Professional Documents

Culture Documents

Glass transition of poly (oxymethylene) -分子运动受限分析1985

Glass transition of poly (oxymethylene) -分子运动受限分析1985

Uploaded by

dong maiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass transition of poly (oxymethylene) -分子运动受限分析1985

Glass transition of poly (oxymethylene) -分子运动受限分析1985

Uploaded by

dong maiCopyright:

Available Formats

Glass Transition of Poly(oxymethy1ene)

Hidematsu Suzuki, Janusz Grebowicz and Bernhard Wunderlich

Department of Chemistry, Rensselaer Polytechnic Institute, Troy, New York 12181, USA

(Manuscript received 22 June I984: accepted 6 Augut 1984)

Heat capacity data of semicrystalline poly(oxymethy1ene) samples, Delrin and Celcon, are analysed in Keywords

order to discuss the glass transition behaviour of this polymer. There are two types of non-crystalline glass transition,

poly(oxymetheylene), the mobile and rigid amorphous parts. The glass transition of the former occurs in a poly(oxymethylene),

rather wider range of temperature: it starts at 180 K and could end at 265 K. The latter, under restraint due heat capacity,

to the crystallites, remains frozen up to the melting temperature. rigid amorphous,

mobile amorphous

1 INTRODUCTION fluoroethylene)." Similarly, the heat capacity data of

poly(oxymethy1ene) will be analysed below.

The glass transition temperature Tg of poly(oxymethy1ene) is

a longstanding problem.' The Tgs reported in the

literature2-' range from 188 to 270 K, just bridging the y and

2 HEAT CAPACITY DATA

p relaxation regions dynamic mechanically and dielectrically

observed. Hojfors et al. state that the p relaxation, at c. Heat capacity data, published by 1980, for linear macro-

270K, involving motion of long segments, can be considered molecues were critically assessed in nine serial articles." For

to be the glass transition.6 The editors of the Polymer (100%) crystalline poly(oxymethylene), the best, selected

Handbook assigned 191K to Tg of this polymer2 and data for a temperature range 0-390K are known as the

Wrasidlo adopted 200K in his review." Nielsen" gave two recommended data." On the other hand, data for (com-

temperatures of 190 and 223 K with the latter in parentheses pletely) amorphous poly(oxymethy1ene) for a similar range

in his table of Tg. Van Krevelen" also cited two ex- of temperature have not been reported so far. Here, the

perimental Tgs like 188/243K, comparing them with his Tg results obtained recently on the molten and supercooled

of 223 K calculated from the additive contributions of given poly(oxymethylene) and poly(ethy1ene oxide) will be used

structure groups. for discussion.'' They can be expressed as

The main problem of the discussion above seems to be that C:(POM)=46.51+0.0372 T (43GS40 K)

the authors tried to find a specific temperature for Tg. The q(PEO)=67.85+0.0668 T (33W30 K)

assignments were done to highest possible precision, but

Here, C, is given in the units of joule per mole of the

often without full explanation of the reasoning for a given repeating unit per kelvin, the superscript a refers to the

choice. Such efforts are not necessarily adequate, since the amorphous state, POM and PEO are the obvious abbrevia-

glass transition occurs over a (time-dependent) temperature

tions of these polymers, and T is the temperature in K. Data

range, and Tg the temperature of half-transition is only one

for the amorphous poly(ethy1ene) are taken from the second

of several characteristics. One must also state the tempera-

article of ref. 17: C;(PE)=17.919+0.4325 T. Based on those

ture interval and the overall change in the quantity used for C, data of the crystalline and amorphous materials, data of

measurement, C, in our case. Such more detailed descrip-

semicrystalline, commercial samples, Delrin and Celcon

tion is particularly necessary for semicrystalline polymers

measured by Dainton et aL2' and ourselves21 will be analy-

which have often a broad range glass transition. sed.

