Professional Documents

Culture Documents

High Flow Direct Acting Valves: Features

Uploaded by

Burhan AyubOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Flow Direct Acting Valves: Features

Uploaded by

Burhan AyubCopyright:

Available Formats

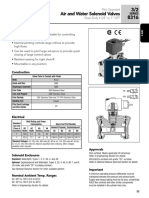

3/2

4

Balanced Poppet Type

High Flow Direct Acting Valves SERIES

Brass and 316 Stainless Steel Bodies • 1/4" NPT 8327

Features

3-WAY

• Designed for high flow piloting with no minimum % ^ )

operating pressure required; e.g. power plants,

refineries, chemical processing

• Balanced Poppet construction for high flow at

minimum power levels

• PTFE rider rings and graphite-filled seals reduce

friction and eliminate sticking to provide

exceptional service life

• 316 Stainless Steel construction for highly

corrosive atmospheres

• Available with manual reset

See Special Service Section

Construction

Valve Parts in Contact with Fluids

Body Brass 316 Stainless Steel

2

Core Tube 305 Stainless Steel U

Stem and Insert 303 Stainless Steel 3 1

Core and Plugnut 430F Stainless Steel

O-ring Holder 430F Stainless Steel

Springs 302 Stainless Steel

NBR FKM

Seals and Discs

VMQ (Low-Temperature Construction)

Rider Ring PTFE

Electrical

Watt Rating and Power

Consumption Spare Coil Part Number

Standard

Coil and AC General Purpose Explosionproof

Class of DC VA VA

Insulation Watts Watts Holding Inrush AC DC AC DC

F 11.6 12 12 12 276000 238710 276002 238714

Standard Voltages: 24/50-60, 120/50-60, 240/50-60, and 480/50-60, or 6, 12, 24,

120, and 240 DC.

Solenoid Enclosures Nominal Ambient Temp. Ranges

Standard: 8327G041 and 042:

For Brass Valves: Standard Solenoid enclosure is Types, 1, 2, 3, 3S, 4, and 4X. -4˚F to 131˚F (-20˚C to 55˚C)

For 316 Stainless Steel valves: Standard Solenoid enclosure is Explosionproof 8327G051 and 052:

and Watertight Types 3, 3S, 4, 4X, 6, and 6P. -40˚F to 131˚F (-40˚C to 55˚C)

Optional: Explosionproof and Watertight, Types 3, 3S, 4, 4X, 6, 6P, 7, and 9. Refer to Engineering Section for details.

(To order, add prefix “EF” or, for Explosionproof Stainless Steel trim and hub

on Brass-Bodied valves, add “EV” to catalog number.) Approvals

See Optional Features Section for other available options. CSA certified. UL listed General Purpose Valves.

SIL (Safety Integrity Level) Information: Meets applicable CE directives.

• PFD (Probability of Failure on Demand) <4x10-7 at a confidence factor of 95%. Refer to Engineering Section for details.

• SFF (Safe Failure Fraction) according to IEC 61508-2 Table A1 is ≥ 0.99.

• Only constructions without manual operators apply to the above criteria. 69

3/2

SERIES

8327 4

Specifications (English units)

3-WAY

Watt Rating/

Cv Flow Maximum Operating 316 Stainless Class of Coil

Pipe Factor Pressure Differential (psi) Max. Brass Body Steel Body Insulation

Size Orifice Ports Ports Air-Inert Light Oil Fluid Const.

(in) Size (in) 1-2 2-3 Gas Water @ 300 SSU Temp. ˚F Catalog Number Catalog Number Ref. AC DC

UNIVERSAL OPERATION (Pressure at any port)

1/4 1/4 .49 .56 150 150 150 176 8327G041 – 1 12.0/F 11.6/F

1/4 1/4 .49 .56 150 150 150 248 – EV8327G042 1 12.0/F 11.6/F

UNIVERSAL LOW-TEMPERATURE OPERATION (Pressure at any port)

1/4 1/4 .49 .56 150 – – 131 8327G051 – 1 12.0/F 11.6/F

1/4 1/4 .49 .56 150 – – 131 – EV8327G052 1 12.0/F 11.6/F

Specifications (Metric units)

Kv Flow Watt Rating/

Factor Maximum Operating 316 Stainless Class of Coil

(m3/h) Pressure Differential (bar) Brass Body Steel Body Insulation

Pipe Orifice Max.

