Professional Documents

Culture Documents

SMAW Butt Joint Evaluation Rubric

Uploaded by

Hairul Effendy Ab MaulodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMAW Butt Joint Evaluation Rubric

Uploaded by

Hairul Effendy Ab MaulodCopyright:

Available Formats

NAME:

MATRIC NO:

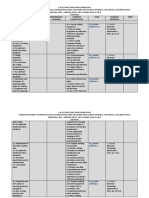

SMAW BUTT JOINT Evaluation Rubric

Needs

Unacceptable Acceptable Very Good

Criteria Improvement TOTAL

1 pts 2 pts 3 pts 4 pts

No welding Two or more of the Majority of the All of the

helmet worn. following safety safety practices following safety

No safety glasses practices violated: are followed. practices were

worn. No welding gloves followed:

Student will not worn. Proper welding

1. Safety be allowed to Incorrect shoes gloves worn.

Practices continue the worn. Proper shoes

assignment. Incorrect clothing worn.

worn. Proper clothing

Hot metal carried worn.

in gloved hand(s). Pliers, etc. used to

carry hot metal.

Bead Bead narrower or The majority of Bead width equals

unsuccessfully wider than width of the bead is equal the width of two

2. Bead Width made. two electrodes to the width of electrodes used.

used. two electrodes

used.

Bead Bead does not form Proper bead Bead has an

unsuccessfully the acceptable shape is not acceptable shape

made. shape - has one of consistent for the for the entire

following entire length of weld.

problems. the bead.

3. Bead Shape

Too flat

Too high and does

not blend into the

base metal at the

weld toes.

Bead Bead has both of Bead has one of Bead has neither

unsuccessfully the following the following of the following

made. problems: problems: problems:

4. Weld Start &

Bead is rough, Bead is rough, Bead is rough,

Finish

narrow and high. narrow and high. narrow and high.

Weld crater is not Weld crater is Weld crater is not

filled in. not filled in. filled in.

Bead More than two of 1 of the No weld defects

unsuccessfully the following following defects are present.

made. defects are present: are present:

Excess spatter is Excess spatter is

present. present.

5. Weld Defects

Bead is not Bead is not

uniform. uniform.

Weld ripples are Weld ripples are

long and pointed. long and

pointed.

TOTAL

/ 20

PROJECT = 15 %

TOTAL x 15%

20

You might also like

- Weld Joints RubricsDocument2 pagesWeld Joints RubricsMaljon Daren Dalangin100% (1)

- MODULE 8 SMAW 11 12 Q2 X 1Document29 pagesMODULE 8 SMAW 11 12 Q2 X 1Marc Cadalin100% (1)

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLDenial BasanovicNo ratings yet

- BS EN 288 - 5 - 1995 Welding ProcedureDocument12 pagesBS EN 288 - 5 - 1995 Welding ProcedureKwong chi hoNo ratings yet

- MIG Welding ProcessDocument12 pagesMIG Welding ProcessHimanshu RaoNo ratings yet

- December 5, 2022 SmawDocument6 pagesDecember 5, 2022 SmawTeacher Ronel SDO NavotasNo ratings yet

- Shielded Metal Arc Welding: Grade 10Document23 pagesShielded Metal Arc Welding: Grade 10Jessel Mejia OnzaNo ratings yet

- Illustrated Parts Data For RADIO TradeDocument37 pagesIllustrated Parts Data For RADIO TradeMD AL Amin RajNo ratings yet

- PDF Q1 Mod 4 SMAW12 EnhancedDocument32 pagesPDF Q1 Mod 4 SMAW12 Enhancedrey ebasanNo ratings yet

- TLE - SM 11 - w2Document4 pagesTLE - SM 11 - w2CrisTopher L CablaidaNo ratings yet

- GMAW Lesson Plan Sets Up Welding MachineDocument7 pagesGMAW Lesson Plan Sets Up Welding MachineJoy BuycoNo ratings yet

- TVL - SM 11 - w8Document4 pagesTVL - SM 11 - w8CrisTopher L CablaidaNo ratings yet

