Professional Documents

Culture Documents

Liebherr L550-L586 enUS 11-07 9713-0 PDF

Uploaded by

shankers_1999Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebherr L550-L586 enUS 11-07 9713-0 PDF

Uploaded by

shankers_1999Copyright:

Available Formats

Wheel Loaders L 550 - L 586

Tipping Load, articulated: 25,680 lb – 45,040 lb

L550L586_US_09_11.indd 1 02.09.11 11:58

L 550 L 556 L 566

Tipping Load, articulated: 2

5,680 lb Tipping Load, articulated: 28,970 lb Tipping Load, articulated: 34,280 lb

Bucket Capacity: 4.2 yd³ Bucket Capacity: 4.7 yd³ Bucket Capacity: 5.2 yd³

Operating Weight: 36,430 lb Operating Weight: 38,070 lb Operating Weight: 49,600 lb

Engine Output: 173 HP*/129 kW Engine Output: 188 HP*/140 kW Engine Output: 255 HP*/190 kW

L 580 L 586

Tipping Load, articulated: 3

9,680 lb Tipping Load, articulated: 45,040 lb

Bucket Capacity: 6.5 yd³ Bucket Capacity: 7.2 yd³

Operating Weight: 54,190 lb Operating Weight: 69,180 lb

Engine Output: 268 HP*/200 kW Engine Output: 335 HP*/250 kW

* according to SAE J1349

2 L 550 – L 586

L550L586_US_09_11.indd 2 02.09.11 11:58

Economy Reliability

The Liebherr driveline reduces wheel loader fuel All the materials used in the Liebherr wheel loaders

consumption by 25 % or more when compared to have passed extensive tests to ensure that they meet

conventional travel gears! Liebherr’s exacting standards even in the toughest

conditions. The advanced concept and proven quality

Performance make Liebherr wheel loaders the benchmark for

The Liebherr driveline allows the Liebherr diesel engine reliability.

to be mounted lengthways in the rear, with the output

shaft facing backwards. Compared to conventionally Comfort

driven wheel loaders, the operating weight is much The ultra-modern cab design with advanced ergonomics,

lower, the tipping load is higher, and more material can continuously variable Liebherr driveline for uninterrupted

be moved each operating hour. tractive force, standard Liebherr ride control, optimum

weight distribution and easy service access due to

unique engine installation lead to extraordinary overall

comfort.

L 550 – L 586 3

L550L586_US_09_11.indd 3 02.09.11 11:58

Lower fuel consumption

• Up to 25% less fuel consumption

5 when compared to conventional

n=? drive machines.

B

2,5 m

35

4 • The Liebherr wheel loaders

30 demonstrate their fuel economy in

T ~ 35 sec.

3 the Liebherr standard normtest.

20 m

25

2

20

15 A 1

4 L 550 – L 586

L550L586_US_09_11.indd 4 02.09.11 11:58

Economy

The Liebherr driveline reduces wheel loader fuel consumption by 25 % or more

when compared to conventional drive machines.

Low operating costs

Minimum costs, Liebherr wheel loaders are unbeatable for economy

High handling capacity compared to conventionally driven wheel loaders.

This is due to the following factors:

− Low fuel consumption thanks to higher efficiency

and low operating weight.

− Practically no brake wear thanks to the hydraulic

braking action of the driveline; this ultimately

reduces repair costs.

− Reduced tire wear due to continuous traction

control. Depending on the working conditions,

there is up to 25 % less wear.

Active environmental protection

Economical use The reduction in fuel lowers emissions, thus

of resources actively protecting resources:

0.3 gal of fuel produces up to 7 lb of carbon dioxide

(CO2). By saving up to 1.3 gal per operating hour,

up to 33,069 lb less CO2 is produced in 1,000

operating hours. Not only are operating costs

reduced but the environment also benefits from

the drastically reduced emissions.

Low noise emission The innovative driveline concept means much

lower noise emission – Liebherr wheel loaders are

significantly quieter in operation.

Reduced brake wear Reduced tire wear

• Even under the toughest working • The tractive force can be adjusted

conditions, the Liebherr travel drive continuously. This stops wheel spins

always brakes hydraulically. The and reduces tire wear by up to 25 %.

mechanical service brake only acts

as a support and is therefore subject

to hardly any wear.

L 550 – L 586 5

L550L586_US_09_11.indd 5 02.09.11 11:58

Liebherr driveline

• Optimum weight distribution thanks

to lengthways-installed Liebherr

diesel engine, output shaft is facing

the rear.

• The variable displacement pumps

on the engine act as counterweight,

thus allowing higher tipping loads

at low operating weight.

• Compact design improves visibility

in all directions.

6 L 550 – L 586

L550L586_US_09_11.indd 6 02.09.11 11:59

Performance

The Liebherr driveline allows the Liebherr diesel engine to be mounted

lengthways in the rear, with the output shaft facing backwards. Compared to

conventionally driven wheel loaders, the operating weight is much lower, the

tipping load is higher, and more material can be moved each operating hour.

Higher performance, lower weight

Higher productivity The combination of the Liebherr driveline and the

unique position of the Liebherr diesel engine allows

higher tipping loads at low operating weight. This

leads to significantly higher productivity because

there is no need for unnecessary counterweight.

Ultra modern Liebherr driveline

Innovative technology Tractive force and speed are automatically

adjusted to the requirements of the operator

without shifting. There is no need for a mechanical

reverse gear because the travel direction is

changed hydraulically.

Flexibility puts them ahead

An all-purpose loader The Industrial lift arm is the ideal tool to complement

the available equipment for the large Liebherr

wheel loaders. This „torque increase“ is the

perfect additional system for your requirements,

especially when operating with heavy equipment

and loads. Their compact design allows these

wheel loaders to maneuver quickly and efficiently

– ideal for handling large volume of material.

Conventional travel gear An all-purpose loader

• Longitudinally mounted diesel engine • The choice between Industrial lift arm

moves the center of gravity further forward. or Z pattern linkage means that the

loader can always be configured for

• Additional counterweight is needed to

every job application – Industrial lift

maintain stability and to increase the

arm for operations with heavy work

tipping load.

arrangements; Z for conventional

• This results in high operating weight material handling.

and poor visibility.

L 550 – L 586 7

L550L586_US_09_11.indd 7 02.09.11 11:59

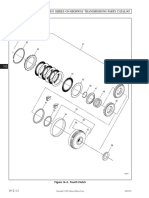

Liebherr driveline

• The Liebherr driveline consists

of two hydraulic motors which

accelerate the loader continuously

from a standstill to maximum

speed, either forwards or in

reverse but without a reversing

gear unit.

8 L 550 – L 586

L550L586_US_09_11.indd 8 02.09.11 11:59

Reliability

All the materials used in the Liebherr wheel loaders have passed extensive tests

to ensure that they meet Liebherr’s exacting standards even in the toughest

conditions. The advanced concept and proven quality make Liebherr wheel

loaders the benchmark for reliability.

Reliable Liebherr driveline

Fewer components The Liebherr driveline includes a self-locking

hydraulic brake, which means the additional wet

brake discs are effectively wear-free. There is no

need for a reversing gear unit – thus minimizing the

number of parts susceptible to wear.

Controlled cooling

The intelligent answer The cooling fan is not driven directly from the

Liebherr diesel engine and produces only the

cooling air output which is actually required. Heat

sensors ensure reliable control. If overheating

should occur, the wheel loader automatically shifts

down to first travel speed range. The reduced

power consumption protects the engine from

overheating. At the same time, the fan speed is

increased to maximum value, thus preventing the

engine from overheating.

Components meet manufacturer’s

quality standards

Everything from Important components such as the engine,

a single source hydraulic cylinders and electronics are developed

and manufactured by Liebherr itself. This ensures

co-ordinated quality from the manufacturer down to

the smallest detail. Liebherr components guarantee

maximum performance and reliability.

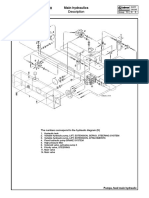

Cooling system Liebherr’s own components

• The cooling system is fitted on the rear • Liebherr has many years of experience

section between the diesel engine and in design, development and construction

the operator’s cab. The cooling air is of diesel engines, hydraulic cylinders and

drawn in directly behind the cab and electronic components. They are matched

blown out upwards at the rear. The fan together down to the smallest detail

speed is varied automatically by heat to guarantee optimum interaction and

sensors that determine the amount of performance.

cooling needed.

• The reversible fan drive is a standard

feature.

L 550 – L 586 9

L550L586_US_09_11.indd 9 02.09.11 11:59

Liebherr control lever

• The Liebherr control lever is used to manage all travel and

working movements of the wheel loader, so that the operator’s

left hand can always remain on the steering wheel. There is no

need to let go of the steering wheel increasing overall safety.

The operator controls the following functions with his right hand:

– Raise and lower attachment

– Fill and dump the bucket

– Automatic bucket return to dig

– Kick down and Gear Hold function

– Auxiliary control buttons for additional hydraulic functions

– Change of travel direction with simultaneous travel start

10 L 550 – L 586

L550L586_US_09_11.indd 10 02.09.11 11:59

Comfort

The ultra modern cab design with advanced ergonomics, continuously variable

Liebherr driveline for uninterrupted tractive force, standard Liebherr ride control,

optimum weight distribution and easy service access due to unique engine

installation position lead to extraordinary overall comfort.

