0% found this document useful (0 votes)

333 views6 pagesAgitator HP and Torque Calculation

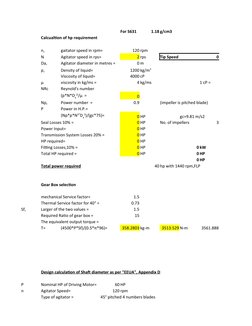

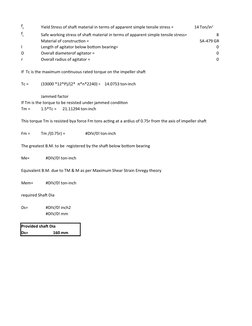

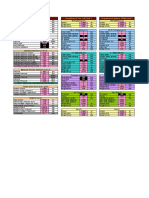

The document calculates the horsepower (HP) requirement for an agitator with a diameter of 0 meters, operating at 120 rpm in a liquid with a density of 1200 kg/m3 and viscosity of 4000 cP. The calculated HP requirement is 0 HP. It then selects a gear box with a ratio of 15 and output torque of 3561.888 N-m. Finally, it calculates the required shaft diameter as 0 mm but selects a provided shaft diameter of 160 mm.

Uploaded by

SagarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

333 views6 pagesAgitator HP and Torque Calculation

The document calculates the horsepower (HP) requirement for an agitator with a diameter of 0 meters, operating at 120 rpm in a liquid with a density of 1200 kg/m3 and viscosity of 4000 cP. The calculated HP requirement is 0 HP. It then selects a gear box with a ratio of 15 and output torque of 3561.888 N-m. Finally, it calculates the required shaft diameter as 0 mm but selects a provided shaft diameter of 160 mm.

Uploaded by

SagarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd