Professional Documents

Culture Documents

Compressed Stabilised Earth Block: A Case Study Report

Uploaded by

Shubham SrivastavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressed Stabilised Earth Block: A Case Study Report

Uploaded by

Shubham SrivastavaCopyright:

Available Formats

Journal of Critical Reviews

ISSN- 2394-5125 Vol 7, Issue 1, 2020

Review Article

COMPRESSED STABILISED EARTH BLOCK: A CASE STUDY REPORT

Priji E. Moses1, Dr.M.P. Chockalingam2, Dr.R. Venkatakrishniah3, P. Dayakar4

1Phd-Scholar, Department of Civil Engineering, Bharath Institute of Higher Education and Research (BIHER), Chennai, India.

2Professor, Department of Civil Engineering, Bharath Institute of Higher Education and Research (BIHER), Chennai, India.

chockalingammp@gmail.com

3 Professor, Department of Civil Engineering, Bharath Institute of Higher Education and Research (BIHER), Chennai, India.

4 Professor, Department of Civil Engineering, Bharath Institute of Higher Education and Research (BIHER), Chennai, India.

Received: 10.11.2019 Revised: 11.12.2019 Accepted: 12.01.2020

ABSTRACT

Compressed Stabilized Earth Block (CSEB) is an innovation which has revived the ancient method of carrying out the task of constructing

economically affordable housing, in many countries around the world. In India, it has been tried in many different geographical locations.

The Government of India have been taking efforts through the Ministry of Housing and Urban Development, with a view to popularize the

scheme of implementing this technology, in rural areas, in each region. It is anticipated that the CSEB-technology will have a great scope

in the future years. This study was undertaken with an objective of conducting a few trials of mix proportions of stabilizing agents such

as lime, cement, or fly ash., in ensuring that the compressive strength of CSEB-specimens are satisfactory.

Key words: Compressed Stabilised Earth Blocks-Innovative Technology-Affordable Housing.

© 2019 by Advance Scientific Research. This is an open-access article under the CC BY license (http://creativecommons.org/licenses/by/4.0/)

DOI: http://dx.doi.org/10.31838/jcr.07.01.111

INTRODUCTION in the house construction task, can be invested in their children’s

The use of earth and mud were in vogue for the past several education and health-care.

thousand years , in many countries around the world. In some

countries, the practice has been historically documented. In The manufacturing of CSEB is considered to be energy-efficient

many other countries, the ancient monuments bear the and cost-effective. Environment-friendly building materials are

testimony for the un-written history. During the 19th Century, a used. On the overall basis, contribution is made to maintain a

chemical material called ‘cement’ was invented, marking a sustainable development. Different research workers have made

turning point in the history of building technology. Due to a contributions to the development of the technology of

faster rate of urbanization, industrialization, and infrastructure Compressed Stabilized Earth Block, in terms of different

development, and the environmental pollution that results has scientific and technological parameters (1,2,3).

been increasing , leading to the undesirable effects such as ‘global CSEBs are considered to be eco-friendly, as these blocks are used

warming’ and the consequent “climate change’. This has as ‘un-burnt’ products. On the contrary, Fired-Bricks use

necessitated on the need for identifying ‘sustainable’ technology, significant quantity of coal or any other fuel, during production,

in every phase of ‘developmental activity’, under the light of which causes the emission of harmful gases such as Carbon

‘carbon foot print’ and ‘damage’ caused to the three elements of Dioxide (CO2). Similarly, the manufacture of cement requires the

the Environment, namely, air, water and land (soil). Therefore, burning of many raw materials which leads to emission of many

the need for developing a sustainable technology, in the housing other harmful gases, including CO2, thus causing Environmental

sector becomes a need of the hour. pollution, producing certain un-desirable effects such as Global

In the light of the fact that 40-millon houses were estimated to be Warming and the consequent Climate Change. This is referred to

constructed by the year 2000, in India, in order to provide a as “carbon foot-print’”in the international literature (4,5,6).