First-class cab design

Comfort cab The ultra-modern, ergonomically planned cab

design allows the operator to achieve better

performance and productivity in the greatest

possible comfort. The displays, controls and

operator’s seat are carefully coordinated to form a

perfect ergonomic unit.

Liebherr control lever All the working and travel functions are operated

precisely and sensitively from a single control lever.

This means accurate and safe handling, and the left

hand always remains on the steering wheel. This

increases the safety at the job site.

Liebherr driveline

Continuously variable The Liebherr driveline allows continuous regulation

transmission of acceleration in all speed ranges, without

noticeable gear shifting or interruption in tractive

force.

Service access

Easy maintenance Because the Liebherr diesel engine is rotated by

180°, the hydraulic pumps, hydraulic tank, hydraulic

tank cut-off valve, air filter and battery main switch

can be reached easily and safely from ground level

by opening a single engine compartment hood. The

engine, pump distributor gear and cooling system

are easily accessible by opening the engine cover.

Hydrostatic fan drive The cooling system is positioned directly behind the

cab, which means there is less dirt and therefore

less maintenance and cleaning resulting in time

and cost savings!

Service access Powerful air-conditioning system

• The unique position of the Liebherr diesel • The standard equipped air-conditioning system

engine provides perfect accessibility for of the large wheel loaders provides the greatest

maintenance. The hydraulic pumps, hydraulic operator comfort for high productivity.

tank, hydraulic tank cut-off valve and

• The air flow is controlled at 4 different levels

battery main switch can be easily and safely

– an automatic air-conditioning system is

accessed from ground level by opening a

available as an option.

single engine compartment hood.

– Air flow in the foot area

– Defroster

– Air flow in the head area

– Air flow in the body area

L 550 – L 586 11

L550L586_US_09_11.indd 11 02.09.11 11:59

Technical Data

L 550 – L 580

Engine L 550 L 556 L 566 L 580 Attachment Hydraulics

Liebherr diesel engine _____________ D934S A6 D934S A6 D936L A6 D936L A6 Design ______________________________ “Load-sensing” swash plate type variable flow pump

Design _________________________ Liebherr diesel engine, water-cooled, exhaust turbo with output and flow control, and pressure cut-off in

charged with intercooler the control block

Cylinder inline ________________ 4 4 6 6 Cooling _____________________________ Hydraulic oil cooling using thermostatically controlled

Combustion process ________ PLD fan and oil cooler

Rated output according Filtering _____________________________ Return line filter in the hydraulic reservoir

to SAE J1349 ________ HP/kW 173/129 188/140 255/190 268/200 Control ______________________________ “Liebherr-Joystick” with hydraulic servo control

at rpm 2,000 2,000 2,000 2,000 Lift circuit ___________________________ Lifting, neutral, lowering

Max. torque ______________ lb ft 611 664 907 974 and float positions controlled by Liebherr joystick

at rpm 1,500 1,300 1,300 1,300 with detent

Displacement _____________ in3 388 428 642 642 Tilt circuit ___________________________ Tilt back, neutral, dump

Bore/Stroke ________________ in 4.8”/5.35” 4.8”/5.91” 4.8”/5.91” 4.8”/5.91” automatic bucket positioning

Air cleaner __________________________ Dry type with main and safety element, pre-cleaner, L 550 L 556 L 566 L 580

service indicator on LCD display Max. flow _____________________ gpm 62 62 77 77

Electrical system Max. pressure __________________ psi 4,206 4,786 5,076 5,076

Operating voltage __________ V 24 24 24 24

Capacity___________________ Ah 143 143 170 170

Alternator_________________ V/A 28/80 28/80 28/80 28/80

Starter motor ___________ V/HP 24/9 24/9 24/9 24/9

The exhaust emissions are below the limits in stage IIIA / Tier 3.

Attachment

Geometry ___________________________ Powerful Z-pattern linkage with tilt cylinder and cast

steel cross-tube

Bearings ____________________________ Sealed

Cycle time at nominal load _______ L 550 L 556 L 566 L 580

Travel Drive Z-bar linkage

Lifting __________________________ 5.5 s 5.5 s 5.5 s 5.5 s

Stepless hydrostatic travel drive Dumping ______________________ 2.3 s 2.3 s 2.0 s 2.0 s

Design ________________________ Swash plate type variable flow pump and two variable Lowering (empty) _____________ 2.7 s 2.7 s 3.5 s 3.5 s

axial piston motors in closed loop circuit with one axle Industrial lift arm

transfer case. Direction of travel is reversed by changing Lifting __________________________ 5.5 s 5.5 s 5.5 s 5.5 s

the flow-direction of the variable-displacement pump Dumping ______________________ 3.5 s 3.5 s 3.5 s 3.5 s

Filtering system ______________ Suction return line filter for closed circuit Lowering (empty) _____________ 2.7 s 2.7 s 3.5 s 3.5 s

Control ________________________ By travel and inching pedal. The inching pedal makes

it possible to control the tractive and directional

forces steplessly at full engine speed. The Liebherr

joystick is used to control forward and reverse travel

Travel speed range ________________ Speed range 1 _____________________________ 0 – 6.2 mph

Speed range 2 and A2 ____________________ 0 – 12.4 mph Operator’s Cab

Speed range A3 ___________________________ 0 – 24.9 mph

The quoted speeds apply with the tires that are Design ______________________________

On elastic bearing on rear section, soundproof

standard equipment on the loader ROPS/FOPS cab. Operator’s door with optional

sliding window, 180° opening angle, fold-out window

on right site with opening angle, front windscreen

made of compound safety glass, green tinted as

standard, side windows made of single-pane safety

Axles glass, grey tinted, continuously adjustable steering

column and joystick control as standard, heatable

Four-wheel drive rear window

Front axle ___________________________ Fixed ROPS roll over protection per DIN/ISO 3471/EN 474-3

Rear axle ____________________________ Center pivot, with 13° oscillating angle to each side FOPS falling objects protection per DIN/ISO 3449/

L 550 L 556 L 566 L 580 EN 474-1

Height of obstacles which

can be driven over ___________ 1’8” 1’8” 1’8” 1’8” Operator’s seat ____________________ 6 way adjustable seat with lap belt, vibration damping

With all four wheels remaining in contact with the and suspension adjustable for the operator’s weight

ground Cab heating and ventilation _______ Operator’s cab with 4-level air control, cooling water

Differentials _________________________ Automatic limited-slip differentials heating, defroster and air conditioning with electronic

Reduction gear _____________________ Planetary final drive in wheel hubs valve control, as well as electronic fresh/recirculated

Track width _________________________ 6’7” with all types of tires (L 550, L 556) air control, filter system with pre-filter, fresh air

7’4” with all types of tires (L 566, L 580) filter and recirculated air filter, easily replaced,

air conditioning as standard

Brakes

Noise Emission

Wear-free service brake ___________ Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator L 550 L 556 L 566 L 580

brake system with wet multi-disc brakes located in ISO 6396

the wheel hubs (two separate brake circuits) LpA (inside cab) _______________ 69 dB(A) 69 dB(A) 69 dB(A) 69 dB(A)

Parking brake ______________________ Electro-hydraulically actuated spring-loaded brake 2000/14/EC

system on the transmission LWA (surround noise) _________ 104 dB(A) 104 dB(A) 105 dB(A) 105 dB(A)

The braking system meets the requirements of the EC guidelines 71/320.

Capacities

Steering

L 550 L 556 L 566 L 580

Design ______________________________

“Load-sensing” swash plate type variable flow pump Fuel tank ________________________ gal 67.3 67.3 92.4 92.4

with pressure cut-off and flow control. Central pivot Engine oil

with two double-acting, damped steering cylinders (including filter change) ________ gal 8.2 8.2 11.4 11.4

Angle of articulation _______________ 40° (to each side) Pump distributor gears ________ gal 0.7 0.7 0.7 0.7

Emergency steering _______________ Electro-hydraulic emergency steering system Transmission ___________________ gal 3.0 3.0 3.0 3.0

Coolant _________________________ gal 11.9 11.9 13.7 13.7

Front axle _______________________ gal 7.9 10.0 13.5 15.3

Rear axle ________________________ gal 7.9 7.9 13.5 13.2

Hydraulic tank __________________ gal 35.7 35.7 35.7 35.7

Hydraulic system, total ________ gal 63.4 63.4 68.7 68.7

Air-condition system R134a __ lb 1.7 1.7 1.7 1.7

12 L 550 – L 586

NTB_L550-586_T_enUS_05.indd 12 02.09.11 12:04

Dimensions

Z-bar linkage

L 550 – L 580

65°

45°

E

F

D

C

B

A I H

49º

J

K

G

L

Loading Bucket L 550 L 556 L 566 L 580

Cutting tools T T T T T T T T

Lift arm length ft in 8’6” 8’6” 8’6” 8’6” 9’7” 9’7” 10’ 10’

Bucket capacity according to ISO 7546 ** yd3 4.2 4.7 4.7 5.0 5.2 5.9 6.5 7.2

Bucket width ft in 8’10” 8’10” 8’10” 8’10” 9’10” 9’10” 10’10” 10’10”

Specific material weight lb/yd3 3,034 2,697 3,034 2,697 3,034 2,697 3,034 2,697

A Dumping height at max. lift height and 45° discharge ft in 9’5” 9’2” 9’4” 9’1” 10’8” 10’5” 10’11” 10’8”

B Dump-over height ft in 11’6” 11’6” 11’6” 11’6” 12’10” 12’10” 13’5” 13’5”

