Professional Documents

Culture Documents

Tadit: Why Condensate Recovery System (CRS) ?

Uploaded by

Himanshu PanchalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tadit: Why Condensate Recovery System (CRS) ?

Uploaded by

Himanshu PanchalCopyright:

Available Formats

Improving your business THERMAX ATMOSPHERIC DE-AERATOR with IMMERSION TUBE

is our business

Facilitates mixing of condensate, flash steam and cold make-up water

Thermax offers products, WHY CONDENSATE RECOVERY SYSTEM (CRS) ? Liberates dissolved gases and oxygen

systems and solutions in energy

and environment engineering to

SS De-aerator head with SS immersion tube

industrial and commercial Steam is a very effective heat transfer medium, due to easy transportability and high

establishments around the world. heat content, it is used in process industry for direct and indirect heat transfer.

Its business expertise covers

heating, cooling, waste heat Atmospheric De-aerator Head is designed to remove dissolved gases and oxygen

recovery, captive power, water from the feed water by proper mixing of condensate, flash steam and cold make up.

treatment & recycling, air pollution When steam is used for indirect heat transfers in heat exchanger, reactors and other Solubility of oxygen and other dissolved gases decreases with rise in temperature

control & waste management and indirect heating equipment it gives off its latent heat(useful heat) to process and and they are released from solution. These gases are then released through the air

converts itself into liquid form known as condensate. This high pressure condensate vent fitted on the de aerator head.

performance chemicals.

when released to atmospheric pressure can no longer hold high heat content. The

excess heat is released as Flash steam.

Thermax brings to customers The mixing action takes place by suitably locating the nozzles and providing spray

extensive experience in industrial screens and baffles. A Thermax flash condensing de-aerator head consists of three

applications and expertise through parts

technology partnerships and High pressure condensate is at almost the same pressure as steam and contains

Atmospheric De-aerator Head, which is bolted to the top of the tank and is

strategic alliances. around 15 to 20% heat of fuel. This heat if recovered shall reduce fuel consumption to

supplied with connections for cold make up, condensate return, flash steam

the extent of 20%.

and recirculation.

Operating from its Head Quarters An immersion tube which distributes the mixed fluids into the tank

in Pune (Western India), Thermax

A guide nozzle for mounting the immersion tube.

has built an international sales &

service network spread over South

East Asia, Middle East Africa,

Russia, UK and the US. It has a

In addition to the fuel savings, boiler quality water is also recovered, and is used in

boiler. This has effect of reduced cost of water and water treatment chemicals.

Further good quality boiler feed water reduces the blowdown losses resulting in fuel

savings. To summarize, the efficient condensate recovery system will ensure

Recirculation system (optional)

MATERIAL OF CONSTRUCTION

TADIT

full-fledged ISO 9001, 2000 and

ISO 14000 accredited + High temperature feed water Atmospheric De-aerator Head SS 304

manufacturing setup.

Immersion Tube SS 304

+ Good quality boiler feed water

Cooling & Heating Division + Lower blowdown losses

DESIGN SPECIFICATIONS

Offers a wide range of steam Design Pressure 5 kg/cm2 (g)

boilers, thermal oil heaters and hot Design Temperature 1580 C

water generators. It has expertise + Lower water treatment losses

in a wide range of fuels - oil, gas,

solid and agro - waste/biomass SAVE FUEL, SAVE ENERGY, SAVE MONEY INSTALLATION

fuels. Supporting a broad array of The de-aerator head is mounted on the feed water tank on a flanged nozzle. Sealing gaskets are used above and below the

industries to generate, transfer and immersion tube flange.

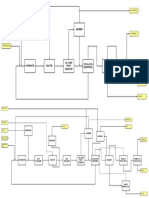

Thermax's CRS is an integrated system comprising of a Flash Steam Generator,

conserve heat for a host of

Steam operated Condensate Transfer Pump and a Deareator Unit with immersion

applications, the divisions products

tube. Pipe work should be preferably of the same size as that of nozzles.

are exported to South East Asia,

Middle East, Africa, Europe, CIS

and SAARC. The flanged nozzle supplied lose to be welded on the top of the FW Tank at a suitable location(reffer GA drawing).

This system recovers efficiently flash steam, hot condensate and feed them to the

feed water tank through a well designed Deareator unit with immersion tube. RECOMMENDATIONS

Cold makeup line - Fit a DCV before connecting to TADIT.

