Professional Documents

Culture Documents

Electrical Testing Proedures

Uploaded by

Udhayakumar VenkataramanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Testing Proedures

Uploaded by

Udhayakumar VenkataramanCopyright:

Available Formats

Inspection and test procedures for Rotating Machinery, Synchronous Motors and

Generators

1. Visual and Mechanical Inspection

2. Electrical Tests

3. Test Values

1. Visual and Mechanical Tests

2. Electrical Tests

4. Pictures:

1. Electrical machine wired for electrical testing

2. The Electrical Machines Laboratory

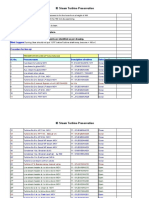

5. TABLE 100.10 – Maximum Allowable Vibration Amplitude

6. TABLE 100.12 – US Standard Fasteners

Inspection and test

procedures of Rotating Machinery, Synchronous Motors and Generators (On photo:

Small machine test set – ee.polyu.edu.hk)

1. Visual and Mechanical Inspection

1. Compare equipment nameplate datawith drawings and specifications.

2. Inspect physical and mechanical condition.

3. Inspect anchorage, alignment, and grounding.

4. Inspect air baffles, filter media, cooling fans, slip rings, brushes, and brush

rigging.

5. Inspect bolted electrical connections for high resistance using one or more of

the following?methods:

1. Use of low-resistance ohmmeter?in accordance with procedure for LR

ohmmeter?usage.

2. Verify tightness of accessible bolted electrical connections by

calibrated torque-wrench?method in accordance with manufacturer?s published

data or Table 100.12? (see below).

3. Perform thermographic survey.

6. Perform special tests such as air-gap spacing and machine alignment.

7. Verify the application of appropriatelubrication and lubrication systems.

8. Verify that resistance temperature detector (RTD) circuits conform to

drawings.

Go to Index ↑

<="" ins="" data-adsbygoogle-status="done" style="box-sizing: border-box; display:

block; height: 250px; min-width: 300px; max-width: 728px; width: 727.688px;">

2. Electrical Tests

1. Perform resistance measurements through bolted connections with a low-

resistance ohmmeter,?if applicable.

2. Perform insulation-resistance tests inaccordance with ANSI/IEEE Standard 43 .

1. Machines larger than 200 horsepower ( 150 kilowatts ):

Test duration shall be for ten minutes. Calculate polarization index.

2. Machines 200 horsepower ( 150 kilowatts ) and less:

Test duration shall be for one minute. Calculate dielectric-absorption ratio.

3. Perform dc dielectric withstand voltage tests on machines rated at 2300

volts and greater in?accordance with ANSI/IEEE Standard 95 .

4. Perform phase-to-phase stator resistance test on machines 2300 volts and

greater.

5. ** Perform insulation power-factoror dissipation-factor tests.

6. ** Perform power-factor tip-up tests.

7. ** Perform surge comparison tests.

8. Perform insulation-resistance test on insulated bearings in accordance with

manufacturer?s?published data, if applicable.

9. Test surge protection devices.

10. Test motor starter.

11. Perform resistance tests on resistance temperature detector (RTD) circuits.

12. Verify operation of machine space heater, if applicable.

13. ** Perform vibration test.

14. Perform insulation-resistance tests on the main rotating field winding, the

exciter-field winding, and the exciter-armature winding in accordance

with ANSI/IEEE Standard 43 .

15. ** Perform an ac voltage-drop test on all rotating field poles.

16. ** Perform a high-potential test on the excitation system in accordance

with ANSI/IEEE Standard?421.3 .

17. Measure resistance of machine-field winding, exciter-stator winding, exciter-

rotor windings,?and field discharge resistors.

18. ** Perform front-to-back resistance tests on diodes and gating tests of

silicon-controlled rectifiers?for field application semiconductors.

19. Prior to re-energizing, apply voltage to the exciter supply and adjust exciter-

field current to?nameplate value.

20. Verify that the field application timer and the enable timer for the power-

factor relay have been?tested and set to the motor drive manufacturer?s

recommended values.

21. ** Record stator current, stator voltage, and field current for the complete

acceleration period?including stabilization time for a normally loaded starting

condition. From the recording?determine the following information:

1. Bus voltage prior to start.

2. Voltage drop at start.

3. Bus voltage at machine full-load.

4. Locked-rotor current.

5. Current after synchronization but before loading.

6. Current at maximum loading.

7. Acceleration time to near synchronous speed.

8. Revolutions per minute (RPM) just prior to synchronization.

9. Field application time.

10. Time to reach stable synchronous operation.

22. ** Plot a V-curve of stator current versus excitation current at approximately

50 percent load to?check correct exciter operation.