C Max. height of bucket bottom ft in 12’ 12’ 12’ 12’ 13’3” 13’3” 14’ 14’

D Max. height of bucket pivot point ft in 12’10” 12’10” 12’10” 12’10” 14’4” 14’4” 15’ 15’

E Max. operating height ft in 17’8” 17’9” 17’11” 18’ 19’3” 19’7” 20’10” 21’1”

F Reach at max. lift height and 45° discharge ft in 3’7” 4’ 3’10” 4’1” 3’10” 4’1” 3’9” 4’

G Digging depth ft in 3” 3” 3” 3” 4” 4” 4” 4”

H Height above cab ft in 11’ 11’ 11’ 11’ 11’8” 11’8” 11’8” 11’8”

I Height above exhaust ft in 9’10” 9’10” 9’10” 9’10” 10’2” 10’2” 10’2” 10’2”

J Ground clearance ft in 1’9” 1’9” 1’9” 1’9” 1’10” 1’10” 1’10” 1’10”

K Wheelbase ft in 10’9” 10’9” 10’9” 10’9” 11’9” 11’9” 12’2” 12’2”

L Overall length ft in 27’ 27’ 27’ 27’5” 29’3” 29’6” 30’6” 30’10”

Turning circle radius over outside bucket edge ft in 21’1” 21’2” 21’2” 21’3” 23’3” 23’4” 24’4” 24’5”

Breakout force (SAE) lbf 28,101 26,527 29,225 26,977 44,962 42,714 39,342 35,969

Tipping load, straight * lb 29,112 28,859 32,826 32,297 39,000 37,501 44,952 44,070

Tipping load, articulated at 37° * lb 26,158 25,937 29,431 28,957 34,943 33,598 40,411 39,617

Tipping load, articulated at 40° * lb 25,684 25,463 28,968 28,505 34,282 32,959 39,683 38,912

Operating weight * lb 36,431 36,575 38,073 38,184 49,604 49,880 54,190 54,520

Tire sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

** Actual bucket capacity may be approx. 10 % larger than the calculation according to ISO 7546 standard. The degree to which the bucket can

be filled depends on the material – see page 24.

= Excavation bucket with back grading edge

= Rehandling bucket

T = Welded-on tooth holder with add-on teeth

L 550 – L 586 13

NTB_L550-586_T_enUS_05.indd 13 02.09.11 12:04

Dimensions

Industrial lift arm

L 550 – L 580

49°

45°

E

F

D

C

B

A I H

48º

K

G

L

Loading Bucket L 550 L 556

Geometry IND IND

Cutting tools T T

Lift arm length ft in 8’6” 8’6”

Bucket capacity according to ISO 7546 ** yd3 3.9 4.3

Bucket width ft in 8’10” 8’10”

Specific material weight lb/yd3 3,034 3,034

A Dumping height at max. lift height and 45° discharge ft in 9’6” 9’4”

B Dump-over height ft in 11’6” 11’6”

C Max. height of bucket bottom ft in 12’5” 12’5”

D Max. height of bucket pivot point ft in 13’4” 13’4”

E Max. operating height ft in 18’4” 18’5”

F Reach at max. lift height and 45° discharge ft in 3’9” 3’10”

G Digging depth ft in 3” 3”

H Height above cab ft in 11’ 11’

I Height above exhaust ft in 9’10” 9’10”

J Ground clearance ft in 1’9” 1’9”

K Wheelbase ft in 10’9” 10’9”

L Overall length ft in 27’3” 27’5”

Turning circle radius over outside bucket edge ft in 21’3” 21’4”

Breakout force (SAE) lbf 28,101 29,225

Tipping load, straight * lb 27,095 30,115

Tipping load, articulated at 37° * lb 24,361 27,039

Tipping load, articulated at 40° * lb 23,920 26,565

Operating weight * lb 37,346 39,110

Tire sizes 23.5R25 L3 23.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

= Excavation bucket with back grading edge for hydraulic quick coupler

IND = Industrial lift arm with parallel guidance including hydraulic quick coupler (only available for L 550 and L 556)

T = Welded-on tooth holder with add-on teeth

14 L 550 – L 586

NTB_L550-586_T_enUS_05.indd 14 02.09.11 12:04

Dimensions

High Lift

L 550 – L 580

E

D

F

B

A

H

I

K

G

L

High Lift L 550 L 556 L 566 L 580

Geometry IND IND IND IND ZK ZK ZK ZK

Cutting tools T T T T T T T T

Lift arm length ft in 9’10” 9’10” 9’10” 9’10” 10’8” 10’8” 10’8” 10’8”

Bucket capacity according to ISO 7546 ** yd3 3.4 3.7 3.7 3.9 4.6 5.2 5.9 6.5

Bucket width ft in 8’10” 8’10” 8’10” 8’10” 9’10” 9’10” 9’10” 10’10”

Specific material weight lb/yd3 3,034 2,697 3,034 2,697 3,034 2,697 3,034 2,697

A Dumping height at max. lift height and 45° discharge ft in 11’8” 11’7” 11’7” 11’4” 12’3” 12’ 11’7” 11’7”

B Dump-over height ft in 13’5” 13’5” 13’5” 13’5” 14’10” 14’10” 14’10” 14’10”

C Max. height of bucket bottom ft in 14’4” 14’4” 14’4” 14’4” 14’8” 14’8” 14’8” 14’8”

D Max. height of bucket pivot point ft in 15’3” 15’3” 15’3” 15’3” 15’8” 15’8” 15’8” 15’8”

E Max. operating height ft in 20‘ 20’1” 20’1” 20’3” 20’3” 20’7” 21’5” 21’5”

F Reach at max. lift height and 45° discharge ft in 3’1” 3’2” 3’2” 3’4” 3’3” 3’6” 4’ 4’

G Digging depth ft in 3” 3” 3” 3” 6” 6” 6” 6”

H Height above cab ft in 11’ 11’ 11’ 11’ 11’8” 11’8” 11’8” 11’8”

I Height above exhaust ft in 9’10” 9’10” 9’10” 9’10” 10’2” 10’2” 10’2” 10’2”

J Ground clearance ft in 1’9” 1’9” 1’9” 1’9” 1’10” 1’10” 1’10” 1’10”

K Wheelbase ft in 10’9” 10’9” 10’9” 10’9” 11’9” 11’9” 12’2” 12’2”

L Overall length ft in 28’7” 28’8” 28’8” 28’11” 30’4” 30’9” 31’5” 31’5”

Turning circle radius over outside bucket edge ft in 21’11” 21’11” 21’11” 22’1” 23’9” 23’11” 24’4” 24’9”

Breakout force (SAE) lbf 25,853 24,729 26,977 25,853 34,845 33,721 33,721 33,721

Tipping load, straight * lb 22,729 22,399 25,221 24,824 33,135 32,717 40,664 40,675

Tipping load, articulated at 40° * lb 20,062 19,775 22,244 21,914 29,101 28,770 35,913 35,913

Operating weight * lb 37,875 37,941 39,617 39,771 50,155 50,398 54,344 54,675

Tire sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

** Actual bucket capacity may be approx. 10 % larger than the calculation according to ISO 7546 standard. The degree to which the bucket can

be filled depends on the material – see page 24.

= Excavation bucket with back grading edge for hydraulic quick coupler / for direct mounting

= Rehandling bucket

IND = Industrial lift arm with parallel guidance including hydraulic quick coupler (only available for L 550 and L 556; illustration see page 14)

ZK = Z-bar linkage

T = Welded-on tooth holder with add-on teeth

L 550 – L 586 15

NTB_L550-586_T_enUS_05.indd 15 02.09.11 12:04

Attachment

Light Material Bucket

L 550 – L 580

Light Material Bucket (heavy material density) L 550 L 556 L 566 L 580

with Bolt-On Cutting Edge STD HL STD HL STD STD STD STD

Geometry IND IND IND IND ZK ZK ZK ZK

Bucket capacity yd3 6.5 5.9 7.8 6.5 8.5 11.1 8.5 11.1

Bucket width ft in 9’8” 9’8” 9’8” 9’8” 10’6” 11’6” 10’6” 11’6”

Specific material weight lb/yd3 1,348 1,348 1,348 1,348 1,686 1,348 2,023 1,686

A Dumping height at max. lift height ft in 8’4” 10’7” 8’ 10’3” 9’11” 9’5” 10’6” 10’

E Max. operating height ft in 19’4” 20’9” 19’11” 21’3” 20’5” 21’1” 21’2” 21’10”

F Reach at maximum lift height ft in 4’9” 4’1” 5’2” 4’4” 4’8” 5’2” 3’11” 4’5”

L Overall length ft in 28’1” 29’4” 28’8” 29’9” 29’8” 30’4” 30’1” 30’9”

Tipping load, straight * lb 25,353 20,503 26,610 23,259 35,979 34,745 43,299 41,976

Tipping load, articulated at 40° * lb 22,355 18,100 23,479 20,503 31,625 30,534 38,228 37,071

Operating weight * lb 38,360 39,110 40,366 40,785 51,346 51,588 54,807 55,490

Tire sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3

Light Material Bucket (light material density) L 550 L 556 L 566 L 580

with Bolt-On Cutting Edge STD HL STD HL STD STD

Geometry IND IND IND IND ZKK ZKK

Bucket capacity yd3 11.8 10.5 13.1 11.8 14.4 18.3

Bucket width ft in 11’2” 11’2” 11’2” 11’2” 12’2” 13’1”

Specific material weight lb/yd3 843 843 843 843 674 674

A Dumping height at max. lift height ft in 7’8” 9’7” 7’5” 9’4” 9’3” 9’1”

E Max. operating height ft in 20’1” 21’3” 20’6” 21’8” 22’5” 23’6”

F Reach at maximum lift height ft in 5’7” 5’ 5’10” 5’3” 7’3” 7’5”

L Overall length ft in 29’3” 30’8” 29’8” 31’1” 31’10” 32’11”

Tipping load, straight * lb 23,942 19,874 26,169 22,277 27,988 30,247

Tipping load, articulated at 40° * lb 21,120 17,527 23,093 19,665 24,604 26,698

Operating weight * lb 40,322 40,631 42,240 42,648 55,733 60,098

Tire sizes 23.5R25 L4 23.5R25 L4 26.5R25 L4 26.5R25 L4

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

STD = Standard lift arm length

HL = High Lift

IND = Industrial lift arm with parallel guidance including hydraulic quick coupler (only available for L 550 and L 556; illustration see page 14).