housing for ‘all’, including the population below ‘poverty-line’,

the task gains significance. With the advent of an ever-increasing METHODOLOGY

population rate, the current scenario is much more challenging Experiments were conducted in the Laboratory to prepare the

than the previous decades, considering the socio-economic specimens of Compressed Stabilized Earth Blocks (CSEBs),by

aspects prevailing in rural India. Therefore, any innovative following procedures indicated in the literature. Tests were

technology in the housing sector sounds reasonable. conducted to evaluate the compressive strength of the dried and

hardened specimens, These are the CSBEs without being

Compressed Stabilized Earth Block (CSEB) is given importance, subjected to burning.

due to its many advantages, such as i) it uses environment- The soil selected was Laterite (Red Earth);. River sand was used

friendly natural materials, ii) it is a sustainable technology, iii) it as an aggregate.

cuts down energy wastage, in terms of carbon–foot print (in Plastic Limit of Soil =55.0%; Liquid Limit of Soil =65.0%.

consideration of energy consumption by using manufactured Plasticity index= 10.0 (Moderately Plastic).

products such as cement, burnt-bricks, etc, (as they require more Soil samples were prepared, and sufficiently mixed with water,

energy to be spent for manufacturing them), iv) the CSEB-system and calculated quantities of stabilizing agents were added, using

supports the involvement of local persons for carrying out Cement (Ordinary Portland Cement, OPC). Lime, and Fly-Ash, in

various operations, thereby, giving them the opportunity of local pre-determined proportions.

employment, v) an opportunity to self-building house owners to The ingredients in the Soil Specimens (labelled as SS-1 to SS-6)

have the pleasant experience of building the walls of ‘their own’, were proportioned as detailed below:

and the houses longed for, and vi) the economical savings availed i) SS-1: Clay 30% plus Sand 70%.

Journal of critical reviews 577

COMPRESSED STABILISED EARTH BLOCK: A CASE STUDY REPORT

ii) SS-2: Clay 20% plus Sand 70%.plus 10%OPC (Ordinary 3. The use of CSEBs seems to indicate a favourable trend in

Portland Cement). respect of strength considerations. However, the cost

iii) SS-3 : Clay20% plus Sand 70% plus Lime 10% analysis and overall economic benefits need to be further

iv) SS-4 : Clay 20%:plus Sand 70%plus Fly Ash 10% investigated

v) SS-5 : Clay 20% plus Sand70%plusOPC5%plus Fly Ash5%

vi) SS-6 : Clay 20% plus Sand 70% plus Lime5% plus Fly Ash

5%

Experimental procedure for casting CSEB

The following steps were followed:

1. Preparation of Soil sample; 2. Quality charcterisation of Soil

Sample; 3. Mixing of Specimens, with varying percentages of

Plasticisers, namely, Lime, OPC, and Fly Ash, as indicated

above. 4. The Mould of Specimens were prepared by Hand

Operated Press). 5. Specimens were dried under the shade

(Shelter).

2. The average size o each Soil Specimen (SS-1 to SS-6) was

273.0mm (L) x 114.0mm (W) x 76.0mm (H), where, L, is the

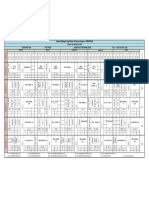

Figure 1: Variation of Compressive Strengrth

Length, W is the Width, and H is the Height. The top surface

area of each Soil Specimen was an average of 31300.0

Sq.mm. On comparison, 5-numbers of Wire-Cut Burnt

Bricks were tested for Compressive strength. The size of

Fired-Bricks (commercial Brand) was 280.0mm(L) x

114.0mm (W) x 80.0mm (H), having a Top Surface area of

31920.0 Sq.mm

3. Testing of Compressive Strength, was Carried out on 6-soil

Specimens, and one Fired Brick Sample, by using UTM

(Universal Testing Machine).