- Welding RubricDocument2 pagesWelding Rubricapi-525855204No ratings yet

- Grade 11 Students Learn Welding SymbolsDocument7 pagesGrade 11 Students Learn Welding SymbolsJhon Vernie Reponte GambitoNo ratings yet

- WPS & PQR - 2021Document82 pagesWPS & PQR - 2021Subramanian RNo ratings yet

- GRADE 12 SMAW MODULE 4A 1st QuarterDocument20 pagesGRADE 12 SMAW MODULE 4A 1st QuarterClare GarcesNo ratings yet

- Cable Configuration: Instructor, Local Tip-Manila Coe Cisco Networking Academy ProgramDocument23 pagesCable Configuration: Instructor, Local Tip-Manila Coe Cisco Networking Academy ProgramPolicarpio D. Tena IINo ratings yet

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocument2 pagesShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa AquitanNo ratings yet

- Teacher-Made Learner's Home Task: Essentials of WeldingDocument5 pagesTeacher-Made Learner's Home Task: Essentials of WeldingSarah Jean Formentera - Paring100% (1)

- TVL-SMAW 12 - Week 6 - Lesson 1 - Welding Procedure SpecificationDocument10 pagesTVL-SMAW 12 - Week 6 - Lesson 1 - Welding Procedure SpecificationNelPalalonNo ratings yet

- TVL Smaw11 Q1 M 10Document10 pagesTVL Smaw11 Q1 M 10Earl Christian BonaobraNo ratings yet

- TVL - SM 11 - w5Document4 pagesTVL - SM 11 - w5CrisTopher L CablaidaNo ratings yet

- SMAW Welding TechniquesDocument6 pagesSMAW Welding TechniquesTeacher Ronel SDO NavotasNo ratings yet

- SMAW (3) EditedDocument5 pagesSMAW (3) EditedPrince Neil SeraphimNo ratings yet

- Weld DefectsDocument5 pagesWeld DefectsMark Joseph PagutaNo ratings yet

- DLL PpeDocument5 pagesDLL PpeChinelle Joseph Sollano TinoyNo ratings yet

- 222Document24 pages222Houman Hatamian100% (1)

- 3RD Quarter Exam Smaw 12 NoteDocument2 pages3RD Quarter Exam Smaw 12 NoteBryan Borje100% (2)

- Final Exam Tle 8 (Exploratory-Smaw) : Table of SpecificationsDocument2 pagesFinal Exam Tle 8 (Exploratory-Smaw) : Table of SpecificationsKrizzie Jade CailingNo ratings yet

- Smaw NC I Cot 1 2023Document22 pagesSmaw NC I Cot 1 2023Words Wero Niar MascarinasNo ratings yet

- LESSON PLAN GRADE 11 SMAWEssentials in Cleaning Root Pass After WeldingDocument2 pagesLESSON PLAN GRADE 11 SMAWEssentials in Cleaning Root Pass After Weldingjoebert agraviadorNo ratings yet

- Welding Test Questions and AnswersDocument9 pagesWelding Test Questions and Answerslouie gerasmiaNo ratings yet

- Butt weld imperfections and defects guideDocument47 pagesButt weld imperfections and defects guidearash59_4uNo ratings yet

- TLE TVL SHIELDED METAL ARC WELDING NCI ACTIVITY SHEET NO. 1 2nd QuarterDocument5 pagesTLE TVL SHIELDED METAL ARC WELDING NCI ACTIVITY SHEET NO. 1 2nd QuarterMaricar CarandangNo ratings yet

- OSD Welding ProcedureDocument6 pagesOSD Welding ProcedureVijayakumar Chandran100% (1)

- Eurocodes steel building design workshopDocument31 pagesEurocodes steel building design workshopglmuralidharNo ratings yet

- Mastery Test Lesson 2 Metal Works 2Document6 pagesMastery Test Lesson 2 Metal Works 2Jessie MirandaNo ratings yet

- DLP - Final-Demo - Weld DefectsDocument11 pagesDLP - Final-Demo - Weld DefectsTrecita BacoNo ratings yet

