Professional Documents

Culture Documents

Power Distribution: Laminated Copper Bars Short-Circuit Withstand Strength To IEC

Uploaded by

Kushtrim MalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Distribution: Laminated Copper Bars Short-Circuit Withstand Strength To IEC

Uploaded by

Kushtrim MalaCopyright:

Available Formats

Power distribution

Laminated copper bars

Short-circuit withstand strength to IEC

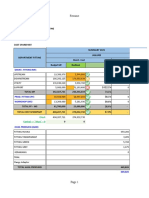

Curve

In In In

Configuration1) (short-circuit Installation

at at at Model No. SV

mm withstand type

70 K2) 50 K2) 30 K2)

strength)

6 x 9 x 0.8 285 A 240 A 180 A – – 3565.005

6 x 15.5 x 0.8 415 A 350 A 265 A a 1 3568.005

10 x 15.5 x 0.8 575 A 480 A 365 A a 1 3569.005

5 x 20 x 1 525 A 435 A 330 A a 1 3570.005

5 x 24 x 1 605 A 510 A 385 A a 1 3571.005

10 x 24 x 1 920 A 770 A 585 A b 1 3572.005

5 x 32 x 1 770 A 645 A 485 A b 2/3 3573.005

10 x 32 x 1 1155 A 965 A 730 A c 2/3 3574.005

5 x 40 x 1 930 A 780 A 590 A b 2/3 3575.005

10 x 40 x 1 1370 A 1145 A 865 A c 2/3 3576.005

5 x 50 x 1 1125 A 940 A 710 A b 2/3 3577.005

10 x 50 x 1 1635 A 1365 A 1030 A c 2/3 3578.005

10 x 63 x 1 1950 A 1610 A 1230 A d 2/3 3579.005

1) Number of lamina x lamina width x lamina thickness

2) The conductor temperature of the laminated copper bar is derived by adding the ambient temperature

and the temperature increase together

Example:

SV 3565.005 carrying 180 A, i.e. the temperature increases by 30 K. At an ambient temperature of 35°C,

this produces a resultant conductor temperature of 35°C + 30 K = 65°C

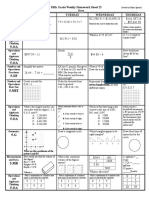

90

Basis of test:

VDE 0660, part 500/IEC 60 439-1. 80

Ip short-circuit current [kA]

Test implemented: d

Dynamic short-circuit withstand 70

strength to IEC 60 439-1 c

60

The dimensions for the support b

50

spacing (l) and for the centre-to- a

centre spacing (a) must be within 40

the specified min./max. limits.

The quotients of l/a can be used to 30

1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9

determine the permissible short- x

circuit current Ip by using curves a

Support spacing (l)

to d. The prescribed installation x=

Centre-to-centre spacing [a]

type must be taken into account.

Support spacing (l) Centre-to-centre spacing (a)

Curve mm mm

min. max. min. max.

a 150 300 34 60

b 150 350 42 85

c 200 400 51 85

d 200 450 81 100

Installation type with universal support SV 3079.000

1 2 3

l

l

a a a

dri1308114en.fm – 2-103 – 1 of 2 Technical details/Power distribution/02.2014

Power distribution

Laminated copper bars

Machining instructions

Bending

R=T

R = Bending radius

T = Lamina thickness

Torsion

M=2xL

M = Bending length

L

L = Lamina width

M

R=T

R = Bending radius

T = Lamina thickness

R

Drilling Drilling or punching must be carried out with extreme care.

When drilling, a drilling jig should be used, if applicable.

Special drilling jigs are available on the market for this purpose.

No coolants or lubricants should be used.

Note:

When drilling, take care to ensure that the lamina are held closely together,

so as to avoid deformation of the contact surfaces.

Punching When punching, appropriate male and female dies for Cu machining should be used.

Punching allows a smooth contact surface to be readily created.

Note:

When punching, take care to ensure that the lamina are held closely together,

so as to avoid deformation of the contact surfaces.