Condensate Return line - Fit a DCV before connecting to TADIT.

Thermax's CRS is a state of the art system using latest engineering practices,

designed to give you savings in fuel cost year after year after year. Vacuum Breaker - Install in vertical position.

Air Vent - Install in vertical position.

SELECTION TABLE

COMMITTED TO DELIVER INNOVATIVE ENERGY SOLUTIONS

Condensate w/o Flash Condensate with flash TADIT

Steam Kg/hr Steam Kg/hr Model

5000 150

10000 200

Refer Thermax for Details

20000 250 Sustainable Solutions in

30000 300 Energy & Environment

COOLING & HEATING DIVISION

Services SBU - FEMS

END CONNECTIONS D - 13, MIDC Industrial Area, R. D. Aga Road,

Chinchwad, Pune 411 019. INDIA

TADIT & nozzles N1, N2, N3 are Tel.: +91-20-2747 5941

Fax: +91-20-2747 7080

provided with flanged end E-mail: info.c&hservices@thermaxindia.com

connections conforming to ANSI-

B16.5 Class # 150, N4, N5 screwed

BSP for air vent and recirculation.

AHMEDABAD 380 006

Tel.: (079) 2657 5408 / 5341 / 7073

Fax: (079) 2657 7270

Cooling & Heating Division

E-mail: mambiar@thermaxindia.com

A

BANGALORE 560 020

B Tel.: (080) 2346 7761 - 64

D Fax: (080) 2346 7760

SELECTION E-mail: adminblr@thermaxindia.com

IMMERSION TUBE LENGTH CHENNAI 600 018

Tel.: (044) 2435 3831 - 34

Immersion tube length is selected L Fax: (044) 2435 3841

based on feed water tank depth. E-mail: chennaidivsupp@thermaxindia.com

Consideration should be given to the HYDERABAD 500 482

nozzle height on which TADIT is to be Tel.: (040) 2339 6820, 2331 0254

fitted. Fax: (040) 2331 2335

C E-mail: hyd_sec@thermaxindia.com

MUMBAI 400 016

Use the following criteria for selecting Tel.: (022) 2204 5391, 2204 5324

Fax: (022) 2204 0859

immersion tube length.

E-mail: psecreta@thermaxindia.com

L = D+ H- 300 mm (for tank depth > 1000 mm) NEW DELHI 110 057

Tel.: (011) 2614 5319, 2614 5701

*Contact HO for tank depths < 1000mm Fax: (011) 2614 5311, 2614 8679

E-mail: psupport@thermaxindia.com

Where L = Immersion tube length, in mm

D = Tank depth, in mm KOLKATA 700 016

Tel.: (033) 2282 6711 - 13

H = Nozzle height, in mm (standard available 150 mm) Fax: (033) 2282 6769

E-mail: mbiswas@thermaxindia.com

Immersion Tube Length (L) have been standardized as 900, 1050, 1200, 1350, 1500,

1650, 1800, 1950, 2100, 2250, 2400 mm VADODRA 390 005

Tel.: (0265) 231 4802, 234 5442

Fax: (0265) 231 0051

E-mail: pbaroda@thermaxindia.com

MODELS & DIMENSIONS

International offices at

TADIT TADIT TADIT TADIT Indonesia, Russia, Kazakstan, Saudi Arabia,

150 200 250 300 Malaysia, Bangladesh, Sri Lanka, Hong Kong, China

Thailand, UAE, Kenya, Nigeria, Brazil, UK, USA

A 440 490 500 500

B 370 420 475 525 Thermax Business Portfolio

C 185 210 235 265

AQUA++

Boilers & Heaters

D 175 200 210 225

N1 65 100 150 150 Absorption Cooling

N2 50 80 80 100

N3 25 40 50 65 Air Pollution Control

N4 15 15 15 15

Captive Power

N5

N6

15

150

25

200

25

250

25

300

THERMAX CONDENSATE RECOVERY SYSTEM

Chemicals AN INTEGRATED SYSTEM COMPRISING OF A FLASH STEAM GENERATOR, STEAM OPERATED CONDENSATE TRANSFER PUMP AND A DEAREATOR UNIT WITH IMMERSION TUBE.