Recently Boyer' analysed the transition temperature data of

some debatable polymers including poly(oxymethy1ene). His

assignments for this polymer are, in the notation, 225K to 3 DISCUSSION

Tg(L) and 313-323K to Tg(U). Here, Tg(L) and Tg(U) are

Figure 1 shows plots of Cp for the crystalline and semicrys-

the lower and upper glass transition temperatures. It is

talline poly(oxymethy1ene) against the temperature. The

assumed that Tg(L) arises from purely amorphous material,

former is the recommended data taken from ref. 18 and the

while Tg(U) arises from amorphous material which is under

latter is the data of Dainton et al. for Delrin whose

restraint due to the crystallites. Accordingly, Tg(L) corres-

crystallinity is assumed to be 67%. As has been well

ponds to the normal Tg of amorphous polymers and Tg(U)

documented, below the glass transition temperature, the

often increases with an increase in crystallinity. Since his

amorphous and crystalline polymers have almost the same

assignments are different from those mentioned above to a

heat capacity. This is confirmed in this figure again. At

large extent and a two-step transition is assumed, it is

180 K, the two curves are seen to start departing. This is the

necessary to reanalyse the heat capacity data available in the

beginning of the glass transition. This transition looks

literature, which were not taken into account in Boyer's

complete at 210K. At the mid-point, 195K, the C, jump of

analysis.

2.4 J mo1-l K-l can be seen from the figure. For a number of

As has been demonstrated frequently since 1962,13the heat polymeric and non-polymeric organic materials, the C jump

capacity at constant pressure C, is a useful quantity which at Tgis known to be 11.3 Jmol-' K-' per mobile unit.2PSince

enables us to discuss quantitatively the glass transition there are two mobile units of methylene and oxygen in this

behaviour. Discussions have already been published for polymer, the expected jump for this particular sample is

p ~ l y - ( e t h y l e n e ) , ' ~ ~poly(propylene)15

'~ and poly(tetra- 2x11.3xthe amorphous fraction, i.e. 7.5 Jmol-'K-'. Accor-

BRITISH POLYMER JOURNAL,VOL. 17, NO. 1 1985 1

I I

35

-

Y

-

I

{ 30

-cp

3

25

)O 300 400

Temperature ( K )

160 200 240 I

Temperature (Kl Fig. 3 Heat capacity of the amorphous poly(oxymethy1ene) as pre-

dicted by the addition scheme of liquid heat capacity. POM3: poly(oxy-

Fig. 1 Plots of C,, for a semicrystalline (wc=67%) sample, Delrin,'" and, trimethylene); PEO: poly(ethyiene oxide); PE: poly(cthy1cnc); whose

crystalline poly(oxymcthylcne)" against temperature. Broken line: for a repeating unit is taken as methylene.

hypothetical sample having the amorphous fraction of 33%.

dingly, the heat capacity curve for Delrin should be like the ity nature of the liquid heat capacity,18,l9 the heat capacity

broken line drawn in the figure. However, the actual C, jump of poly(oxymethy1ene) may be calculated by the simple

is clearly too small for a full glass transition. This means that subtraction of the contribution of the methylene group, as is

only one-third of the amorphous materials in Delrin gets full shown in Fig. 3. Again, the end of the glass transition

mobility at 195 K, while two-thirds remain frozen. temperature seems to be around 26SK. Hojfors et aL6

looked upon this temperature as Tg, although they under-

In Fig. 2 the heat capacity of liquid poly(oxymethy1ene) is stood that the y1 relaxation at c. 205K involved motion of

depicted. When the line is extrapolated to lower tempera- short segments in disordered regions.

ture, as is shown in a broken line, the proper heat capacity

deviation from that of the crystalline poly(oxymethy1ene) Next, the heat capacity at 26SK of Delrin and Celcon with

can be seen at 26SK. This could be the end of the glass the different thermal treatments will be considered. In Fig.

transition. Since that is a rather long extrapolation, two 4,those data are plotted against the crystallinity wc.Usually,

other estimates are presented in the succeeding figure in the linear crystallinity extrapolation allows us to estimate the

support of the long straight-line extrapolation.

Poly(ethy1ene oxide) and poly(oxytrimethy1ene) are polyox-

60

ides which have lower melting temperatures. This character I I I

eliminates a longer extrapolation. According to the additiv-

Mobile amorphous

70 0 Celcon

50 - Y

- -

I

.

0 Delrin

0

Y

E

-

I

-.

0 7

60 E

?