Technical details/Power distribution/02.2014 dri1308114en.fm – 2-103 – 2 of 2

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Bushing Insulators: Other Medium Voltage EquipmentDocument4 pagesBushing Insulators: Other Medium Voltage EquipmentjalilemadiNo ratings yet

- MCCB Abh403cDocument3 pagesMCCB Abh403chakiman.irecNo ratings yet

- RS SeriesDocument1 pageRS SeriesAkmalNo ratings yet

- AutoVentil Catalogue 2018 2019Document632 pagesAutoVentil Catalogue 2018 2019Bratislav GrujicicNo ratings yet

- Belt conveyor system component detailsDocument1 pageBelt conveyor system component detailsMuzani SyukurNo ratings yet

- SECOND FLOOR BEAM DESIGNDocument6 pagesSECOND FLOOR BEAM DESIGNBanda 007No ratings yet

- 2005 Glass Dem 040516Document12 pages2005 Glass Dem 040516葉健生No ratings yet

- DESIGN OPTIMIZATIONDocument35 pagesDESIGN OPTIMIZATIONdasun1988No ratings yet

- DRAFTDocument7 pagesDRAFTsNo ratings yet

- Intereste D in NBFC Documen T List Mail To CustomerDocument5 pagesIntereste D in NBFC Documen T List Mail To CustomerSunil JoshiNo ratings yet

- Charts & tables on Socomec busbar support fault levelsDocument1 pageCharts & tables on Socomec busbar support fault levelsmuqtar4uNo ratings yet

- LS Metasol CB QUICK SELECTION GUIDEDocument14 pagesLS Metasol CB QUICK SELECTION GUIDEmagsino ronaldNo ratings yet

- Cu or Al Xlpe Swa PVCDocument4 pagesCu or Al Xlpe Swa PVCSafdar AliNo ratings yet

- Trevi Benne CS Shear Appetite GuideDocument1 pageTrevi Benne CS Shear Appetite GuideKarikalan JayNo ratings yet

- Welding CableDocument4 pagesWelding CablegsbkrishnanNo ratings yet

- Tightening torques for Silumin and ferrous screw connectionsDocument2 pagesTightening torques for Silumin and ferrous screw connectionsLetacio OliveiraNo ratings yet

- Part Number SDAF 22330, Inch Straight Bore Mounting Pillow Block SDAF222 and SDAF223 SeriesDocument3 pagesPart Number SDAF 22330, Inch Straight Bore Mounting Pillow Block SDAF222 and SDAF223 SeriesMuhammad UmairNo ratings yet

- 3 Steel Grating Catalogue 2010 - SERIES 1 PDFDocument6 pages3 Steel Grating Catalogue 2010 - SERIES 1 PDFPablo MatrakaNo ratings yet

- SellingPrice Apartment 8septDocument1 pageSellingPrice Apartment 8septazharmeyerNo ratings yet

- Cu Chart Schnieder ElectricDocument2 pagesCu Chart Schnieder ElectricHamad GulNo ratings yet

- SW 2 KV VFD Cable Formal Data SheetDocument2 pagesSW 2 KV VFD Cable Formal Data Sheetjuan pablo castro gallegoNo ratings yet

- Enclosed Switch CatalogueDocument28 pagesEnclosed Switch CatalogueSteveMateNo ratings yet

- Standards Approvals & Certificates: Rutil-Bazik Örtülü Elektrod - Non Alloyed SteelsDocument1 pageStandards Approvals & Certificates: Rutil-Bazik Örtülü Elektrod - Non Alloyed SteelsBeshoy RedaNo ratings yet

- NKN E-2X (ST) YDocument3 pagesNKN E-2X (ST) YShittu TajudeenNo ratings yet

- 3AG Screw Terminal: Fuse Blocks and ClipsDocument4 pages3AG Screw Terminal: Fuse Blocks and ClipsAshish KrishnaNo ratings yet

- X Te Interface Serv LetDocument2 pagesX Te Interface Serv LetValeria Rendon NoyolaNo ratings yet

- SIMpull XHHW 2 Copper WireDocument3 pagesSIMpull XHHW 2 Copper Wireanton baskoroNo ratings yet

- Eton S A0001030147 1Document2 pagesEton S A0001030147 1Nacho AlvarezNo ratings yet

- Excavator Pin Carrier DimensionsDocument5 pagesExcavator Pin Carrier DimensionsCleyton L. Alves100% (4)

- Steel Qty 150+883 BCDocument12 pagesSteel Qty 150+883 BCsriharsha boyapatiNo ratings yet

- Baghouse Filter SpecificationsDocument2 pagesBaghouse Filter SpecificationsHassan SleemNo ratings yet

- Structural Sections - Mild SteelDocument1 pageStructural Sections - Mild SteelTanzeem JanNo ratings yet