23. ** If the range of exciter adjustment and machine loading permit,reduce

excitation to cause power?factor to fall below the trip value of the power-factor

relay. Verify relay operation.

** OPTIONAL

3. Test Values

3.1 Visual and Mechanical Test Values

1. Inspection:

1. Air baffles shall be clean and installed in accordance with

manufacturer?s published?data.

2. Filter media shall be clean and installed in accordance with

manufacturer?s published?data.

3. Cooling fans shall operate.

4. Slip ring alignment shall be within manufacturer?s published

tolerances.

5. Brush alignment shall be within manufacturer?s published tolerances.

6. Brush rigging shall be in accordance with manufacturer?s published

data.

2. Compare bolted connection resistance values to values of similar

connections. Investigate any?values that deviate from similar bolted connections

by more than 50 percent of the lowest?value.

3. Bolt-torque levels should be in accordance with manufacturer?s published

data. In the absence?of manufacturer?s published data, use Table 100.12 (see

below)

4. Results of thermographic survey to be analysed.

5. Air-gap spacing and machine alignment shall be in accordance with

manufacturer?s published?data.

3.2 Electrical Test Values

1. Compare bolted connection resistance values tovalues of similar connections.

Investigate any?values that deviate from similar bolted connections by more

than 50 percent of the lowest?value.

2. The dielectric absorption ratio or polarization index shall not be less than

1.0. The?recommended minimum insulation resistance (IR 1 min) test results in

megaohms shall be?corrected to 40? C and read as follows:

1. IR 1 min = kV + 1 for most windings made before 1970 ( kV is the

rated machine terminal-to-terminal voltage in rms kV )

2. IR 1 min = 100 megohms for most dc armatureand ac windings built

after 1970 (form-wound coils).

3. IR 1 min = 5 megohms for most machines and random-wound stator

coils and form-wound coils rated below 1 kV.

–

NOTE: Dielectric withstand voltage and surge comparison tests shall not be

performed?on machines having values lower than those indicated above.

3. If no evidence of distress or insulation failure is observed by the end of

the total time of voltage?application during the dielectric withstand test, the test

specimen is considered to have passed?the test .

4. Investigate phase-to-phase stator resistance values that deviate by more than

five percent.

5. Power-factor or dissipation-factor values shall be compared to manufacturer?s

published data.?In the absence of manufacturer?s published data these values

will be compared with previous?values of similar machines.

6. Tip-up values shall indicate no significant increase in power factor.

7. If no evidence of distress, insulation failure, orlack of waveform nesting is

observed by the end?of the total time of voltage application during the surge

comparison test, the test specimen is?considered to have passed the test .

8. Insulation resistance of bearings shall be within manufacturer?s published

tolerances. In the?absence of manufacturer?s published tolerances, the

comparison shall be made to similar?machines.

9. Test results of surge protection devices shall be in accordance with

procedures for testing of LV surge arresters.

10. Test results of motor starter equipment shall be in accordance with?

procedures for testing of motor starter equipment.

11. RTD circuits shall be in accordance with system design intent and machine

protection device?manufacturer?s published data.

12. Heaters shall be operational.

13. Vibration amplitudes of the uncoupled and unloaded machine shall not

exceed values shown in? Table 100.10 (see below). If values exceed, perform

complete vibration analysis.

14. The recommended minimum insulation resistance (IR1 min) test results in

megaohms shall be?corrected to 40? C and read as follows:

1. IR 1 min= kV + 1 for most windings made before 1970, all field

windings (kV is the rated machine terminal-to-terminal voltage in rms kV )

2. IR 1 min= 100 megohms for most dc armature and ac windings built

after 1970 (form-wound coils).

3. IR 1 min= 5 megohms for most machines and random-wound stator

coils and form-wound coils rated below 1 kV.

–

NOTE: Dielectric withstand voltage, high-potential, and surge comparison tests

shall?not be performed on machines having values lower than those indicated

above.

15. The pole-pole AC voltage drop shall not exceed 10 percent variance

between poles.

16. If no evidence of distress or insulation failure is observed by the end of

the total time of voltage?application during the dielectricwithstand test, the

winding is considered to have passed the?test.

