0% found this document useful (0 votes)

710 views4 pagesK-Gauge Hla 600: Independent High Level and Overfill Alarm System

The K-Gauge HLA 600 system is an independent high level and overfill alarm system that monitors cargo tank levels. It uses proven capacitive level sensor technology and meets international regulations for preventing tank overfill. The system provides dedicated level sensors for each tank, along with control panels that display sensor status and trigger audible and visual alarms to stop cargo loading if the tank reaches high or overfill levels. It is a modular system that can be configured for different vessel types and number of tanks.

Uploaded by

Pavel ViktorCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

710 views4 pagesK-Gauge Hla 600: Independent High Level and Overfill Alarm System

The K-Gauge HLA 600 system is an independent high level and overfill alarm system that monitors cargo tank levels. It uses proven capacitive level sensor technology and meets international regulations for preventing tank overfill. The system provides dedicated level sensors for each tank, along with control panels that display sensor status and trigger audible and visual alarms to stop cargo loading if the tank reaches high or overfill levels. It is a modular system that can be configured for different vessel types and number of tanks.

Uploaded by

Pavel ViktorCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Overview

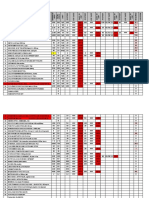

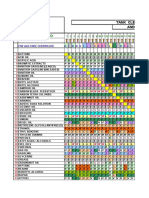

- System Features

- System Configuration

- Rules and Regulations

- Technical Specifications

- Features