Size Size Ports Ports Air-Inert Light Oil Fluid Const.

(in) (mm) 1-2 2-3 Gas Water @ 300 SSU Temp. ˚C Catalog Number Catalog Number Ref. AC DC

UNIVERSAL OPERATION (Pressure at any port)

1/4 6 .42 .48 10 10 10 80 8327G041 – 1 12.0/F 11.6/F

1/4 6 .42 .48 10 10 10 120 – EV8327G042 1 12.0/F 11.6/F

UNIVERSAL LOW-TEMPERATURE OPERATION (Pressure at any port)

1/4 6 .42 .48 10 – – 55 8327G051 – 1 12.0/F 11.6/F

1/4 6 .42 .48 10 – – 55 – EV8327G052 1 12.0/F 11.6/F

Dimensions: inches (mm)

FLOW DIAGRAMS

OPERATION DE-ENERGIZED ENERGIZED Const. Ref. 1

NORMALLY 1 2 1 2

CLOSED

PRESSURE 3 3

AT 3

NORMALLY 1 2 1 2

OPEN

PRESSURE 3 3

AT 1

UNIVERSAL 1 2 1 2

PRESSURE AT

ANY PORT 3 3

IMPORTANT: Valves may be mounted in any position.

70

You might also like

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Push Button Manual Reset Valves: FeaturesDocument2 pagesPush Button Manual Reset Valves: FeaturesrockieballNo ratings yet

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UgiopetrizzoNo ratings yet

- Catalog Series 342 General Service Direct Acting Brass Stainless Steel Bodies 1 4 3 8 NPT Asco en 3844084Document2 pagesCatalog Series 342 General Service Direct Acting Brass Stainless Steel Bodies 1 4 3 8 NPT Asco en 3844084Karim AhmedNo ratings yet

- 3-Way General Service Solenoid ValvesDocument31 pages3-Way General Service Solenoid ValvesJuan Carlos Pardo RimachiNo ratings yet

- Asco Series 344 Piston Poppet CatalogDocument4 pagesAsco Series 344 Piston Poppet CatalogSANKAR SIVANNo ratings yet

- Air and Water Solenoid Valves: FeaturesDocument4 pagesAir and Water Solenoid Valves: FeaturesZuñiga AntonioNo ratings yet

- Quick Exhaust Solenoid Valves: NC NODocument4 pagesQuick Exhaust Solenoid Valves: NC NOMuhammad AsadNo ratings yet

- Pilot Operated Piston/Poppet Solenoid Valves for Air and WaterDocument4 pagesPilot Operated Piston/Poppet Solenoid Valves for Air and Waterluthfie4uNo ratings yet

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UDevinNo ratings yet

- Emerson Asco 3 2 Series 8300 8315 General Service Solenoid Valves PG 47 50 CatalogDocument4 pagesEmerson Asco 3 2 Series 8300 8315 General Service Solenoid Valves PG 47 50 CatalogAli KianersiNo ratings yet

- Pilot Operated Air and Water Solenoid ValvesDocument4 pagesPilot Operated Air and Water Solenoid ValvesDevinNo ratings yet

- General Service Solenoid Valves: FeaturesDocument4 pagesGeneral Service Solenoid Valves: FeaturesMar SolNo ratings yet

- Astm A75Document4 pagesAstm A75gefNo ratings yet

- General Service Solenoid Valves: FeaturesDocument4 pagesGeneral Service Solenoid Valves: FeaturesabrahamNo ratings yet

- General Service Solenoid Valves: FeaturesDocument4 pagesGeneral Service Solenoid Valves: FeaturesDanielEscobarMontecinosNo ratings yet

- Asco 8344 PDFDocument2 pagesAsco 8344 PDFOsman Lopez SalasNo ratings yet

- Asco Series 401 Direct Mount Pilot CatalogDocument2 pagesAsco Series 401 Direct Mount Pilot CatalogAntonio SerranoNo ratings yet

- Asco 8325Document4 pagesAsco 8325Aletz AlegríaNo ratings yet

- Catalog Series 223 Asco en 3674094Document2 pagesCatalog Series 223 Asco en 3674094LouisNo ratings yet