- Activity On Measuring (Pull Push Rule)Document2 pagesActivity On Measuring (Pull Push Rule)Robert Pugayan0% (1)

- TLE - Shielded Metal Arc Welding 9 ThirdDocument4 pagesTLE - Shielded Metal Arc Welding 9 ThirdFlorinda Gagasa100% (1)

- TVL-SMAW 12 - Week 6 - Lesson 2 - Welding Techniques and ProcedureDocument10 pagesTVL-SMAW 12 - Week 6 - Lesson 2 - Welding Techniques and ProcedureNelPalalonNo ratings yet

- FINAL SMAW-12-Quarter-3-module 4 PDFDocument20 pagesFINAL SMAW-12-Quarter-3-module 4 PDFRandy Sacatani100% (1)

- Shielded Metal Arc Welding Summative TestDocument4 pagesShielded Metal Arc Welding Summative TestFelix MilanNo ratings yet

- LESSONPLAN-for-SMAW-12-WEEK-1 RAMON OPSIMARDocument3 pagesLESSONPLAN-for-SMAW-12-WEEK-1 RAMON OPSIMARelizer encarnacion100% (1)

- Grade 10 DLP (6th)Document2 pagesGrade 10 DLP (6th)Rico CalamboNo ratings yet

- DLP August 22, 2022 SmawDocument3 pagesDLP August 22, 2022 SmawTeacher Ronel SDO Navotas100% (1)

- 5 Welding EssentialsDocument4 pages5 Welding EssentialsdrexNo ratings yet

- Semi - Detailed Lesson Plan in Prepare Hand ToolsDocument6 pagesSemi - Detailed Lesson Plan in Prepare Hand ToolsRuel John Barrientos ClamianoNo ratings yet

- Identify Welding DefectsDocument2 pagesIdentify Welding Defectsronald curayagNo ratings yet

- Grades 11 Lesson Plan I. Objectives: Basic JointsDocument3 pagesGrades 11 Lesson Plan I. Objectives: Basic JointsCrisTopher L CablaidaNo ratings yet

- Q1, Module 1, Lesson4Document11 pagesQ1, Module 1, Lesson4Jerome A. Gomez100% (1)

- Angle Grinder Assembly GuideDocument21 pagesAngle Grinder Assembly GuideMichael Angelo LumanogNo ratings yet

- RUBRIC Shielded-Metal-Arc-WeldingDocument6 pagesRUBRIC Shielded-Metal-Arc-Weldingfrederic asejoNo ratings yet

- Summative Test Shielded Metal Arc Welding NC IiDocument1 pageSummative Test Shielded Metal Arc Welding NC IiSalapar-Tulas RS100% (1)

- SHS - SLK - Inudstrial Arts Smaw Marking or Locating Weld DefectsDocument20 pagesSHS - SLK - Inudstrial Arts Smaw Marking or Locating Weld Defectsiammhon100% (1)

- SAN ROQUE NATIONAL HIGH SCHOOL Shielded Metal Arc Welding AssessmentDocument7 pagesSAN ROQUE NATIONAL HIGH SCHOOL Shielded Metal Arc Welding AssessmentTeacher Ronel SDO NavotasNo ratings yet

- Content Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting EquipmentDocument9 pagesContent Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting Equipmentlip100% (1)

- Cot Smaw March 7 2021 Isagani AbrilDocument4 pagesCot Smaw March 7 2021 Isagani Abrilisagani abrilNo ratings yet

- Lesson Plan in SmawDocument3 pagesLesson Plan in SmawTrecita BacoNo ratings yet

- Weld Carbon Steel Plates in Flat Position GuideDocument7 pagesWeld Carbon Steel Plates in Flat Position Guidetibo bursioNo ratings yet

- SMAW Prayer and Welding ToolsDocument39 pagesSMAW Prayer and Welding ToolsTalakag TnhsNo ratings yet

- TLE - IA - Shielded Metal Arc Welding (SMAW) Grades 7-10 04.06.2014Document18 pagesTLE - IA - Shielded Metal Arc Welding (SMAW) Grades 7-10 04.06.2014dyllan100% (1)