ZK = Z-bar linkage ZKK = Z-bar linkage with tilt cylinder support and hydraulic quick coupler (“Lumberjack”)

16 L 550 – L 586

NTB_L550-586_T_enUS_05.indd 16 02.09.11 12:04

Attachment

High-Dump Bucket

L 550 – L 580

E

A F

High-Dump Bucket (heavy material density) L 550 L 556 L 566 L 580

with Bolt-On Cutting Edge STD HL STD HL STD STD

Geometry IND IND IND IND ZK ZK

Bucket capacity yd3 5.9 5.2 6.5 5.9 8.5 8.5

Bucket width ft in 8’10” 8’10” 8’10” 8’10” 10’6” 10’6”

Specific material weight lb/yd3 1,348 1,348 1,348 1,348 1,348 1,686

A Dumping height at max. lift height ft in 14’11” 16’6” 15’1” 16’11” 17’5” 18’2”

E Max. operating height ft in 21’11” 23’4” 22’6” 23’11” 24’11” 25’8”

F Reach at maximum lift height ft in 5’10” 5’1” 6‘ 5’5” 6’ 5’5”

L Overall length ft in 29’ 30’4” 29’4” 30’8” 31’8” 32’10”

Tipping load, straight * lb 22,619 19,290 24,295 20,856 30,093 37,016

Tipping load, articulated at 40° * lb 19,952 17,020 21,429 18,386 26,455 32,673

Operating weight * lb 39,374 39,881 41,931 41,799 54,697 58,158

Tire sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3

High-Dump Bucket (light material density) L 550 L 556 L 566 L 580

with Bolt-On Cutting Edge STD HL STD HL STD STD

Geometry IND IND IND IND ZKK ZKK

Bucket capacity yd3 10.5 9.2 12.4 10.5 14.4 17.0

Bucket width ft in 11’2” 11’2” 11’2” 11’2” 12’2” 13’1”

Specific material weight lb/yd3 843 843 843 843 674 674

A Dumping height at max. lift height ft in 14’9” 15’11” 15’1” 16’5” 14’11” 15’8”

E Max. operating height ft in 22’6” 23’6” 23’5” 24’5” 27’2” 28’2”

F Reach at maximum lift height ft in 5’10” 5’1” 6’1” 5’4” 6’9” 6’10”

L Overall length ft in 29’2” 30’6” 29’8” 31’ 31’7” 32’8”

Tipping load, straight * lb 21,848 18,453 24,162 20,547 25,441 28,285

Tipping load, articulated at 40° * lb 19,268 16,204 21,318 18,133 22,355 24,978

Operating weight * lb 40,542 41,402 42,461 43,420 56,394 61,244

Tire sizes 23.5R25 L4 23.5R25 L4 26.5R25 L4 26.5R25 L4

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

STD = Standard lift arm length

HL = High Lift

IND = Industrial lift arm with parallel guidance including hydraulic quick coupler (only available for L 550 and L 556; illustration see page 14).

ZK = Z-bar linkage ZKK = Z-bar linkage with tilt cylinder support and hydraulic quick coupler (“Lumberjack”)

L 550 – L 586 17

NTB_L550-586_T_enUS_05.indd 17 02.09.11 12:04

Attachment

Fork Carrier and Fork

L 550 – L 580

F min.

600

F max.

E

C

G F

L

FEM IV Fork Carrier and Fork

with Quick Change Device L 550 L 556 L 566 L 580

Geometry ZK IND ZK IND ZK ZK

A Lifting height at max. reach ft in 5’10” 6’ 5’10” 6’ 6’6” 6’6”

C Max. lifting height ft in 12’1” 12’7” 12’1” 12’7” 13’7” 14’3”

E Max. operating height ft in 15’4” 15’10” 15’4” 15’10” 17’5” 18’2”

F Reach at loading position ft in 3’4” 3’3” 3’4” 3’3” 4’1” 4’3”

F max. Max. reach ft in 5’5” 5’6” 5’5” 5’6” 6’5” 6’6”

F min. Reach at max. lifting height ft in 2’9” 2’6” 2’9” 2’6” 3’4” 2’9”

G Fork length ft in 4’11” 4’11” 4’11” 4’11” 5’11” 5’11”

L Length – basic machine ft in 23’6” 23’6” 23’6” 23’6” 26’ 26’7”

Tipping load, straight * lb 20,150 20.260 22,862 22,619 25,574 31,173

Tipping load, articulated at 40° * lb 17,780 17,857 20,172 19,952 22,487 27,073

Recommended payload for uneven ground

= 60 % of tipping load, articulated 1) lb 10,031 10,714 12,103 11,971 12,974 16,535

Recommended payload for smooth surfaces

= 80 % of tipping load, articulated 1) lb 12,787 2) 14,285 14,3302) 15,961 17,295 19,489 2)

Operating weight * lb 36,145 36,376 37,655 38,062 50,078 53,539

Tire sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

1) According to EN 473-3 and ISO 14397

2) Payload on forks is limited by tilt cylinder

ZK = Z-bar linkage

IND = Industrial lift arm with parallel guidance including hydraulic quick coupler (only available for L 550 and L 556; illustration see page 14).

18 L 550 – L 586

NTB_L550-586_T_enUS_05.indd 18 02.09.11 12:04

Attachment

Log Grapple (Industrial lift arm)

L 550 – L 580

Q

20°

45°

F 45

F 20

I

20°

A 20 H

A 45

C

Q

C1

F max. K

L

Log Grapple L 550 L 556 L 566 L 580

Geometry IND IND ZKK ZKK

A20 Discharge height at 20° ft in 11’9” 11’9” 11’2” 11’11”

A45 Discharge height at 45° ft in 9’11” 9’8” 8’10” 9’5”

C Max. grapple opening in loading position ft in 7’9” 8’10” 9’10” 11’1”

C1 Max. grapple opening ft in 8’1” 9’9” 10’10” 12’

E Max height ft in 20’9” 21’3” 24’7” 25’7”

F20 Reach at max. lifting height at 20° discharge ft in 5’9” 6’2” 7’8” 7’4”

F45 Reach at max. lifting height at 45° discharge ft in 4’8” 5’ 5’1” 5’5”

F max. Max. outreach ft in 8”9” 9’3” 10’8” 10’11”

H Height above cab ft in 11’ 11’ 11’9” 11’9”

I Manipulation height ft in 14’10” 14’10” 17’1” 17’9”

J Ground clearance ft in 1’9” 1’9” 1’10” 1’10”

K Wheelbase ft in 10’9” 10’9” 11’9” 12’2”

L Overall length ft in 27’11” 28’5” 31’6” 32’9”

Width over tires ft in 8’9” 8’9” 9’7” 9’7”

Q Grapple diameter in2 2,790 3,720 4,805 5,425

Grapple width ft in 5’3” 5’3” 5’11” 5’11”

Payload * lb 13,889** 14,109** 18,078** 20,283**

Operating weight * lb 41,645** 43,100** 57,276** 61,399**

Tire sizes 23.5R25 L4 23.5R25 L4 26.5R25 L4 26.5R25 L4

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

** Data with rear tyres filled with water

IND = Industrial lift arm with parallel guidance including hydraulic quick coupler (only available for L 550 and L 556; illustration see page 14).

ZKK = Z-bar linkage with tilt cylinder support and hydraulic quick coupler (“Lumberjack”)

L 550 – L 586 19

NTB_L550-586_T_enUS_05.indd 19 02.09.11 12:04

Technical Data

Engine Attachment Hydraulics

Liebherr diesel engine _____________ D936L A6 Design ______________________________ “Load-sensing” swash plate type variable flow pump

Design _________________________ Liebherr diesel engine, water-cooled, exhaust turbo with output and flow control, and pressure cut-off in

charged with intercooler the control block

Cylinder inline ________________ 6 Cooling _____________________________ Hydraulic oil cooling using thermostatically controlled

Combustion process ________ PLD fan and oil cooler

Rated output according Filtering _____________________________ Return line filter in the hydraulic reservoir

to SAE J1349 _________________ 335 HP (250 kW) at 2,000 rpm Control ______________________________ “Liebherr-Joystick” with hydraulic servo control

Max. torque ___________________ 1,172 lb ft at 1,500 rpm Lift circuit ___________________________ Lifting, neutral, lowering

Displacement _________________ 642 in 3 and float positions controlled by Liebherr joystick

Bore/Stroke ___________________ 4.8”/5.91” with detent

L 586

Air cleaner __________________________ Dry type with main and safety element, pre-cleaner, Tilt circuit ___________________________ Tilt back, neutral, dump

service indicator on LCD display automatic bucket positioning

Electrical system Max. flow ___________________________ 108 gpm

Operating voltage ____________ 24 V Max. pressure ______________________ 4,786 psi

Capacity_______________________ 170 Ah

Alternator______________________ 28 V/80 A

Starter motor _________________ 24 V/9 HP

The exhaust emissions are below the limits in stage IIIA / Tier 3.

