BS in chemical engi-

Teknologi Malaysia (CEPP, UTM). She re- neering from Texas A&M University (US),

ceived her BEng degree in chemical engi- an MSc in advanced control from the Univer-

neering from the Universiti Teknologi Ma- sity of Manchester Institute of Science and

laysia and is currently pursuing her MSc Technology (UK), and is currently complet-

research work in CEPP, UTM. She conducted ing his PhD in herbal processing at the Chemi-

her industrial attachment at a local pharma- cal Engineering Pilot Plant, Universiti Teknologi Malaysia.

ceutical production plant where this project is carried out. At His area of work includes the application of process simula-

the plant, she assisted the plant management team to evalu- tion tools to pharmaceutical modelling and he is currently

ate different debottlenecking schemes for various pharma- working on model-based phytochemical processing design

ceutical production processes using computer-aided process and optimization focusing on the standarization of herbal

simulation tools. She can be contacted via e-mail: extracts for pharmaceutical applications. He can be con-

tanjully@yahoo.co.uk or by phone: +60(12)-6670382. tacted via e-mail: shiva@ums.edu.my or shiva@cepp.utm.my,

Chemical Engineering Pilot Plant, Universiti Teknologi by phone: +60(88)-320000 ext. 3064, or by fax: +60(88)-

Malaysia, 81310 Skudai, Johor, Malaysia. 320348.

Chemical Engineering Program, School of Engineering

Dominic C. Y. Foo is an Assistant Professor and Information Technology, Universiti Malaysia Sabah,

at the University of Nottingham Malaysia. Locked Bag 2073, 88999, Kota Kinabalu, Malaysia.

Prior to this position, he served as a Post-

graduate Researcher at the Chemical Engi- Ramlan A. Aziz is a Professor and Director

neering Pilot Plant, Universiti Teknologi of the Chemical Engineering Pilot Plant,

Malaysia (CEPP, UTM), where this work Universiti Teknologi Malaysia. He obtained

was completed. He obtained his BEng, MEng, his BEng and MEng from the University of

and PhD from the Universiti Teknologi Ma- Manchester Institute of Science and Tech-

laysia, all in chemical engineering. His main areas of work nology (UMIST, UK). His main areas of work

include that of process synthesis, analysis, and design for include developing small and medium scale

cleaner production and efficient manufacturing. He makes enterprises in Malaysia through process and

use of computer-aided process design and simulation tools in product development based on natural products and

optimizing and debottlenecking batch manufacturing pro- bioprocessing. He is a member of the Filtration Society of UK

cesses, such as pharmaceutical, fine, and specialty chemical and has served as a Vice President for Institution of Chemical

production. He is a member of the Institution of Engineers, Engineers Malaysia (IChEM). He can be contacted via e-

Malaysia (IEM) and the Institution of Chemical Engineers mail: ramlan@cepp.utm.my, by phone: +60(07)-5531662 or

UK (IChEM) Malaysia Branch, previously known as the by fax: +60(07)-5569706. His Web site is http://www.cepp.

Institution of Chemical Engineers Malaysia (IChEM). He utm.my/.

can be contacted via e-mail: Dominic.Foo@nottingham.edu.my Chemical Engineering Pilot Plant, Universiti Teknologi

or foodominic@ yahoo.com, by phone: +60(03)-89248130, or Malaysia, 81310 Skudai, Johor, Malaysia.

by fax: +60(03)-89248017. His personal Web site is http://

www.geocities.com/foodominic/.

School of Chemical and Environmental Engineering, Uni-

versity of Nottingham Malaysia Campus, Broga Rd., 43500

Semenyih, Selangor, Malaysia.

©Copyright ISPE 2006 JULY/AUGUST 2006 PHARMACEUTICAL ENGINEERING 9

You might also like

- A Guide To Blend Uniformity: Overview of Blending Process and EquipmentDocument6 pagesA Guide To Blend Uniformity: Overview of Blending Process and Equipmentmailtorubal2573100% (1)

- Line Balancing Theory of ConstraintsDocument3 pagesLine Balancing Theory of Constraintsmonti_1234No ratings yet

- Design of Aseptic Process SimulationDocument5 pagesDesign of Aseptic Process SimulationFranck BureNo ratings yet

- Manufactura CelularDocument10 pagesManufactura CelularLizbeth Lima HanccoNo ratings yet