May 2007

Special inspection and certification available on request

In view of our constant endavor to improve the quality of our products, we reserve the right to alter or change specifications without prior notice. Water & Waste Solutions

You might also like

- TactsDocument4 pagesTactsYashuNo ratings yet

- Steam26b Condensing PDFDocument3 pagesSteam26b Condensing PDFAnonymous Q9i062VNo ratings yet

- Genie: Hot Water Driven Vapor Absorption MachineDocument39 pagesGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyNo ratings yet

- Thermax Double Effect Steam Fired Vam BrochureDocument24 pagesThermax Double Effect Steam Fired Vam BrochureMinhazur Rahman Sakib100% (1)

- CyrogenicDocument4 pagesCyrogenicBayu SaputraNo ratings yet

- Thermax Double Effect Direct Fired BrochureDocument24 pagesThermax Double Effect Direct Fired BrochurePushpak RadadiyaNo ratings yet

- Evaporation For Instant Coffee Plants Tcm11 54061Document1 pageEvaporation For Instant Coffee Plants Tcm11 54061Hung DoNo ratings yet

- Howden_PreEngHeaters_BrochureDocument12 pagesHowden_PreEngHeaters_BrochurecreativesafeNo ratings yet

- Boiler Performance ImproveDocument5 pagesBoiler Performance Improvehwang2No ratings yet

- Improving Air Preheater PerformanceDocument11 pagesImproving Air Preheater PerformancejaveddvcNo ratings yet

- 0 Air-Cooled Condenser Brochure (Feb 2020)Document4 pages0 Air-Cooled Condenser Brochure (Feb 2020)David PierreNo ratings yet

- Biomass BoilersDocument20 pagesBiomass BoilersCarlos Rojas SilvaNo ratings yet

- Steam Tip Sheet #18Document2 pagesSteam Tip Sheet #18Muhammad NaeemNo ratings yet

- Heat Recovery From Smelt Dissolving Tank Vent 2009-01-26Document3 pagesHeat Recovery From Smelt Dissolving Tank Vent 2009-01-26hanzancnc7No ratings yet

- Returning Condensate to the BoilerDocument3 pagesReturning Condensate to the BoilerAulia RahmadsyahNo ratings yet

- Thermax Vapor Absorption Chillers From 207 TR to 1680 TRDocument12 pagesThermax Vapor Absorption Chillers From 207 TR to 1680 TRKetan ChandravadiyaNo ratings yet

- Internal Epoxy Coating in Surface CondenserDocument14 pagesInternal Epoxy Coating in Surface CondenserChaudhari SanketNo ratings yet

- Pressurized Deaerator Spec PDFDocument9 pagesPressurized Deaerator Spec PDFkosmc123No ratings yet

- Performance Increase of Steam Turbine Condensers by CFD AnalysisDocument10 pagesPerformance Increase of Steam Turbine Condensers by CFD AnalysisAbdullah RobbaniNo ratings yet

- Cooling & Heating: Revomax SeriesDocument4 pagesCooling & Heating: Revomax SeriesBoonaa KiyyaNo ratings yet

- Biomass Fired BoilersDocument12 pagesBiomass Fired Boilersnathabbu100% (2)

- C150 PCS 08 04 en Us - 2015 PDFDocument4 pagesC150 PCS 08 04 en Us - 2015 PDFRania ToumiNo ratings yet

- Thermal Fluid Heating SolutionsDocument8 pagesThermal Fluid Heating SolutionsJosé Pedro MagalhãesNo ratings yet

- A Critical Review On Heat Exchangers Used in Oil Refinery: March 2015Document6 pagesA Critical Review On Heat Exchangers Used in Oil Refinery: March 2015Maamer ZaydNo ratings yet

- Steam Desuperheating: Reliability - High End Technology - SimplicityDocument12 pagesSteam Desuperheating: Reliability - High End Technology - SimplicitynidhinNo ratings yet

- 41-183.0 Steam GenerationDocument8 pages41-183.0 Steam GenerationGeovannyNo ratings yet

- d3 PDFDocument12 pagesd3 PDFHoang TungNo ratings yet

- AGUAdens English VersionDocument12 pagesAGUAdens English VersionJosé MacedoNo ratings yet

- Thermax spentwash co-generation solutions for distilleriesDocument6 pagesThermax spentwash co-generation solutions for distilleriesPrashanth VaranasiNo ratings yet

- 54goodsAPEC eDocument37 pages54goodsAPEC eRico MaligayaNo ratings yet

- BVG - UVG Series: Compressors & Gas Treatment Systems For Wet Gases ApplicationsDocument8 pagesBVG - UVG Series: Compressors & Gas Treatment Systems For Wet Gases ApplicationsSteven TurnerNo ratings yet

