Professional Documents

Culture Documents

LT JSK37-05 - Rebuild - 5th Wheel Lock PDF

LT JSK37-05 - Rebuild - 5th Wheel Lock PDF

Uploaded by

Henry MorenoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LT JSK37-05 - Rebuild - 5th Wheel Lock PDF

LT JSK37-05 - Rebuild - 5th Wheel Lock PDF

Uploaded by

Henry MorenoCopyright:

Available Formats

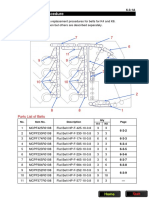

LOCK REPLACEMENT

PROCEDURES

FOR JSK 37 SERIES FIFTH WHEELS

Cushion and Lock Jaw Rebuild Kit (For L.H. only)

Part #SK 73221-50Z

1 2 3 4 5 6

8 7

Item Description Part No. Item Description Part No.

1 Cushion ring bolt SK 73121-55 6 Ring SK 2106-70

2 Cushion Ring Assembly SK 79002-00 7 Lubricating kit SK 3108-02

3 Lock jaw SK 1489LZ 8 Lock jaw pivot pin SK 72106-67

4 Lock jaw spring SK 847

5 Eye bolt SK 2106-69

The right to alter specifications is reserved. Page 1 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

Important: Rebuilding should be considered when all of the

available adjustment is used and the lock tester

moves fore and aft 1/8” when properly locked.

INSPECTION

1. EXAMINE TOPPLATE SURFACE

If the topplate surface is worn down to the

grease groove at any point, the top plate

should not be rebuilt it should be discarded.

(see figure 1)

2. MEASURE TWO PARTS FIGURE 1

Measure the cushion ring and the lock jaw, the fifth wheel should be rebuilt if the

dimension shown is worn to .69” (17.5mm). (see figures 2 and 3)

.69 Inches .69 Inches

FIGURE 2 FIGURE 3

The right to alter specifications is reserved. Page 2 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

DISASSEMBLY

1. CLOSE THE LOCKING MECHANISM.

Pull the release handle out and swing Now let the release handle slide

the lock jaw into the closed position slowly to the closed position

(see figure 4a). (see figure 4b).

FIGURE 4a FIGURE 4b

2. REMOVE DOUBLE COIL SPRING.

Using a suitable tool remove the spring

from casting lug first (see figure 5).

FIGURE 5

3. OPEN THE LOCKING MECHANISM.

Slide the release handle to the

opened position (see figure 6).

FIGURE 6

The right to alter specifications is reserved. Page 3 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

DISASSEMBLY con’t

4. REMOVE THE CIRCLE RING.

Remove the circle ring securing the lock jaw spring (see figure 7a) and allow

extension spring to relax (see figure 7b).

FIGURE 7a FIGURE 7b

5. REMOVE THE CUSHION RING AND RETAINER.

Remove the (4) cushion ring bolts using a 5/16” Allen wrench (see figure 8a).

Then, pry out the cushion ring retainer from the casting and remove the cushion

ring (see figure 8b).

FIGURE 8a FIGURE 8b

6. REMOVE THE LOCK JAW PIVOT PIN.

Thread one of the cushion ring bolts into the lock jaw pivot pin (see figure 9a) and

lift the pin from the casting (see figure 9b).

FIGURE 9a FIGURE 9b

The right to alter specifications is reserved. Page 4 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

DISASSEMBLY con’t

7. REMOVE THE LOCK JAW. FIGURE 10

Remove the lock jaw by reaching under

the top plate and sliding the lock out of

the casting (see figure 10).

8. REMOVE THE LUBRICATION LINE. FIGURE 11

Remove the lubrication line from the

lock jaw.

RE-ASSEMBLY

FIGURE 12

1. INSTALL THE LUBRICATION LINE.

Re-attach the lubrication line to the lock jaw.

2. INSTALL THE LOCK JAW. FIGURE 13

Be sure to install the lock jaw in the same

orientation it was removed (see figure 13).

3. INSTALL THE CIRCLE RING. FIGURE 14

Place the end of the eye bolt through

the casting rib and secure with the

circle ring (see figure 14).

The right to alter specifications is reserved. Page 5 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

RE-ASSEMBLY con’t

FIGURE 15

4. INSTALL THE LOCK JAW PIVOT PIN.

Lubricate the lock jaw pivot pin and

secure the lock jaw by inserting it into

the casting through the slot in the lock

jaw (see figure 15).

5. INSTALL THE CUSHION RING AND RETAINER.

Carefully line up the bolt holes (see figure 16a), and then install (4) new cushion ring

bolts. Tighten and torque bolts to 45 ft-lbs (see figure 16b).