- Scale-Up of Chemical Engineering Process: Prof H R ShahDocument27 pagesScale-Up of Chemical Engineering Process: Prof H R Shahatgtegtrhrh100% (1)

- Main Index Installation, Operation and Maintenance Manual: 1.0 Index Reverse Osmosis SystemDocument142 pagesMain Index Installation, Operation and Maintenance Manual: 1.0 Index Reverse Osmosis SystemMile InriNo ratings yet

- Operations Research Perspectives: SciencedirectDocument10 pagesOperations Research Perspectives: Sciencedirectwilmervh.iNo ratings yet

- BioPharm - Scale Down - Upstream PDFDocument9 pagesBioPharm - Scale Down - Upstream PDFGeetanjali HubliNo ratings yet

- 2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesDocument8 pages2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesHubert BonamisNo ratings yet

- Simulation Model in LeanDocument12 pagesSimulation Model in Leandrrmm2sNo ratings yet

- A Study For Optimum Productivity Yield in 0.16 M Mixed of Wafer Fabrication FacilityDocument4 pagesA Study For Optimum Productivity Yield in 0.16 M Mixed of Wafer Fabrication FacilitykamaveriyanNo ratings yet

- Design and Optimization of A Large Scale Biopharmaceutical Facility Using Process Simulation and Scheduling ToolsDocument9 pagesDesign and Optimization of A Large Scale Biopharmaceutical Facility Using Process Simulation and Scheduling ToolsIRFAN AHANGERNo ratings yet

- Scale Down Biopharma - EIB 2013 PDFDocument17 pagesScale Down Biopharma - EIB 2013 PDFGeetanjali HubliNo ratings yet

- Virtual Cellular Manufacturing Configuring Routing FlexibilityDocument13 pagesVirtual Cellular Manufacturing Configuring Routing FlexibilityDrMohamed MansourNo ratings yet

- Coupling Simulation and Optimization For An Integrated Production and Maintenance Planning in Manufacturing SystemsDocument5 pagesCoupling Simulation and Optimization For An Integrated Production and Maintenance Planning in Manufacturing Systemswilmervh.iNo ratings yet

- Solid Dose: Sponsored byDocument25 pagesSolid Dose: Sponsored byAbou Tebba SamNo ratings yet

- Articulo Control de La CalidadDocument12 pagesArticulo Control de La CalidadCamilo EstradaNo ratings yet

- Pharmaceutical Pilot Scale UpDocument51 pagesPharmaceutical Pilot Scale UpDerejeNo ratings yet

- Industrial Flexibility New2 2021-2Document7 pagesIndustrial Flexibility New2 2021-2chermatisarahNo ratings yet

- Inventory Levels On Throughput: The Effect of Work-In-Process and Lead TimesDocument6 pagesInventory Levels On Throughput: The Effect of Work-In-Process and Lead TimesTino VelazquezNo ratings yet

- Pilot Plant Scale UpDocument7 pagesPilot Plant Scale UpDrx Rinku KunduNo ratings yet

- Kanikuła-Koch2010 Chapter MethodologyOfDesigningDisassemDocument8 pagesKanikuła-Koch2010 Chapter MethodologyOfDesigningDisassemAziz BenNo ratings yet

- RefineryWide Sim HEMag March PDFDocument3 pagesRefineryWide Sim HEMag March PDFnaraNJORNo ratings yet

- Operations Status and Bottleneck Analysis and Improvement of A Batch Process Manufacturing Line Using Discrete Event SimulationDocument12 pagesOperations Status and Bottleneck Analysis and Improvement of A Batch Process Manufacturing Line Using Discrete Event SimulationkinfegetaNo ratings yet

- Planning The Inflow of Products For Production LevellingDocument4 pagesPlanning The Inflow of Products For Production LevellingPratik PatilNo ratings yet

- Informe Final de ArtículosDocument10 pagesInforme Final de ArtículosAstri rivera Rivera ChiroqueNo ratings yet

- Strategies For Improving Capsule Filling EfficiencyDocument4 pagesStrategies For Improving Capsule Filling EfficiencySangram KendreNo ratings yet

- Tact Time StudyDocument10 pagesTact Time StudyAtul SharmaNo ratings yet

- 3 Job Shop Scheduling PDFDocument7 pages3 Job Shop Scheduling PDF123away123No ratings yet

- 1994c Apcom Slovenie Opti MoinhoDocument10 pages1994c Apcom Slovenie Opti MoinhoDirceu NascimentoNo ratings yet