- 8551 Stainless SteelDocument2 pages8551 Stainless SteelkicsnerNo ratings yet

- Asco Series 040 NC CatalogDocument4 pagesAsco Series 040 NC CatalogrtgeorgeNo ratings yet

- Asco Valve 8327Document2 pagesAsco Valve 8327Yorkist100% (1)

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongNo ratings yet

- FT - 8210 - V. SolenoideDocument6 pagesFT - 8210 - V. SolenoideClaudia Patricia Carazas SarmientoNo ratings yet

- Plastic Body Solenoid Valves: FeaturesDocument2 pagesPlastic Body Solenoid Valves: FeaturesAkash NatkutNo ratings yet

- Valvula ASCO Falcon SB2500Document2 pagesValvula ASCO Falcon SB2500Elmer HuashuayoNo ratings yet

- Pneumatically Operated 3/2 Way Seat ValveDocument5 pagesPneumatically Operated 3/2 Way Seat ValvekicsnerNo ratings yet

- Asco Series 214 Gas Shutoff CatalogDocument8 pagesAsco Series 214 Gas Shutoff CatalogJavier EspinosaNo ratings yet

- Asco8210 PDFDocument6 pagesAsco8210 PDFoscar_rent_torresNo ratings yet

- Catalog Direct Acting 1 8 To 1 4 NPT Series 320 Asco en 7381674Document4 pagesCatalog Direct Acting 1 8 To 1 4 NPT Series 320 Asco en 7381674Ali KianersiNo ratings yet

- Asco 362 - 562 Series Solenoid ValvesDocument31 pagesAsco 362 - 562 Series Solenoid ValvesYonis Cordoba0% (1)

- 364 SS Spool Valves SolenoidDocument12 pages364 SS Spool Valves SolenoidvivianaNo ratings yet

- SOLENOID VALVE ASCO LowPower - Gseries - R8 PDFDocument14 pagesSOLENOID VALVE ASCO LowPower - Gseries - R8 PDFNUR AFIFAHNo ratings yet

- Emerson Asco Low Power Solenoid ValvesDocument13 pagesEmerson Asco Low Power Solenoid ValvesAlejandro Valles LagunaNo ratings yet

- Tamperproof High-Shock Manual Reset Valves: FeaturesDocument2 pagesTamperproof High-Shock Manual Reset Valves: FeaturesDio MaseraNo ratings yet

- Vc d v Kea Kfa Kla Spira Trol Ti d413 03Document8 pagesVc d v Kea Kfa Kla Spira Trol Ti d413 03Rinto SilalahiNo ratings yet

- Asco Long Life Valves CatalogDocument4 pagesAsco Long Life Valves Catalog胡伟No ratings yet

- Asco Series 210 Gas Shutoff No CatalogDocument2 pagesAsco Series 210 Gas Shutoff No CatalogManuel ParraNo ratings yet

- Asco 8345 - 4.09R2Document2 pagesAsco 8345 - 4.09R2Aletz AlegríaNo ratings yet

- Direct Acting Solenoid ValvesDocument4 pagesDirect Acting Solenoid ValvesAnonymous 6VCG1YRdNo ratings yet

- 8040 NC PilotDocument4 pages8040 NC PilotMaximilianoAlvarezNo ratings yet

- Direct Acting Solenoid Valves SpecificationsDocument4 pagesDirect Acting Solenoid Valves SpecificationsjiseobNo ratings yet

- Asco Series Maglatch 3 Way Catalog PDFDocument2 pagesAsco Series Maglatch 3 Way Catalog PDFPrashant Kumar mishraNo ratings yet

- 3-Way Valve LongLifeDocument4 pages3-Way Valve LongLifesconquest ETONo ratings yet

- General Service Solenoid Valves for Fluid ControlDocument4 pagesGeneral Service Solenoid Valves for Fluid Controlpacho916No ratings yet

- VH86 Series High Pressure Multi Purpose Ball ValvesDocument4 pagesVH86 Series High Pressure Multi Purpose Ball ValvesTran Duc DungNo ratings yet

- Electric Actuated 3-Way Ball ValvesDocument6 pagesElectric Actuated 3-Way Ball ValvesRADHAKRISHNANNo ratings yet