- ACCS-B, ACCR-B, HEB-D, EB-D, EBR-D, VEB-D SeriesDocument20 pagesACCS-B, ACCR-B, HEB-D, EB-D, EBR-D, VEB-D SeriesDB ChiaNo ratings yet

- SteamInjectionHeating SteamSparge SpargingEfficiencyvsSteamInjectionHeating TB 6 20101210Document4 pagesSteamInjectionHeating SteamSparge SpargingEfficiencyvsSteamInjectionHeating TB 6 20101210Herlina ChandraNo ratings yet

- Waste Heat Recovery Potential in Textile IndustriesDocument5 pagesWaste Heat Recovery Potential in Textile IndustriesSherin MithranNo ratings yet

- Hurst STACKmaster-EconomizerDocument2 pagesHurst STACKmaster-Economizerz018125No ratings yet

- Vallourec Tube-Alloy Vacuum Insulated Tubing - 3Document1 pageVallourec Tube-Alloy Vacuum Insulated Tubing - 3Raakze MoviNo ratings yet

- PDF Usdsd FSD DSD Esd FSD Series 12 2022-46-37070Document20 pagesPDF Usdsd FSD DSD Esd FSD Series 12 2022-46-37070Firman AldianNo ratings yet

- SWC Endothermic GeneratorDocument4 pagesSWC Endothermic GeneratorNenad PetrovicNo ratings yet

- Swimming Pool Air Management Danx BrochureDocument8 pagesSwimming Pool Air Management Danx BrochureFotocopiadora IugrNo ratings yet

- Solid Waste ManagementDocument2 pagesSolid Waste ManagementYe PhoneNo ratings yet

- Water Cooled PACAug 2018Document17 pagesWater Cooled PACAug 2018Iwan RusmanaNo ratings yet

- Spirax Trap Review GST - 33 PDFDocument22 pagesSpirax Trap Review GST - 33 PDFFrank UrsNo ratings yet

- Superheaters and ReheaterDocument16 pagesSuperheaters and ReheaterBudi NortonNo ratings yet

- Condensate Recovery Pump: Recovering Maximum Possible EnergyDocument4 pagesCondensate Recovery Pump: Recovering Maximum Possible EnergySupport, SP Tech SolutionsNo ratings yet

- GasConditioningTowers-RedecamGroup 1664087203547Document3 pagesGasConditioningTowers-RedecamGroup 1664087203547YhaneNo ratings yet

- SERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsDocument8 pagesSERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsEngr Mohammad FarhanNo ratings yet

- Energy Recovery Leaflet FR - LRDocument8 pagesEnergy Recovery Leaflet FR - LRZidan SongmoNo ratings yet

- Spirax FREME Flash Recovery Energy Management Equipment PDFDocument6 pagesSpirax FREME Flash Recovery Energy Management Equipment PDFGuillermoNo ratings yet

- Uhde reformer design advantages for versatile hydrogen productionDocument5 pagesUhde reformer design advantages for versatile hydrogen productionOctavio FrancoNo ratings yet

- 41-266.0 Icebreaker - CondensateRecoveryDocument1 page41-266.0 Icebreaker - CondensateRecoverybkarakoseNo ratings yet

- SB PS-Turbo Ver.2.1 enDocument5 pagesSB PS-Turbo Ver.2.1 engreyhound726415No ratings yet

- Grundfosliterature 6153788Document6 pagesGrundfosliterature 6153788Nuñez HarryNo ratings yet

- Steam: Dry and Wet SteamDocument6 pagesSteam: Dry and Wet SteamSyed Inamullah ShahNo ratings yet

- Air Preheater Air Preheater Steam Air Heater Shell and TubeDocument4 pagesAir Preheater Air Preheater Steam Air Heater Shell and TubeJayant Deshmukh100% (1)

- Charge air cooler for diesel and gas engines GEA_KelvionDocument5 pagesCharge air cooler for diesel and gas engines GEA_Kelvionantoine.mussard54No ratings yet

- Renotech Condenser Pre-Cooling Boosts PerformanceDocument7 pagesRenotech Condenser Pre-Cooling Boosts PerformanceRenotech salesNo ratings yet

- Brochure Thermal Fluid July 2021 Issue1Document5 pagesBrochure Thermal Fluid July 2021 Issue1Kazem QarebeiglooNo ratings yet

