Professional Documents

Culture Documents

Air Eliminators: Din PN 16 ANSI 125 DN 15 To 25mm 1/2" To 1" TL 11, 11P

Uploaded by

Denis MarcosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Eliminators: Din PN 16 ANSI 125 DN 15 To 25mm 1/2" To 1" TL 11, 11P

Uploaded by

Denis MarcosCopyright:

Available Formats

TL

Steam traps

Air eliminators

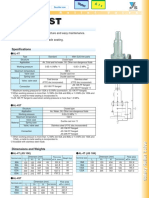

DIN PN 16 DN 15 to 25mm TL 11, 11P

ANSI 125 1/2" to 1"

Application

For deaeration of liquid lines, through the float

mechanism that modulates the seat opening,

possible to see the elimination of the air pockets

that endanger the liquid circulation.

Main characteristics

- Internal mechanism simplicity, which

facilitates, greatly, cases of maintenance;

- Minimum maintenance.

Presentation

Air eliminator composed of: body, cover,

and internal mechanism (assembly) of

sealing.

Installation

The TL 11 air eliminator must be installed in

high places or end oflines, where there is

greater accumulation of air. A ball valve must

be forecasted before the eliminator to facilitate

TL 11 TL 11P

maintenance operations when necessary.

Technical competence, materials and connections

Operation

Model TL 11P TL 11

The air contained in the system is drained Nominal Diameter (mm) 15 20 25

to the outside enviroment through the seat

(pol) 1/2" 3/4" 1"

orifice. The closing occurs imediattely upon

the arrival of the liquid inside the air Max.service pressure. (bar man.) 13 16

eliminator. The closing happpens through Max. correspondent temp. (°C ) 100 200

the internal mechanism, that, with the

Materials

raising float, presses the needle against the

No Description Quant. Specification

seat.

1 Cover 1 ASTM A 126 B ASTM A 126 B

2 Body 1 ASTM A 126 B ASTM A 126 B

3 Gasket 1* Hidraulic cardboard Hidraulic cardboard

4 Hex. head screw 6 - Carbon steel

5 Round head screw 1 - AISI 304

6 Lever 1 - AISI 304

7 Seat 1* AISI 304 AISI 304

Measures and weights 8 Support 1 - AISI 304

Model TL 11P TL 11 9 Axle 1 - AISI 304

10 Needle 1 - AISI 304

Measures (mm) 11 Float 1 Polyethylene AISI 304

A 140 139

12 Label and rivets 1+2 Aluminium Aluminium

B 76 108

- 129 13 Shutter 1 - Zinced carbon steel

C

14 Retaining ring 1* - AISI 304

Approx. weight. (kg) 1,50 2,80 Connections Thread BSP / NPT

*Recommended spare parts

Edition: 09/08 PR-01.80.10-I

Steam traps

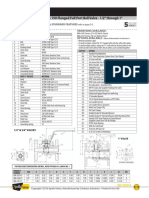

Flow chart

Capacity chart TL 11

ASCA TL 11 air eliminator can be supplied

with two differents seats, can be seen on

the capacity chart on the left. According to

the pressure differtential, the fllow and the

process flow, seat 1 or seat 2 is chosen.

Data for sizing

ASCA will make pleasure the sizing.

For this purpose must be supplied:

Sede 1 - Service pressure;

Sede 2 - Type of seat (1 or 2);

CAPACITY - Nm³/h

- Type of forecasred connection;

CAPACITY - SCFM

- Nominal diameter of the eliminator.

Standard specification

Thermal-thermodynamic steam traps fore

steam

Model TL 11....................................from ASCA

According to prospect PR-01.80.10-I

Connections.....................................................

Type of seat ....................................................

As per norm .................................................

Pressure class ..........................................

Nominal diameter .............................................

DIFFERENTIAL PRESSURE

Flow tableTL11P

Differential pressure (bar) 0,5 1 2 4 6 9 10

Capacity (Nm³/h) 0,9 1,6 3,0 5,0 7,1 9,8 10,5

ASCA EQUIPAMENTOS INDUSTRIAIS LTDA.

202. Fernandes da Cunha,Street- Vigário Geral - Rio de Janeiro - RJ - COD 21241-300 We resertv the right of introducing fast

Tel.: (21) 2472-6900 - Fax (21) 3014-7622 - e-mail: office@asca.com.br modifications of technical order.

homepage: http://www.asca.com.br coPYRIGHT 2000 BY ASCA INDUSTRIAL EQUIPMENTS LTDA.