- Bomba Centrifuga Sihi Modelo ZLND32160, ZLND40200 ZLND80400Document8 pagesBomba Centrifuga Sihi Modelo ZLND32160, ZLND40200 ZLND80400Cristian RodríguezNo ratings yet

- Motor Starters: Explosionproof, Dust-Ignitionproof, WatertightDocument37 pagesMotor Starters: Explosionproof, Dust-Ignitionproof, WatertightWaseem ArshadNo ratings yet

- AAS 920 618A Thermometrics Cable Probe Temperature 1608255Document5 pagesAAS 920 618A Thermometrics Cable Probe Temperature 1608255megatornadoNo ratings yet

- SAE FlangeDocument1 pageSAE FlangeOon VincentNo ratings yet

- Weight CalculationDocument4 pagesWeight CalculationAnonymous S95iXwfLANo ratings yet

- AFY RomanaDocument1 pageAFY RomanaOlaru GabrielaNo ratings yet

- Everything You Need to Know About Corten Steel Grades and SpecificationsDocument8 pagesEverything You Need to Know About Corten Steel Grades and SpecificationsadihindNo ratings yet

- HGP Series Generator Type: Molded Case Circuit BreakersDocument8 pagesHGP Series Generator Type: Molded Case Circuit BreakersLOI HONo ratings yet

- Microwave SLC Capacitors with Bordered DesignsDocument2 pagesMicrowave SLC Capacitors with Bordered DesignsrolandseNo ratings yet

- Brodski Kabel BXHOZO-HFTGDocument2 pagesBrodski Kabel BXHOZO-HFTGBozo BasicNo ratings yet

- SV GB Zubh 104-123 PDFDocument20 pagesSV GB Zubh 104-123 PDFTiti Mulat KusumaningrumNo ratings yet

- Features / BenefitsDocument54 pagesFeatures / Benefitsomar.ash8888No ratings yet

- Esfera Cilindro Cuadrado PlacaDocument4 pagesEsfera Cilindro Cuadrado Placarichard ccahuana laymeNo ratings yet

- Nsgafou (1) Cable TypeDocument1 pageNsgafou (1) Cable TypeBinay Kumar ChoudharyNo ratings yet

- Verification Example - Coped Beam: GeometryDocument4 pagesVerification Example - Coped Beam: Geometrybramo96No ratings yet

- Elec2 PDFDocument1 pageElec2 PDFNitin GandhareNo ratings yet

- Qty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountDocument1 pageQty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountNitin GandhareNo ratings yet

- NTPC AntaDocument1 pageNTPC AntaVamsi ManojNo ratings yet

- 5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052Document3 pages5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052MahfudNo ratings yet

- Side LocksDocument2 pagesSide LocksVictor Villouta LunaNo ratings yet

- Caddy Speed Link: Concuerda Con Los Requisitos de La Normativa DIN 4102-2, para 30 Minutos A 30% de Su Carga MáximaDocument4 pagesCaddy Speed Link: Concuerda Con Los Requisitos de La Normativa DIN 4102-2, para 30 Minutos A 30% de Su Carga MáximaMENELADONo ratings yet

- ITT American Electric Steel Poles Spec Sheet 2-79Document8 pagesITT American Electric Steel Poles Spec Sheet 2-79Alan MastersNo ratings yet

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- Plan of Foundation Bar Bending Schedule of Pier Foundation: Ø12 Rings@140c/c P6Document1 pagePlan of Foundation Bar Bending Schedule of Pier Foundation: Ø12 Rings@140c/c P6Pradip ThapaNo ratings yet

- 04 RJDocument2 pages04 RJMinhNo ratings yet

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Document2 pages5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCNo ratings yet

- Ti50FT Ti55FT ManualDocument132 pagesTi50FT Ti55FT ManualAlejandroZappaNo ratings yet

- Softstarters Type PSTX30... PSTX1250 User Manual Short FormDocument258 pagesSoftstarters Type PSTX30... PSTX1250 User Manual Short FormKushtrim MalaNo ratings yet

- 4-Cylinder Diesel Engine (1.9 L Engine)Document278 pages4-Cylinder Diesel Engine (1.9 L Engine)bgboy27100% (2)

- 1ZSE 5492-124 en Rev 6Document36 pages1ZSE 5492-124 en Rev 6Kushtrim MalaNo ratings yet

- VW Golf TDI - PD Engine IssuesDocument46 pagesVW Golf TDI - PD Engine IssuesKushtrim MalaNo ratings yet