Attachment

Geometry ___________________________ Powerful Z-pattern linkage with tilt cylinder and cast

steel cross-tube

Bearings ____________________________ Sealed

Travel Drive Cycle time at nominal load _______ Lifting ________________________________________________ 6.5 s

Dumping ____________________________________________ 3.0 s

Stepless hydrostatic travel drive Lowering (empty) ___________________________________ 4.0 s

Design ________________________ Swash plate type variable flow pump and two

variable axial piston motors in closed loop circuit

with one axle transfer case. Direction of travel

is reversed by changing the flow-direction of the

variable-displacement pump

Filtering system ______________ Suction return line filter for closed circuit

Operator’s Cab

Control ________________________ By travel and inching pedal. The inching pedal makes Design ______________________________

On elastic bearing on rear section, soundproof

it possible to control the tractive and directional ROPS/FOPS cab. Operator’s door with optional

forces steplessly at full engine speed. The Liebherr sliding window, 180° opening angle, fold-out window

joystick is used to control forward and reverse travel on right site with opening angle, front windscreen

Travel speed range ________________ Speed range 1 _____________________________ 0 – 5.0 mph made of compound safety glass, green tinted as

Speed range 2 and A2 ____________________ 0 – 9.9 mph standard, side windows made of single-pane safety

Speed range A3 ___________________________ 0 – 21.7 mph glass, grey tinted, continuously adjustable steering

The quoted speeds apply with the tires that are column and joystick control as standard, heatable

standard equipment on the loader rear window

ROPS roll over protection per DIN/ISO 3471/

EN 474-3

FOPS falling objects protection per DIN/ISO 3449/

Axles EN 474-1

Liebherr Operator’s seat __________ 6 way adjustable seat with lap belt, vibration damping

and suspension adjustable for the operator’s weight

Four-wheel drive Cab heating and ventilation _______ Operator’s cab with 4-level air control, cooling water

Front axle ___________________________ Fixed heating, defroster and air conditioning with electronic

Rear axle ____________________________ Center pivot, with 13° oscillating angle to each side valve control, as well as electronic fresh/recirculated

Height of obstacles which air control, filter system with pre-filter, fresh air

can be driven over ___________ 1’9” filter and recirculated air filter, easily replaced,

With all four wheels remaining in contact with the air conditioning as standard

ground

Differentials _________________________ Automatic limited-slip differentials

Reduction gear _____________________ Planetary final drive in wheel hubs

Track width _________________________ 7’10” with all types of tires

Noise Emission

ISO 6396 ____________________________ LpA (inside cab) = 69 dB(A)

2000/14/EC _________________________ LWA (surround noise) = 107 dB(A)

Brakes

Wear-free service brake ___________ Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator

brake system with wet multi-disc brakes located in

the wheel hubs (two separate brake circuits)

Capacities

Parking brake ______________________ Electro-hydraulically actuated spring-loaded brake Fuel tank ________________________________________________________________________________ 114,8 gal

system on the transmission Engine oil (including filter change) _____________________________________________________ 11.4 gal

The braking system meets the requirements of the EC guidelines 71/320. Pump distributor gears _________________________________________________________________ 2.0 gal

Transmission _____________________________________________________________________________ 3.0 gal

Coolant __________________________________________________________________________________ 15.6 gal

Front axle ________________________________________________________________________________ 23.8 gal

Rear axle _________________________________________________________________________________ 14.8

Steering Hydraulic tank ___________________________________________________________________________ 47.6

gal

gal

Hydraulic system, total _________________________________________________________________ 92.5 gal

Design ______________________________

“Load-sensing” swash plate type variable flow pump Air-condition system R134a ____________________________________________________________ 3.0 lb

with pressure cut-off and flow control. Central pivot

with two double-acting, damped steering cylinders

Angle of articulation _______________ 37° (to each side)

Emergency steering _______________ Electro-hydraulic emergency steering system

20 L 550 – L 586

NTB_L550-586_T_enUS_05.indd 20 02.09.11 12:04

Dimensions

Z-bar linkage

65°

45°

E

L 586

F

D

C

B

A I H

49º

J

K

G

L

Loading Bucket STD HL STD HL STD HL

Cutting tool ROB ROB T T T T

Lift arm length ft in 10’4” 11’4” 10’4” 11’4” 10’4” 11’4”

Bucket capacity according to ISO 7546 ** yd3 6.5 6.5 7.2 7.2 7.9 7.9

Bucket width ft in 11’2” 11’2” 11’2” 11’2” 11’2” 11’2”

Specific material weight lb/yd3 3,371 3,034 3,034 2,697 2,697 2,360

A Dumping height at max. lift height and 45° discharge ft in 10’11” 12’3” 10’10” 12’3” 10’8” 12’

B Dump-over height ft in 13’7” 14’9” 13’7” 14’9” 13’7” 14’9”

C Max. height of bucket bottom ft in 14’1” 15’8” 14’2” 15’7” 14’2” 15’7”

D Max. height of bucket pivot point ft in 15’3” 16’8” 15’3” 16’7” 15’3” 16’7”

E Max. operating height ft in 21’ 22’4” 21’4” 22’10” 21’5” 22’11”

F Reach at max. lift height and 45° discharge ft in 4’6” 4’6” 4’7” 4’6” 4’8” 4’7”

G Digging depth ft in 6” 6” 4” 4” 4” 4”

H Height above cab ft in 12’4” 12’4” 12’3” 12’3” 12’3” 12’3”

I Height above exhaust ft in 10’11” 10’11” 10’10” 10’10” 10’10” 10’10”

J Ground clearance ft in 1’11” 1’11” 1’11” 1’11” 1’11” 1’11”

K Wheelbase ft in 12’10” 12’10” 12’10” 12’10” 12’10” 12’10”

L Overall length ft in 32’8” 33’10” 32’7” 33’8” 32’8” 33’9”

Turning circle radius over outside bucket edge ft in 27’1” 27’9” 27’1” 27’9” 27’3” 27’11”

Breakout force (SAE) lbf 52,830 51,706 52,830 51,706 50,582 49,458

Tipping load, straight * lb 50,023 43,883 50,221 44,114 48,633 42,659

Tipping load, articulated at 37° * lb 44,853 39,353 45,040 39,551 43,607 38,228

Operating weight * lb 71,838 72,554 69,181 69,887 69,996 70,768

Tire sizes 29.5R25 L5 29.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

** Actual bucket capacity may be approx. 10 % larger than the calculation according to ISO 7546 standard. The degree to which the bucket can

be filled depends on the material – see page 24.

= Rock bucket with oblique base for quarrying applications

= Rehandling bucket

STD = Standard lift arm length

HL = High Lift

ROB = Rock bucket with delta cutting edge, welded-on tooth holder with add-on teeth and bolted intermediate sections

T = Welded-on tooth holder with add-on teeth

L 550 – L 586 21

NTB_L550-586_T_enUS_05.indd 21 02.09.11 12:04

Attachment

Light Material Bucket

L 586

Light Material Bucket

with Bolt-On Cutting Edge

Bucket capacity yd3 11.1 14.4

Bucket width ft in 11’6” 12’2”

Specific material weight lb/yd3 1,854 1,348

A Dumping height at max. lift height ft in 10’3” 9’8”

E Max. operating height ft in 22’ 22’5”

F Reach at maximum lift height ft in 5’ 5’10”

L Overall length ft in 32’8” 33’8”

Tipping load, straight * lb 47,796 46,120

Tipping load, articulated at 37° * lb 42,868 41,204

Operating weight * lb 69,401 70,702

Tire sizes 29.5R25 L3 29.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

22 L 550 – L 586

NTB_L550-586_T_enUS_05.indd 22 02.09.11 12:04

Attachment

Fork Carrier and Fork

Seite ist rechts 2 mm schmäler

F min.

L 586

600

F max.

E

C

G F

L

FEM IV Fork Carrier and Fork

with Quick Change Device

A Lifting height at max. reach ft in 6’11”

C Max. lifting height ft in 14’6”

E Max. operating height ft in 18’5”

F Reach at loading position ft in 4’3”

F max. Max. reach ft in 6’8”

F min. Reach at max. lifting height ft in 3’4”

G Fork length ft in 5’11”

L Length – basic machine ft in 27’9”

Tipping load, straight * lb 36,243

Tipping load, articulated at 37° * lb 32,496

Recommended payload for uneven ground

= 60 % of tipping load, articulated 1) lb 19,488

Recommended payload for smooth surfaces

= 80 % of tipping load, articulated 1) lb 22,046 2)

Operating weight * lb 66,976

Tire sizes 29.5R25 L3

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load.

1) According to EN 473-3 and ISO 14397

2) Useful load limited due to FEM IV fork carrier and forks

L 550 – L 586 23

NTB_L550-586_T_enUS_05.indd 23 02.09.11 12:04

Tipping Load

Seite ist rechts 15 mm schmäler (Klappseite)/Diese Seite enthält transparente Objekte

ISO 7546

What is tipping load? Pay load. Bucket capacity.