17. The measured resistance values of motor-field windings, exciter-stator

windings, exciter-rotor?windings, and field-discharge resistors shall be compared

to manufacturer?s published data. In?the absence of manufacturer?spublished

data, the comparison shall be made to similar?machines.

18. Resistance test results of diodes and gating tests of silicon-controlled

rectifiers shall be in?accordance with industry standards and system design

requirements.

19. Exciter power supply shall allow exciter-field current to be adjusted to

nameplate value.

20. Application timer and enable timer for power-factor relay test results shall

comply with?manufacturer?s recommended values.

21. Recorded values shall be in accordance with system design requirements.

22. Plotted V-curve shall indicate correct exciter operation.

23. When reduced excitation falls below trip value for the power-factorrelay, the

relay shall?operate.

Electrical machine wired for electrical testing

Electrical machine wired for

electrical testing (photo credit: komel.katowice.pl)

The Electrical Machines Laboratory

The Electrical

Machines Laboratory (photo credit: ee.polyu.edu.hk)

TABLE 100.10

Maximum Allowable Vibration Amplitude

Table 100.10 – Maximum Allowable Vibration Amplitude

TABLE 100.12

US Standard Fasteners – Bolt-Torque Values for Electrical Connections

Table 100.12.1 – Heat-Treated Steel – Cadmium or Zinc Plated

Table 100.12.2 – Silicon Bronze Fasteners

Table 100.12.3 – Aluminum Alloy Fasteners

Ta

ble 100.12.4 – Stainless Steel Fasteners

a. Consult manufacturer for equipment supplied with metric fasteners.

b. This table is based on bronze alloy bolts having a minimum tensile strength of

70,000 pounds per square inch.

c. This table is based on aluminum alloy bolts having a minimum tensile strength

of 55,000 pounds per square inch.

d. This table is to be used for the following hardware types:

Bolts, cap screws, nuts, flat washers, locknuts (18?8 alloy)

Belleville washers (302 alloy).

Reference:?ANSI/NETA Standard for Acceptance Testing Specifications for Electrical

Power Equipment and Systems

You might also like

- Testing Motor by BakerDocument11 pagesTesting Motor by BakerAhmad Nazri100% (1)

- Understanding Generator Stator Winding LeaksDocument28 pagesUnderstanding Generator Stator Winding Leaksnareshvkkd100% (1)

- Elcid Elan-V4.04Document142 pagesElcid Elan-V4.04Luis Fernando GranadosNo ratings yet

- GVPI Assessment-EASA 2014 v2Document7 pagesGVPI Assessment-EASA 2014 v2mersiumNo ratings yet

- History of Power SystemDocument6 pagesHistory of Power SystemAmr Diaa El-Din El-FawalNo ratings yet

- Bhel Mini Pro Report On Turbo Generators 1Document53 pagesBhel Mini Pro Report On Turbo Generators 1Akirakumar100% (1)

- El-CID Testing PDFDocument16 pagesEl-CID Testing PDFA.YOGAGURUNo ratings yet

- Protection SchemesDocument20 pagesProtection SchemesMohamed Wahid100% (1)

- DGA Ebook WebDocument16 pagesDGA Ebook Webjulio cesar silvaNo ratings yet

- Diagnostic Tests and Condition Monitoring of Electrical MachinesDocument3 pagesDiagnostic Tests and Condition Monitoring of Electrical Machineslbk50No ratings yet

- CT & CVTDocument67 pagesCT & CVTlrpatraNo ratings yet

- BHEL Manufactures Turbo Generators up to 200MWDocument8 pagesBHEL Manufactures Turbo Generators up to 200MWPraveen KumarNo ratings yet

- 20121130133052209Document5 pages20121130133052209freddysh4330No ratings yet

- 35MW Generator Test ReportDocument10 pages35MW Generator Test ReportAshok KumarNo ratings yet

- Earthing in Electrical Network - Purpose, Methods and MeasurementDocument33 pagesEarthing in Electrical Network - Purpose, Methods and Measurementmsaadi717No ratings yet

- BH CurveDocument5 pagesBH Curvekrish3291No ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Megger InsulationtesterDocument67 pagesMegger InsulationtesterNh Chuminda YapaNo ratings yet

- Micadur Compact Industry Insulation System For RotatingDocument8 pagesMicadur Compact Industry Insulation System For Rotatingreygrant3900100% (2)

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsFrom EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsNo ratings yet