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Technische Dokumentation Technical Documentation: XOMOX Ball Valves Type Kva / KVL / KVKDocument28 pagesTechnische Dokumentation Technical Documentation: XOMOX Ball Valves Type Kva / KVL / KVKTonyNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Bronze Globe ValveDocument1 pageBronze Globe ValveCarlos BritoNo ratings yet

- Parts List MAGNETIC PUMPDocument3 pagesParts List MAGNETIC PUMPErick Moreira ValdezNo ratings yet

- Argus HK35Document2 pagesArgus HK35Felipe Gamboa GálvezNo ratings yet

- F Series - Floating Ball ValvesDocument8 pagesF Series - Floating Ball ValvesCarlos Alberto Aguilera MendezNo ratings yet

- Uploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFDocument8 pagesUploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFMonica CarrenoNo ratings yet

- Ba LLV Alv Es: Valves & EquipmentDocument13 pagesBa LLV Alv Es: Valves & EquipmentravishankarNo ratings yet

- EBARA - Pump TFS TLSDocument8 pagesEBARA - Pump TFS TLSMuhammad Imam MuthahharNo ratings yet

- Steam Trap FT450Document3 pagesSteam Trap FT450joel angel Pinedo GamarraNo ratings yet

- Small Size Valves CatalogDocument5 pagesSmall Size Valves Cataloguli hasibuanNo ratings yet

- KV Tripple Eccentric Butterfly Valve-LinDocument12 pagesKV Tripple Eccentric Butterfly Valve-LinWelma JohnsonNo ratings yet

- Type C: Hopper Shape Knife Gate ValveDocument13 pagesType C: Hopper Shape Knife Gate ValveAbdur Rohman Al BaabNo ratings yet

- Data Sheets Series 155 FloatingDocument4 pagesData Sheets Series 155 Floatingbayarjargal SuwdusNo ratings yet

- SLC 1 Spec SheetDocument2 pagesSLC 1 Spec SheetArstNo ratings yet

- Features::: 3-Way Stainless Steel Ball Valve Reduce Port, 1000WOG, PN16/40 WB-05TLDocument1 pageFeatures::: 3-Way Stainless Steel Ball Valve Reduce Port, 1000WOG, PN16/40 WB-05TLsimbamikeNo ratings yet

- Opw API Coupler - CleanedDocument6 pagesOpw API Coupler - Cleanedger80No ratings yet

- Fire Fighting Pump Model FSPA and CNPA: Compliance To NFPA 20Document14 pagesFire Fighting Pump Model FSPA and CNPA: Compliance To NFPA 20Gage Cendk HNo ratings yet

- Sant List April-2017Document61 pagesSant List April-2017Javed HasanNo ratings yet

- 105 PDFDocument1 page105 PDFUyabNo ratings yet

- Argus FK76MDocument2 pagesArgus FK76MFelipe Gamboa Gálvez100% (1)

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- Series 64 Screwed End Ball ValvesDocument2 pagesSeries 64 Screwed End Ball ValvesProcess Controls & ServicesNo ratings yet

- S80 - Sales Borchure EnglishDocument2 pagesS80 - Sales Borchure Englishevilnemesis133No ratings yet

- Z-TIDE Pressure Reducing Valve - Series RE: Thread / Flange Type Thread Type Does Not Have Part No. 11Document1 pageZ-TIDE Pressure Reducing Valve - Series RE: Thread / Flange Type Thread Type Does Not Have Part No. 11JackNo ratings yet

- ISO Standard End-Suction Centrifugal Pumps NJK Series: PP-H PVDF Etfe PVDF CFRPVDFDocument7 pagesISO Standard End-Suction Centrifugal Pumps NJK Series: PP-H PVDF Etfe PVDF CFRPVDFstar enggNo ratings yet

- Argus FK75Document2 pagesArgus FK75Felipe Gamboa GálvezNo ratings yet

- ISO Standard End-Suction Centrifugal Pumps NJRP Series: GFRPP PP-HDocument7 pagesISO Standard End-Suction Centrifugal Pumps NJRP Series: GFRPP PP-HBrijesh GajjarNo ratings yet

- 3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CDocument5 pages3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CAbigail Lupe Aguilar YapuraNo ratings yet

- Ball Valves - API 6D - CatalogueDocument7 pagesBall Valves - API 6D - CatalogueCésar SantanaNo ratings yet

- SS-E-04 - RID Air ToqueDocument8 pagesSS-E-04 - RID Air ToqueagrovadoNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Technical Bulletin: NAF Setball SF Ball Sector ValvesDocument16 pagesTechnical Bulletin: NAF Setball SF Ball Sector ValvesFahmi HaidiNo ratings yet