RESULTS

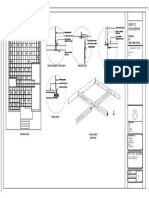

The compressive Tests on the 8-Specimens of CSEBs, and the Figure 2: Variation of Dry Density versus Moisture Content

Commercial Brand of Burnt-Clay Brick are shown in Table-1.

The Compressive Strengths of Compressed Stabilsed Earth Brick REFERENCES

Specimens varied from a minimum value of 0.557 N/sq.mm (in 1. Peter Walker, 1997, “Characterisation of Pressed Earth

SS-1, soil specimen without any Stabilising Agent) to a maximum Blocks in Compression”, 11th International Brick/Block

value of 2.718 N/sq.mm (in SS-2, soil specimen with Cement as Masonry Conference, Tongi University, Shanghai, China, 14-

the Stabilising agent), as presented in Table-1. Figure-1 presents 16, Oct. 1997, Proceedings : pp.1-10.

the variation of Dry Density of the CSEBs against Moisture 2. Patowary, B.N., Nath, N., Hussain, I., and Kakoti, H.J. June

content in the Soil Blocks. The optimum percentage was 12.5% 2015, “Study of Compressed Stabilised Earth Block”,

yielding a DD of 1.70 gm/cc. International Journal of Scientific and Research

Publications, 5(6) : 1-4. (ISSN 2250-3153).

Table 1: Compressive Strength of Specimens of CSEBs tested 3. Sofi, A.A., Wani, R.A.,anzoor, A., 2016, “Cement Stabiized

in the Laboratory Earth Blocks (CSEB) : An Economic and Eco-friendly

Building Material”, IOSR Journal of

4. Mechanical and Civil Engineering (IOSR-JMCE). 3(6) : Ver.V

(Nov-Dec.2016).

5. Bei, G., and Papayianni, I., 2003, “Compressive Strength of

Compressed Earth Block Masonry”, Transactions on the

Built Environment 2003”,

6. Vol.66, WIT Press.

7. Jangrid, S., and Darade, M., 2017, “Study on Compressed

Stabilised earth Blocks”, International Research Journal of

Engineering and

8. Technology (IRJET), 4(2): 1279-1285.

9. Riza, F.V., Rahman, I.A., Zaidi, A.M.A., 2010, “A Brie Review

of Compressed Stabilised Earth c Brick (CSEB)”,

Proceedings : 2010-International

10. Conference on Science and Social Research (CSSR 2010),

11. Kuala Lumpur, Malaysia. ode 1725-1984.

12. Vekaria A, Gigani Y, Belemkar S. "Cardiovascular Indications

CONCLUSIONS and Complications of Recombinant Human

1. The comparison of Compressive strength between CSEB Erythropoietin." Systematic Reviews in Pharmacy 2.1

specimens and the Burnt Brick samples indicated that the (2011), 43-47. Print. doi:10.4103/0975-8453.83438

CSEB with 70% Sand and 20% Clay and 10% Ordinnary

Portland Cement gave the maximum compressive strength

of 2.718 N/sq.mm. This amounts to 68.2% o the

Compressive Strength (3.984 N/sq.mm, as shown in Table-

1) achievable in the case of Burnt-Bricks. .

2. The addition of Lime or Fly ah do not show a competitive

performance in respect of Compressive strength..