- Latex Electrical Insulating Gloves Class 4Document1 pageLatex Electrical Insulating Gloves Class 4Kushtrim MalaNo ratings yet

- 5991691341923Document10 pages5991691341923Joe RanteNo ratings yet

- VW Golf TDI - PD Engine IssuesDocument46 pagesVW Golf TDI - PD Engine IssuesKushtrim MalaNo ratings yet

- Latex Electrical Insulating Gloves Class 4Document1 pageLatex Electrical Insulating Gloves Class 4Kushtrim MalaNo ratings yet

- 1LAB000614-Oil Reclamation - Eng-REV PDFDocument2 pages1LAB000614-Oil Reclamation - Eng-REV PDFKushtrim MalaNo ratings yet

- BNK2727 Psfi3018ukDocument1 pageBNK2727 Psfi3018ukKushtrim MalaNo ratings yet

- BNK2727 Psfi3018ukDocument1 pageBNK2727 Psfi3018ukKushtrim MalaNo ratings yet

- Areva T&D Ag: Life Cycle Extension Measures On High Voltage Circuit-BreakersDocument5 pagesAreva T&D Ag: Life Cycle Extension Measures On High Voltage Circuit-BreakersKushtrim MalaNo ratings yet

- General Conditions of Contract For The Supply of Machinery and Spare Parts 2001Document2 pagesGeneral Conditions of Contract For The Supply of Machinery and Spare Parts 2001Kushtrim MalaNo ratings yet

- 1ZSC000562-ACV en Rev A (Spare Parts UCG) - Pdfx1aDocument4 pages1ZSC000562-ACV en Rev A (Spare Parts UCG) - Pdfx1aKushtrim MalaNo ratings yet

- List of Ais Spare Parts 2008: Issue Date: 13.02.08 Valid Until: 31.12.08Document14 pagesList of Ais Spare Parts 2008: Issue Date: 13.02.08 Valid Until: 31.12.08Kushtrim MalaNo ratings yet

- 1ZSC000562-ACV en Rev A (Spare Parts UCG) - Pdfx1aDocument4 pages1ZSC000562-ACV en Rev A (Spare Parts UCG) - Pdfx1aKushtrim MalaNo ratings yet

- Water Supply and Sewage Disposal PDFDocument192 pagesWater Supply and Sewage Disposal PDFKushtrim MalaNo ratings yet

- Power Transformer Service: Nationwide Service - 24 Hour SupportDocument1 pagePower Transformer Service: Nationwide Service - 24 Hour SupportKushtrim MalaNo ratings yet

- Oil Condition and Dissolved Gas Analysis Sampling GuideDocument2 pagesOil Condition and Dissolved Gas Analysis Sampling GuideAbdullah GhannamNo ratings yet

- Valvoline Hydrol HLP 68Document1 pageValvoline Hydrol HLP 68Kushtrim MalaNo ratings yet

- Hitachi ABB Transformer ServiceDocument8 pagesHitachi ABB Transformer ServiceKushtrim MalaNo ratings yet

- Siemens Sirius 3RW30 3RW40 Manual PDFDocument212 pagesSiemens Sirius 3RW30 3RW40 Manual PDFElias Nassif GomezNo ratings yet

- 5492 0031-93 en Rev ADocument2 pages5492 0031-93 en Rev AKushtrim MalaNo ratings yet

- Water Supply and Sewage Disposal PDFDocument192 pagesWater Supply and Sewage Disposal PDFKushtrim MalaNo ratings yet

- 50 ADocument1 page50 AKushtrim MalaNo ratings yet

- Baying Systems TS 8: Height 2000 MM, Depth 600 MMDocument1 pageBaying Systems TS 8: Height 2000 MM, Depth 600 MMKushtrim MalaNo ratings yet

- Epoxy Resin Insulators and Silicon Rubber Insulators Industrial TradingDocument49 pagesEpoxy Resin Insulators and Silicon Rubber Insulators Industrial Tradingsajjad_pirzadaNo ratings yet

- Baying Systems TS 8: Height 2000 MM, Depth 600 MMDocument1 pageBaying Systems TS 8: Height 2000 MM, Depth 600 MMKushtrim MalaNo ratings yet

- TMDI Lesson Plan in Storing and Reconstituting StocksDocument5 pagesTMDI Lesson Plan in Storing and Reconstituting StocksDiane VillNo ratings yet