- Partial Discharge As A Quality Assurance Test For Motor Stator WindingsDocument6 pagesPartial Discharge As A Quality Assurance Test For Motor Stator WindingsKUNALJAYNo ratings yet

- Air Blast Circuit BreakerDocument19 pagesAir Blast Circuit Breakerkuttr100% (5)

- Instruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)Document40 pagesInstruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)PraveenKvNo ratings yet

- Insulation Resistance of Power TransformerDocument16 pagesInsulation Resistance of Power TransformerMELVIN100% (3)

- How To Maintain Sf6 Circuit BreakerDocument6 pagesHow To Maintain Sf6 Circuit BreakerijsretNo ratings yet

- Operating Experience With A Generator End WindingDocument14 pagesOperating Experience With A Generator End WindingutherunixNo ratings yet

- Transformer Failure AnalysisDocument12 pagesTransformer Failure AnalysisABHINAV SAURAVNo ratings yet

- MR - On Load Tap Changer For DTs - F0338803 - ECOTAP - VPD - EN PDFDocument24 pagesMR - On Load Tap Changer For DTs - F0338803 - ECOTAP - VPD - EN PDFalbertohiggs6100% (1)

- Bearing HeaterDocument5 pagesBearing HeaterAnand KatariyaNo ratings yet

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionFrom EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionNo ratings yet

- BS 4999-143-1987 Requirements For Rotating Electrical MachinDocument8 pagesBS 4999-143-1987 Requirements For Rotating Electrical MachinJames AlejoNo ratings yet

- Bathroom Electrical Zones ExplainedDocument5 pagesBathroom Electrical Zones ExplainedDelkan16No ratings yet

- Lightning Arrestor: To:-Deepa S NDocument11 pagesLightning Arrestor: To:-Deepa S NMadhu SagarNo ratings yet

- Upgrading The ProtectionDocument4 pagesUpgrading The ProtectionMukesh KumarNo ratings yet

- Device Function Numbers for Power Distribution EquipmentDocument10 pagesDevice Function Numbers for Power Distribution EquipmentSherleanne PintoNo ratings yet

- 40MVA Trafo Test ProcedureDocument10 pages40MVA Trafo Test ProcedureGuru Mishra100% (3)

- EMC Based LPS For HV SubstationDocument66 pagesEMC Based LPS For HV SubstationDede Rochman100% (1)

- Cable TerminationDocument2 pagesCable Terminationapandey070273No ratings yet

- Electrical Design A Good Practice Guide Pub 123Document92 pagesElectrical Design A Good Practice Guide Pub 123JOSE LUIS FALCON CHAVEZNo ratings yet

- Manufacturing and Testing of Turbo GeneratorsDocument84 pagesManufacturing and Testing of Turbo Generatorsgnikhilreddy2No ratings yet

- PAT TestDocument28 pagesPAT Testmanzoor hassanNo ratings yet

- Z Z Z Z: General RemarksDocument11 pagesZ Z Z Z: General Remarksadi nu100% (1)

- Doubly Fed Induction GeneratorDocument8 pagesDoubly Fed Induction GeneratorMashood NasirNo ratings yet

- Improved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationDocument9 pagesImproved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Capacitor calculation for detune filterDocument2 pagesCapacitor calculation for detune filtersalmanNo ratings yet

- Article Ultrasonic or TevDocument2 pagesArticle Ultrasonic or Tevanchak99No ratings yet

- The Case of Failed TransformerDocument84 pagesThe Case of Failed Transformerlbk50100% (1)

- Transformer Earth FaultDocument5 pagesTransformer Earth FaultvyroreiNo ratings yet

- ABB RET 521 TRANS DIFFERENTIAL PROTECTION INSTALLATION and COMMISSIONING MANUALDocument67 pagesABB RET 521 TRANS DIFFERENTIAL PROTECTION INSTALLATION and COMMISSIONING MANUALNima Mahmoudpour100% (1)

- SchneiderElectric 091911Document18 pagesSchneiderElectric 091911Hadi ParviniNo ratings yet

- A Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Document8 pagesA Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Ritaban R. BanerjeeNo ratings yet

- Single Core Cables in ParallelDocument1 pageSingle Core Cables in ParallelAamirMalik100% (1)

- Phase Discontinuity Protection FunctionDocument14 pagesPhase Discontinuity Protection FunctionrajeshNo ratings yet

- High VoltageDocument5 pagesHigh VoltageAnnie ToddNo ratings yet

- Test stator core integrityDocument3 pagesTest stator core integrityvishiwizard100% (1)