- Cellular ManufacturingDocument10 pagesCellular ManufacturingjosicremaNo ratings yet

- GCP Sect8 Packaging PerformanceDocument10 pagesGCP Sect8 Packaging Performancelevanvui161No ratings yet

- Mixing Simulationtoolsin Process DevelopmentDocument4 pagesMixing Simulationtoolsin Process Developmentkumar_chemicalNo ratings yet

- Expert Systems With Applications: Joaquín Bautista, Rocío Alfaro-Pozo, Cristina Batalla-GarcíaDocument15 pagesExpert Systems With Applications: Joaquín Bautista, Rocío Alfaro-Pozo, Cristina Batalla-GarcíadedendjatiNo ratings yet

- Real-Time Bottleneck Detection and Prediction To Prioritize Fault Repair in Interlinked Production LinesDocument6 pagesReal-Time Bottleneck Detection and Prediction To Prioritize Fault Repair in Interlinked Production LinesDevlina PriliantiNo ratings yet

- Modelling An Ice Cream Factory For Debottlenecking (Technical Report)Document6 pagesModelling An Ice Cream Factory For Debottlenecking (Technical Report)pangregisterlang99No ratings yet

- Man Simulation 1Document13 pagesMan Simulation 1kushkimNo ratings yet

- Something About Unicorns and Majestic BeastsDocument9 pagesSomething About Unicorns and Majestic BeastsDanny JaliusNo ratings yet

- Heliyon: Okpala Charles Chikwendu, Anozie Stephen Chima, Mgbemena Chika EdithDocument9 pagesHeliyon: Okpala Charles Chikwendu, Anozie Stephen Chima, Mgbemena Chika EdithDIEGO FERNANDO HUAMANI TORRESNo ratings yet

- Jaureguibecker 2015Document4 pagesJaureguibecker 2015Murat AquaNo ratings yet

- 6 MaaloufDocument9 pages6 Maalouflechiquan2497No ratings yet

- Ideal Peptide PlantDocument4 pagesIdeal Peptide PlantjoesuhreNo ratings yet

- Case Study-Automation in ManufacturingDocument14 pagesCase Study-Automation in ManufacturingRohitNo ratings yet

- Synopsis of ProjectDocument6 pagesSynopsis of Projecthirak_buronNo ratings yet

- 1 s2.0 S0278612522000838 MainDocument18 pages1 s2.0 S0278612522000838 MainMann StrongNo ratings yet

- Poves Calderno2019Document5 pagesPoves Calderno2019wachoNo ratings yet

- Fill Finish March 2011Document10 pagesFill Finish March 2011Paulo Roberto Chiarolanza VilelaNo ratings yet

- Gev - Cor - 08 - 2004Document25 pagesGev - Cor - 08 - 2004Guilherme VieiraNo ratings yet

- Pilot Plant OperationDocument21 pagesPilot Plant Operationsandeep_waliaNo ratings yet

- Journal of Manufacturing Systems: Jun-Ho Lee, Cong Zhao, Jingshan Li, Chrissoleon T. PapadopoulosDocument13 pagesJournal of Manufacturing Systems: Jun-Ho Lee, Cong Zhao, Jingshan Li, Chrissoleon T. PapadopoulosDanny AucancelaNo ratings yet

- Multi-Product Production CyclingDocument9 pagesMulti-Product Production CyclingRicardo TrevinoNo ratings yet

- Molded Pulp Lot-Sizing and SchedulingDocument32 pagesMolded Pulp Lot-Sizing and SchedulingGuillermoNo ratings yet

- The Design and Operation of A Facility For Filling Hard Shell Gelatin CapsulesDocument28 pagesThe Design and Operation of A Facility For Filling Hard Shell Gelatin Capsulespharmashri5399100% (4)

- Five Best PracticesDocument10 pagesFive Best PracticesAntHony K-ianNo ratings yet

- Moshe Article PDFDocument16 pagesMoshe Article PDFicingrockNo ratings yet

- PSEAsia2013 99 PDFDocument6 pagesPSEAsia2013 99 PDFMostofa RubalNo ratings yet

- Application of Queuing Theory in Quality Control of Multi-Stage Flexible Flow ShopDocument8 pagesApplication of Queuing Theory in Quality Control of Multi-Stage Flexible Flow ShopsyafiraNo ratings yet

