Professional Documents

Culture Documents

Cycle Step: Regulates Single Welding Droplets

Cycle Step: Regulates Single Welding Droplets

Uploaded by

Javier MiramontesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cycle Step: Regulates Single Welding Droplets

Cycle Step: Regulates Single Welding Droplets

Uploaded by

Javier MiramontesCopyright:

Available Formats

/ Perfect Welding / Solar Energy / Perfect Charging

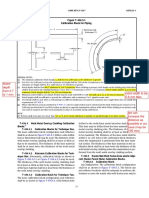

CMT

Cycle Step Regulates

Single welding

droplets

Highest level of repeatability

/ The set number of welding droplets per

welding spot allow for unique repeatability.

DEFINED SPOT SIZE

/ Exact welding spot size repeatability

/ No welding reinforcement

Minimal heat input

/ Even the thinnest of sheets can be welded

Hold point

through easily controllable heat input. 1 mm elo coated Filler wire: CuSi3 1 mm

Vd: 11,5 m/min Number of CMT-cycles: 8

PERFECT WELD SEAM APPEARANCE

/ Defined welding cycles allow high-quality

visible welding seams – spatter-free

Applications

Cycle Step

Visible welding seams with defined jointing √

Welding thin sheets with tolerances √

Fine overlay welding √

Additive welding applications √ Lap joint

Support by bonding techniques through defined 3 mm aluminum Filler wire: AlSi5 1,2 mm

√ Vd: 7,7 m/min Number of CMT-cycles: 18

distances (distance points)

Vs: 50 cm/min Break time: 0,16 s

Hold points for bonded joints √

Welding in position √

What‘s your

welding challenge?

www.fronius.com Let’s get connected.

You might also like

- Magnetic Particle TestingDocument3 pagesMagnetic Particle TestingKurniawanNo ratings yet

- User'S Manual: June 2006 T.O. #33D7-22-32-1Document194 pagesUser'S Manual: June 2006 T.O. #33D7-22-32-1Pierpaolo AparoNo ratings yet

- AA0850126 Rev 02Document10 pagesAA0850126 Rev 02Manish KumarNo ratings yet

- Weld DecayDocument1 pageWeld DecaySaid Alauddeen FaiszNo ratings yet

- Question 1 of 25Document7 pagesQuestion 1 of 25antonio larotta100% (1)

- General Level-II QuestionsDocument4 pagesGeneral Level-II QuestionsGomathi SankarNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- CWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)Document8 pagesCWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedNo ratings yet

- Module 4 Weld Geometry and Welding Symbols-1Document87 pagesModule 4 Weld Geometry and Welding Symbols-1Miki Jaksic100% (1)

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocument7 pagesMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimNo ratings yet

- Welding Inspection and CertificationDocument30 pagesWelding Inspection and Certificationmahmoud_allam3No ratings yet

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeNo ratings yet

- Ssab Astm A537 C2Document2 pagesSsab Astm A537 C2vasotermiNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- Cordon Off - 4 (00000003)Document1 pageCordon Off - 4 (00000003)Anonymous PlyxbQ3tNo ratings yet

- Welding Engineer Exam SyllubusDocument2 pagesWelding Engineer Exam SyllubuskapsarcNo ratings yet

- Scenario 1 S: Lamelar Tearing Occur in Set In? orDocument6 pagesScenario 1 S: Lamelar Tearing Occur in Set In? orBeny ZulNo ratings yet

- DefectDocument2 pagesDefectanon_90890103100% (1)

- 6-Laser Beam Welding MFTDocument11 pages6-Laser Beam Welding MFTRamu AmaraNo ratings yet

- Gas Cutting WLDNG Process - 06 - Module 6Document100 pagesGas Cutting WLDNG Process - 06 - Module 6sskiitb100% (1)

- Catalog 2017 Winter Spring PDFDocument52 pagesCatalog 2017 Winter Spring PDFLhagva DalaibatNo ratings yet

- NDT Magnetic Particle (Home Study) PDFDocument411 pagesNDT Magnetic Particle (Home Study) PDFdonciriusNo ratings yet

- Hot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaDocument4 pagesHot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaraajmrkNo ratings yet

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Document60 pages3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- International Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas WeldingDocument60 pagesInternational Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas Weldingresky marantinanNo ratings yet

- Asme Sec V A-15-2006Document4 pagesAsme Sec V A-15-2006Muhammed Abo-FandoodNo ratings yet

- JIS5402 For FRC Rooftile PDFDocument5 pagesJIS5402 For FRC Rooftile PDFQuảng Nguyễn HồngNo ratings yet

- Guidance To Understanding Implications of IRMERDocument52 pagesGuidance To Understanding Implications of IRMERrochimNo ratings yet