- Smaw 9 Q3 W1Document6 pagesSmaw 9 Q3 W1Words Wero MascarinasNo ratings yet

- TLE - Shielded Metal Arc Welding 10 ThirdDocument4 pagesTLE - Shielded Metal Arc Welding 10 ThirdFlorinda GagasaNo ratings yet

- Sir Silva Cot (Final)Document2 pagesSir Silva Cot (Final)Jay Mark BibosoNo ratings yet

- A Detailed Lesson Plan in Shielded Metal Arc Welding I. Objective: Learners Will Be Able To Identify Different Weld Symbols II. Subject MatterDocument6 pagesA Detailed Lesson Plan in Shielded Metal Arc Welding I. Objective: Learners Will Be Able To Identify Different Weld Symbols II. Subject MatterTrecita BacoNo ratings yet

- Welding Safety and ProceduresDocument6 pagesWelding Safety and ProceduresKim PinedaNo ratings yet

- Grade 12 Automotive Servicing ModuleDocument39 pagesGrade 12 Automotive Servicing ModuleHERNAN JAY BUYOK100% (1)

- Module 1 SMAW 11 12 Q2 1Document13 pagesModule 1 SMAW 11 12 Q2 1Marc CadalinNo ratings yet

- Mce03 Midterm ExaminationDocument2 pagesMce03 Midterm ExaminationShiela May SantamenaNo ratings yet

- Week 6 - Mechanical Testing - Part 2-UlearnDocument26 pagesWeek 6 - Mechanical Testing - Part 2-UlearnHairul Effendy Ab MaulodNo ratings yet

- 4.LA 1501-3 PT RecordDocument1 page4.LA 1501-3 PT RecordjeyasekarNo ratings yet

- Lab Test: Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument6 pagesLab Test: Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodNo ratings yet

- M A T E Ri AL S Fo R Tan K: Hakko Eightron E-TB Pressure Hose, High Quality Pressure HosesDocument2 pagesM A T E Ri AL S Fo R Tan K: Hakko Eightron E-TB Pressure Hose, High Quality Pressure HosesHairul Effendy Ab MaulodNo ratings yet

- Week 6 - Mechanical Testing - Part 2-UlearnDocument26 pagesWeek 6 - Mechanical Testing - Part 2-UlearnHairul Effendy Ab MaulodNo ratings yet

- Mechanical Testing and Fracture AnalysisDocument52 pagesMechanical Testing and Fracture AnalysisHairul Effendy Ab MaulodNo ratings yet

- Manufacturing Lab Report RubricDocument2 pagesManufacturing Lab Report RubricHairul Effendy Ab MaulodNo ratings yet

- Labtest Betp1323 - Rolling - Answer SchemeDocument2 pagesLabtest Betp1323 - Rolling - Answer SchemeHairul Effendy Ab MaulodNo ratings yet

- Week 6 - Mechanical Testing - Part 2-UlearnDocument26 pagesWeek 6 - Mechanical Testing - Part 2-UlearnHairul Effendy Ab MaulodNo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument2 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodNo ratings yet

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDocument5 pagesFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodNo ratings yet

- BMMP 1303 Lab Test Welding 1819Document4 pagesBMMP 1303 Lab Test Welding 1819Hairul Effendy Ab MaulodNo ratings yet

- BEKS Subjects SynopsisDocument3 pagesBEKS Subjects SynopsisHairul Effendy Ab MaulodNo ratings yet

- Rubrik For BETP1323 LAB ACTIVITYDocument2 pagesRubrik For BETP1323 LAB ACTIVITYHairul Effendy Ab MaulodNo ratings yet

- Material Selection Homework AnswersDocument2 pagesMaterial Selection Homework AnswersHairul Effendy Ab MaulodNo ratings yet

- TUTORIAL Material Testing 5Document1 pageTUTORIAL Material Testing 5Hairul Effendy Ab MaulodNo ratings yet

