Professional Documents

Culture Documents

Format For Startups - KAU RABI PDF

Uploaded by

cmashtamoorthyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Format For Startups - KAU RABI PDF

Uploaded by

cmashtamoorthyCopyright:

Available Formats

Steel Wool

<<LOW COST SOLAR AIR HEATER LOGO

Focus Area- State: Kerala Drying

Chamber at

Renewable Energy

Baffles

outlet

Stage: MVP(Prototype)

Problem Statement

Paste PICTURE 1

• High initial investment for a solar air heater due to expensive materials

and labour intensive fabrication.

• Solar radiation is highly varying from season to season and also Steel Wool

throughout a day. (absorber)

Fan at the

• This level of instability and high investment is not a cost effective and Technology

Polyethylene Foam

inlet

better solution for drying.

Technology Description Prototype Arrangement

• A solar air heater can absorb the solar heat energy and utilize it to produce hot air. Hot air is circulated in a drying

chamber where agricultural crops are kept.

• Our cost effective solution: Use locally available and cheaper materials with a design compatible for mass production.

• The objectives include: identification of raw material, design, manufacturing and performance analysis.

• Developed a prototype with cheaper materials as shown in figure.

Incubated at: KAU RAFTAAR Agri Business Incubator, Thrissur, Kerala

LOW COST SOLAR AIR HEATER LOGO

Pilot/ trials conducted USP

• Prototype is developed and tested on

February and March 2020. • Low cost: Approximate cost of a solar air heater in market with 2 m2

• Average CO2 emission savings: 1 tonne area - ₹ 80,000- ₹ 90,000

CO2 will be reduced by replacing an

.Proposing Design- ₹15,000- ₹16,000

electric heater with this prototype. • Compatible design for mass production

• Average Units generated in a day: 4.4 • Technical support, quality assurance and certification.

kWh

• Average payback period: 1.72 years

Unit Sold till date: ___Nil__ Units Revenue: Rs__0___ Number of Customers: _0___

Unit Costs

Rs. 15,500

Incubated at: KAU RAFTAAR Agri Business Incubator, Thrissur, Kerala

You might also like

- Type Test Report: ClientDocument28 pagesType Test Report: ClientcerkadilerNo ratings yet

- HPC 4dl 07 0011 2014 DCT HV Pilc Screened Cables WithdrawnDocument4 pagesHPC 4dl 07 0011 2014 DCT HV Pilc Screened Cables WithdrawncmashtamoorthyNo ratings yet

- 00-N - Commu-Atv 61Document209 pages00-N - Commu-Atv 61cmashtamoorthyNo ratings yet

- GU - Cabine MT BT (EN) - 1VCP000591 1511Document88 pagesGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariNo ratings yet

- June 30, 2010Document41 pagesJune 30, 2010TTPL ProjectsNo ratings yet

- CPWD Works Manual 2019: DraftDocument63 pagesCPWD Works Manual 2019: DraftSagar SoibamNo ratings yet

- Atv61 Programming Manual en 1760649 07Document263 pagesAtv61 Programming Manual en 1760649 07ytran_hatinh2071No ratings yet

- Star Delta DiagramDocument2 pagesStar Delta Diagramgarv84090% (10)

- 04-Industry-1540386707 WiproDocument20 pages04-Industry-1540386707 WiprocmashtamoorthyNo ratings yet

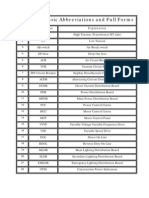

- Electrical Abbreviations and Full FormsDocument5 pagesElectrical Abbreviations and Full Formsraja.shriram89% (125)

- Electrical Abbreviations and Full FormsDocument5 pagesElectrical Abbreviations and Full Formsraja.shriram89% (125)

- Format For Startups - KAU RABI PDFDocument2 pagesFormat For Startups - KAU RABI PDFcmashtamoorthyNo ratings yet

- June 30, 2010Document41 pagesJune 30, 2010TTPL ProjectsNo ratings yet

- Safety Requirements For COM of Electrical Plants & LinesDocument20 pagesSafety Requirements For COM of Electrical Plants & LinesRami ReddyNo ratings yet

- State Wise Data: Table NoDocument17 pagesState Wise Data: Table Nosameer bakshiNo ratings yet

- ATV61S Installation Manual en 1760643 06Document49 pagesATV61S Installation Manual en 1760643 06ainur romadhoniNo ratings yet

- Altivar 61: Communication Parameters User's ManualDocument132 pagesAltivar 61: Communication Parameters User's ManualsimbamikeNo ratings yet

- Routine Verification Checklist ABBDocument5 pagesRoutine Verification Checklist ABBMustapha HadjriNo ratings yet

- Routine Test Report Sheet 1: Power Switchgear and Controlgear Assembly (PSC)Document1 pageRoutine Test Report Sheet 1: Power Switchgear and Controlgear Assembly (PSC)Mustapha HadjriNo ratings yet

- Report For Routine Verification (Routine Test Report) : Power Switchgear and Controlgear AssemblyDocument3 pagesReport For Routine Verification (Routine Test Report) : Power Switchgear and Controlgear AssemblywaqarNo ratings yet