- Api 571 CorrosionDocument5 pagesApi 571 CorrosionArun GuptaNo ratings yet

- API 510 Daily Exam 8 (OPEN) : 2. Tick Only One Alternative Which You Think Is Most AppropriateDocument5 pagesAPI 510 Daily Exam 8 (OPEN) : 2. Tick Only One Alternative Which You Think Is Most AppropriateShanawas Abdul RazakNo ratings yet

- EW 512 6 Nondestructive TestingDocument37 pagesEW 512 6 Nondestructive TestingHarun HodžićNo ratings yet

- Welding AWS B1.11Document22 pagesWelding AWS B1.11Ali SASSINo ratings yet

- 0455e - Welding Inspector Visual Acuity Record PDFDocument1 page0455e - Welding Inspector Visual Acuity Record PDFAbu HanifaNo ratings yet

- 331 Heat Treatment: ASME B31.3-2012Document4 pages331 Heat Treatment: ASME B31.3-2012Stephen RajNo ratings yet

- Product Technology ASNT Module 5Document8 pagesProduct Technology ASNT Module 5Raje GunaNo ratings yet

- RT Pipeline Crawler PDFDocument12 pagesRT Pipeline Crawler PDFAnonymous 5qPKvmuTWCNo ratings yet

- Resistance Welding WpsDocument1 pageResistance Welding WpsQwertyNo ratings yet

- Lecture 7 Intergranular CorrosionDocument18 pagesLecture 7 Intergranular Corrosionprakush01975225403No ratings yet

- Piping TCG Caliberation BlockDocument1 pagePiping TCG Caliberation BlockAhmed Abd ElmegeedNo ratings yet

- Tech Manual MVP Series 2017.1 WIP 3Document73 pagesTech Manual MVP Series 2017.1 WIP 3Chav HoangNo ratings yet

- IIW-India Project Format - DocDocument13 pagesIIW-India Project Format - DocRameshBaskaranNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- 344.2 Visual Examination: Para. 344.7Document1 page344.2 Visual Examination: Para. 344.7NDTInstructorNo ratings yet

- WC-514 - Weld Discontinuities PDFDocument1 pageWC-514 - Weld Discontinuities PDFNathanLaertePiaiNo ratings yet

- P2d Op ManualDocument114 pagesP2d Op ManualDaniel BernardNo ratings yet

- Standard Test Method For Radioscopic Examination of WeldmentsDocument5 pagesStandard Test Method For Radioscopic Examination of WeldmentsWagner Renato AraújoNo ratings yet

- Cswip Section 13 Mig Mag WeldingDocument23 pagesCswip Section 13 Mig Mag WeldingNsidibe Michael EtimNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- Defects and Discontinuities: Boiler and Mechanical PowerDocument78 pagesDefects and Discontinuities: Boiler and Mechanical PowerthejusNo ratings yet

- Normalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionDocument3 pagesNormalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionAnonymous izrFWiQNo ratings yet

- Resistance Welding Electrodes: Tips With Tapered Shanks Nose Types A, B, C, D, E & FDocument9 pagesResistance Welding Electrodes: Tips With Tapered Shanks Nose Types A, B, C, D, E & FreachfsrNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- N1P 1.5 P1T2 BLK LDocument2 pagesN1P 1.5 P1T2 BLK LRijo RajanNo ratings yet

- Spread Sheet of Plate Girder-Is800-2007Document3 pagesSpread Sheet of Plate Girder-Is800-2007yedida v r aviswanadhNo ratings yet

- 01 Track 2 - Armaki2 - 019 GDIS-Advantages of Fortiform 980 GI - Superior Weldability PDFDocument17 pages01 Track 2 - Armaki2 - 019 GDIS-Advantages of Fortiform 980 GI - Superior Weldability PDFSilverio AcuñaNo ratings yet

- Hoist Chains: For Manual and Motor-Driven HoistsDocument12 pagesHoist Chains: For Manual and Motor-Driven HoistsjoosuasinagaNo ratings yet

- PCB Terminal Block - MKDS 3/ 2-5,08 - 1711725: Why Buy This ProductDocument5 pagesPCB Terminal Block - MKDS 3/ 2-5,08 - 1711725: Why Buy This ProductJonathan Llewellyn AndradaNo ratings yet

- Classic 6 Midwoofer: Type Number: 18W/8545K00 FeaturesDocument2 pagesClassic 6 Midwoofer: Type Number: 18W/8545K00 FeaturesfulgenNo ratings yet

- Vifa BC14SG-49-08Document2 pagesVifa BC14SG-49-08TNNo ratings yet