-

3 -

-

Y

f-- /-

3

-

I

0 40

5 50

-

3

2

Rigid amorphous \

40

3c

0 25 50 75

3c w c (%I

Fig. 4 Crystallinity extrapolation of heat capacity for semicrystalline

Temperature t K I

samples with various thermal treatments.2' Open circle: Celcon; closed

Fig. 2 Heat capacity of the amorphous poly(oxymethylene), C,; as circle: Delrin, closed circle with pip; from ref. 20. Datum at w"=lOO%,

derived in ref. 19, and of the crystalline one, Ci. Broken line: linear from ref. 18; upper datum at wc=O%, extrapolated from of

extrapolation of C.: amorphous polyfoxymethylene).

z BRITISH POLYMER JOURNAL,VOL. 17, NO. 1 1985

I I I 1 4 CONCLUSIONS

I Liq.POM . 1 The glass transition of

methylene) starts at 180K.

semicrystalline poly(oxy-

There are two types of non-crystalline poly(oxy-

methylene), which are distinguishable between 180 K

and the melting temperature. They may be called the

mobile and rigid amorphous parts.

The mobile amorphous part of this polymer shows the

glass transition in a rather wider range of temperature.

A fractional, but noticeable glass transition occurs at

195K, which is in accord with the result of

d i l a t ~ m e t r y The

. ~ ~ full transition might be complete at

265 K, which is close to the p-transition temperature

dynamic mechanically observed.

The rigid amorphous part remains unchanged up to the

melting temperature. The two-step nature of the glass

transition, as observed on poly(ethylene), is not obvious

for poly(oxymethy1ene).

5 ACKNOWLEDGEMENTS

Temperoture ( K 1

This work has been supported by the National Science

Fig. 5 Comparison of experimental and calculated heat capacities. Foundation, Polymers Program, Grant No. DMR 8317097.

Thick line: data of Delrin by Dainton er al." Dotted line: C,, guessed for

0% crystallin sample. Dash-dotted line: C , calculated for samples with References

w'=67% (33% mobile amorphous) and 80% (20% mobile and 13% rigid

amorphous). 1 See, for example, Boyer, R.F., in Encyclopedia of Polym. Sci. and

Technol., Ed. Bikales, N.M., Suppl. Vol. 2, p. 746. New York:

Wiley and Sons.

2 Lee, W.A. & Rutherford, R.A., in Polymer Handbook, Eds

Brandrup, J. & Immergut, E.H., 2nd edn, 1975,111-139. New York:

heat capacity of the amorphous p ~ l y m e r . ' ~However,

,'~ the Wiley-Interscience.

value extrapolated here is much lower than that extrapolated 3 Kumler, P.L. & Boyer, R.F., Macromolecues, 1976, 6 , 903.

from the molten heat capacity. 4 Privalko, V.P., Polym. Scz. USSR, 1976, 18, 1392.

5 Enns, J.B. & Simha, R., J . Macromol. Sci., Phys., 1977, B13, 25.

This means that the crystallinity is not a structure parameter 6 Hojfors, R.J., Baer, E. & Geil, P.H., J . Macromol. Sci. Phys., 1977,

adequate enough to describe the variation of the heat 813, 323.

capacity of poly(oxymethy1ene). Another structure para- 7 Brew, B., Clements, J., Davies, G.R., Jakeways, R. & Ward, J.M.,

meter is necessary, which may be interpreted as the 'rigid J . Polym. Sci., Polym. Phys. E d . , 1979, 17, 351. 8.

amorphous' part of the amorphous fraction. The other part 8 Blumberg, A.V. & Niemira, E.R., J . Polym. Sci., Polym. Phys. Ed.,

of the amorphous fraction can be renamed as the 'mobile 1979, 17, 1891.

9 Boyer, R.F., Br. Polym. J . , 1982, 14, 163.

amorphous' part. The former, under heavy restraint due to

10 Wrasidlo, W., Adv. Polym. Sci., 1974, 13, 1.

the crystallites, is supposed to have the same heat capacity 11 Nielsen, L.E., Mechanical Properties of Polymers and Composites,

as the crystalline fraction, while the latter is nothing but the 1974, New York: Marcel Dekker.

normal amorphous material. It can be said from Fig. 4 that 12 Van Krevelen, D.W., with the collaboration of Hoftyzer, P.J.,

at 265K, 43% of the amorphous fraction of these samples Properties of Polymers, 2nd edn, 1976. Amsterdam: Elsevier.

corresponds to the mobile amorphous part, That is, roughly 13 Wunderlich, B., J . Chem. Phys., 1962, 37, 1203. See also, J . Polym.

speaking, the normal amorphous fraction of these samples is Sci., 1963, C1, 41.

only 20%. 14 Gaur, U. & Wunderlich, B., Macromolecules, 1980, 13, 445.

