Professional Documents

Culture Documents

Steam Explosion-Beacon

Uploaded by

mkkamarajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Explosion-Beacon

Uploaded by

mkkamarajCopyright:

Available Formats

This issue sponsored by

http://www.aiche.org/CCPS/Publications/Beacon/index.aspx

www.aiche.org/ccps www.iomosaic.com

Messages for Manufacturing Personnel

Are you sure that vessel is empty? April 2017

In 1991, an explosion and fire occurred in a 50,000 barrel-per-day Fluid

Catalytic Cracker (FCC) unit in a refinery that was being brought online after

a seven-week shutdown for maintenance. Tragically, six workers lost their

lives and eight others were injured in the event. Property damage was reported

to be about $23 million and business interruption loss was estimated to be $44

million. What caused this terrible explosion? It was not caused by a runaway

reaction, or a flammable leak, or static ignition. It was caused by – water!

The vertical pressure vessel (F7) that exploded was used to separate heavy

oil from solid catalyst dust in the process. During the shutdown, oil was

drained from all process equipment and the equipment was cleaned, inspected,

and refurbished to be fit for service. As part of the startup procedure, steam

was purged to displace any air in the system before oil was fed to the process.

It was recognized by operations that the temperature in the process equipment

was low enough to condense some of this purge steam into water. So, any

water that condensed was collected and pumped to the F7 vessel. The normal

startup procedure required the operating crew to drain the water from F-7

before any hot oil was introduced. However, there was a block valve in the

wrong (closed) position that prevented the water from draining from F7. The

rapid expansion of the steam overpressurized F7, and it ruptured violently. The oil released by the explosion then

ignited, and the fire engulfed the FCC. The fire burned for about 2-1/2 hours before finally being extinguished.

Did you know? What can you do?

There are many reports of steam explosions involving hot When returning equipment to service

material unintentionally coming in contact with water (see the following maintenance, make sure that it is

October 2015 Beacon for another example). completely clean and does not contain

Water expands by about 1600 times when it vaporizes to steam. anything that could be incompatible with

This means that one US pint (~ ½ l) of water can generate process materials or operating conditions.

enough vapor to fill almost four 55 US gallon (~ 200 l) drums! Do not deviate from your plant’s startup

procedures.

Use checklists and written procedures for

startup. Some process plants operate for

many years between maintenance and other

shutdowns. You should not rely on your

memory for this critical operation which

you may not do very often.

If you find valves in the wrong position or

To prepare for maintenance, water is often used to clean or other equipment in the incorrect status

flush equipment. The water can collect in low points in during startup, get help to understand all

equipment and piping and could contact hot or incompatible potential consequences before changing

materials if it is not completely removed before re-start. valve position or other equipment status.

Liquid water + hot material = steam explosion danger!

©AIChE2017. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for any

commercial purpose without express written consent of AIChE is strictly prohibited. Contact us at ccps_beacon@aiche.org or 646-495-1371.

The Beacon is usually available in Afrikaans, Arabic, Catalan, Chinese, Czech, Danish, Dutch, English, Filipino, French, German, Greek, Gujarati, Hebrew, Hindi, Indonesian,

Italian, Japanese, Korean, Malay, Marathi, Persian (Farsi), Polish, Portuguese, Romanian, Russian, Spanish, Swedish, Telugu, Thai, Turkish, and Vietnamese.

You might also like

- Harvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsFrom EverandHarvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsNo ratings yet

- 2015-08 Safety Beacon - Operational ReadinessDocument1 page2015-08 Safety Beacon - Operational Readinessأحمد موريسNo ratings yet

- Procedure For Starting and Stopping of Sewage Treatment Plant On A ShipDocument4 pagesProcedure For Starting and Stopping of Sewage Treatment Plant On A ShipILHAMNo ratings yet

- Cla FiltersDocument22 pagesCla FiltersAce Dynamics IndiaNo ratings yet

- Operation and Maintenance Manual For Onsite Wastewater Systems.... 0..0 PDFDocument63 pagesOperation and Maintenance Manual For Onsite Wastewater Systems.... 0..0 PDFنيرمين احمدNo ratings yet

- Sewage Treatment Plant Main Points.Document2 pagesSewage Treatment Plant Main Points.mohamed bakryNo ratings yet

- Pro Installation Pflege Hinweise enDocument3 pagesPro Installation Pflege Hinweise enSwiss CoffeeNo ratings yet

- A Hidden Chain of Hazards: What Can You Do? What Happened?Document1 pageA Hidden Chain of Hazards: What Can You Do? What Happened?Abdullah AnarNo ratings yet

- Kreepy Krauly EZ Vac Owners Manual EnglishDocument16 pagesKreepy Krauly EZ Vac Owners Manual EnglishandyvtranNo ratings yet

- UOP Operations Skills For The 21st Century PaperDocument16 pagesUOP Operations Skills For The 21st Century PaperOmar EzzatNo ratings yet