Journal of critical reviews 578

You might also like

- VinodDocument5 pagesVinodUdaykumar PhatakNo ratings yet

- Energy Saving and Sustainable ConstructionDocument41 pagesEnergy Saving and Sustainable Constructionali_aslam_30No ratings yet

- Constitutive Models For Fibre Reinforced Soil BricksDocument21 pagesConstitutive Models For Fibre Reinforced Soil BricksCristianDiazNo ratings yet

- The Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteDocument6 pagesThe Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteIJRASETPublicationsNo ratings yet

- Carlos Ignacio 2020 J. Phys. - Conf. Ser. 1529 032045Document7 pagesCarlos Ignacio 2020 J. Phys. - Conf. Ser. 1529 032045Marco DiazNo ratings yet

- Studies On Stabilized Mud Block As A Construction MaterialDocument6 pagesStudies On Stabilized Mud Block As A Construction MaterialIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Partial Replacement of Cement with Corn Cob AshDocument12 pagesPartial Replacement of Cement with Corn Cob AshSagarKasarlaNo ratings yet

- Use of Waste Plastic and GBFS in Road ConstructionDocument11 pagesUse of Waste Plastic and GBFS in Road ConstructionHafiz YousafNo ratings yet

- 1.1 General: Parameter Optimisation For Producing Fired Bricks Using Organic Solid WasteDocument30 pages1.1 General: Parameter Optimisation For Producing Fired Bricks Using Organic Solid WasteHarendra Kumar YadavNo ratings yet

- The Use of Wet Milling Concrete Slurry To Substitute CementDocument10 pagesThe Use of Wet Milling Concrete Slurry To Substitute CementMD. MUSHFIQUE -US-SALEHEEN, 180051234No ratings yet

- Ijaret 11 01 007Document7 pagesIjaret 11 01 007shiva krishnaNo ratings yet

- The Development of Stabilised Clay-Hemp Building Material For Sustainability and Low Carbon UseDocument11 pagesThe Development of Stabilised Clay-Hemp Building Material For Sustainability and Low Carbon UseAndré Botelho da FonsecaNo ratings yet

- Final-Manuscript Group1Document15 pagesFinal-Manuscript Group1jerico mangalindanNo ratings yet

- Satya ProductsDocument15 pagesSatya Productssatyakeshs guttalNo ratings yet

- Assessing the Durability of Concrete Using Powdered Cork as Fine AggregatesDocument22 pagesAssessing the Durability of Concrete Using Powdered Cork as Fine AggregatesMeynard CadacioNo ratings yet

- D Brick AggregateDocument40 pagesD Brick AggregateHekato AssumiNo ratings yet

- Performance Evaluation of Hollow Concrete Blocks Made with Sawdust Replacement of SandDocument8 pagesPerformance Evaluation of Hollow Concrete Blocks Made with Sawdust Replacement of Sandkumar shantveerayyaNo ratings yet

- Use of Rice Husk Ash As Partial Replacement With CDocument4 pagesUse of Rice Husk Ash As Partial Replacement With Cabideenmaryam2017No ratings yet

- Development of A Stabilized Natural Fiber-ReinforcDocument9 pagesDevelopment of A Stabilized Natural Fiber-ReinforcMounia Ait Ben HamouNo ratings yet

- ThesisDocument62 pagesThesisWaquar TaiyebNo ratings yet

- Effect of Sawdust in ConcreteDocument4 pagesEffect of Sawdust in ConcretemadehNo ratings yet

- Case Studies in Construction Materials: Short CommunicationDocument8 pagesCase Studies in Construction Materials: Short Communicationrajaram huptaNo ratings yet

- A Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionDocument11 pagesA Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionIJRASETPublications100% (1)

- Mechanical Behaviour of Lateritic Soil Stabilized With Bone Ash and Hydrated Lime For Sustainable Building ApplicationsDocument13 pagesMechanical Behaviour of Lateritic Soil Stabilized With Bone Ash and Hydrated Lime For Sustainable Building ApplicationsjoNo ratings yet

- Shot-Earth For Sustainable Constructions PDFDocument13 pagesShot-Earth For Sustainable Constructions PDFFarida Diab SarmoukNo ratings yet

- New Soil Stabilization Research PaperDocument22 pagesNew Soil Stabilization Research PaperBhavsar NilayNo ratings yet

- Case Studies in Construction Materials: E.R. Grist, K.A. Paine, A. Heath, J. Norman, H. PinderDocument7 pagesCase Studies in Construction Materials: E.R. Grist, K.A. Paine, A. Heath, J. Norman, H. PinderTojcha TlalliNo ratings yet