- R. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZDocument7 pagesR. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZLuqmanNo ratings yet

- Hydrogen Generation For Modern Refineries 2009Document7 pagesHydrogen Generation For Modern Refineries 2009Raudah RahimiNo ratings yet

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- Chiller Plant Design GuideDocument24 pagesChiller Plant Design GuideNeal JohnsonNo ratings yet

- Joule ThomsonDocument10 pagesJoule Thomsonanoopkmr18120% (1)

- Chiller Energy Use Estimating ToolDocument5 pagesChiller Energy Use Estimating Toolnshsharma7475No ratings yet

- Techniques for Measuring Mixing in Mechanically Agitated VesselsDocument69 pagesTechniques for Measuring Mixing in Mechanically Agitated VesselsMarek PawelNo ratings yet

- Chiller ThermoDocument2 pagesChiller ThermoHimanshu PanchalNo ratings yet

- Comparing Boiler Efficiency Calculation MethodsDocument21 pagesComparing Boiler Efficiency Calculation Methodsวรศิษฐ์ อ๋องNo ratings yet

- Prtial VolumeDocument11 pagesPrtial Volumemakcodetech100% (2)

- FUG shortcut distillation of hydrocarbon mixtureDocument87 pagesFUG shortcut distillation of hydrocarbon mixtureAmey BodkeNo ratings yet

- Energy Conservation TipsDocument16 pagesEnergy Conservation TipsHimanshu PanchalNo ratings yet

- 9b2b PDFDocument24 pages9b2b PDFHimanshu PanchalNo ratings yet

- Pump sizing calculationDocument6 pagesPump sizing calculationAtty Atty100% (1)

- Estimation of Utility CostsDocument4 pagesEstimation of Utility CostsEdgar HuancaNo ratings yet

- WoodTech Touchwood InteriorDocument2 pagesWoodTech Touchwood InteriorHimanshu PanchalNo ratings yet

- Packing Pressure Drop Prediction at Low Operating Pressure Is There Anything NewDocument11 pagesPacking Pressure Drop Prediction at Low Operating Pressure Is There Anything NewAmir AbbaszadehNo ratings yet

- Project Understanding & Queries - 191222 PDFDocument1 pageProject Understanding & Queries - 191222 PDFHimanshu PanchalNo ratings yet

- Book2.1 - BkUp200127Document48 pagesBook2.1 - BkUp200127Himanshu PanchalNo ratings yet

- American Production of Synthetic Camphor From Turpentine: I. (Iubelmannand H. W.KlxisyDocument6 pagesAmerican Production of Synthetic Camphor From Turpentine: I. (Iubelmannand H. W.KlxisyHimanshu PanchalNo ratings yet

- Schematics-Vinyl AcetateDocument2 pagesSchematics-Vinyl AcetateHimanshu PanchalNo ratings yet

- Thermal Decomposition of Cumene Hydroper PDFDocument6 pagesThermal Decomposition of Cumene Hydroper PDFHimanshu PanchalNo ratings yet

- Assessment of The Physicochemical Proper PDFDocument4 pagesAssessment of The Physicochemical Proper PDFHimanshu PanchalNo ratings yet

- MC09 Technology Valuation ProsDocument46 pagesMC09 Technology Valuation ProsHimanshu PanchalNo ratings yet

- Unsteady State Heat XferDocument5 pagesUnsteady State Heat XferHimanshu PanchalNo ratings yet

- 13 Venting Requirements PDFDocument4 pages13 Venting Requirements PDFAngel LugoNo ratings yet

- The Gujarat Factories Rules 1963 PDFDocument365 pagesThe Gujarat Factories Rules 1963 PDFAlpesh ValaNo ratings yet

- Unsteady State Heat XferDocument5 pagesUnsteady State Heat XferHimanshu PanchalNo ratings yet

- Agitated VesselsDocument6 pagesAgitated VesselsHimanshu PanchalNo ratings yet

- 3 The Manufactories Storage and Import of Hazardous Chemical Rules 1989Document24 pages3 The Manufactories Storage and Import of Hazardous Chemical Rules 1989Himanshu PanchalNo ratings yet

- Best Practice Guidelines For Safe Un Loading of Road Freight VehiclesDocument66 pagesBest Practice Guidelines For Safe Un Loading of Road Freight VehiclesJUAN ANTONIO MOLINANo ratings yet