- Steam Trap FT450Document3 pagesSteam Trap FT450joel angel Pinedo GamarraNo ratings yet

- Gas Shutoff Valves: FeaturesDocument136 pagesGas Shutoff Valves: FeaturesJuan BejaranoNo ratings yet

- 8314 - Hseriesr1 Asco VentiliDocument4 pages8314 - Hseriesr1 Asco VentiliNandor KermeciNo ratings yet

- Ycms35 - Item 1-2 CatalogueDocument4 pagesYcms35 - Item 1-2 CatalogueChinhNo ratings yet

- RedHat II Spool Valve FeaturesDocument4 pagesRedHat II Spool Valve FeaturesSayak GhoshNo ratings yet

- 8356 NSFR7Document4 pages8356 NSFR7v8wfm8d8r7No ratings yet

- ASCO Valve 8345 Spec R2Document2 pagesASCO Valve 8345 Spec R2Calvin HaleyNo ratings yet

- ASCO 35-1 General Service 3-Way Valves PDFDocument36 pagesASCO 35-1 General Service 3-Way Valves PDFprsiva2420034066No ratings yet

- Compass Report (Ps 139, 5.0 MMSCFD)Document1 pageCompass Report (Ps 139, 5.0 MMSCFD)Burhan AyubNo ratings yet

- Compass Report (Ps 139, 5.0 MMSCFD)Document1 pageCompass Report (Ps 139, 5.0 MMSCFD)Burhan AyubNo ratings yet

- Bhit Field OptimizationDocument19 pagesBhit Field OptimizationBurhan AyubNo ratings yet

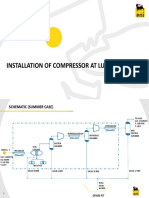

- Installation of Compressor at LundaliDocument2 pagesInstallation of Compressor at LundaliBurhan AyubNo ratings yet

- Badhra Field OptimizationDocument17 pagesBadhra Field OptimizationBurhan AyubNo ratings yet

- Relocation of C6 From SVSDocument8 pagesRelocation of C6 From SVSBurhan AyubNo ratings yet

- Air-Driven, High Flow, High Pressure Liquid Pump: Series AHL33-2DDocument4 pagesAir-Driven, High Flow, High Pressure Liquid Pump: Series AHL33-2DBurhan AyubNo ratings yet

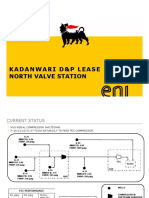

- Kadanwari D&P Lease North Valve StationDocument5 pagesKadanwari D&P Lease North Valve StationBurhan AyubNo ratings yet

- N-Line Valves: Quality PlanDocument5 pagesN-Line Valves: Quality PlanBurhan AyubNo ratings yet

- Kadanwari D&P Lease North Valve StationDocument5 pagesKadanwari D&P Lease North Valve StationBurhan AyubNo ratings yet

- Kadanwari Produced Water System AnalysisDocument15 pagesKadanwari Produced Water System AnalysisBurhan AyubNo ratings yet

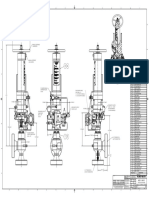

- 3-PU101-PR-DI-034-01 To 3-PU101-PR-DI-034-25Document30 pages3-PU101-PR-DI-034-01 To 3-PU101-PR-DI-034-25Burhan AyubNo ratings yet

- For Materials of Construction, See Engineering Parts List: N-Line ValvesDocument2 pagesFor Materials of Construction, See Engineering Parts List: N-Line ValvesBurhan AyubNo ratings yet

- Resolving Piping and Instrumentation Diagram CommentsDocument16 pagesResolving Piping and Instrumentation Diagram CommentsBurhan Ayub100% (1)

- Layer of Protection Analysis (LOPA) Methodology: Technical Center of Excellence in AEC in 2020Document1 pageLayer of Protection Analysis (LOPA) Methodology: Technical Center of Excellence in AEC in 2020Didika HerlambangNo ratings yet

- Solution Manual An Introducing To Reliability and EngineeringDocument64 pagesSolution Manual An Introducing To Reliability and EngineeringGidion SaputraNo ratings yet