- Vol. 49. No. 07 July 2022 第 49 卷第 07 期 2022 年 月 湖南大学学 报(自然科学版) Journal of Hunan University(Natural Sciences)Document29 pagesVol. 49. No. 07 July 2022 第 49 卷第 07 期 2022 年 月 湖南大学学 报(自然科学版) Journal of Hunan University(Natural Sciences)AnjaliNo ratings yet

- Cost Optimization of Geopolymer Concrete PavementDocument11 pagesCost Optimization of Geopolymer Concrete PavementIJRASETPublicationsNo ratings yet

- Ali Sarmah STOTENPaper2017Document10 pagesAli Sarmah STOTENPaper2017Terry McManamanNo ratings yet

- Study For The Relevance of Coconut Shell Aggregate Concrete Ooring TilesDocument11 pagesStudy For The Relevance of Coconut Shell Aggregate Concrete Ooring TilesSharanayya ShankinNo ratings yet

- Soil Stabilization Using Plastic Chips, Granules & Sugarcane Bagasse Ash Mixture-IJRASETDocument11 pagesSoil Stabilization Using Plastic Chips, Granules & Sugarcane Bagasse Ash Mixture-IJRASETIJRASETPublications100% (1)

- A Result Paper On Impacts of Using Sisal Fiber With Mineral Filler On Dense Bound MacadamDocument5 pagesA Result Paper On Impacts of Using Sisal Fiber With Mineral Filler On Dense Bound MacadamEditor IJTSRDNo ratings yet

- STABILIZING SOIL WITH INDUSTRIAL WASTESDocument15 pagesSTABILIZING SOIL WITH INDUSTRIAL WASTESvikas chawlaNo ratings yet

- An Experimental Study On Stabilization of Black Cotton Soil by Using Quarry Dust and Lime MixtureDocument3 pagesAn Experimental Study On Stabilization of Black Cotton Soil by Using Quarry Dust and Lime MixtureInnovative Research Publications100% (2)

- Stabilization of Clay With Using Waste Beverage Can: SciencedirectDocument5 pagesStabilization of Clay With Using Waste Beverage Can: SciencedirectArham SheikhNo ratings yet

- Mud-Concrete Slab System For Sustainable ConstructionDocument11 pagesMud-Concrete Slab System For Sustainable ConstructionrohanthaNo ratings yet

- Major Project A4Document22 pagesMajor Project A4Vamshi ChinthalaNo ratings yet

- Que Dou 2021Document18 pagesQue Dou 2021henryNo ratings yet

- Nagmani Final ProjectDocument34 pagesNagmani Final ProjectPrints BindingsNo ratings yet

- Abstrac 1Document5 pagesAbstrac 1aldousstack235No ratings yet

- Impact of Micro Silica Fume On Engineering Properties of Expansive SoilDocument6 pagesImpact of Micro Silica Fume On Engineering Properties of Expansive SoilIJSTENo ratings yet

- Research Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustDocument3 pagesResearch Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustjasimabdNo ratings yet

- Case Studies in Construction MaterialsDocument13 pagesCase Studies in Construction MaterialsLusman SulaimanNo ratings yet

- An Experimantal Study On Behaviour of Hollow Fly Ash ConcreteDocument7 pagesAn Experimantal Study On Behaviour of Hollow Fly Ash ConcreteMohamed Taher JebariNo ratings yet

- International Journal of EngineeringDocument8 pagesInternational Journal of EngineeringhhNo ratings yet

- Stabilization of Clay With Using Waste Beverage Can: SciencedirectDocument6 pagesStabilization of Clay With Using Waste Beverage Can: Sciencedirectrohmanzaky52No ratings yet

- Dissertation or Thesis Research Proposal Should Follow The Format GivenDocument4 pagesDissertation or Thesis Research Proposal Should Follow The Format GivenRajat JangirNo ratings yet