- An Investigation of Lead-Time e Ects in Manufacturing/ Remanufacturing Systems Under Simple PUSH and PULL Control StrategiesDocument20 pagesAn Investigation of Lead-Time e Ects in Manufacturing/ Remanufacturing Systems Under Simple PUSH and PULL Control StrategiesBunty EvolNo ratings yet

- Dynamic Operator Training Simulators For Sulphuric Acid, Phosphoric Acid, and DAP Production UnitsDocument10 pagesDynamic Operator Training Simulators For Sulphuric Acid, Phosphoric Acid, and DAP Production UnitsAdios ANo ratings yet

- Considerations For Estimating The Costs of Pilot-Scale FacilitiesDocument9 pagesConsiderations For Estimating The Costs of Pilot-Scale FacilitiesAlex100% (1)

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Critical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.From EverandCritical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.No ratings yet

- Excipient Risk AssessmentDocument6 pagesExcipient Risk Assessmentmailtorubal2573No ratings yet

- Terminal Sterilization of Pharmaceutical ProductsDocument8 pagesTerminal Sterilization of Pharmaceutical Productsmailtorubal2573No ratings yet

- Fda On Statistical ApproachesDocument33 pagesFda On Statistical Approachesmailtorubal2573No ratings yet

- Catalent Belgium, Brussels, Belgium 8.19.22 483Document10 pagesCatalent Belgium, Brussels, Belgium 8.19.22 483mailtorubal2573No ratings yet

- Water Vapor Transmission of Materials: Standard Test Methods ForDocument12 pagesWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573No ratings yet

- PI 045 1 PICS Guideline On Excipient GMP Risk AssessmentDocument7 pagesPI 045 1 PICS Guideline On Excipient GMP Risk Assessmentmailtorubal2573No ratings yet

- Stage 6 Monograph 25 Feb 2011Document3 pagesStage 6 Monograph 25 Feb 2011mailtorubal2573No ratings yet

- Stratified Sampling of CapsuleDocument23 pagesStratified Sampling of Capsulemailtorubal2573No ratings yet

- Sample Sizes in Uniformity Measurements - The Role of USPDocument25 pagesSample Sizes in Uniformity Measurements - The Role of USPmailtorubal2573No ratings yet

- Method Development and Column Selection: How The Fluorophenyl Phase Provides The Power of Hilic and Reversed-Phase Modes in One ColumnDocument10 pagesMethod Development and Column Selection: How The Fluorophenyl Phase Provides The Power of Hilic and Reversed-Phase Modes in One Columnmailtorubal2573No ratings yet

- INN FileDocument14 pagesINN Filemailtorubal2573No ratings yet

- Uniformity of Dosage Units, Part 1: Acceptance Value: Peer-ReviewedDocument10 pagesUniformity of Dosage Units, Part 1: Acceptance Value: Peer-Reviewedmailtorubal2573No ratings yet

- Dissolution Rate Enhancement of Fenofibrate Using Liquisolid Tablet TechniqueDocument7 pagesDissolution Rate Enhancement of Fenofibrate Using Liquisolid Tablet Techniquemailtorubal2573No ratings yet

- Appendices A and B: API SpecificationDocument1 pageAppendices A and B: API Specificationmailtorubal2573No ratings yet

- Bisimilar Final Draft 23-01-2018 PDFDocument59 pagesBisimilar Final Draft 23-01-2018 PDFmailtorubal2573No ratings yet

- How To Make Hand Sanitiser GelDocument1 pageHow To Make Hand Sanitiser Gelmailtorubal2573No ratings yet

- PM2105 ComplianceDocument28 pagesPM2105 Compliancemailtorubal2573No ratings yet

- Gynomix: Soft Gelatin CapsuleDocument1 pageGynomix: Soft Gelatin Capsulemailtorubal2573No ratings yet

- Giz2012 0398en Eu Who GuidelinesDocument51 pagesGiz2012 0398en Eu Who Guidelinesmailtorubal2573No ratings yet

- ICH Q6 Decision Tree For Microbiology D PDFDocument1 pageICH Q6 Decision Tree For Microbiology D PDFmailtorubal2573No ratings yet

- EF15April29 2 MaryMurry AmwayDocument25 pagesEF15April29 2 MaryMurry Amwaymailtorubal2573No ratings yet