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Battery Room Design AspectsDocument4 pagesBattery Room Design AspectsUdhayakumar VenkataramanNo ratings yet

- Improves Concrete Characteristics FA100 S Type FDocument1 pageImproves Concrete Characteristics FA100 S Type FUdhayakumar VenkataramanNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Construction Incident Engineering Reports: Collapses & FatalitiesDocument21 pagesConstruction Incident Engineering Reports: Collapses & FatalitiesUdhayakumar VenkataramanNo ratings yet

- 660 MW IIoT AspectsDocument17 pages660 MW IIoT AspectsUdhayakumar VenkataramanNo ratings yet

- Improves Concrete Characteristics FA100 S Type FDocument1 pageImproves Concrete Characteristics FA100 S Type FUdhayakumar VenkataramanNo ratings yet

- Top 5 Troubleshooting Issues For Blower SystemsDocument4 pagesTop 5 Troubleshooting Issues For Blower SystemsUdhayakumar VenkataramanNo ratings yet

- Boiler CommissioningDocument29 pagesBoiler Commissioningbratishkaity100% (8)

- Foundation DetailDocument1 pageFoundation DetailUdhayakumar VenkataramanNo ratings yet

- An Overview of Power Sector of BangladeshDocument36 pagesAn Overview of Power Sector of BangladeshJahid MasudNo ratings yet

- Extend Gear Coupling Life: of Can Be ofDocument5 pagesExtend Gear Coupling Life: of Can Be ofUdhayakumar VenkataramanNo ratings yet

- Woven Sacks DPR Input - Odissa GoIDocument3 pagesWoven Sacks DPR Input - Odissa GoIUdhayakumar VenkataramanNo ratings yet

- Ash Utilisation in TATADocument5 pagesAsh Utilisation in TATAUdhayakumar VenkataramanNo ratings yet

- BFP Performance Assessment Article HelpfulDocument10 pagesBFP Performance Assessment Article HelpfulUdhayakumar VenkataramanNo ratings yet

- Technical Specification ColtcsDocument60 pagesTechnical Specification Coltcsproloy12No ratings yet

- Keeping Your Lubrication Program in The CrosshairsDocument4 pagesKeeping Your Lubrication Program in The CrosshairsUdhayakumar VenkataramanNo ratings yet

- Energy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaDocument6 pagesEnergy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaUdhayakumar VenkataramanNo ratings yet

- Different Type of Motors For Industrial DrivesDocument5 pagesDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNo ratings yet

- Four important precautions for installing cables and busbar systemsDocument11 pagesFour important precautions for installing cables and busbar systemsUdhayakumar VenkataramanNo ratings yet

- Sliding Pressure Operation of Large Conventional Steam Power UnitDocument6 pagesSliding Pressure Operation of Large Conventional Steam Power UnitUdhayakumar VenkataramanNo ratings yet

- Different Type of Motors For Industrial DrivesDocument5 pagesDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNo ratings yet

- Energy Efficient Motor AspectsDocument3 pagesEnergy Efficient Motor AspectsUdhayakumar VenkataramanNo ratings yet

- Handbook - Energy Management For Motor Driven Systems PDFDocument123 pagesHandbook - Energy Management For Motor Driven Systems PDFmnt6176No ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- Electrical Quality DeviesDocument12 pagesElectrical Quality DeviesUdhayakumar VenkataramanNo ratings yet

- Master Wall Catalogue August 2019Document152 pagesMaster Wall Catalogue August 2019Udhayakumar VenkataramanNo ratings yet

- Faults On Electrical SystemDocument21 pagesFaults On Electrical Systemjosh bradley100% (3)

- Lesson Learnt From Biomass PlantsDocument31 pagesLesson Learnt From Biomass PlantsUdhayakumar VenkataramanNo ratings yet

- Sliding Pressure Control BasicsDocument4 pagesSliding Pressure Control BasicsUdhayakumar VenkataramanNo ratings yet

- UP33TOP140KGAAZ01B - Datasheet - Garun 40KL - DatasheetDocument2 pagesUP33TOP140KGAAZ01B - Datasheet - Garun 40KL - DatasheetAnton TonchevNo ratings yet

- Characteristics of Ideal Op-AmpDocument14 pagesCharacteristics of Ideal Op-AmpShubham MannaNo ratings yet

- Laser Security System For HomeDocument19 pagesLaser Security System For HomeSelvakumar SubramaniNo ratings yet