- 04-SOP No. ENG-GEN-015-01 Internal Cleaning of Water ReservoirDocument6 pages04-SOP No. ENG-GEN-015-01 Internal Cleaning of Water ReservoirAjlan KhanNo ratings yet

- MANUAL DE SERVEI XTX200 Tungsteno ATX200 XTX100 (2008)Document18 pagesMANUAL DE SERVEI XTX200 Tungsteno ATX200 XTX100 (2008)Joan Pladeveya SelvasNo ratings yet

- Batch DistillationDocument6 pagesBatch DistillationDhananjay KadamNo ratings yet

- What If Your Process Is Acting Differently?: Messages For Manufacturing PersonnelDocument1 pageWhat If Your Process Is Acting Differently?: Messages For Manufacturing PersonnelJahan ZaibNo ratings yet

- Venturi Scrubber Unit. Operator's Manual (Ecom) (Techne 02-2007) (41s) PDFDocument41 pagesVenturi Scrubber Unit. Operator's Manual (Ecom) (Techne 02-2007) (41s) PDFR_M_M_No ratings yet

- A Hidden Chain of Hazards: Messages For Manufacturing PersonnelDocument1 pageA Hidden Chain of Hazards: Messages For Manufacturing PersonnelÅdnAn MehmOodNo ratings yet

- Sewage Treatment PlantDocument5 pagesSewage Treatment PlantFe CaprichoNo ratings yet

- Manual de Servei XTX200XTX100XTX50 (2011)Document23 pagesManual de Servei XTX200XTX100XTX50 (2011)Joan Pladeveya SelvasNo ratings yet

- Compressors and Steam GeneratorsDocument6 pagesCompressors and Steam GeneratorsEmmanuelNo ratings yet

- Averil Nivya ReportDocument35 pagesAveril Nivya ReportMustafa AhsanNo ratings yet

- What If Your Agitator Fails?: Did You Know? What Can You Do?Document1 pageWhat If Your Agitator Fails?: Did You Know? What Can You Do?mkkamarajNo ratings yet

- Feeco: NPK Production Plant Process AuditDocument11 pagesFeeco: NPK Production Plant Process AuditCarlosNo ratings yet

- Installation Manual Seawater SW9000-LX - PalmerolaDocument89 pagesInstallation Manual Seawater SW9000-LX - PalmerolaLuis MejiaNo ratings yet

- Pre-Commissioning: Appita Journal April 2013Document7 pagesPre-Commissioning: Appita Journal April 2013Siti NurhidayahNo ratings yet

- APM002 Rotary EvaporatorDocument9 pagesAPM002 Rotary EvaporatorMukarram MudjahidNo ratings yet

- VHP DegassDocument6 pagesVHP Degassdimitris plotasNo ratings yet

- KeepingWaterOutofYourStorageSystem Updated 2Document13 pagesKeepingWaterOutofYourStorageSystem Updated 2haifuleddyNo ratings yet

- Rotary Evaporator Fact SheetDocument3 pagesRotary Evaporator Fact SheetAbid ZiaNo ratings yet

- Tank MaintenanceDocument17 pagesTank MaintenancetoanvmpetrologxNo ratings yet

- Aqualung - Calypso - 1er Étage - Technique ManualDocument15 pagesAqualung - Calypso - 1er Étage - Technique ManualLaurent LeclercqNo ratings yet

- Palm OilDocument5 pagesPalm OilKian Seng TanNo ratings yet

- Fluval MSF ManualDocument61 pagesFluval MSF ManualMarcio KawamotoNo ratings yet

- What Is Water Efficiency?Document11 pagesWhat Is Water Efficiency?NASHRA HASANNo ratings yet

- Eliminator Owners Manual PDFDocument15 pagesEliminator Owners Manual PDFmurbietaNo ratings yet

- Fluval Manual 082002Document32 pagesFluval Manual 082002datashifterNo ratings yet

- Water in Fuel TanksDocument12 pagesWater in Fuel TanksLuis Carlos Rocero PuertoNo ratings yet

- AutoclaveDocument29 pagesAutoclaveMathesis ConsultoraNo ratings yet

- Steam Stripper: Review The Revamp: Installation Failings and Other Issues Can Impair PerformanceDocument5 pagesSteam Stripper: Review The Revamp: Installation Failings and Other Issues Can Impair PerformancerahulNo ratings yet

- 2011-03 Bad Things Can Come in Small PackagesDocument1 page2011-03 Bad Things Can Come in Small Packagesahugandkiss77071No ratings yet

- CWP™ Clean Water Plant: Operating InstructionsDocument9 pagesCWP™ Clean Water Plant: Operating InstructionsAris FebrianNo ratings yet

- Installation, Operation and Maintenance ManualDocument7 pagesInstallation, Operation and Maintenance ManualWattsNo ratings yet

