Professional Documents

Culture Documents

ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PH: ACCORDING TO EN ISO 9606-1:2013

Uploaded by

Klaipeda K.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PH: ACCORDING TO EN ISO 9606-1:2013

Uploaded by

Klaipeda K.Copyright:

Available Formats

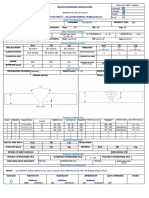

Welder’s qualification test certificate

ACCORDING TO EN ISO 9606-1:2013

Designation examples of this Standard

ISO 9606-1 141 T BW FM4 S s3.6 D60 PH ss nb

INTERNATIONAL product type filler material

STANDARD weld details

type of weld dimension of

welding process test piece

filler material

grouping welding position

welding processeses types of weld welding positions weld details

according to EN ISO 4063 BW butt weld according to EN ISO 6947 BW butt weld

FW fillet weld ss single side welding

111 manual metal arc welding PA flat position mb material backing

114 self-shielded tubular cored arc welding PB horizontal vertical position nb welding with no material backing

121 submerged arc welding with solid wire electrod (partly mechanized) PC horizontal position gb gas backing

125 submerged arc welding with tubular cored electrode (partly mechanized) FW PD horizontal overhead position fb flux backing

131 MIG welding with solid wire electrode PE overhead position bs welding from both sides

135 MAG welding with solid wire electrode PF vertical up position ci consumable insert

136 MAG welding with flux cored electrode PG vertical down position

138 MAG welding with metal cored electrode H-L045 inclined position welding upwards FW fillet weld

141 TIG welding with solid filler material (wire/rod) J-L045 inclined position welding downwards sl single layer

142 autogenous TIG welding PH pipe position for welding upwards ml multi-layer

143 TIG welding with tubular cored filler material (wire/rod) PJ pipe position for welding downwards

145 TIG welding using reducing gas and solid filler material (wire/rod) BW 311 oxyacetylene welding

15 plasma arc welding lw leftward welding

311 oxyacetylene welding rw rightward welding

product types filler material

T Tube covered electrodes

P Plate Route A plate flat position

A acid covering

P B basic covering or electrode core – basic

vertical down

T C cellulosic covering

R rutile covering or electrode core – rutile, slow-freezing slag position

RA rutile – acid covering

RB rutile – basic covering

RC rutile – cellulosic covering

RR rutile – thick covering

vertical up

Route B position

03 rutile basic covering

10 cellulosic covering

11 cellulosic covering

horizontal

12 rutile covering vertical position

13 rutile covering

14 rutile + iron powder covering

15 basic covering

16 basic covering

filler material grouping 18

19

basic + iron powder covering

limenite covering

20 iron oxide covering

J-L045

24 rutile + iron powder covering inclined position

Group Filler material for welding of Examples of applicable standards 27 iron oxide + iron powder covering welding

28 basic + iron powder covering downwards

FM1 Non-alloy and fine grain steels ISO 2560, ISO 14341, ISO 636, ISO 45 basic covering

14171, ISO 17632 48 basic covering

FM2 High-strength steels ISO 18275, ISO 16834, ISO 26304, H-L045

ISO 18276 inclined

cored wire

FM3 Creep-resisting steels Cr < 3,75 % ISO 3580, ISO 21952, ISO 24598, M metal cored electrode or metal powder position horizontal

ISO 17634 P electrode core – rutile, fast-freezing slag welding position

V electrode core – rutile or basic/fluoride upwards

FM4 Creep-resisting steels 3,75 < Cr < 12 % ISO 3580, ISO 21952, ISO 24598, W electrode core – basic/fluoride, slow-freezing slag

ISO 17634 Y electrode core – basic/fluoride, fast-freezing slag

Z electrode core – other types

FM5 Stainless and heat-resisting steels ISO 3581, ISO 14343, ISO 17633

FM6 Nickel and nickel alloys ISO 14172, ISO 18247 any other el ds

S solid wire electrode – solid rod tt w

nm no filler material

bu

horizontal

overhead position

vertical down

position

dimensions of test piece

et welds

s deposited thickness fil l

t material thickness vertical up

D outside tube diameter D position

overhead position

www.nkprojects.eu

Notified bodies for the welder‘s qualification test are regulated by European directives,

t

regulations or standards which apply to approved certification personnel or to

s

accreditation according to DIN EN ISO / IEC 17024 for the holding of the welder‘s

qualification test.