Load at center of gravity of working equip- The pay load must not exceed 50 % of the The bucket volume is determined from the

ment, so that the wheel loader just begins to tipping load when articulated. pay load.

Tipping load, articulated

tip over the front axle. This is equivalent to a static stability-margin Pay load =

2

This the most unfavorable static-load position factor of 2.0.

for the wheel loader. Pay load (lb)

Bucket capacity =

Lifting arms horizontal, wheel loader fully Specific bulk weight of

articulated at center pivot. material (lb/yd3)

Bulk Material Densities and Bucket Filling Factors

lb/yd3 % lb/yd3 % lb/yd3 %

Gravel, moist 3,203 105 Clay, natural 2,697 110 Granite 3,034 95

dry 2,697 105 dry 2,360 110 Limestone, hard 2,781 95

wet, 24” – 1’97” 3,371 105 wet 2,781 105 soft 2,613 100

dry, 24” – 1’97” 2,865 105 Clay and gravel, dry 2,360 110 Sandstone 2,697 100

crushed stone 2,528 100 wet 2,697 100 Slate 2,950 100

Sand, dry 2,528 110 Earth, dry 2,191 115 Bauxite 2,360 100

moist 3,034 115 wet excavated 2,697 110 Gypsum, broken 3,034 100

wet 3,203 110 Topsoil 1,854 110 Coke 0,843 110

Gravel and sand, dry 2,865 105 Weathered rock Slag, broken 3,034 100

wet 3,371 100 50 % rock, 50 % earth 2,865 100 Coal 1,854 110

Sand and clay 2,697 110 Basalt 3,287 100

Tires

Size and Change of Width over tires Change in vertical

tread code operating weight dimensions Use

lb ft in in

L 550

Goodyear 20.5R25 RT-3B L3 – 1,235 8’9” – 1.57 Gravel

Goodyear 20.5R25 RL-5K L5 + 106 8’9” + 0.12 Stone, Recycling

Michelin 20.5R25 XHA2 L3 – 1,279 8’8” – 1.57 Gravel

Michelin 20.5R25 XLD D2A L5 – 326 8’8” – 0.55 Stone, Mining spoil

Michelin 20.5R25 XMINE D2 L5 + 265 8’9” 0 Stone, Recycling

L 550/L 556

Bridgestone 23.5R25 VJT L3 + 309 8’8” + 0.24 Gravel

Bridgestone 23.5R25 VSDL L5 + 2,081 8’9” + 2.76 Stone, Recycling

Goodyear 23.5R25 RL-5K L5 + 1,746 8’9” + 2.36 Stone, Recycling

Goodyear 23.5R25 RT-3B L3 + 340 8’9” + 0.98 Gravel

Goodyear 23.5R25 GP-4D L4 + 723 8’8” + 0.79 Sand, Gravel, Industry

Goodyear 23.5R25 TL-3A+ L3 + 626 8’8” + 1.42 Gravel, Earthworks

Michelin 23.5R25 XHA2 L3 0 8’8” 0 Gravel

Michelin 23.5R25 XLD D2A L5 + 1,349 8’9” + 1.38 Stone, Mining spoil

Michelin 23.5R25 XMINE D2 L5 + 1,675 8’9” + 2.36 Stone, Recycling

L 566

Bridgestone 23.5R25 VJT L3 – 895 9’9” – 1.69 Gravel

Bridgestone 23.5R25 VSDL L5 + 882 9’9” + 0.59 Stone, Recycling

Goodyear 23.5R25 RL-5K L5 + 547 9’9” + 0.39 Stone, Recycling

Michelin 23.5R25 XMINE D2 L5 + 476 9’10” + 0.39 Stone, Recycling

Michelin 23.5R25 XLD D2A L5 + 150 9’9” – 0.59 Stone, Mining spoil

Michelin 23.5R25 XHA2 L3 – 1,199 9’9” – 1.93 Gravel

L 566/L 580

Bridgestone 26.5R25 VJT L3 + 353 9’9” + 0.59 Gravel

Bridgestone 26.5R25 VSDL L5 + 2,654 9’9” + 2.36 Stone, Recycling

Goodyear 26.5R25 RL-5K L5 + 2,328 9’9” + 2.36 Stone, Recycling

Goodyear 26.5R25 RT-3B L3 + 917 9’9” + 0.98 Gravel

Goodyear 26.5R25 GP-4D L4 + 961 9’9” + 1.06 Sand, Gravel, Industry

Goodyear 26.5R25 TL-3A+ L3 + 767 9’9” + 1.22 Gravel, Earthworks

Michelin 26.5R25 XHA2 L3 0 9’9” 0 Gravel

Michelin 26.5R25 XLD D2A L5 + 1,534 9’9” + 1.57 Stone, Mining spoil

Michelin 26.5R25 XMINE D2 L5 + 2,407 9’10” + 2.36 Stone, Recycling

L 586

Bridgestone 29.5R25 VJT L3 + 181 10’8” + 1.77 Gravel

Bridgestone 29.5R25 VSDL L5 + 3,104 10’8” + 2.56 Stone, Scrap

Goodyear 29.5R25 RL-5K L5 + 3,668 10’10” + 2.36 Industry, Stone

Michelin 29.5R25 XHA2 L3 0 10’8” 0 Gravel

Michelin 29.5R25 XLD D2A L5 + 1,975 10’8” + 0.79 Stone, Mining spoil, Recycling

Michelin 29.5R25 XMINE D2 L5 + 2,690 10’9” + 1.57 Stone, Scrap

Before operating the vehicle with tire foam filling or tire protection chains, please discuss this with the factory.

L 550 – L 586 24

NTB_L550-586_T_enUS_05.indd 24 02.09.11 12:04

Equipment

550

556

566

580

586

550

556

566

580

586

Basic Machine Instruments for:

Seite ist rechts 15 mm schmäler (Klappseite)

Exhaust pipe – stainless steel + + + + + Timer for hours of operation • • • • •

Automatic central lubrication system + + + + • Flashing turn signals • • • • •

Battery master switch • • • • • Diagnosis system • • • • •

Fuel particle filter + + + + + Rev. counter • • • • •

Electronic crowding force control • • • • • Forward – reverse travel • • • • •

Electronical theft protection with/without driver identification + + + + + Travel speed ranges and gear selected • • • • •

Automatic travel mode • • • • • High-beam headlights • • • • •

Headlights • • • • • Fuel reserve • • • • •

Ride control • • • • • Engine oil temperature • • • • •

Particle protection for radiator + + + + + Reverse travel • • • • •

Large-mesh radiator + + + + – Speedometer • • • • •

Pre-heat system for cold starting • • • • • Clock • • • • •

Creep speed/Cruise control • • • • • Diesel engine pre-heat • • • • •

Combined inching-braking system • • • • • Forward travel • • • • •

Multi-disc limited slip differentials in both axles • • • • •

Noise suppression package + + + + –

LiDAT Standard (Liebherr Data Transfer System) + + + + +

550

556

566

580

586

LiDAT Plus (extended Liebherr Data Transfer System)

Liebherr travel gear

+

•

+

•

+

•

+

•

+

•

Warning Lights for:

Liebherr biodegradable hydraulic oil + + + + + Battery charge • • • • •

Air cleaner system with pre-filter • • • • • Flow through emergency steering system • • • • •

Reversible fan drive • • • • • Parking brake • • • • •

Emergency steering system • • • • • Hydraulic oil temperature • • • • •

Back-up alarm + + + + + Air cleaner blockage • • • • •

Road ballast – – – – – Engine oil pressure • • • • •

Lockable doors, service flap and engine hood • • • • • Engine overheat • • • • •

Rubber widening for rear (in steel) and front mudguards – – – – +

Toolbox with toolkit • • • • •

Weighing device (integrated) + + + + +

Towing hitch

Two working area lights at rear

•

•

•

•

•

•

•

•

•

•

Audible Warnings

550

556

566

580

586

Two tail lights

12.4 mph speed limiting

•

+

•

+

•

+

•

+

•

+

for:

Overheat of hydraulic fluid • • • • •

Engine oil pressure • • • • •

Engine overheat • • • • •

550

556

566

580

586

Operator’s Cab Emergency steering system • • • • •

Storage box • • • • •

Lockable storage compartment • • • • •

550

556

566

580

586

Ashtray

Operator’s package

•

•

•

•

•

•

•

•

•

•

Function Keys for:

Operator’s seat – 6 way adjustable • • • • • Working lights rear • • • • •

Operator’s seat with active suspension, with seat climate control Working lights front • • • • •

– – + + +

and seat heating Electronic tractive force adaptation • • • • •

Operator’s seat – heated and air suspended + + + + + Speed range selection • • • • •

Fire extinguisher 4 lb + + + + + Headlights • • • • •

Cup holder • • • • • Ride control • • • • •

Height-adjustable steering column + + + + + Parking brake • • • • •

Horn • • • • • Blower • • • • •

Joystick steering + + + + + Heater • • • • •

Floor mat • • • • • Hoist kick-out + + + + +

Coat hook • • • • • Air conditioning • • • • •

Air conditioning system • • • • • Creep speed • • • • •

Storage box with cooling function + + + + + Mode switch • • • • •

LED operating spotlight, front/rear + + + + + Amber beacon • • • • •

Liebherr joystick control – adjustable • • • • • Automatic bucket positioner • • • • •