15 Grebowicz, J., Lau, S.-F. & Wunderlich, B., J . Polym. Sci. 1984, C71,

In Fig. 5 the calculated and measured heat capacity curves 19.

are compared with each other. The calculated curve for the 16 Lau, S.-F., Suzuki, H. & Wunderlich, B., J . Polym. Sct., Polym.

sample having the original crystallinity of 67% does not fit to Phys. Ed., 1984, 22, 379.

the experimental curve at all. However, when the mobile 17 Wunderlich, B. etal., J . Phys. Chem. Ref. Data, 1981,10,89,119,1001,

amorphous part is set to be 20%, a reasonable fit can be 1051; 1982,11,313,1065; 1983, 12,29,65,91.

obtained up to the beginning of melting. This means that the 18 The third article of ref. 17.

19 Suzuki, H. & Wunderlich, B., Makromol. Chem., in press.

rigid amorphous part does not get any mobility up to the

20 Dainton, F.S., Evans, D.M., Hoare, F.E. & Melia, T.P., Polymer,

temperature of melting of crystallites. Similar results are 1962, 3, 263.

obtained for samples having different crystallinities. This 21 Suzuki, H., Grebowicz, J. & Wunderlich, B., J . Polym. SCL, Polym.

view is supported by the fact that no obvious transition can Phys. Ed., in press.

be seen on the experiment Cp- T curve between 250 K and 22 Wunderlich, B., J . Phys. Chem., 1960, 64, 1052.

the premelting temperature. 23 Stehling, F.S. & Mandelkern, L., J . Polym. Sci., 1969, B7, 255.

BRITISH POLYMER JOURNAL,VOL. 17, NO. 1 1985 3

You might also like

- China - Green Tire Technology Specification-绿色轮胎技术规范Document15 pagesChina - Green Tire Technology Specification-绿色轮胎技术规范dong maiNo ratings yet

- Glasübergang Und Schmelzen PEEKDocument9 pagesGlasübergang Und Schmelzen PEEK高亚男No ratings yet

- Morgan p915 01Document1 pageMorgan p915 01Hendri HolsenNo ratings yet

- Chen2009Heat Transfer Characteristics of Oscillating Flow Regenerators in Cryogenic Temperature Range Below 20 KDocument7 pagesChen2009Heat Transfer Characteristics of Oscillating Flow Regenerators in Cryogenic Temperature Range Below 20 KJacyNo ratings yet

- CAPACCIODocument6 pagesCAPACCIOapi-3733260No ratings yet

- CHOYDocument21 pagesCHOYapi-3733260No ratings yet

- Thermogravimetric Analysis (TGA) 熱重量分析法Document33 pagesThermogravimetric Analysis (TGA) 熱重量分析法雨No ratings yet

- Combustion and Flame: Jyuung-Shauu Chern, Allan N. HayhurstDocument9 pagesCombustion and Flame: Jyuung-Shauu Chern, Allan N. HayhurstDan SweeneyNo ratings yet

- 18-Thermal Conductivities of Silicon and Germanium in Solid and Liquid States Measured by Non-Stationary Hot Wire Method With Silica Coated ProbeDocument11 pages18-Thermal Conductivities of Silicon and Germanium in Solid and Liquid States Measured by Non-Stationary Hot Wire Method With Silica Coated Probedemon.mn1992No ratings yet

- Transferencia de Calor y Masa Entre El Baño Líquido y La Lecho de Criolita SólidaDocument14 pagesTransferencia de Calor y Masa Entre El Baño Líquido y La Lecho de Criolita SólidaOctaviano MichinelNo ratings yet

- 0022 3093 (71) 90043 3Document18 pages0022 3093 (71) 90043 3Leonardo VitoriaNo ratings yet

- Effects of Lu and Ni Substitution On Thermoelectric Properties of Ca Co ODocument6 pagesEffects of Lu and Ni Substitution On Thermoelectric Properties of Ca Co OAhmed Khalid HussainNo ratings yet