- Gambia - AEWA PROJECT Final REPORT PDFDocument14 pagesGambia - AEWA PROJECT Final REPORT PDFAhmed ZeravaniNo ratings yet

- Cold Work PermitDocument1 pageCold Work PermitcmashtamoorthyNo ratings yet

- Witnessed Routine Test Report Form PDFDocument8 pagesWitnessed Routine Test Report Form PDFSyed Mahaboob BashaNo ratings yet

- Altivar 61: Metasys N2 User's ManualDocument35 pagesAltivar 61: Metasys N2 User's ManualcmashtamoorthyNo ratings yet

- T & C For Google Bundled OfferDocument2 pagesT & C For Google Bundled OffercmashtamoorthyNo ratings yet

- Motor Manufacturing Process FlowDocument8 pagesMotor Manufacturing Process FlowcmashtamoorthyNo ratings yet

- NEMA Locked Motor CodesDocument1 pageNEMA Locked Motor CodescmashtamoorthyNo ratings yet

- NEMA Locked Motor CodesDocument1 pageNEMA Locked Motor CodescmashtamoorthyNo ratings yet

- T & C For Google Bundled OfferDocument2 pagesT & C For Google Bundled OffercmashtamoorthyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Unit5 TestDocument3 pagesUnit5 TestAndrea MészárosnéNo ratings yet

- FALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewDocument51 pagesFALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewVAHEESNo ratings yet

- Location: Map of Naga CityDocument2 pagesLocation: Map of Naga Citycatherine boragayNo ratings yet

- Assessment in The Affective DomainDocument19 pagesAssessment in The Affective DomainChano MorenoNo ratings yet

- ChartDocument27 pagesChartFlorijan ŠafarNo ratings yet

- Resectoscopio 8677 Richard WolfDocument25 pagesResectoscopio 8677 Richard WolfManuel FloresNo ratings yet

- JAMB Biology Past Questions 1983 - 2004Document55 pagesJAMB Biology Past Questions 1983 - 2004Keith MooreNo ratings yet

- iGCSE Biology Section 1 Lesson 1Document44 pagesiGCSE Biology Section 1 Lesson 1aastha dograNo ratings yet

- QuestionnaireDocument2 pagesQuestionnaireMili Gada100% (8)

- Lithium Battery Handling RegulationDocument11 pagesLithium Battery Handling RegulationFan Man ChungNo ratings yet

- Dental Hygienist Learning Outcomes Form v1.2Document32 pagesDental Hygienist Learning Outcomes Form v1.2Karman Deep Singh100% (1)

- Ball Bearing Units Stainless SeriesDocument5 pagesBall Bearing Units Stainless SeriesRicardo KharisNo ratings yet

- School Administration and Supervision MAED 605Document24 pagesSchool Administration and Supervision MAED 605Jaynie Ann TapdasanNo ratings yet

- Review Related LiteratureDocument3 pagesReview Related LiteratureHanz EspirituNo ratings yet

- P13Document21 pagesP13Saeful AzizNo ratings yet

- (Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFDocument441 pages(Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFMuhammad AliNo ratings yet

- Msds M-Toluoyl ChlorideDocument4 pagesMsds M-Toluoyl ChloridecrisNo ratings yet

- Jean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Document209 pagesJean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Mi na100% (1)

- Astm c126 Jtvo9242Document5 pagesAstm c126 Jtvo9242Nayth Andres GalazNo ratings yet

- Child DevelopmentDocument12 pagesChild DevelopmentPija Mohamad100% (1)

- ControllingDocument3 pagesControllingGenesis_Y_Gall_6808No ratings yet

- Notice: Environmental Statements Availability, Etc.: Syngenta Crop Protection, Inc., Et Al.Document8 pagesNotice: Environmental Statements Availability, Etc.: Syngenta Crop Protection, Inc., Et Al.Justia.comNo ratings yet

- 5754 Almg3 5754 Almg3 Almg3 Almg3 5754 Almg3 Almg3 Almg3 Almg3Document3 pages5754 Almg3 5754 Almg3 Almg3 Almg3 5754 Almg3 Almg3 Almg3 Almg3InfoNo ratings yet

- A Little BookDocument75 pagesA Little Bookfati_cenNo ratings yet

- Test Unit 2 Urbanisation L P 12Document9 pagesTest Unit 2 Urbanisation L P 12Xuân NguyenNo ratings yet

- B 700 FDocument25 pagesB 700 FMohammed HdyliNo ratings yet

- Matriculation Chemistry Amino Acids-Part-1Document24 pagesMatriculation Chemistry Amino Acids-Part-1iki292No ratings yet

- Steel Scrap Recycling Policy 06.11.2019 PDFDocument31 pagesSteel Scrap Recycling Policy 06.11.2019 PDFAnshul SableNo ratings yet

- Marine Turtle Survey Along The Sindh CoastDocument106 pagesMarine Turtle Survey Along The Sindh CoastSyed Najam Khurshid100% (1)

- Impact of Odor From A Landfill Site On Surrounding Areas: A Case Study in Ho Chi Minh City, VietnamDocument11 pagesImpact of Odor From A Landfill Site On Surrounding Areas: A Case Study in Ho Chi Minh City, VietnamNgọc HảiNo ratings yet