45 FT/LBS

FIGURE 16a FIGURE 16b

6. CLOSE THE LOCKING MECHANISM.

Pull the release handle out and swing Now slide the release handle

the lock jaw into the closed position into the closed position

(see figure 17a). (see figure 17b).

FIGURE 17a FIGURE 17b

7. ATTACH DOUBLE COIL SPRING.

Using a suitable tool attach the spring as shown (see figure 5).

The right to alter specifications is reserved. Page 6 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

RE-ASSEMBLY con’t

8. CHECK ADJUSTMENT - Lock and unlock several times using a lock tester.

A. THE LOCK IS PROPERLY ADJUSTED IF:

The wheel locks and unlocks easily each

time and the lock tester rotates freely.

B. THE LOCK IS TOO LOOSE IF: You feel fore-

aft play when pulling and pushing on the

lock tester handle (see figure 18)

C. THE LOCK IS TOO TIGHT IF: The lock tester

does not rotate freely when attempting to

rotate it in the lock. (See figure 19)

Look for movement

of kingpin in lock Disengage Hook

Rotate Lock

Tester

Pull & Push

Handle FIGURE 18

FIGURE 19

9. CORRECT IMPROPER ADJUSTMENT

TURN ADJUSTMENT SCREW

CLOCKWISE COUNTER CLOCKWISE

A. IF IT IS TOO TIGHT: loosen the jam nut, turn the

adjustment screw clockwise one full turn and reset

the jam nut. Then, lock and unlock several times,

repeat if necessary.

B. IF IT IS TOO LOOSE: loosen the jam nut, turn the

IF TOO TIGHT IF TOO LOOSE

adjustment screw counterclockwise one full turn

and reset the jam nut. Then, lock and unlock

several times, repeat if necessary.

The right to alter specifications is reserved. Page 7 of 7

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT JSK37-05 Rev.F

You might also like

- Caterpillar 3500b Disassembly Assembly Manual 558 PagesDocument558 pagesCaterpillar 3500b Disassembly Assembly Manual 558 Pagesroland100% (1)

- Cylinder Liner ProjectionDocument4 pagesCylinder Liner ProjectionFernando Daniel Saez VillarrealNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Manual Minicargador Caterpillar bh27 y bh30Document5 pagesManual Minicargador Caterpillar bh27 y bh30Pedro BarriosNo ratings yet

- Transmision 580 CaseDocument2 pagesTransmision 580 Caseadrian monter lugoNo ratings yet

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- OM SM Ruston RK270 540pages PDFDocument541 pagesOM SM Ruston RK270 540pages PDFnaya aninditaNo ratings yet

- Maintenance Manual Sisu SR 463 Hub ReductionDocument22 pagesMaintenance Manual Sisu SR 463 Hub Reductionmliugong100% (1)

- Manual Reparacao ME4 547957ENDocument172 pagesManual Reparacao ME4 547957ENPaulo SousaNo ratings yet

- Technology of Machine Tools: Universal Cutter and Tool GrinderDocument64 pagesTechnology of Machine Tools: Universal Cutter and Tool GrinderAnibal Daza100% (1)

- Component Code ZZ: Printed in Japan (02) 1Document15 pagesComponent Code ZZ: Printed in Japan (02) 1Jose A. Basanta H.No ratings yet

- VOLVO EW160B-7 Frame and WheelDocument18 pagesVOLVO EW160B-7 Frame and WheelPIKO MOBNo ratings yet

- Chapter 7 Shaper Operation-1Document22 pagesChapter 7 Shaper Operation-1علاءإدريسNo ratings yet

- U.S. Blind Stitch 718-2 PDFDocument38 pagesU.S. Blind Stitch 718-2 PDFsemoyapaNo ratings yet

- Ez Ev Es 20170901 PDFDocument43 pagesEz Ev Es 20170901 PDFNma ColonelnmaNo ratings yet

- VOLVO EC210B NC EC210BNC EXCAVATOR Service Repair Manual PDFDocument23 pagesVOLVO EC210B NC EC210BNC EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- LT SK37U 03 Maintenance 37U 5th WheelDocument3 pagesLT SK37U 03 Maintenance 37U 5th WheelFernando Salamanca100% (1)

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- Clutch Hino 5.5Document5 pagesClutch Hino 5.5Yeam_90No ratings yet

- Toro Belt ReplacementDocument9 pagesToro Belt ReplacementsuspectnixNo ratings yet

- Duplex Oil Filter - AdjustDocument3 pagesDuplex Oil Filter - Adjustbenjir shuvoNo ratings yet

- CH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsDocument46 pagesCH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsEnrrique LaraNo ratings yet

- Removal: 1. Remove Rear WheelsDocument1 pageRemoval: 1. Remove Rear WheelssalusfrankNo ratings yet