Anzeige_Poster_Schweissverfahren_engl.indd 1 26.04.2012 15:09:19

DVS_Anzeige_08-2013.indd 1 28.8.2013 09:33:00

You might also like

- Tech Pub 248D Welding Performance Qualification PDFDocument242 pagesTech Pub 248D Welding Performance Qualification PDFCory100% (2)

- Fastners ManualDocument153 pagesFastners ManualRonny Andalas100% (1)

- Tasks and Responsibilities of RWCDocument1 pageTasks and Responsibilities of RWCKDT100% (1)

- Htbook11 PDFDocument17 pagesHtbook11 PDFComan EduardNo ratings yet

- CSA W47.1 and CSA W59 Exam questions study guideDocument5 pagesCSA W47.1 and CSA W59 Exam questions study guideAlex Alex100% (2)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Magnetic MaterialsDocument9 pagesMagnetic MaterialsЈован ПродановићNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Engineering Materials Book by Dr. M. A. AzizDocument237 pagesEngineering Materials Book by Dr. M. A. AzizBashirul IslamNo ratings yet

- Poster - Welding Positions - en PDFDocument1 pagePoster - Welding Positions - en PDFmjaric8150% (2)

- WQT 316L 2 MMDocument1 pageWQT 316L 2 MMdavood abbasiNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- DIN EN 287-1 - 05-2004 - enDocument37 pagesDIN EN 287-1 - 05-2004 - enZlatan MilutinovicNo ratings yet

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Arc Basics - FA 2009 ISO 14175 Revised StandardDocument10 pagesArc Basics - FA 2009 ISO 14175 Revised StandardCatalinNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNo ratings yet

- How To Read An Oil Analysis Report by Jim FitchDocument42 pagesHow To Read An Oil Analysis Report by Jim FitchRodrigo Silva100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Din en Iso 15614 - 5 - 2004Document28 pagesDin en Iso 15614 - 5 - 2004Alfalloy Testing and Inspection Services Pvt. Ltd.No ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Application DIN 2303Document8 pagesApplication DIN 2303Marcelle Poll100% (1)

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Document33 pages112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosNo ratings yet

- Iso 15609-1-2019Document19 pagesIso 15609-1-2019HarikeshRana100% (2)

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- Filler Materials TestingDocument34 pagesFiller Materials TestingSunilNo ratings yet

- Corporate Presentation 3/26/2013 - 1Document18 pagesCorporate Presentation 3/26/2013 - 1Jose ManuelNo ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- Tacom Weld Code SteelDocument165 pagesTacom Weld Code SteelAles Kubat0% (1)

- Poster en ISO 9606 1 2013 English PDFDocument1 pagePoster en ISO 9606 1 2013 English PDFmarkoredsNo ratings yet

- Iso 17639 2022Document10 pagesIso 17639 2022Marcus Gimenes0% (1)

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- Iso 14344 2010Document9 pagesIso 14344 2010MOHAMEDNo ratings yet

- EN 15085 Part 5 - GaneshDocument36 pagesEN 15085 Part 5 - GaneshNiranjan Rajavel TigerNo ratings yet

- Iso 17640 2017 en PDFDocument11 pagesIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaNo ratings yet

- Model WopqDocument2 pagesModel WopqAnilkumarGopinathanNairNo ratings yet

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- KGP-Flamme Cutting Proce For BEI PDFDocument4 pagesKGP-Flamme Cutting Proce For BEI PDFoomoomNo ratings yet

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- Welder Qualification CertificateDocument2 pagesWelder Qualification CertificateNguyen Thanh BinhNo ratings yet

- PDFDocument15 pagesPDFkumarkk1969No ratings yet

- Wps 15614 TemplateDocument2 pagesWps 15614 Template0502raviNo ratings yet

- SB410 (JIS) - Worldwide Equivalent Grades 11Document1 pageSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- EN ISO 15792-1 (2008) A1 (2011) (E) CodifiedDocument3 pagesEN ISO 15792-1 (2008) A1 (2011) (E) CodifiedQuality Team50% (2)