- Thermodynamic Properties of Minerals (Short Article) - A. Navrotsky (1995) WWDocument11 pagesThermodynamic Properties of Minerals (Short Article) - A. Navrotsky (1995) WWmonicaingenieraNo ratings yet

- 10 1016@j Polymertesting 2013 05 007Document22 pages10 1016@j Polymertesting 2013 05 007Ricardo VelozNo ratings yet

- Kapitza Resistance and Thermal Conductivity of Kapton in Superfluid HeliumDocument15 pagesKapitza Resistance and Thermal Conductivity of Kapton in Superfluid HeliumPaulo CesarNo ratings yet

- Thermoelectric Properties of P-Type SrTiO3Document12 pagesThermoelectric Properties of P-Type SrTiO3Chandrani NathNo ratings yet

- Lau Et Al-1984-Journal of Polymer Science Polymer Physics Edition PDFDocument27 pagesLau Et Al-1984-Journal of Polymer Science Polymer Physics Edition PDFwmcf231091No ratings yet

- Calculation of Thermophysical Properties of Carbon and Low Alloyed Steels For Modeling of Solidification ProcessesDocument8 pagesCalculation of Thermophysical Properties of Carbon and Low Alloyed Steels For Modeling of Solidification ProcessesFernanda ClainNo ratings yet

- 31 Komatsu, T PDFDocument6 pages31 Komatsu, T PDFhimamahanNo ratings yet

- Partial Molar Volumes of Nio and Coo Liquids: Implications For The Pressure Dependence of Metal-Silicate PartitioningDocument13 pagesPartial Molar Volumes of Nio and Coo Liquids: Implications For The Pressure Dependence of Metal-Silicate PartitioningirrekirremannNo ratings yet

- Crystallization Kinetics of Poly (Aryl Ether Ether Ketone) : Time-Temperature-Transformation AND Continuous-Cooling-Transformation DiagramsDocument11 pagesCrystallization Kinetics of Poly (Aryl Ether Ether Ketone) : Time-Temperature-Transformation AND Continuous-Cooling-Transformation DiagramsNajib RahmanNo ratings yet

- SuperfluidityDocument14 pagesSuperfluidityPaulo CesarNo ratings yet

- Thermal Relaxation and Heat Transport in The Spin Ice Material Dy Ti ODocument25 pagesThermal Relaxation and Heat Transport in The Spin Ice Material Dy Ti OS GrixNo ratings yet

- Plastic and Glassy Crystpllline States of Methane: A Monte Carlo S Lula On Study SDocument4 pagesPlastic and Glassy Crystpllline States of Methane: A Monte Carlo S Lula On Study SYashonathSubramanianNo ratings yet

- Potentiostatic Testing of Oxygen Reduction On Polymer Carbon Electrodes PDFDocument13 pagesPotentiostatic Testing of Oxygen Reduction On Polymer Carbon Electrodes PDFIT InventoryNo ratings yet

- Che 135 Process Engineering LaboratoryDocument9 pagesChe 135 Process Engineering LaboratoryMichael Jemziel GulayNo ratings yet

- Thermoelectric Power of Cadmium Oxide: Home Search Collections Journals About Contact Us My IopscienceDocument10 pagesThermoelectric Power of Cadmium Oxide: Home Search Collections Journals About Contact Us My IopscienceVigneshwaran MuruganNo ratings yet

- Poli MeroDocument9 pagesPoli MeroJ EnriQue AlcNo ratings yet

- 4.thermal Conductivity Measurement of GFRP PDFDocument8 pages4.thermal Conductivity Measurement of GFRP PDFMICHEL RAJNo ratings yet

- Selfordering Process of Phenanthrene Polyesters Observed by The Simultaneous DSCXRD Method2002journal of Thermal Analysis and CalorimetryDocument9 pagesSelfordering Process of Phenanthrene Polyesters Observed by The Simultaneous DSCXRD Method2002journal of Thermal Analysis and CalorimetryPaulo Venicio Alves VieiraNo ratings yet

- Govpub C13Document28 pagesGovpub C13Pavel KosevNo ratings yet

- Measurement of Thermal Conductivity of The Supports of CUORE CryostatDocument3 pagesMeasurement of Thermal Conductivity of The Supports of CUORE CryostatvladimirNo ratings yet

- CHEE 3369 Sample Exam 2 ProblemsDocument2 pagesCHEE 3369 Sample Exam 2 ProblemsChris HieuNo ratings yet

- Numerical Simulation With Comsol Multiphysics of CDocument8 pagesNumerical Simulation With Comsol Multiphysics of CJonathan ArboledaNo ratings yet

- The Crystallinity of Peek CompositesDocument3 pagesThe Crystallinity of Peek CompositesArquimedes FilhoNo ratings yet

- Annealing Effects of Polymers and Their Underlying Molecular MechanismsDocument10 pagesAnnealing Effects of Polymers and Their Underlying Molecular MechanismsManonmani DNo ratings yet

- ULTRA MEGA COMPI ADONIS SHORT With Rowen PDFDocument80 pagesULTRA MEGA COMPI ADONIS SHORT With Rowen PDFLaurenze SariNo ratings yet

- Jam 2Document5 pagesJam 2save isbhuNo ratings yet

- Sample Lab ReportDocument13 pagesSample Lab ReportJellyShapes0% (1)

- Partition of Plastic Work Into Heat and Stored PDFDocument11 pagesPartition of Plastic Work Into Heat and Stored PDFAsad MaqsoodNo ratings yet

- An Experimental Study of The Selective Oxidation of Ethene in A Wall Cooled Tubular Packed Bed ReactorDocument6 pagesAn Experimental Study of The Selective Oxidation of Ethene in A Wall Cooled Tubular Packed Bed ReactorLim Xiu XianNo ratings yet

- And The Glass Transition: Supercooled LiquidsDocument9 pagesAnd The Glass Transition: Supercooled LiquidskevincanNo ratings yet

- Heat and Mass Transfer by S K Mondal T&QDocument216 pagesHeat and Mass Transfer by S K Mondal T&Qajaykrishna_9983% (6)

- UntitledDocument11 pagesUntitledeNo ratings yet

- Leach 1993Document8 pagesLeach 1993Franco LeónNo ratings yet

- Effect of Annealing On Thermal Properties and Crystalline Structure of Polyamides. Nylon 12 (Polylaurolactam)Document7 pagesEffect of Annealing On Thermal Properties and Crystalline Structure of Polyamides. Nylon 12 (Polylaurolactam)CFNo ratings yet

- Heat TransferDocument17 pagesHeat TransferRakesh Singh kushwahaNo ratings yet

- Thermal Analysis of Heat Pipe Shell-Fin Structures With Selective Coatings Under RadiationDocument7 pagesThermal Analysis of Heat Pipe Shell-Fin Structures With Selective Coatings Under RadiationLuis ReyesNo ratings yet

- Heat ExchangeDocument16 pagesHeat ExchangeGiova RossiNo ratings yet

- Cinetica de CristalizacionDocument18 pagesCinetica de Cristalizacionbeatriz salazarNo ratings yet

- Phase Behaviors of Room Temperature IoniDocument5 pagesPhase Behaviors of Room Temperature Ionihusainramadhan784No ratings yet

- TECreview ImprovecoefficientDocument17 pagesTECreview ImprovecoefficienthalimberdiNo ratings yet

- Olszak Humienik2000Document7 pagesOlszak Humienik2000sbaa kenzaNo ratings yet

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Tables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiFrom EverandTables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Liquid Helium Technology: Proceedings of the International Institute of Refrigeration Commission 1, Boulder (U.S.A.) 1966From EverandLiquid Helium Technology: Proceedings of the International Institute of Refrigeration Commission 1, Boulder (U.S.A.) 1966No ratings yet

- Filler-Elastomer Interactions. Part VII. Study On Bound Rubber-1993Document15 pagesFiller-Elastomer Interactions. Part VII. Study On Bound Rubber-1993dong maiNo ratings yet

- Functional thiol ionic liquids as novel interfacial modifiers in SBRHNTs composites-交联密度 PDFDocument8 pagesFunctional thiol ionic liquids as novel interfacial modifiers in SBRHNTs composites-交联密度 PDFdong maiNo ratings yet

- Factors Influencing The Flocculation Process in Silica-Reinforced Natural Rubber CompoundsDocument16 pagesFactors Influencing The Flocculation Process in Silica-Reinforced Natural Rubber Compoundsdong maiNo ratings yet