- Series 3250 Globe Control Valve Type 3251 Pneumatic Control Valves Type 3251/3271 and Type 3251/3277Document14 pagesSeries 3250 Globe Control Valve Type 3251 Pneumatic Control Valves Type 3251/3271 and Type 3251/3277Mohamed RaafatNo ratings yet

- FLOWTEK - Ficha Tecnica-ComprimidoDocument8 pagesFLOWTEK - Ficha Tecnica-ComprimidoJosé BrionesNo ratings yet

- Air Torque 4THGU-E-06Document26 pagesAir Torque 4THGU-E-06agrovado0% (1)

- Trampa Tipo Balde JH7 TLVDocument2 pagesTrampa Tipo Balde JH7 TLVAriel InsaurraldeNo ratings yet

- Serie 080 RTC CouplingsDocument2 pagesSerie 080 RTC CouplingsHIDRAFLUIDNo ratings yet

- 04 Mobile Foam Cart CMFCDocument6 pages04 Mobile Foam Cart CMFCuki12345No ratings yet

- TB14b-eco ENDocument6 pagesTB14b-eco ENagrovadoNo ratings yet

- BOQ For Bought Out Items (Compressed Air) PDFDocument2 pagesBOQ For Bought Out Items (Compressed Air) PDFsppatilNo ratings yet

- Data Sheet Purgador PT65-40Document2 pagesData Sheet Purgador PT65-40Douglas Tondello100% (1)

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- NAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsDocument2 pagesNAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- Air CompressorDocument1 pageAir CompressorSabiha Mahafuza ZozoneeNo ratings yet

- Data Sheet - UPRV R2-5Document4 pagesData Sheet - UPRV R2-5vipulsingh130No ratings yet

- Goulds Pumps NPE 316 Stainless Steel Pumps Repair Parts Manual RNPE R7 2 21Document4 pagesGoulds Pumps NPE 316 Stainless Steel Pumps Repair Parts Manual RNPE R7 2 21downeywang666No ratings yet

- Hi-Lo Pilot - Ruelco 4202 SS-2 - SpringDocument4 pagesHi-Lo Pilot - Ruelco 4202 SS-2 - SpringNavas100% (1)

- Brochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDocument6 pagesBrochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDt BarusNo ratings yet

- 88A-200 SERIES: Carbon Steel ASME Class 150 Flanged Full Port Ball Valve - 1/2" Through 1"Document9 pages88A-200 SERIES: Carbon Steel ASME Class 150 Flanged Full Port Ball Valve - 1/2" Through 1"alan quispe coronelNo ratings yet

- High Flow Direct Acting Valves: FeaturesDocument2 pagesHigh Flow Direct Acting Valves: FeaturesBurhan AyubNo ratings yet

- Vacuum Breaker Safety Valve795Document2 pagesVacuum Breaker Safety Valve795Zulfeqar AliNo ratings yet

- ART 1310 Rev1Document1 pageART 1310 Rev1mohdmmedniyaz786No ratings yet

- OlgahDocument12 pagesOlgahDaniel BahamondeNo ratings yet

- Section 1720 Data - 2Document10 pagesSection 1720 Data - 2Andri AjaNo ratings yet

- Normec Internal FootvalveDocument2 pagesNormec Internal FootvalveL.kolekarNo ratings yet

- Free Float Steam Trap: Model Ductile Cast Iron Cast IronDocument2 pagesFree Float Steam Trap: Model Ductile Cast Iron Cast IronSamerNo ratings yet

- GLT Ball Valve Trunnion 300#Document5 pagesGLT Ball Valve Trunnion 300#Sugeng WahyudiNo ratings yet

- Air Eliminators: Din PN 16 ANSI 125 DN 15 To 25mm 1/2" To 1" TL 11, 11PDocument2 pagesAir Eliminators: Din PN 16 ANSI 125 DN 15 To 25mm 1/2" To 1" TL 11, 11PDenis MarcosNo ratings yet

- Acs4001a SrvguideDocument6 pagesAcs4001a SrvguideDenis MarcosNo ratings yet

- 1.6 - Manual Valvula 788Document8 pages1.6 - Manual Valvula 788Denis MarcosNo ratings yet

- 1.1 - Monitor de Aterramento - 8030Document2 pages1.1 - Monitor de Aterramento - 8030Denis MarcosNo ratings yet

- Switch Yard & Protection SystemDocument48 pagesSwitch Yard & Protection SystemDharmendra GargNo ratings yet