- Thesis Proposal 2014333059 & 2014333062Document11 pagesThesis Proposal 2014333059 & 2014333062Rakash MondalNo ratings yet

- Rice - Husk - Abhishek (1) .Docx 21Document29 pagesRice - Husk - Abhishek (1) .Docx 21Abhi ShekNo ratings yet

- Production of hollow blocks using waste plastic and sandDocument17 pagesProduction of hollow blocks using waste plastic and sandMauricio David Ruiz Odar100% (1)

- Comparative Study On Coconut Shell Aggregate With Conventional ConcreteDocument4 pagesComparative Study On Coconut Shell Aggregate With Conventional Concretepenta63No ratings yet

- Mechanical Behaviour of Composite Produced With Quarry DustDocument10 pagesMechanical Behaviour of Composite Produced With Quarry DustMiggy YangNo ratings yet

- Experimental Investigation of Concrete Using Coconut Shell As A Coarse Aggregate Replacement IJERTV6IS040769Document6 pagesExperimental Investigation of Concrete Using Coconut Shell As A Coarse Aggregate Replacement IJERTV6IS040769Chinni KranthiNo ratings yet

- Potential of Quarry Dust and Cow Dung As Stabilisers For Black Cotton Soil Eco-Blocks For HousingDocument9 pagesPotential of Quarry Dust and Cow Dung As Stabilisers For Black Cotton Soil Eco-Blocks For HousingChidananda GNo ratings yet

- Characteristicsofconcretecontaining EPSDocument30 pagesCharacteristicsofconcretecontaining EPSAhmed AhmedNo ratings yet

- Compressive Strength of Concrete by Using Coconut Shell: Parag S. Kambli, Sandhya R. MathapatiDocument7 pagesCompressive Strength of Concrete by Using Coconut Shell: Parag S. Kambli, Sandhya R. MathapatiIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Maraveas 2020 Production of Sustainable Construction MaterialsDocument29 pagesMaraveas 2020 Production of Sustainable Construction MaterialsGabriele MeloNo ratings yet

- Soils for Landscape Development: Selection, Specification and ValidationFrom EverandSoils for Landscape Development: Selection, Specification and ValidationRating: 5 out of 5 stars5/5 (1)

- Fire Safety High Rise Building PDFDocument23 pagesFire Safety High Rise Building PDFShubham SrivastavaNo ratings yet

- India International CentreDocument20 pagesIndia International CentreAnoop Sharma62% (13)

- Fire Safety High Rise Building PDFDocument25 pagesFire Safety High Rise Building PDFnunukantaNo ratings yet

- An Account of Critical Regionalism in Diverse Building Types in Postcolonial Indian ArchitectureDocument25 pagesAn Account of Critical Regionalism in Diverse Building Types in Postcolonial Indian ArchitectureShubham SrivastavaNo ratings yet

- Consider One of India's Premier Cultural InstitutionDocument14 pagesConsider One of India's Premier Cultural InstitutionShubham Srivastava0% (1)

- General ReqDocument19 pagesGeneral ReqVincent VivekNo ratings yet

- Indira Gandhi National Centre For The Arts: Janpath, New Delhi - 110 001Document4 pagesIndira Gandhi National Centre For The Arts: Janpath, New Delhi - 110 001Shubham SrivastavaNo ratings yet

- Fire Safety High Rise Building PDFDocument23 pagesFire Safety High Rise Building PDFShubham SrivastavaNo ratings yet

- Sample Letters PDFDocument6 pagesSample Letters PDFShubham SrivastavaNo ratings yet

- 1970 Illinois Constitution: Annotated For LegislatorsDocument149 pages1970 Illinois Constitution: Annotated For LegislatorsShubham SrivastavaNo ratings yet

- Congrats on being shortlisted for Blubirch's second roundDocument2 pagesCongrats on being shortlisted for Blubirch's second roundShubham SrivastavaNo ratings yet