- Key Coal TrendsDocument22 pagesKey Coal Trendsفردوس سليمانNo ratings yet

- International Material Grade Comparison TableDocument9 pagesInternational Material Grade Comparison Tablenyamuk06100% (4)

- R3 PDFDocument13 pagesR3 PDFaliNo ratings yet

- RefractoriesDocument16 pagesRefractoriespandianvijaybharathi100% (1)

- Casting Alloys - PPT - 2nd BDS 1Document92 pagesCasting Alloys - PPT - 2nd BDS 1Syeda Umaima FathimaNo ratings yet

- Laeticia Rodrigues - P21008 - MetullurgyDocument2 pagesLaeticia Rodrigues - P21008 - MetullurgyLAETICIA RODRIGUESNo ratings yet

- Lindgren, 1907Document23 pagesLindgren, 1907CesarVargasSalasNo ratings yet

- OUZENDocument80 pagesOUZENPLATIN DESIGNNo ratings yet

- L3 - Connectors-in-Fpd 1Document47 pagesL3 - Connectors-in-Fpd 1ALAA IBRAHIM IBRAHIMNo ratings yet

- Material Grade Comparison TableDocument8 pagesMaterial Grade Comparison Tableatee_hua66No ratings yet

- Coal SlagDocument4 pagesCoal SlagSivaratnam NavatharanNo ratings yet

- Minerals Hardness Worksheet: Reading The ScaleDocument2 pagesMinerals Hardness Worksheet: Reading The ScaleTrollzxNo ratings yet

- ABRASIVESDocument5 pagesABRASIVES147No ratings yet

- Lecture 3 Rock-Forming MineralsDocument25 pagesLecture 3 Rock-Forming MineralsMiguel FeijaoNo ratings yet

- Injection Molding Resin Shrink and Vents PDFDocument1 pageInjection Molding Resin Shrink and Vents PDFEco TefuNo ratings yet

- Https WWW - Gemselect.com PDF-files Gemstone-Hardness-Chart GemselectDocument9 pagesHttps WWW - Gemselect.com PDF-files Gemstone-Hardness-Chart GemselectAlvaro GuarinNo ratings yet

- MINERALSDocument15 pagesMINERALSBea Dacillo BautistaNo ratings yet

- Welding of Cast IronDocument10 pagesWelding of Cast IronKrishnendu RouthNo ratings yet

- Coal Specification From IndonesiaDocument5 pagesCoal Specification From IndonesiaAris CahyonoNo ratings yet

- How Do Atoms Arrange Themselves To Form Solids?: Simple CubicDocument29 pagesHow Do Atoms Arrange Themselves To Form Solids?: Simple CubicAbduljabbar Tudu IbrahimNo ratings yet

- Core (STEM) - EarthScience-SLMG11Q1W1-Identify Common Rock-Forming Minerals Using Their Physcial and Chemical PropertiesDocument18 pagesCore (STEM) - EarthScience-SLMG11Q1W1-Identify Common Rock-Forming Minerals Using Their Physcial and Chemical PropertiesRM L. JamandronNo ratings yet

- Solidification ProcessingDocument14 pagesSolidification ProcessingTrupti Ranjan DasNo ratings yet

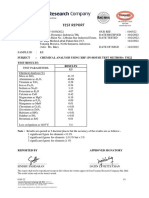

- Subject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: ResultsDocument2 pagesSubject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: Resultstri yuda khalidNo ratings yet

- Effect of Grain Size On Mechanical Properties of MetalsDocument7 pagesEffect of Grain Size On Mechanical Properties of MetalsMuhannad MohammedNo ratings yet

- Potential Applications of Metallic GlassesDocument8 pagesPotential Applications of Metallic GlassesKibria ShabbirNo ratings yet

- Introduction To Polymer CrystallizationDocument12 pagesIntroduction To Polymer Crystallizationalina.tlekkabylova270202No ratings yet

- Chicinas AbsDocument5 pagesChicinas AbsSari Ramadhani MeutuahNo ratings yet

- Data Sheet AL-BRONZEDocument1 pageData Sheet AL-BRONZEAris WicaksonoNo ratings yet

- Solidification Structure of Aluminum AlloysDocument10 pagesSolidification Structure of Aluminum Alloys이연지No ratings yet

- Non Metallic MaterialsDocument16 pagesNon Metallic Materialsthisisjinesh100% (1)