- Agricrop9 ModuleDocument22 pagesAgricrop9 ModuleMaria Daisy ReyesNo ratings yet

- Jenny Randles - Mind Monsters - Invaders From Inner Space (1990)Document219 pagesJenny Randles - Mind Monsters - Invaders From Inner Space (1990)DirkTheDaring11100% (15)

- Economics Not An Evolutionary ScienceDocument17 pagesEconomics Not An Evolutionary SciencemariorossiNo ratings yet

- Data Table CarbonDocument2 pagesData Table Carbonyodaswarrior33% (15)

- Physics ProjectDocument12 pagesPhysics ProjectRita SharmaNo ratings yet

- Achmad Nurdianto, S.PD: About MeDocument2 pagesAchmad Nurdianto, S.PD: About Medidon knowrezNo ratings yet

- Module 4.Document16 pagesModule 4.Sania MaqsoodNo ratings yet

- Resume summary of monthly sparepart costs and production in 2021Document590 pagesResume summary of monthly sparepart costs and production in 2021winda listya ningrumNo ratings yet

- E-Ship Assignment 2 Utkarsh Surjey MBA-FT-EDocument3 pagesE-Ship Assignment 2 Utkarsh Surjey MBA-FT-Eutkarsh surjeyNo ratings yet

- DL1 - Epicyclic Gear Train & Holding Torque ManualDocument4 pagesDL1 - Epicyclic Gear Train & Holding Torque Manualer_arun76100% (1)

- BITS Vulnerability Management Maturity ModelDocument19 pagesBITS Vulnerability Management Maturity ModelJack JacksonNo ratings yet

- RADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintDocument392 pagesRADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintLafayers100% (2)

- 3 6 17weekly Homework Sheet Week 23 - 5th Grade - CcssDocument3 pages3 6 17weekly Homework Sheet Week 23 - 5th Grade - Ccssapi-328344919No ratings yet

- GE 5 Purposive Communication Course OverviewDocument10 pagesGE 5 Purposive Communication Course OverviewHarold LuceroNo ratings yet

- Oven Nordson ElectronicDocument60 pagesOven Nordson ElectronicDanijela KoNo ratings yet

- STAUFF Catalogue 1 STAUFF Clamps English TERBARU RemovedDocument5 pagesSTAUFF Catalogue 1 STAUFF Clamps English TERBARU RemovedBayuAnggaraNo ratings yet

- Chapter 5 PresentationDocument35 pagesChapter 5 PresentationSabeur Dammak100% (1)

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- Cylinder Head Cover, 6T-830 and 6ta-830 Emissions Certified EngineDocument3 pagesCylinder Head Cover, 6T-830 and 6ta-830 Emissions Certified EngineJose A PerezNo ratings yet

- Volkswagen 2.0L TDI Common Rail Engine Service TrainingDocument90 pagesVolkswagen 2.0L TDI Common Rail Engine Service TrainingАлла Харютина100% (1)

- Cryptography and Network Security": Sir Syed University of Engineering & TechnologyDocument5 pagesCryptography and Network Security": Sir Syed University of Engineering & TechnologySehar KhanNo ratings yet

- DLP 6 LO2 Safe Disposal of Tools and MaterialsDocument13 pagesDLP 6 LO2 Safe Disposal of Tools and MaterialsReybeth Tahud Hamili - Matus100% (2)

- 6.1 Futures and Options AnalysisDocument2 pages6.1 Futures and Options AnalysisSuraj DecorousNo ratings yet

- IAS Mains Electrical Engineering 1994Document10 pagesIAS Mains Electrical Engineering 1994rameshaarya99No ratings yet

- Accident Avoiding Bumper SystemDocument3 pagesAccident Avoiding Bumper SystemDeepak DaineNo ratings yet

- QP 7721-Sobha-B+g+8-2town-Pahse IiDocument2 pagesQP 7721-Sobha-B+g+8-2town-Pahse IirajatNo ratings yet

- Function Apollo Amadeus: Sign In/OutDocument16 pagesFunction Apollo Amadeus: Sign In/OutMabs GaddNo ratings yet

- Gerunds vs InfinitivesDocument87 pagesGerunds vs InfinitivesDeby NavarroNo ratings yet

- National Institute of Technology Calicut: Department of Computer Science and EngineeringDocument8 pagesNational Institute of Technology Calicut: Department of Computer Science and EngineeringArun ManuNo ratings yet