- Ssab Astm A537 C2Document2 pagesSsab Astm A537 C2vasotermiNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Duties of The RWCDocument3 pagesDuties of The RWCbluegalago100% (1)

- DRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Document18 pagesDRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Osu AmpawanonNo ratings yet

- ISO 15510 - Part 1Document5 pagesISO 15510 - Part 1Zdenko MahacekNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Untitled 6Document1 pageUntitled 6அன்புடன் அஸ்வின்No ratings yet

- Poster Weldingpositions en SWDocument1 pagePoster Weldingpositions en SWAbin sha john The gipsyNo ratings yet

- Production 2020 NK ProjectsDocument13 pagesProduction 2020 NK ProjectsKlaipeda K.No ratings yet

- Presentation NK Projects 3Document9 pagesPresentation NK Projects 3Klaipeda K.No ratings yet

- BG 2Document1 pageBG 2Klaipeda K.No ratings yet

- NK ProjectsDocument13 pagesNK ProjectsKlaipeda K.No ratings yet

- Welding Defects 3Document39 pagesWelding Defects 3jesonelite100% (1)

- Tle-Ia-Smaw: Quarter 0 - Module 1 Use Basic Hand Tools and EquipmentDocument25 pagesTle-Ia-Smaw: Quarter 0 - Module 1 Use Basic Hand Tools and EquipmentAnalyn Taguran BermudezNo ratings yet

- Shaper, Slotter and PlanerDocument9 pagesShaper, Slotter and PlanerRenjith RajendraprasadNo ratings yet

- Metals and Non-Metals NotesDocument18 pagesMetals and Non-Metals NotesAzeem IqbalNo ratings yet

- Methods of Pipe JoiningDocument4 pagesMethods of Pipe JoiningVidhi KoshtiNo ratings yet

- Gate Valve STD SpecificationsDocument1 pageGate Valve STD SpecificationsMunishTrichyNo ratings yet

- Separate Chemistry: Higher Tier in BoldDocument16 pagesSeparate Chemistry: Higher Tier in BoldzipperNo ratings yet

- Spring Steel Production ProgramDocument15 pagesSpring Steel Production ProgramhdierkeNo ratings yet

- ASTM E747-04 - Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyDocument14 pagesASTM E747-04 - Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyMelissa SammyNo ratings yet

- Structural Systems Engineering GuideDocument67 pagesStructural Systems Engineering Guidejucar fernandezNo ratings yet

- TZM LAB Equipment-原件Document15 pagesTZM LAB Equipment-原件Emily AiNo ratings yet

- GR 5 Term 2 2020 Ns T Resource PackDocument38 pagesGR 5 Term 2 2020 Ns T Resource PackLorraine NoloNo ratings yet

- Hammer Unions - Hammer UnionsDocument5 pagesHammer Unions - Hammer UnionsiswantmachooNo ratings yet

- Tablero Nema 4xDocument4 pagesTablero Nema 4xMarco GarcíaNo ratings yet

- Piping CodesDocument11 pagesPiping CodesDavid Ricardo DiazNo ratings yet

- Theory: Mechanical & Systems Engineering Laboratory Assignment 2: Brinell Hardness TestDocument20 pagesTheory: Mechanical & Systems Engineering Laboratory Assignment 2: Brinell Hardness Testbodkhe harshNo ratings yet

- Chemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpDocument13 pagesChemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpEdinsonNo ratings yet

- Er420 130623 5014 CV Ult Method Statement For Bakau Piling To 1500mm RC BoxDocument3 pagesEr420 130623 5014 CV Ult Method Statement For Bakau Piling To 1500mm RC BoxMyo Thawta HtunNo ratings yet

- Đông Hô Nhiêt Suku PDFDocument2 pagesĐông Hô Nhiêt Suku PDFTháiSơnTrầnNo ratings yet

- Bergara Full Catalog 2015Document13 pagesBergara Full Catalog 2015mjmellandNo ratings yet

- Advanced welding electrode for aluminium bronzesDocument1 pageAdvanced welding electrode for aluminium bronzesAris WicaksonoNo ratings yet

- Top Notch Purlin Installation GuideDocument38 pagesTop Notch Purlin Installation GuideRobert EshwerNo ratings yet