- Amity University Lucknow CampusDocument23 pagesAmity University Lucknow CampusShubham SrivastavaNo ratings yet

- P Email For An InternshipDocument1 pageP Email For An InternshipShahrin KamaruzamanNo ratings yet

- Satyam SrivastavaDocument1 pageSatyam SrivastavaShubham SrivastavaNo ratings yet

- Shushtar New Town in Khuzestan, IranDocument37 pagesShushtar New Town in Khuzestan, IranShubham SrivastavaNo ratings yet

- Global WarmingDocument35 pagesGlobal WarmingShubham SrivastavaNo ratings yet

- Hreh PDFDocument178 pagesHreh PDFabs shakilNo ratings yet

- Sheet 3Document1 pageSheet 3Shubham SrivastavaNo ratings yet

- Índice de Desarrollo Humano de La ONUDocument286 pagesÍndice de Desarrollo Humano de La ONUMontevideo PortalNo ratings yet

- Scheme - Syllabus - Arch - 3rd - Sem - onwardsNNDocument95 pagesScheme - Syllabus - Arch - 3rd - Sem - onwardsNNShubham SrivastavaNo ratings yet

- Development of Compressed Stabilized Earth Block As An Eco-Friendly and Sustainable Wall Making MaterialDocument5 pagesDevelopment of Compressed Stabilized Earth Block As An Eco-Friendly and Sustainable Wall Making MaterialShubham SrivastavaNo ratings yet

- Ar2017weather PDFDocument144 pagesAr2017weather PDFbuzzzNo ratings yet

- SBSSTC Ferozepur: School OF ArchitectureDocument1 pageSBSSTC Ferozepur: School OF ArchitectureShubham SrivastavaNo ratings yet

- Shaheed Bhagat Singh State Technical Campus - FEROZEPUR: Urban Design - I Urban Design - IDocument1 pageShaheed Bhagat Singh State Technical Campus - FEROZEPUR: Urban Design - I Urban Design - IShubham SrivastavaNo ratings yet

- SBSSTC Ferozepur: School OF ArchitectureDocument1 pageSBSSTC Ferozepur: School OF ArchitectureShubham SrivastavaNo ratings yet

- Office ceiling, partition and counter detailsDocument1 pageOffice ceiling, partition and counter detailsShubham SrivastavaNo ratings yet

- SBSSTC Ferozepur: School OF ArchitectureDocument1 pageSBSSTC Ferozepur: School OF ArchitectureShubham SrivastavaNo ratings yet

- Office layout and detailsDocument1 pageOffice layout and detailsShubham SrivastavaNo ratings yet

- Office ceiling, partition and counter detailsDocument1 pageOffice ceiling, partition and counter detailsShubham SrivastavaNo ratings yet

- Preliminary Sewage Treatment ComponentsDocument3 pagesPreliminary Sewage Treatment ComponentsJudy Ann CastorNo ratings yet

- Fast Pyrolysis of Biomass A Handbook Volume 2 PDFDocument2 pagesFast Pyrolysis of Biomass A Handbook Volume 2 PDFMatthew0% (1)

- Blume, Alcohol Can Be A GasDocument1 pageBlume, Alcohol Can Be A GasBlack Hat100% (1)

- Waste Management: Materials Recovery FacilityDocument3 pagesWaste Management: Materials Recovery FacilityJanine Lorraine BritanicoNo ratings yet

- Plenary 2.1 LAGUNA DE BAY CASE STUDY FOR SUSTAINABLE FISHERIES DEVELOPMENTDocument49 pagesPlenary 2.1 LAGUNA DE BAY CASE STUDY FOR SUSTAINABLE FISHERIES DEVELOPMENTRelie ArambuloNo ratings yet

- EPA PCB Inspection ManualDocument346 pagesEPA PCB Inspection ManualdtausdemoreNo ratings yet