- Process Hazard AnalysisDocument19 pagesProcess Hazard AnalysisAnandababuNo ratings yet

- IEC 61511 SIL Assessment and IEC 61508 SIL Verification 4-Day TrainingDocument2 pagesIEC 61511 SIL Assessment and IEC 61508 SIL Verification 4-Day TrainingMuhammad.Saim100% (1)

- SIL Verification Sample ReportDocument8 pagesSIL Verification Sample ReportAyman FawzyNo ratings yet

- Alarms As Layer of Protection 2012Document24 pagesAlarms As Layer of Protection 2012btjajadiNo ratings yet

- Safety Relays - PSR-SCP-24UC/ESM4/3X1/1X2/B - 2963776: Key Commercial DataDocument7 pagesSafety Relays - PSR-SCP-24UC/ESM4/3X1/1X2/B - 2963776: Key Commercial Dataadnene gharssallahNo ratings yet

- AB Control Logix Cert - EZ135!05!09Document1 pageAB Control Logix Cert - EZ135!05!09kennymagallanesNo ratings yet

- Process Hazard Analysis GuideDocument20 pagesProcess Hazard Analysis GuideAdenike AdebolaNo ratings yet

- Risk Based Maintenance PDFDocument19 pagesRisk Based Maintenance PDFCarlos Porras100% (1)

- SIL Verification of Legacy System V3Document12 pagesSIL Verification of Legacy System V3Anonymous H0xnVVXypgNo ratings yet

- 105M6369 Cda 000Document65 pages105M6369 Cda 000Rabah AmidiNo ratings yet

- Manual Multifunction Device 3TK2845 EN 201509071425559335Document70 pagesManual Multifunction Device 3TK2845 EN 201509071425559335felipezambranoNo ratings yet

- RDSO SPN 211 2019 Ver-1.0 d5 FINAL 05.07.2019Document23 pagesRDSO SPN 211 2019 Ver-1.0 d5 FINAL 05.07.2019mohamed suhailNo ratings yet

- Spnu 511 BDocument79 pagesSpnu 511 BRăzvan PopaNo ratings yet

- SIL Safety Integrity Level: Tools & ReferencesDocument13 pagesSIL Safety Integrity Level: Tools & ReferencesSteve Forster100% (1)

- Functional Safety ManagementDocument8 pagesFunctional Safety ManagementasimozmaNo ratings yet

- Isograph RASWG PresentationDocument41 pagesIsograph RASWG Presentationjohn100% (1)

- 8316 Series-Sil IIDocument2 pages8316 Series-Sil IItree_99No ratings yet

- Safety Design of LNG Import/Export PlantsDocument13 pagesSafety Design of LNG Import/Export Plantsravikb27100% (1)

- Kinetix 5500 Servo Drives: User ManualDocument258 pagesKinetix 5500 Servo Drives: User ManualDanot Alvarado CasaresNo ratings yet

- AB ControlerDocument114 pagesAB ControlerFONAI VIOREL AURELNo ratings yet

- Pos Functional Safety 1003920-En-05Document1 pagePos Functional Safety 1003920-En-05HOSSEINNo ratings yet

- Abb Acs800 Inverter Series BrochureDocument21 pagesAbb Acs800 Inverter Series Brochurekvramanan_1No ratings yet

- HART GuideDocument174 pagesHART GuideKyle StackNo ratings yet

- Shell - Process Safeguarding Flow SchemesDocument37 pagesShell - Process Safeguarding Flow SchemesIgnatios Staboulis100% (1)

- Catalogo Sinumerik 828Document222 pagesCatalogo Sinumerik 828Macchi_RJNo ratings yet

- Functional safety manual for Liquiphant M/S with electronic insert FEL54Document12 pagesFunctional safety manual for Liquiphant M/S with electronic insert FEL54Imran HaiderNo ratings yet

- SilDocument15 pagesSilMohamed Elsayed Hasan0% (1)

- En 13463-6-2005 Non-Electrical Equipment For Use in Potentially Explosive Atmospheres - Protection by Control of Ignition Source BDocument24 pagesEn 13463-6-2005 Non-Electrical Equipment For Use in Potentially Explosive Atmospheres - Protection by Control of Ignition Source BjosethompsonNo ratings yet