Professional Documents

Culture Documents

Blabo2 EN PDF

Blabo2 EN PDF

Uploaded by

aquialguienOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blabo2 EN PDF

Blabo2 EN PDF

Uploaded by

aquialguienCopyright:

Available Formats

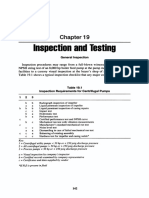

Advanced

SHORT CLEANING TIME Tank Cleaning Technology

NO PERSONNEL EXPOSURE

MINIMIZATION OF SLUDGE using the Blabo® System

REDUCED OVERALL CLEANING COST (Crude Oil Washing)

S.T.S. TANK CLEANING SERVICES, S.A.

C/ Ercilla, 18 – 2º Izq.

E-48009 BILBAO

Phone: +34 944 257 240

Fax: +34 944 232 439

sts@ sts-tank.com

www.sts-tank.com

© 2010 S.T.S. Tank Clearing Services, S.A. All rights reserved.

Blabo® is a registered trademark of Oreco A/S.

The Blabo® System used by STS The Blabo® System Applied to a Floating Applications of the BLABO® System

The Blabo® process system was developed and patented by ORECO A/S (Denmark),

or Fixed roof Tank Cleaning:

which is specifically geared to the cleaning of large crude and fuel oil tanks.

The process system – called BLABO® System – is unique in combining automated The tank cleaning machines are hydraulically driven and the liquid jets fluidize • Black oil tanks (crude, fuel heavy vacuum gas oil).

tank cleaning with simultaneous sludge separation. The process does not require the the bottom sludge layer, enabling recirculation and processing. • Slops oil.

involvement of manual labour inside the tank and it delivers the cleaned out sludge • Ballast tanks and other difficult-to-clean tanks.

in its two main components:

Hairpin pipe

• Hydrocarbons.

• Solids (inorganic components).

Extra nozzle es

Preparation of a crude oil storage tank

By means of energy (electricity/steam) only and

using light crude oil and the treated sludge itself for inspection/hot work with the

as the primary cleaning media, the process is Tank

capable of removing and separating 100-150 m³

Pontoon

wall

BLABO® System

of sludge/day. The Blabo® System adopted by STS Nozzle

From BLABO®

consists of two parts and a third one as an optional Support leg Re-circulation module Main advantages:

stage.

To BLABO®

Sludge Suction module

• Minimizes hydrocarbon emission to the air.

Sump

• Tank cleaning is performed much faster than the

conventional/manual way.

• Significantly reducing the down-time of the

tanks (up to 70%).

Tank with or floating roof Blabo® Process Modules

• Minimizes usage of water, air and gas oil for

Fixed Roof

cleaning.

Skimming Separation (optional) • Non-man entry system (minimal health and safety

risks to staff).

Oil

Oil/Water

Water

Separator Hydrocarbons

Tack cleaning Solid/Liquid Solids

machines: RJH

Pre- Feed

Steam Pump

The Agaleus Group

heat

Tack cleaning filter pump exchanger

The first part, which is placed inside the tank to be machines: SNS

Hydro-

Is a total waste management group comprising of a

cyclones

cleaned, consists of a number of specially designed Sump variety of different operations, providing a wide range

Suction Re-circulation

Toftejorg tank cleaning machines (SNS). of services. Agaleus provides consultancy, transportation,

They are positioned inside the tank through tank segregation, recovery, recycling and management for

openings (manways, bleeder vents etc.) in such a hazardous waste.

way that all parts of the tank can be reached by jets

of treated oil sludge. The SNSs are connected to

Tank wall the second part which is placed outside the tank

Tank cleaning

machine to be cleaned.

The second part Blabo I, the recirculation module,

S.T.S. Tank Cleaning Services, S.A.

TANK

consists of pumps, filters, heat exchangers and

hydrocyclons. This part treats and heats the “sludge” Is a member of the Agaleus Group.

so that it can be recirculated back into the tank S.T.S. is active as specialist contractors for automatic

through the jets. cleaning & recovery of crude and fuel oil tanks in Europe

In this way, more sludge is fluidized and can be using the ORECO BLABO® System.

Some of the main features offered by the

pumped out for separation in the third optional part.