- Lab Test - 1 - Colour Contrast Penetrant TestDocument2 pagesLab Test - 1 - Colour Contrast Penetrant TestHairul Effendy Ab MaulodNo ratings yet

- Material Competition Slide-CommentedDocument7 pagesMaterial Competition Slide-CommentedHairul Effendy Ab MaulodNo ratings yet

- The Structure and Properties of Polymers: Also Known AsDocument15 pagesThe Structure and Properties of Polymers: Also Known AsDiki yunikaNo ratings yet

- Tutorial 1Document3 pagesTutorial 1Raiham EffendyNo ratings yet

- Tutorial 1Document3 pagesTutorial 1Raiham EffendyNo ratings yet

- Rubric Lab 2 (LATHE Report)Document1 pageRubric Lab 2 (LATHE Report)Hairul Effendy Ab MaulodNo ratings yet

- Welding Procedure Data Sheet for Steel Groups 1-3Document1 pageWelding Procedure Data Sheet for Steel Groups 1-3suronocaturatmojoNo ratings yet

- ZEBRA VT SPARE PARTS CATALOG TABLE OF CONTENTSDocument18 pagesZEBRA VT SPARE PARTS CATALOG TABLE OF CONTENTSJOSEALBERICHNo ratings yet

- 95-01 - Panel Installation, Instrument: Illustrated Parts DataDocument15 pages95-01 - Panel Installation, Instrument: Illustrated Parts DataDiana Carolina Beltran PeñaNo ratings yet

- Short Form CatalogueDocument41 pagesShort Form CatalogueCharlie KebasoNo ratings yet

- BS en 287-6-2010Document26 pagesBS en 287-6-2010CocaCodaNo ratings yet

- 00109-Fwds-0237 - Rev A - Furnace Start Up System F-32, F-33, F-34, F-49, F-50, F-51 & SEE DRAWING NO 00109-1E0237 - REV ADocument2 pages00109-Fwds-0237 - Rev A - Furnace Start Up System F-32, F-33, F-34, F-49, F-50, F-51 & SEE DRAWING NO 00109-1E0237 - REV AAlanka PrasadNo ratings yet

- Size - Bolt Depot - US Recommended Bolt Torque TableDocument2 pagesSize - Bolt Depot - US Recommended Bolt Torque Tableirfan KahramanNo ratings yet

- Approved List of Manufacturers: CategoryDocument3 pagesApproved List of Manufacturers: Categorytomj9104No ratings yet

- Methods of Pipe JoiningDocument4 pagesMethods of Pipe JoiningVidhi KoshtiNo ratings yet

- Augmented ArcDocument4 pagesAugmented Arcvictor lima saldañaNo ratings yet

- ARTICLE I (Weld. Gen. Requirement)Document9 pagesARTICLE I (Weld. Gen. Requirement)Yadi KusmayadiNo ratings yet

- Tuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & MetallurgyDocument5 pagesTuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & Metallurgyzulfadli izaraeeNo ratings yet

- XLR XX SeriesDocument1 pageXLR XX SeriesJuan FerchoNo ratings yet

- Advanced Welding TechniquesDocument5 pagesAdvanced Welding Techniquesharsha vardhanNo ratings yet

- Ind Enclosures PDFDocument17 pagesInd Enclosures PDFAbdul Azis SaifuddinNo ratings yet

- Pan FeederDocument1 pagePan FeederAngelloNo ratings yet

- P B S S L: Illow Lock ET Crew OCKDocument2 pagesP B S S L: Illow Lock ET Crew OCKDxFxNo ratings yet

- Question Bank For Je-Ii/BrDocument11 pagesQuestion Bank For Je-Ii/BrBryan GrayNo ratings yet

- Welder Diameter Limitation ASME SEC IXDocument1 pageWelder Diameter Limitation ASME SEC IXkumarNo ratings yet

- Async Activity - Business Analytics - Delos Reyes, Valerey A. BSAIS4Document5 pagesAsync Activity - Business Analytics - Delos Reyes, Valerey A. BSAIS4Valerey Delos ReyesNo ratings yet