- Experiment 2: Water Flow Measurement WLF 922 Objectives: Process Control & Instrumentation Laboratory BKF3791Document5 pagesExperiment 2: Water Flow Measurement WLF 922 Objectives: Process Control & Instrumentation Laboratory BKF3791PMNo ratings yet

- Infusion Quiz 3Document6 pagesInfusion Quiz 3Dip Ayan MNo ratings yet

- JKLDocument9 pagesJKLanon_314301380No ratings yet

- Fuel Dispensing and Vapour Recovery ValvesDocument2 pagesFuel Dispensing and Vapour Recovery Valvesbr1404No ratings yet

- 3-1 Dynamic Light ScatteringDocument5 pages3-1 Dynamic Light ScatteringAmal PatelNo ratings yet

- Modulation Option On R90-160 Installation InstructionDocument23 pagesModulation Option On R90-160 Installation InstructionLiviu HogeaNo ratings yet

- Design of Pressure Vessel by Using ASME Sec-VIII Div-1Document6 pagesDesign of Pressure Vessel by Using ASME Sec-VIII Div-1jhaamit4No ratings yet

- Chapter-2 Energy Dissipation StructureDocument15 pagesChapter-2 Energy Dissipation StructureGoytom yigezuNo ratings yet

- General Layout of Modern Steam Power PlantDocument15 pagesGeneral Layout of Modern Steam Power PlanttabishkhanaligNo ratings yet

- Series: Innovative Split Case PumpsDocument3 pagesSeries: Innovative Split Case PumpssenaNo ratings yet

- Flashcards - Topic 2.3 Thermal Processes - CAIE Physics IGCSEDocument19 pagesFlashcards - Topic 2.3 Thermal Processes - CAIE Physics IGCSESaurabh.DeoNo ratings yet

- Fiberbond Fiberglass Piping Systems Series 20FR16-C: DescriptionDocument2 pagesFiberbond Fiberglass Piping Systems Series 20FR16-C: DescriptionANDERSON NERESNo ratings yet

- Nitric Oxide PFDDocument16 pagesNitric Oxide PFDPrashit JainNo ratings yet

- Ultrasonic Flowmeter Low Cost BrochureDocument3 pagesUltrasonic Flowmeter Low Cost BrochureCarlos Vilca JeriNo ratings yet

- Data Sheets FOR Pressure Safety ValvesDocument8 pagesData Sheets FOR Pressure Safety Valvessunildubey02No ratings yet

- Case Study On Rain Water Harvesting in NepalDocument12 pagesCase Study On Rain Water Harvesting in NepalArpeet NeupaneNo ratings yet

- New ReviewerDocument3 pagesNew ReviewerEun Ji KimNo ratings yet

- Aircraft Heat ExchangersDocument3 pagesAircraft Heat ExchangersDalibor Stevic100% (1)

- Nuclear Engineering and Design: Giorgio Besagni, Gaël R. Guédon, Fabio InzoliDocument16 pagesNuclear Engineering and Design: Giorgio Besagni, Gaël R. Guédon, Fabio InzoliRABIUL ISLAMNo ratings yet

- Final Control ElementDocument16 pagesFinal Control ElementSanchit KhannaNo ratings yet

- System Saver Series Single Cartridge Air DryersDocument52 pagesSystem Saver Series Single Cartridge Air DryersModestasNo ratings yet

- Free Water PassageDocument46 pagesFree Water PassageAbiued EjigueNo ratings yet

- Design and Analysis of A Hypersonic Inlet WithDocument8 pagesDesign and Analysis of A Hypersonic Inlet WithArun G NairNo ratings yet

- BFD, PFD and PnidDocument9 pagesBFD, PFD and PnidKuatnNo ratings yet

- ANSYS FLUENT 12.0 User's Guide - 7.2 - PorousDocument13 pagesANSYS FLUENT 12.0 User's Guide - 7.2 - Porousabhya1987No ratings yet

- Refractory NotesDocument3 pagesRefractory NotesSarbajit Sanjat KumarNo ratings yet

- Reverse Osmosis Basics - Toray Reverse Osmosis Basics - Knowledge Base - Toray Membrane - TorayDocument2 pagesReverse Osmosis Basics - Toray Reverse Osmosis Basics - Knowledge Base - Toray Membrane - ToraySantosh Kumar SinghNo ratings yet

- Hydraulic of DozerDocument83 pagesHydraulic of DozerLinzaw OoNo ratings yet

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDocument11 pagesModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)