- 2007 Acrylonitrile BrochureDocument36 pages2007 Acrylonitrile BrochureMarcomexicoNo ratings yet

- Clean Air ActDocument48 pagesClean Air ActEphraim Gieronymus Esteban80% (10)

- What Is Climate Change and Why Is It HappeningDocument9 pagesWhat Is Climate Change and Why Is It HappeningleiNo ratings yet

- Marpol FinishDocument202 pagesMarpol FinishBim AranasNo ratings yet

- Science Investigatory Project For Grade 8Document11 pagesScience Investigatory Project For Grade 8Anne Regner100% (1)

- Envt Ext SankarDocument16 pagesEnvt Ext SankarAnand PandeyNo ratings yet

- CH 12 OTHER SERVICES IN BUILDINGSDocument10 pagesCH 12 OTHER SERVICES IN BUILDINGSPratik GhimireNo ratings yet

- Acceptance of Works Inspection ChecklistDocument6 pagesAcceptance of Works Inspection ChecklistJulius Mak'Oderoh100% (1)

- The P-B Polywell A Different Kind of Nuclear Energy (William W Flint)Document299 pagesThe P-B Polywell A Different Kind of Nuclear Energy (William W Flint)THE NIKOLA TESLA INSTITUTE100% (2)

- OSU Environmental Engineering CoursesDocument2 pagesOSU Environmental Engineering CoursesJulia AokiNo ratings yet

- Fluid Waste Disposal Environmental Science Engineering and TechnologyDocument384 pagesFluid Waste Disposal Environmental Science Engineering and TechnologyMiroslav Aleksic100% (2)

- Marikina City Waste Management OfficeDocument4 pagesMarikina City Waste Management OfficeNixon Dellosa83% (6)

- Michael Braungart - CRADLE TO CRADLE Design - An Innovative ToolDocument78 pagesMichael Braungart - CRADLE TO CRADLE Design - An Innovative ToolFabio De LeonardisNo ratings yet

- 3150 FM Bwew0083Document2 pages3150 FM Bwew0083Bishop Ojonuguwa AmehNo ratings yet

- Waste Mitigation StrategiesDocument8 pagesWaste Mitigation StrategiesAishwarya SangalNo ratings yet

- Nitric Acid ProductionDocument46 pagesNitric Acid Productionbotolwa80% (5)

- Livestock's Long Shadow: Environmental Issues and OptionsDocument416 pagesLivestock's Long Shadow: Environmental Issues and OptionsOrlando FigueiredoNo ratings yet

- CQM+ Heat BalanceDocument19 pagesCQM+ Heat BalancesoumitrabanNo ratings yet

- Safety Data Sheet: Ultrasil® VN 3 (Insilco)Document6 pagesSafety Data Sheet: Ultrasil® VN 3 (Insilco)Bharat ChatrathNo ratings yet

- Probset3. MaterialbalancesDocument8 pagesProbset3. MaterialbalancesAbi MukundNo ratings yet

- LDC 1972Document2 pagesLDC 1972Akash RadhakrishnanNo ratings yet

- Inorganic Products from Smog and Its Effects on HealthDocument3 pagesInorganic Products from Smog and Its Effects on HealthMichael MatnaoNo ratings yet

- Vinyl ChlorideDocument11 pagesVinyl ChloridesylviealNo ratings yet

- 1 s2.0 S0149197022000981 MainDocument10 pages1 s2.0 S0149197022000981 Mainabdul daudNo ratings yet

- Gold Production and Its Environmental ImpactDocument37 pagesGold Production and Its Environmental ImpactN. SasidharNo ratings yet

- STS Waste ManagementDocument2 pagesSTS Waste ManagementMariel SalangsangNo ratings yet

- Human Activities Notes For Form TwoDocument3 pagesHuman Activities Notes For Form TwoedwinmasaiNo ratings yet

- Rotary Kiln Handbook NEW PDFDocument56 pagesRotary Kiln Handbook NEW PDFMuhammad Tufail75% (4)

- Paper Bags Cannot Save Our EnvironmentDocument4 pagesPaper Bags Cannot Save Our EnvironmentTorisha BaldomeroNo ratings yet

- Elcosmo PDFDocument19 pagesElcosmo PDFLewKarKeongNo ratings yet

- Going The Extra MileDocument2 pagesGoing The Extra MileLes PickfordNo ratings yet