Radio set + + + + + Wash/wipe system for rear window • • • • •

Provision for radio including speakers + + + + + Float position • • • • •

Rear view monitoring with camera + + + + + Road travel • • • • •

Interior rear-view mirror • • • • • Hazard warning lights • • • • •

Amber beacon + + + + + Additional hydraulics • • • • •

Soundproof ROPS/FOPS cab with tinted safety glass front

• • • • •

windshield, heated rear window

Wash/wipe system for windscreen and rear window • • • • •

550

556

566

580

586

Sliding window

Protective ventilation system

+

+

+

+

+

+

+

+

+

+

Equipment

Windshield guard + + + + + Automatic hoist kick out – adjustable + + + + +

Sun visor • • • • • Automatic bucket positioner – adjustable • • • • •

Dust filter system + + + + + Fork carrier and lift forks + + + + +

12 V Outlet • • • • • High Lift arms + + + + +

First aid kit + + + + + High-dump bucket + + + + +

Adjustable steering column • • • • • Log grapple + + + + +

Four working area lights at front • • • • • Hydraulic quick-change device + + + + +

Hot water heater with defroster and recycled-air system • • • • • Hydraulic servo control of working hydraulics • • • • •

Wide angle mirror + + + + + Industrial lift arm + + + + –

Xenon working lights front + + + + + Comfort control + + + + +

Two or four working area lights rear + + + + + Loading buckets with and without teeth, or bolt-on cutting edge + + + + +

2in1 steering system – changeable + + + + – Country-specific versions + + + + +

550-586 07.11

Light material bucket + + + + +

Float position • • • • •

• = Standard, + = Option, – = not available Z-bar linkage • • • • •

3rd hydraulic control circuit + + + + +

All illustrations and data may differ from standard equipment. Subject to change without notice. 3rd and 4th hydraulic control circuits + + + + +

L 550 – L 586 25

NTB_L550-586_T_enUS_05.indd 25 02.09.11 12:05

The Liebherr Group of Companies

Wide Product Range State-of-the-art Technology

The Liebherr Group is one of the largest construction To provide consistent, top quality products, Liebherr

equipment manufacturers in the world. Liebherr’s high- attaches great importance to each product area, its

value products and services enjoy a high reputation in components and core technologies. Important modules

many other fields, too. The wide range includes domes- and components are developed and manufactured in-

Seite ist rechts 2 mm schmäler

tic appliances, aerospace and transportation systems, house, for instance the entire drive and control techno-

machine tools and maritime cranes. logy for construction equipment and mining trucks.

Exceptional Customer Benefit Worldwide and Independent

Every product line provides a complete range of models Hans Liebherr founded the Liebherr family company in

in many different versions. With both their technical excel- 1949. Since that time, the enterprise has steadily grown

lence and acknowledged quality, Liebherr products offer to a group of more than 120 companies with nearly

a maximum of customer benefits in practical application. 33,000 employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

in Bulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.us

Printed in Germany by Typodruck RG-BK-RP LBH/PM 10409520-2-07.11_enUS

Liebherr Construction Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607, USA

콯 +1 (757) 245 5251, Fax +1 (757) 928 8701

www.liebherr.us, E-Mail: info.lce@liebherr.com

NTB_RS_US_Klapp_5.indd 1

NTB_L550-586_T_enUS_05.indd 26 02.12.10

02.09.1115:20

12:05

You might also like

- NTB L550-L586 enUS 11-07 9713-0Document26 pagesNTB L550-L586 enUS 11-07 9713-0amaraaonNo ratings yet

- Wheel Loader L 586: Product InformationDocument16 pagesWheel Loader L 586: Product InformationcraigNo ratings yet

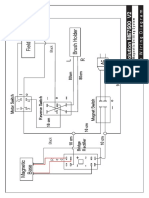

- Me7500 110v 230vDocument2 pagesMe7500 110v 230vMohamed ShabanNo ratings yet

- Meet The: The New Standard in Terminal TractorsDocument5 pagesMeet The: The New Standard in Terminal TractorsEstefahnia CabezasNo ratings yet

- Groeneveld Automatic Greasing SystemsDocument8 pagesGroeneveld Automatic Greasing SystemskamalNo ratings yet

- Kam Hybrid - ToC Europe - 090610v2Document31 pagesKam Hybrid - ToC Europe - 090610v2sajjad_naghdi241No ratings yet

- DS450 Shop Manual (Prelim)Document94 pagesDS450 Shop Manual (Prelim)GuruRacerNo ratings yet

- Allison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogDocument38 pagesAllison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogMarcos LunaNo ratings yet

- r914b Us NTB - 7376 0Document24 pagesr914b Us NTB - 7376 0FranciscoOliveira100% (1)

- Designed With You in Mind.: Leading The IndustryDocument2 pagesDesigned With You in Mind.: Leading The IndustryEstefahnia Cabezas100% (1)

- PlanosDocument29 pagesPlanosPCM PortengeNo ratings yet

- Optima 85-100 enDocument64 pagesOptima 85-100 enagapitpl50% (2)

- Mg550-Engine ElectricalDocument12 pagesMg550-Engine Electricalsianas1706No ratings yet

- Potencia PDFDocument5 pagesPotencia PDFJosé A. MaravíNo ratings yet

- Allison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogDocument6 pagesAllison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogMarcos LunaNo ratings yet

- Cat 966M CM20190323-60875-42013Document16 pagesCat 966M CM20190323-60875-42013Mostafa SaadNo ratings yet

- Instruction Book Iqan-Mc2: Publ No HY17-8388-IB/UK Edition October, 2008Document37 pagesInstruction Book Iqan-Mc2: Publ No HY17-8388-IB/UK Edition October, 2008feukamNo ratings yet

- Hiab XS 166 K 17 Ton Capacity Crane SpecsDocument2 pagesHiab XS 166 K 17 Ton Capacity Crane SpecsMunteanu MihaiNo ratings yet

- Drilling Rig Specification for Driltech Mission D40KWDocument2 pagesDrilling Rig Specification for Driltech Mission D40KWAnonymous CD0suI9No ratings yet

- Allison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogDocument6 pagesAllison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogMarcos LunaNo ratings yet

- Electric Man-Down Turret TruckDocument6 pagesElectric Man-Down Turret Truckwill wuNo ratings yet

- KC TD Liftace Rs 01, CATALOGODocument7 pagesKC TD Liftace Rs 01, CATALOGOFernando TaibaNo ratings yet

- Heavy Lift Trucks 20-30 Ton Technical SpecsDocument12 pagesHeavy Lift Trucks 20-30 Ton Technical Specsbatuhany90No ratings yet

- INGLERS 85 - 547874EN Aire AcondicionadoDocument40 pagesINGLERS 85 - 547874EN Aire AcondicionadoNelson Ruiz100% (1)

- Manifold Block Boom /: Bloc RelevageDocument5 pagesManifold Block Boom /: Bloc Relevageyao nestorNo ratings yet

- Expand Your Reach: Large Crane FamilyDocument5 pagesExpand Your Reach: Large Crane FamilyaltogarNo ratings yet

- Hiab XS377CLX Loadchart CWDocument2 pagesHiab XS377CLX Loadchart CWJuan Diego ArizabalNo ratings yet

- Ferrari - Cap2 Sicurezze F121618 EDocument21 pagesFerrari - Cap2 Sicurezze F121618 EYoseth Jose Vasquez ParraNo ratings yet

- Brochure bl60b bl70bDocument28 pagesBrochure bl60b bl70bMichael Puma ZeaNo ratings yet

- Catalogo Comercial Reach Raymond 7000 SeriesDocument28 pagesCatalogo Comercial Reach Raymond 7000 SeriesLeonardo VargasNo ratings yet

- Automatic Greasing SystemDocument70 pagesAutomatic Greasing SystemDatNo ratings yet

- Wiring Diagram Cummins EngineDocument8 pagesWiring Diagram Cummins EngineRendy MechanicNo ratings yet

- Wterex: '775 SERIESDocument15 pagesWterex: '775 SERIESNguyễn NamNo ratings yet

- Aisle Width E15 386Document6 pagesAisle Width E15 386Jankovski22 MaksNo ratings yet

- Hydraulic Supply and Return (Figure 9-1) : Unit Code L177 Europe 06/2005Document42 pagesHydraulic Supply and Return (Figure 9-1) : Unit Code L177 Europe 06/2005Melwyn FernandesNo ratings yet

- Hy17 8536 Uk - M402LSDocument24 pagesHy17 8536 Uk - M402LSArmoos OsmoarNo ratings yet

- PDC SERIES OPERATION AND MAINTENANCE MANUALDocument188 pagesPDC SERIES OPERATION AND MAINTENANCE MANUALDmitryNo ratings yet

- 1232E Datasheet enDocument6 pages1232E Datasheet enASIFNo ratings yet

- Contractor Equipment Hydraulic System Diagram and Component GuideDocument1 pageContractor Equipment Hydraulic System Diagram and Component GuideANH LÊNo ratings yet

- Hydraulic System: DescriptionDocument59 pagesHydraulic System: DescriptionKristian FonNo ratings yet

- Eme Brochure - 2022Document16 pagesEme Brochure - 2022Aru NaveenNo ratings yet

- Liebherr Floating Transfer Solutions OverviewDocument16 pagesLiebherr Floating Transfer Solutions OverviewHùng Lê VănNo ratings yet