- Toroidal TransformersDocument6 pagesToroidal TransformersCallofDutymobile FunnycompilationNo ratings yet

- OA 1 - Measurements and KinematicsDocument12 pagesOA 1 - Measurements and KinematicsRay ChuaNo ratings yet

- Finalreport SwetasinghDocument19 pagesFinalreport Swetasinghsaurav kumarNo ratings yet

- Lipped Channel (Baja Kanal C Ringan) : Product SpecificationsDocument2 pagesLipped Channel (Baja Kanal C Ringan) : Product SpecificationsrahmatsanjayaNo ratings yet

- Data sheet for Smart Line Modules BooksizeDocument1 pageData sheet for Smart Line Modules BooksizeBanupriya BalasubramanianNo ratings yet

- Ecuación Fundamental de Engranajes Planetarios (Ecuación de Willis) - Tec-ScienceDocument12 pagesEcuación Fundamental de Engranajes Planetarios (Ecuación de Willis) - Tec-ScienceDanny Joel C SNo ratings yet

- Thermal power plants and coal production in IndiaDocument7 pagesThermal power plants and coal production in Indiaanup kumarNo ratings yet

- 5KW PWMDocument20 pages5KW PWMmaster chibukingNo ratings yet

- REGULATED POWER SUPPLY DESIGNDocument76 pagesREGULATED POWER SUPPLY DESIGNManish YangalNo ratings yet

- Psychrometrics of DryingDocument7 pagesPsychrometrics of DryingNurul Atikah JapryNo ratings yet

- EC1255-Measurements and Instrumentation: Two Mark Question AnswerDocument8 pagesEC1255-Measurements and Instrumentation: Two Mark Question AnswervjospinNo ratings yet

- Solar EnergyDocument91 pagesSolar EnergyAKANKSHANo ratings yet

- JEE Physics Class Companion Guide for Constrained Motion, NLM and FrictionDocument167 pagesJEE Physics Class Companion Guide for Constrained Motion, NLM and FrictionThe IndianNo ratings yet

- TRANE CCU MP40 Controller Points List For BACNET Jun09-E4Document7 pagesTRANE CCU MP40 Controller Points List For BACNET Jun09-E4Leila BenmohamedNo ratings yet

- HCM434EDocument8 pagesHCM434E3efooNo ratings yet

- Edrolo ch3Document42 pagesEdrolo ch3YvonneNo ratings yet

- Irlz44Z Irlz44Zs Irlz44Zl: Automotive MosfetDocument13 pagesIrlz44Z Irlz44Zs Irlz44Zl: Automotive MosfetrickiaqpNo ratings yet

- 02-2 Excitation CourseDocument31 pages02-2 Excitation CourseShamendu Roy RohitNo ratings yet

- APsystems Microinverter QS1 For North America Datasheet - Rev3.0 - 2021 02 19 1Document2 pagesAPsystems Microinverter QS1 For North America Datasheet - Rev3.0 - 2021 02 19 1donovan garciaNo ratings yet

- GEN4 DM (G4) Series - MPPT - User Manual - V1.04Document2 pagesGEN4 DM (G4) Series - MPPT - User Manual - V1.04sonia soniaNo ratings yet

- B.Inggris Kelompok 8Document15 pagesB.Inggris Kelompok 8Agustinus GiyaiNo ratings yet

- Revision of Chapter 10 - Electrical Maintenance Schedule of LHB Manual (Electrical)Document50 pagesRevision of Chapter 10 - Electrical Maintenance Schedule of LHB Manual (Electrical)Harsh Vardhan SinghNo ratings yet

- Lewin's Circuit Paradox: Joseph Henry Laboratories, Princeton University, Princeton, NJ 08544Document10 pagesLewin's Circuit Paradox: Joseph Henry Laboratories, Princeton University, Princeton, NJ 08544aiace00No ratings yet

- Investigations On Biulding Thermal PerformancesDocument4 pagesInvestigations On Biulding Thermal PerformancesBryan RuttoNo ratings yet

- The Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air HeatersDocument7 pagesThe Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air Heatersaxel_oscNo ratings yet

- Wa0000.Document48 pagesWa0000.mayanksingh05752No ratings yet

- Versatile Rectifier Modules Function as Power Supplies or Battery ChargersDocument2 pagesVersatile Rectifier Modules Function as Power Supplies or Battery ChargerszeroseyaNo ratings yet