- Remo 62Document1 pageRemo 62salusfrankNo ratings yet

- Biselador de 3 AntorchasDocument7 pagesBiselador de 3 AntorchasIrving Israel IrvingNo ratings yet

- Description: Rear AxleDocument16 pagesDescription: Rear AxleNoe CuandonNo ratings yet

- Manual de Reparación Motores Rineer M015 MACOYDocument10 pagesManual de Reparación Motores Rineer M015 MACOYEdgar ContrerasNo ratings yet

- Kick Start Pawl Replacement - A4Document3 pagesKick Start Pawl Replacement - A4barun1977No ratings yet

- 6-3. Belt RepDocument28 pages6-3. Belt RepAbdul MuhidNo ratings yet

- Rear Shock and Spring2 OHDocument3 pagesRear Shock and Spring2 OHRomy MNo ratings yet

- UN32C5000QF-Disassembly & ReassemblyDocument3 pagesUN32C5000QF-Disassembly & Reassemblysure2kNo ratings yet

- First: United States PatentDocument7 pagesFirst: United States Patentyraju88No ratings yet

- Roller Circle - Check and AdjustDocument3 pagesRoller Circle - Check and AdjustGilney FreitasNo ratings yet

- Rear Axle Beam ReplacementDocument5 pagesRear Axle Beam ReplacementRomy M100% (1)

- t156 1 Forklift Merlo P35.9ev Oem Service ManualDocument100 pagest156 1 Forklift Merlo P35.9ev Oem Service ManualChomi100% (1)

- WB97R 5e0Document18 pagesWB97R 5e0Facu oscar Perez PavonNo ratings yet

- Rocker Shaft AssemblyDocument3 pagesRocker Shaft Assemblyma.powersourceNo ratings yet

- Nicholas Hacko - Fine Watches: Do It Yourself Project: Seiko 7S26 For Novice HorologistsDocument8 pagesNicholas Hacko - Fine Watches: Do It Yourself Project: Seiko 7S26 For Novice Horologistsblackarrow1990No ratings yet

- Emco D2000 Swivel PartsDocument2 pagesEmco D2000 Swivel Partsaldo2306No ratings yet

- SureShade Roller Assembly Instructions 052020Document4 pagesSureShade Roller Assembly Instructions 052020Davor GiaconiNo ratings yet

- Removal: Torx Screw Screw CaseDocument2 pagesRemoval: Torx Screw Screw CaseMoh DeBrNo ratings yet

- Reductor Llantas Ro-56Document39 pagesReductor Llantas Ro-56DavidNo ratings yet

- Brake Oil Pump, Shaft Seal, Changing (Serial No. - 1826) : ToolDocument3 pagesBrake Oil Pump, Shaft Seal, Changing (Serial No. - 1826) : ToolAbdulhamit KatılmışNo ratings yet

- MT Series - ServiceDocument8 pagesMT Series - ServiceВаня БойкоNo ratings yet

- J3 Axis R-2000iCDocument14 pagesJ3 Axis R-2000iCCesar PuenteNo ratings yet

- Engine RemovalDocument13 pagesEngine RemovalShuraihMehlNo ratings yet

- Part PabrikDocument2 pagesPart PabrikNaldy NaldyNo ratings yet

- ML Couplings Instruction ManualDocument4 pagesML Couplings Instruction ManualGer BosNo ratings yet

- Section 8005: Removal and Installation of The Attachement CylindersDocument14 pagesSection 8005: Removal and Installation of The Attachement CylindersJefferson PaixãoNo ratings yet

- 8005Document14 pages8005Renato Assis da SilvaNo ratings yet

- Air Starting Motor - Disassemble (SENR1126-36)Document11 pagesAir Starting Motor - Disassemble (SENR1126-36)redminote12pro.5garNo ratings yet

- 6000-700E Installation Operation Maintenance InstructionsDocument8 pages6000-700E Installation Operation Maintenance InstructionsliengsamsonNo ratings yet

- Ns/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Document3 pagesNs/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Luca TrottaNo ratings yet

- PL218 Glute Trainer Service Manual: Johnson Issue Date Edition 01 Doc No. Revision Date Edition TimeDocument14 pagesPL218 Glute Trainer Service Manual: Johnson Issue Date Edition 01 Doc No. Revision Date Edition TimeSrboljub KitanovicNo ratings yet

- w040001 PDFDocument31 pagesw040001 PDFresolution8878No ratings yet

- Страницы из 3.0L-181CID-Parts-Manual - 5 PDFDocument1 pageСтраницы из 3.0L-181CID-Parts-Manual - 5 PDFАлександрNo ratings yet

- Bulldozer Blade Tilt: Operation and Maintenance ManualDocument2 pagesBulldozer Blade Tilt: Operation and Maintenance ManualPutra JawaNo ratings yet

- Full Tilt Feller PDFDocument13 pagesFull Tilt Feller PDFViniciusCamargosNo ratings yet

- Hydraulic Rock Drill Hexi: AND ANDDocument7 pagesHydraulic Rock Drill Hexi: AND ANDStgo TurcoNo ratings yet

- M SR 0008 PDFDocument2 pagesM SR 0008 PDFMoh DeBrNo ratings yet

- KULLICK Kettentrenngeraete EngDocument8 pagesKULLICK Kettentrenngeraete Engborosak88No ratings yet

- 2012 Fork Service ManualDocument36 pages2012 Fork Service ManualFer SabidongNo ratings yet

- Substituição Do Redutor J2 e J3 - R2000iADocument21 pagesSubstituição Do Redutor J2 e J3 - R2000iAmarino5trischNo ratings yet

- Sporting Rifle M07As Match/M07Af MatchDocument24 pagesSporting Rifle M07As Match/M07Af MatchGer Adinolfi-FebreNo ratings yet

- Servicing ClutchDocument52 pagesServicing ClutchAdugna KasimNo ratings yet

- Unified Thread StandardDocument5 pagesUnified Thread StandardNapiorkowskiNo ratings yet

- Grenadier Guards Basic Handbook KnowledgeDocument11 pagesGrenadier Guards Basic Handbook KnowledgeAryaOriginNo ratings yet

- Trade Price List: September 2016Document28 pagesTrade Price List: September 2016Jhon SanfraNo ratings yet

- Übersicht SOTS BeanstandteileDocument1 pageÜbersicht SOTS Beanstandteilelwin84.lwNo ratings yet

- fc8716 142Document6 pagesfc8716 142Роман ПрокопчукNo ratings yet

- ALFA LAVAL Cetetherm Mini CityDocument4 pagesALFA LAVAL Cetetherm Mini CityWSNo ratings yet

- Model No. GA4040 100MM ANGLE GRINDERDocument3 pagesModel No. GA4040 100MM ANGLE GRINDERSaud DhopawnkarNo ratings yet

- Katalog Elevator Lift #Rev1Document19 pagesKatalog Elevator Lift #Rev1Wataru Ardhy MizunoNo ratings yet

- Part List KubotaDocument1 pagePart List KubotaYosy PrastiyoNo ratings yet

- M15 Series Jockey Pump ControllersDocument1 pageM15 Series Jockey Pump ControllersshafivuddinNo ratings yet

- High Tensile: Hexagon Flange Bolts DIN 6921Document1 pageHigh Tensile: Hexagon Flange Bolts DIN 6921Mauro MiguelNo ratings yet

- Lab Session # 1: To Find Diameter of Solid Pins Using Vernier CalliperDocument9 pagesLab Session # 1: To Find Diameter of Solid Pins Using Vernier CalliperZukhruff DollNo ratings yet

- Duct Weight EstimatingDocument16 pagesDuct Weight EstimatingfghabboonNo ratings yet

- Assembly Procedure For A Modular BAC MK6H1CXXXC3H4X42A6Document26 pagesAssembly Procedure For A Modular BAC MK6H1CXXXC3H4X42A6Toso Eko PurwantoNo ratings yet

- Synthesis and AnalysisDocument31 pagesSynthesis and Analysiskunal shegokarNo ratings yet

- Aset WTP HarapanDocument7 pagesAset WTP HarapanReinhard SimbolonNo ratings yet

- Metal-Cutting Saws: Unit 5Document44 pagesMetal-Cutting Saws: Unit 5Krunal GandhiNo ratings yet

- 3q CarpentryDocument3 pages3q CarpentryUnamono BenaventeNo ratings yet

- Q Wid 200734Document3 pagesQ Wid 200734AndiNo ratings yet

- HW # 13 PDFDocument3 pagesHW # 13 PDFarshad gabary100% (2)

- FOOD PROCESSING (FISH) ModuleDocument18 pagesFOOD PROCESSING (FISH) ModuleJoseph CoralesNo ratings yet

- PP3-B1265E Instruction Manual (Periodical Maintenance and Inspections)Document42 pagesPP3-B1265E Instruction Manual (Periodical Maintenance and Inspections)Rodolfo PeñaNo ratings yet

- Types and Characteristics of Grinding Equipment and Circuit FlowsheetsDocument11 pagesTypes and Characteristics of Grinding Equipment and Circuit FlowsheetsLUIS ENRIQUE VILCA ESPINOZANo ratings yet

- Strip Guiding On The Uncoiler: Application / Function PrincipleDocument2 pagesStrip Guiding On The Uncoiler: Application / Function PrincipleAlphaNo ratings yet