BLABO® System adopted by STS are:

The third optional part Blabo II, or separation module

Pump

• No personnel is required inside tanks

(heat exchangers, settling tanks and decanter) carry

during cleaning.

on with the final separation of the different

• Maximum recovery of hydrocarbons

components of the heavy solids sludge.

(more than 95%).

Heating-Recirculation Finally and before the opening of the tank, a very

• Environmental-friendly process

in detail cleaning can be carried out by hot water

minimizing waste disposal.

and biodegradable detergent.

• Overall tank cleaning costs reduced.

Separation

Inorganics Hydrocarbons

You might also like

- Door SheetDocument9 pagesDoor SheetAnilkumarNo ratings yet

- Machine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To FasDocument6 pagesMachine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To Fashcsharma1967No ratings yet

- Optimum Detailed Design of 13000 m3 Oil Storage TaDocument6 pagesOptimum Detailed Design of 13000 m3 Oil Storage TaHenrikNo ratings yet

- Surface Preparation and Painting ProcedureDocument10 pagesSurface Preparation and Painting ProcedureNenad TomicNo ratings yet

- API 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016Document31 pagesAPI 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016amit4179100% (1)

- Sludge in COS TankDocument28 pagesSludge in COS TankJose BijoyNo ratings yet

- Descon Engineering - Abu Dhabi: Procedure For Chemical Cleaning of Heat Exchanger/ Fin Fan CoolerDocument4 pagesDescon Engineering - Abu Dhabi: Procedure For Chemical Cleaning of Heat Exchanger/ Fin Fan CoolerMohammad Fazal KhanNo ratings yet

- Corrosion Inhibitors For Reinforced ConcreteDocument25 pagesCorrosion Inhibitors For Reinforced ConcreteVENKATESHNo ratings yet

- Tank ComponentsDocument4 pagesTank ComponentssafwanNo ratings yet

- Coalescers SeparatorsDocument3 pagesCoalescers SeparatorsMadan KumawatNo ratings yet

- Tank Cleaning Method For TankersDocument4 pagesTank Cleaning Method For TankersErsin SaltNo ratings yet

- PPDM Lite Architectural PrinciplesDocument17 pagesPPDM Lite Architectural PrinciplesaquialguienNo ratings yet

- Blabo Tank Cleaning SystemDocument8 pagesBlabo Tank Cleaning Systemirfanlarikhotmailcom100% (1)

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- Basics of Rubber Rheometry & RheographDocument11 pagesBasics of Rubber Rheometry & RheographBHUSHAN SONWANE0% (1)

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- Tank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ADocument59 pagesTank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ABurak GülenNo ratings yet

- Tank Cleaning Robotic ServicesDocument2 pagesTank Cleaning Robotic ServicesgmitsutaNo ratings yet

- 4 SOP-Tank Farm Final Sent To ZonesDocument37 pages4 SOP-Tank Farm Final Sent To ZonesVijayNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- WindTower WebinarSlidesDocument27 pagesWindTower WebinarSlidesJuby James100% (1)

- BTE Dome Brochure Jun 10Document2 pagesBTE Dome Brochure Jun 10م.ذكى فضل ذكىNo ratings yet

- 3 s2.0 B9780884156864500508 MainDocument4 pages3 s2.0 B9780884156864500508 MainAmal KaNo ratings yet

- Marine Fuel Oil RMG 380 (Ifo 380)Document1 pageMarine Fuel Oil RMG 380 (Ifo 380)Dino MandicNo ratings yet

- Abrasive BlastingDocument52 pagesAbrasive Blastinglwin_oo2435100% (1)

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- Garnet SpecificationDocument2 pagesGarnet SpecificationskNo ratings yet

- Sea Water For HydrotestDocument2 pagesSea Water For HydrotestNakkolopNo ratings yet

- 300m3 Circular Ground Reservior BoqDocument4 pages300m3 Circular Ground Reservior BoqMiko Abi100% (2)

- Envelop Protective Covers Material SpecificationsDocument2 pagesEnvelop Protective Covers Material SpecificationsronhuttonNo ratings yet

- Oil SpillDocument31 pagesOil SpillArthur James De TorresNo ratings yet

- PDO Approved Inspection BodiesDocument15 pagesPDO Approved Inspection BodiesMohammed Rizwan AhmedNo ratings yet

- Principal Types of Atmospheric Storage TanksDocument9 pagesPrincipal Types of Atmospheric Storage Tanksmohsen ranjbarNo ratings yet

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pages650-680 Rev 4 - Hydrostatic Test ExemptionspediNo ratings yet

- Tank Cleaning Guide BP 2004Document1 pageTank Cleaning Guide BP 2004mabrouk2013No ratings yet

- Tubular Vent BinderDocument12 pagesTubular Vent BinderbayuNo ratings yet

- Challenging The Organic "Zinc Rich" Primer StandardDocument9 pagesChallenging The Organic "Zinc Rich" Primer Standardaliabdulhamid100% (2)

- Design and Study of Floating Roofs For Oil Storage TanksDocument12 pagesDesign and Study of Floating Roofs For Oil Storage TanksDavid RodriguesNo ratings yet

- Sealing Compounds From Project Sales CorpDocument34 pagesSealing Compounds From Project Sales CorpProject Sales CorpNo ratings yet

- Corrosion Application Library ManualDocument230 pagesCorrosion Application Library ManualMiguel Angel Holguin MontañoNo ratings yet

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocument4 pagesDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNo ratings yet

- HEATEXDocument34 pagesHEATEXSiddharthNo ratings yet

- 2006 Mohammed AzadDocument82 pages2006 Mohammed AzadIGNyomanAnomWijayaNo ratings yet

- Pipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge TavesDocument51 pagesPipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge Tavesnathgsurendra100% (2)

- Storage TanksDocument2 pagesStorage Tanksarif99pakNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Corrosion Performance TestsDocument252 pagesCorrosion Performance TestsChatchai Manathamsombat100% (1)

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- FRP PresentationDocument21 pagesFRP PresentationKhairul AnwarNo ratings yet

- FSK-E290-006-A4-0 Quality Control Plan (QC Plan)Document4 pagesFSK-E290-006-A4-0 Quality Control Plan (QC Plan)Amir Reza RashidfarokhiNo ratings yet

- Zinga Vs ZRCDocument1 pageZinga Vs ZRCMarco Antonio Moncerrate100% (1)

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Surge Tank Ps PDFDocument2 pagesSurge Tank Ps PDFsutanNo ratings yet

- Filter Design Data (24 Oct20)Document2 pagesFilter Design Data (24 Oct20)Hedi Ben MohamedNo ratings yet

- Dr. Bugs Tan ADIPEC Conference PaperDocument23 pagesDr. Bugs Tan ADIPEC Conference PaperDr Bugs Tan100% (1)

- Equipment Used During VentingDocument9 pagesEquipment Used During VentingRahulChoudharyNo ratings yet

- 8.T-ProofCrete 709 13-03-28Document2 pages8.T-ProofCrete 709 13-03-28Shamsul IslamNo ratings yet

- Robots in Shipbuilding Industry (1160) PDFDocument9 pagesRobots in Shipbuilding Industry (1160) PDFWahyu WahyurachmatdhaniNo ratings yet

- Tank Bottom Scraper Zickert - enDocument22 pagesTank Bottom Scraper Zickert - enzxc007No ratings yet

- Spark Gaps: Dehn (Uk) LTDDocument8 pagesSpark Gaps: Dehn (Uk) LTDElectromacnetist ElectrodNo ratings yet

- Ugandan Hydrocarbon Asset Realisation PlanDocument15 pagesUgandan Hydrocarbon Asset Realisation PlancenkodaNo ratings yet

- PS Series Tensioner BrochureDocument4 pagesPS Series Tensioner BrochureAbdullah Muhamad ZahdiNo ratings yet

- PACT MBR & MBBR Catalogue PDFDocument4 pagesPACT MBR & MBBR Catalogue PDFMohammed Rafi ShaikhNo ratings yet

- Y Gravity Belt Thickener BGTDocument4 pagesY Gravity Belt Thickener BGTYousef AlipourNo ratings yet

- Blabo SafetyDocument10 pagesBlabo SafetyaquialguienNo ratings yet

- Leviton 47611-5GB 47611-8GB Gigabit SwitchDocument2 pagesLeviton 47611-5GB 47611-8GB Gigabit SwitchaquialguienNo ratings yet