- Lca CDMDocument9 pagesLca CDMnghiasipraNo ratings yet

- 4 Vertical Shaft Brick Kiln (VSBK) PDFDocument4 pages4 Vertical Shaft Brick Kiln (VSBK) PDFhoangpalestineNo ratings yet

- Persuasive Speech - DonkinDocument2 pagesPersuasive Speech - Donkinapi-314977937No ratings yet

- Sewer and Sewerage System PDFDocument87 pagesSewer and Sewerage System PDFSky Blue100% (2)

- AcknowledgementDocument4 pagesAcknowledgementGarima RajpurohitNo ratings yet

- Code of Practice on Sewerage and Sanitary WorksDocument15 pagesCode of Practice on Sewerage and Sanitary WorksSteven PohNo ratings yet

- Biogas in The Netherlands: From A Innovation System PerspectiveDocument12 pagesBiogas in The Netherlands: From A Innovation System PerspectiveSanne de GrootNo ratings yet

- Malawi Climate Change PresentationDocument14 pagesMalawi Climate Change PresentationOxfam Youth and SchoolsNo ratings yet

- Sustainable Landfills: The Future of Land Disposal of Municipal Solid Waste (MSW)Document29 pagesSustainable Landfills: The Future of Land Disposal of Municipal Solid Waste (MSW)Andre Suito100% (1)

- 04 - Oxygen Demand PDFDocument25 pages04 - Oxygen Demand PDFEruvin Ike SumisuNo ratings yet

- 01.1 Malthus Vs BoserupDocument19 pages01.1 Malthus Vs BoserupJoanNo ratings yet

- Redesigning BoilersDocument28 pagesRedesigning BoilersProjectsNo ratings yet

- ST Lucia Lead Acid Battery Recycling Program3Document47 pagesST Lucia Lead Acid Battery Recycling Program3Nurul HidayahNo ratings yet

- Listening Comprehension TaskDocument1 pageListening Comprehension TaskAngie AyureNo ratings yet

- Solid Waste Management A Case Study of Jaipur City IJERTCONV4IS23003Document4 pagesSolid Waste Management A Case Study of Jaipur City IJERTCONV4IS23003manjuNo ratings yet

- The Shadow of Urbanization: Infrastructure Planning for Guwahati's Peri-Urban InterfaceDocument2 pagesThe Shadow of Urbanization: Infrastructure Planning for Guwahati's Peri-Urban InterfaceYASH PRAJAPATINo ratings yet

- My Seminar ReportDocument20 pagesMy Seminar Reportsudhir_9219956000% (2)

- 1 MLD STP Layout-ModelDocument1 page1 MLD STP Layout-Modelgnbuildtech Pvt ltdNo ratings yet

- How The Global Appetite For Sand Is Fuelling A CrisisDocument4 pagesHow The Global Appetite For Sand Is Fuelling A CrisisTushar AgrawalNo ratings yet

- Strategy For Sustainability Management in The UN System 2020-2030Document4 pagesStrategy For Sustainability Management in The UN System 2020-2030Environmental Governance Programme (EGP) for Sustainable Natural Resource ManagementNo ratings yet

- Joint Proposal To Complete Record For Phase 1 and Phase 2Document13 pagesJoint Proposal To Complete Record For Phase 1 and Phase 2L. A. PatersonNo ratings yet

- Dpo 2018-03-000 (Anti Littering)Document5 pagesDpo 2018-03-000 (Anti Littering)Mary Chris100% (1)

- Nitrogen, Ammonia: Salicylate Method Method 8155 0.01 To 0.80 MG/L NH - N Powder PillowsDocument8 pagesNitrogen, Ammonia: Salicylate Method Method 8155 0.01 To 0.80 MG/L NH - N Powder PillowsFlor LopezNo ratings yet

- Water Unit 1-NotesDocument35 pagesWater Unit 1-NotesEng Venance MasanjaNo ratings yet