- Pappu Suryanarayana Murthy: Career ObjectiveDocument3 pagesPappu Suryanarayana Murthy: Career ObjectiveSuurya PrabhathNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Saudi Electricity Company - Southern Region (Saudi Arabia)Document7 pagesSaudi Electricity Company - Southern Region (Saudi Arabia)azeemmet9924No ratings yet

- Hazardous Area Heater Crex 020 Old Version 2721512-544292Document2 pagesHazardous Area Heater Crex 020 Old Version 2721512-544292Achintya KarmakarNo ratings yet

- Ze Gcs04a20-Eng 247-270Document24 pagesZe Gcs04a20-Eng 247-270ikrima BenNo ratings yet

- Electrical Equipment in Hazardous LocationsDocument41 pagesElectrical Equipment in Hazardous LocationsSAYEDNo ratings yet

- Curriculum Vitae: Contact DetailsDocument3 pagesCurriculum Vitae: Contact DetailsDhileepNo ratings yet

- From The Desk of Mark Hamilton A Prime-Literature Neothink Nugget For Neothink Members-OnlyDocument8 pagesFrom The Desk of Mark Hamilton A Prime-Literature Neothink Nugget For Neothink Members-Onlyphilosophe662511No ratings yet

- Mazda rx7Document3 pagesMazda rx7Jon WestNo ratings yet

- SR No. Beneficiary Name Scheme Name Purpose Amount Utr No. (Bank TXN Id) Bank TXN Date Status Failure Reason Credit Date Uidasper Bank Acctnumber Asperbank Favoringas Perbank Bankiinas PerbankDocument3 pagesSR No. Beneficiary Name Scheme Name Purpose Amount Utr No. (Bank TXN Id) Bank TXN Date Status Failure Reason Credit Date Uidasper Bank Acctnumber Asperbank Favoringas Perbank Bankiinas PerbankAnand ReddyNo ratings yet

- Hardware Compatibility List (HCL) For Veritas Storage Foundation (TM) and High Availability Solutions 4.1 MP2 For SolarisDocument5 pagesHardware Compatibility List (HCL) For Veritas Storage Foundation (TM) and High Availability Solutions 4.1 MP2 For SolarisbennialNo ratings yet

- w170 w190 w230c - 30644gb 123bbDocument20 pagesw170 w190 w230c - 30644gb 123bbJIMISINGNo ratings yet

- CSS ExercisesDocument8 pagesCSS ExercisesWarnnie MusahNo ratings yet

- Design of Anchor Bolts Embedded in Concrete MasonryDocument9 pagesDesign of Anchor Bolts Embedded in Concrete MasonryYoesuf DecipherNo ratings yet

- 4037 PDFDocument10 pages4037 PDFasfaruk2556No ratings yet

- Vale International Pellet Plant PDFDocument2 pagesVale International Pellet Plant PDFSrinivasanNo ratings yet

- Move All Database Objects From One Tablespace To AnotherDocument2 pagesMove All Database Objects From One Tablespace To AnotherJabras GuppiesNo ratings yet

- DIAGRAMA - 2007 - NEW YarisDocument1 pageDIAGRAMA - 2007 - NEW YarisLuis M. Valenzuela Arias50% (2)

- A1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767Document16 pagesA1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767MuseNo ratings yet

- Fire Risk Assessment ChecklistDocument10 pagesFire Risk Assessment Checklistm. absiyeNo ratings yet

- 2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.Document3 pages2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.des1982No ratings yet

- Acti 9 & Compact NSX/NS: Short Form Selection Chart - 2011Document1 pageActi 9 & Compact NSX/NS: Short Form Selection Chart - 2011Pierre-Jac VenterNo ratings yet

- Skills, Techniques and Production in Contemporary Art HANDOUT PDFDocument4 pagesSkills, Techniques and Production in Contemporary Art HANDOUT PDFKeyy TaezaNo ratings yet

- Agent CompatibilityDocument9 pagesAgent Compatibilityajilani2014No ratings yet

- BCA-529 Linux & Unix PDFDocument102 pagesBCA-529 Linux & Unix PDFmayur malviyaNo ratings yet

- 1 Starting Time Calculation 2Document15 pages1 Starting Time Calculation 2Sankalp MittalNo ratings yet

- Cs2000 Universal Translations3006a 50 SGDocument508 pagesCs2000 Universal Translations3006a 50 SGAleksandr BashmakovNo ratings yet

- Hotel Cleaning Equipment Used byDocument9 pagesHotel Cleaning Equipment Used byLeonardo ViridisNo ratings yet

- Mica PDFDocument2 pagesMica PDFomarNo ratings yet