- Technical Data: Kalmar Contmaster Drs4531-S5Document4 pagesTechnical Data: Kalmar Contmaster Drs4531-S5ВиталийNo ratings yet

- Cylinder PDFDocument3 pagesCylinder PDFdinhvuNo ratings yet

- Parts Transmission Clark 28000Document15 pagesParts Transmission Clark 28000Paul Jhon Solis huariNo ratings yet

- Linde Service Guide: ArrangementDocument2 pagesLinde Service Guide: ArrangementTrần Đức Phi100% (1)

- Injectors, Pressure Pipes and Leak-Off Line TAMD71B AUX PDFDocument2 pagesInjectors, Pressure Pipes and Leak-Off Line TAMD71B AUX PDFKALIL100% (1)

- Freightliner Freightliner: Business Class M 2 Utility Business Class M 2Document8 pagesFreightliner Freightliner: Business Class M 2 Utility Business Class M 2PercyLeonNo ratings yet

- Electric ForkliftDocument46 pagesElectric ForkliftYakupovmmNo ratings yet

- Genie GS 2032, GS 2632, GS 3232 SpecificationsDocument2 pagesGenie GS 2032, GS 2632, GS 3232 SpecificationsKestutisNo ratings yet

- Cummins QSM11 engine spare parts listDocument167 pagesCummins QSM11 engine spare parts listIvan Martínez LopezNo ratings yet

- Manitou - MT 1235 PDFDocument2 pagesManitou - MT 1235 PDFWalter BustamanteNo ratings yet

- Ficha Tecnica Montacargas OMDocument4 pagesFicha Tecnica Montacargas OMjose paez0% (1)

- Service Parts List for Transmission 15.7TE27418-81 4265011Document24 pagesService Parts List for Transmission 15.7TE27418-81 4265011Satria TrianaNo ratings yet

- Unit 41 Transmission 1 PDFDocument17 pagesUnit 41 Transmission 1 PDFIlham Nazarudin AkmalNo ratings yet

- Linde EN Ds v10 br5021 en F 0119Document6 pagesLinde EN Ds v10 br5021 en F 0119Nadeem AhmedNo ratings yet

- Fd15-50 Operation Manual (G.gcpower)Document68 pagesFd15-50 Operation Manual (G.gcpower)Andres BengocheaNo ratings yet

- MITSUBISHI FG25NMDocument547 pagesMITSUBISHI FG25NMDaniel TavaresNo ratings yet

- Wheel Loaders L 550 - L 580 Specs and Fuel EfficiencyDocument28 pagesWheel Loaders L 550 - L 580 Specs and Fuel EfficiencyHtun NayWinNo ratings yet

- Liebherr L 556 User ManualDocument28 pagesLiebherr L 556 User ManualNik ShaginNo ratings yet

- Ec380dl PDFDocument24 pagesEc380dl PDFshankers_1999No ratings yet

- Essential Guide To Stock InvestingDocument19 pagesEssential Guide To Stock Investingleorbalaguru100% (1)

- Ec480dl PDFDocument32 pagesEc480dl PDFshankers_1999No ratings yet

- 5Khrk @R J?A@"Ki Qopekj3A?Djkhkcu R ?P: The Volvo Way To High Performance and Reduced Emission LevelsDocument16 pages5Khrk @R J?A@"Ki Qopekj3A?Djkhkcu R ?P: The Volvo Way To High Performance and Reduced Emission Levelsshankers_1999No ratings yet

- Dynapac SD2500CS Dynapac SD2500CS: Large Pavers Large PaversDocument3 pagesDynapac SD2500CS Dynapac SD2500CS: Large Pavers Large Paversshankers_1999No ratings yet

- Productbrochure Ec700c en 21 20000581-E PDFDocument24 pagesProductbrochure Ec700c en 21 20000581-E PDFshankers_1999No ratings yet

- Ficha GRW15Document2 pagesFicha GRW15shankers_1999No ratings yet

- The New Volvo FMX: Volvo Trucks. Driving ProgressDocument22 pagesThe New Volvo FMX: Volvo Trucks. Driving Progressshankers_1999No ratings yet

- Dynapac Large Tracked Paver Range: Dynapac SD2530CS / SD2550CSDocument12 pagesDynapac Large Tracked Paver Range: Dynapac SD2530CS / SD2550CSshankers_1999No ratings yet

- Hamm AG - SteckbriefDocument2 pagesHamm AG - Steckbriefshankers_1999No ratings yet

- Dynapac Tandem Asphalt RollerDocument4 pagesDynapac Tandem Asphalt Rollershankers_1999No ratings yet

- HDFC Branch ListDocument32 pagesHDFC Branch Listshankers_1999No ratings yet

- Essential Guide To Stock InvestingDocument19 pagesEssential Guide To Stock Investingleorbalaguru100% (1)

- Produktblad EC290BDocument16 pagesProduktblad EC290BvitaliyNo ratings yet

- Dynapac SD2500CS Dynapac SD2500CS: Large Pavers Large PaversDocument3 pagesDynapac SD2500CS Dynapac SD2500CS: Large Pavers Large Paversshankers_1999No ratings yet

- IndiamapDocument1 pageIndiamapshankers_1999No ratings yet

- Help plan your Ernakulam trip with Sona Travels ticketDocument2 pagesHelp plan your Ernakulam trip with Sona Travels ticketAkshay T ManikhandanNo ratings yet

- Essential Guide To Stock InvestingDocument19 pagesEssential Guide To Stock Investingleorbalaguru100% (1)

- Haulpack HD 730EDocument79 pagesHaulpack HD 730EdwiNo ratings yet

- 206-06 Hydraulic Brake Actuation PICKUP JMCDocument7 pages206-06 Hydraulic Brake Actuation PICKUP JMCRusonegroNo ratings yet

- 2012 Yamaha FZS10BW Service Repair Manual PDFDocument60 pages2012 Yamaha FZS10BW Service Repair Manual PDFjkmoseiodkkNo ratings yet

- Compact Wheel Loader and Pivot Steer Teleloader Product Range 2014/IIDocument52 pagesCompact Wheel Loader and Pivot Steer Teleloader Product Range 2014/IIDragos Manole0% (1)

- Study of Braking SystemsDocument2 pagesStudy of Braking SystemsBarsanu AlexNo ratings yet

- Automobile Engineering Syllabus - CompressedDocument3 pagesAutomobile Engineering Syllabus - CompressedsanmaykalheNo ratings yet

- Service Bulletin No. 10-08 - Aker SolutionsDocument6 pagesService Bulletin No. 10-08 - Aker SolutionsReda HmrNo ratings yet

- Honda ShineDocument8 pagesHonda ShineAnantha RajaNo ratings yet

- 793C Off-Highway Truck Hoist System Service TrainingDocument16 pages793C Off-Highway Truck Hoist System Service TrainingJose VidalNo ratings yet

- Availability Report HINO PT - BIIDocument353 pagesAvailability Report HINO PT - BIIMuhammad Maulani MuttaqinNo ratings yet

- Railway Brake ShoesDocument6 pagesRailway Brake ShoesAugusto dos SantosNo ratings yet

- Composite As Friction MaterialDocument19 pagesComposite As Friction Materialperhaps4uNo ratings yet

- Zollern WinchDocument20 pagesZollern WinchKOK100% (3)

- 03) Mazda-Allegro Manual de Taller Tren DelanteroDocument35 pages03) Mazda-Allegro Manual de Taller Tren DelanteroJohn Jairo MontoyaNo ratings yet

- Yamaha Raptor 50 Service Manual Opti SHDocument236 pagesYamaha Raptor 50 Service Manual Opti SHMoppie Hofstede50% (2)

- Cessna 172 R Question BankDocument12 pagesCessna 172 R Question BankAshwathNo ratings yet

- Ottawa Yard TruckDocument68 pagesOttawa Yard TruckASHLYN PRICENo ratings yet

- DG450 Hook Operation ManualDocument11 pagesDG450 Hook Operation ManualHala Dawod100% (2)

- 777 D CaterpillarDocument14 pages777 D CaterpillarRizky PratamaNo ratings yet

- Camion Minero 797B PDFDocument4 pagesCamion Minero 797B PDFAlexander CaluaNo ratings yet

- OM SBA 3000 Vic 4000 Atl 4 7Document33 pagesOM SBA 3000 Vic 4000 Atl 4 7ovyttNo ratings yet

- Foremost W750Document104 pagesForemost W750HernanNo ratings yet

- Modern Automotive TechnologyDocument97 pagesModern Automotive TechnologyMarew GetieNo ratings yet

- Crane Inspection PDFDocument1 pageCrane Inspection PDFKachur AlekseyNo ratings yet

- Anti-Lock Braking SystemDocument17 pagesAnti-Lock Braking SystemDhananjay Titarmare100% (1)

- Linde Treinamento PDFDocument226 pagesLinde Treinamento PDFGFEmpilhadeirasLondrina100% (3)

- Cargo Crane and Self Loader Mounting ManualDocument214 pagesCargo Crane and Self Loader Mounting ManualMatias Contreras KöbrichNo ratings yet

- Force of GravityDocument22 pagesForce of GravityBiplobNo ratings yet

- Data Sheet 7900 Electric en 2019Document3 pagesData Sheet 7900 Electric en 2019kazibeiglooNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (53)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4.5 out of 5 stars4.5/5 (21)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)From EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)No ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)