- Especificaciones Técnicas - EV5016TURBODocument3 pagesEspecificaciones Técnicas - EV5016TURBOaquialguienNo ratings yet

- Data Sheet Windows2008ServerDocument2 pagesData Sheet Windows2008ServeraquialguienNo ratings yet

- Aspect: Range IntroductionDocument32 pagesAspect: Range IntroductionJIYADHNo ratings yet

- TTP 28 HDocument18 pagesTTP 28 HDongNo ratings yet

- TheoryDocument3 pagesTheoryAhmad SyamilNo ratings yet

- Annex 4 PDFDocument2 pagesAnnex 4 PDFbesaret100% (1)

- Short Circuit Kitchen HoodDocument5 pagesShort Circuit Kitchen Hoodpsn_kylmNo ratings yet

- Refinery Fertilizer: Mouse Click To Advance To The Next SlideDocument16 pagesRefinery Fertilizer: Mouse Click To Advance To The Next SlideashirNo ratings yet

- Cavatex W7 MCTDocument2 pagesCavatex W7 MCTAndrei PopescuNo ratings yet

- Mechanical Project ListDocument7 pagesMechanical Project ListPavan Kumar BalagamNo ratings yet

- 11 KV HT VCBDocument8 pages11 KV HT VCBKEYSTONE INFRA PVT LTD0% (1)

- Abu Dhabi International Airport: Structured Cabling System Layout Level 3.1 Sector 5.24CDocument1 pageAbu Dhabi International Airport: Structured Cabling System Layout Level 3.1 Sector 5.24CRavikiran SeshapuNo ratings yet

- Industrial Waste Materials in ConcreteDocument43 pagesIndustrial Waste Materials in ConcretejohnNo ratings yet

- Material Benefits: Common Metals Utilizing The ISF ProcessDocument2 pagesMaterial Benefits: Common Metals Utilizing The ISF Processsandbad2No ratings yet

- Nano Concrete AbstractDocument5 pagesNano Concrete AbstractNArendra REddy100% (2)

- H408 Handout 2013 Spring Updated 07 Apr 2015wDocument11 pagesH408 Handout 2013 Spring Updated 07 Apr 2015wAbid AnuarNo ratings yet

- Pewe MBBR BrochureDocument1 pagePewe MBBR Brochurelifemillion2847No ratings yet

- CHE4613LAB7Document6 pagesCHE4613LAB7Huda AlkhouriNo ratings yet

- Microsoft Word - Fitter QuestionDocument6 pagesMicrosoft Word - Fitter QuestionVikashKumarNo ratings yet

- Local Control Stations For Zone 1 and Zone 21: Fields of ApplicationDocument2 pagesLocal Control Stations For Zone 1 and Zone 21: Fields of Applicationthankam punnenNo ratings yet

- Accs r407c CatalogueDocument16 pagesAccs r407c CatalogueMohd FirdhausNo ratings yet

- TaclobanDocument8 pagesTaclobanMarvin GonzalesNo ratings yet

- Unit 1 - 1 - Introduction To Manufacturing & CastingDocument33 pagesUnit 1 - 1 - Introduction To Manufacturing & Castingsubash naraharasettiNo ratings yet

- Transmision Automatica Rexton (Manual de Taller) PDFDocument60 pagesTransmision Automatica Rexton (Manual de Taller) PDFCarlos Car - Per0% (1)

- 2022 Yuhong Export Achievement Reference ListDocument19 pages2022 Yuhong Export Achievement Reference ListadboltsalesNo ratings yet

- VCTDS 02565 enDocument12 pagesVCTDS 02565 enCosmin100% (1)

- Test Physics Ch#13 Test SeesDocument2 pagesTest Physics Ch#13 Test SeesRashid JalalNo ratings yet

- API 571 Study Guide-Practice Questions For API 570 Exam-Corrosion Under Insulation - CUI (4.3.3)Document5 pagesAPI 571 Study Guide-Practice Questions For API 570 Exam-Corrosion Under Insulation - CUI (4.3.3)NIMANo ratings yet

- Fence Gate CatalogDocument3 pagesFence Gate CatalogtempfencingNo ratings yet