- Orbit Article Molecular Sieve Dehydration Switching ValvesDocument12 pagesOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- Indim - Um - gmv5 Condensador User ManualDocument162 pagesIndim - Um - gmv5 Condensador User ManualJoaquin de la CruzNo ratings yet

- PROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalDocument6 pagesPROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalcsNo ratings yet

- Domestic Heat Pump Instruction ManualDocument20 pagesDomestic Heat Pump Instruction Manualhegi100% (1)

- And Owners Manual: Operating InstructionsDocument16 pagesAnd Owners Manual: Operating InstructionsJoe SeraphinNo ratings yet

- 1788-40 Portable Hand Washing Station ManualDocument10 pages1788-40 Portable Hand Washing Station Manualzivkovic brankoNo ratings yet

- 1788-40 Portable Hand Washing Station ManualDocument10 pages1788-40 Portable Hand Washing Station Manualzivkovic brankoNo ratings yet

- Model:: 7. 5kg Top Loadi NG Washi NG Machi NeDocument33 pagesModel:: 7. 5kg Top Loadi NG Washi NG Machi NeHadi BitarNo ratings yet

- Sugar Cane Wastewater Treatment PlantDocument7 pagesSugar Cane Wastewater Treatment PlanteztwarinzNo ratings yet

- Condensate Recovery in HVAC System - Mudassar Idris RautDocument32 pagesCondensate Recovery in HVAC System - Mudassar Idris RautMudassar Idris RautNo ratings yet

- Boss 107 Installation M1.1 PDFDocument16 pagesBoss 107 Installation M1.1 PDFEduardo E Hernandez AguirreNo ratings yet

- Audit 011 Auditing Utilities System SampleDocument4 pagesAudit 011 Auditing Utilities System SampleFiroz TanwarNo ratings yet

- Fluval 04Document27 pagesFluval 04steve-gNo ratings yet

- Xsmall hd8743Document48 pagesXsmall hd8743Constantin PetrisorNo ratings yet

- Manual-Acid Digestion VesselDocument10 pagesManual-Acid Digestion VesselocintezaNo ratings yet

- S1126 3 NuAire Horizontal Laminar Flow Work Bench 7 08Document2 pagesS1126 3 NuAire Horizontal Laminar Flow Work Bench 7 08Krishna RajNo ratings yet

- Chapter 8 - Plant Safety and LayoutDocument46 pagesChapter 8 - Plant Safety and LayoutaimanrslnNo ratings yet

- Aqualung - Calypso, Titan, Octopus - 2ème Étage - Technique ManualDocument20 pagesAqualung - Calypso, Titan, Octopus - 2ème Étage - Technique ManualLaurent LeclercqNo ratings yet

- Maintenance ManualDocument7 pagesMaintenance Manualingenieria1 ebNo ratings yet

- Hazardous Area ClassificationDocument4 pagesHazardous Area ClassificationmkkamarajNo ratings yet

- Adis-Question BankDocument1 pageAdis-Question BankmkkamarajNo ratings yet

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajNo ratings yet

- General Guidelines For Preparing The Project Report On Safety in IndustryDocument5 pagesGeneral Guidelines For Preparing The Project Report On Safety in IndustrymkkamarajNo ratings yet

- ADIS - P-4 (@1-04) Criteria For Plant Siting and Layout - (64) - 2017Document64 pagesADIS - P-4 (@1-04) Criteria For Plant Siting and Layout - (64) - 2017mkkamarajNo ratings yet

- 04 CMDB Training Roll Out 2015Document8 pages04 CMDB Training Roll Out 2015mkkamarajNo ratings yet

- 01 CMDB Training Preparations 2015Document7 pages01 CMDB Training Preparations 2015mkkamarajNo ratings yet

- Requestor: Document Event Receiver Subject TextDocument1 pageRequestor: Document Event Receiver Subject TextmkkamarajNo ratings yet

- Contractor Safety Checklist: No. Yes No N/A Points AchivevedDocument6 pagesContractor Safety Checklist: No. Yes No N/A Points Achivevedmkkamaraj100% (1)

- Contractor Management Database Information On The Allocation of Access GroupsDocument3 pagesContractor Management Database Information On The Allocation of Access GroupsmkkamarajNo ratings yet

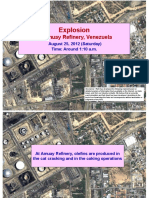

- ADIS - P-4 (@1-03.8) Venezuela Disaster - (2012) - Aug. 2017 - (49) .PpsDocument49 pagesADIS - P-4 (@1-03.8) Venezuela Disaster - (2012) - Aug. 2017 - (49) .PpsmkkamarajNo ratings yet

- ADIS - Ch-4 Safety in Plant Operation and MaintenanceDocument20 pagesADIS - Ch-4 Safety in Plant Operation and MaintenancemkkamarajNo ratings yet

- ADIS - P-4 (@1-03.7) Thai Oil Refinery Explosion - (1999) - Aug. 2017Document15 pagesADIS - P-4 (@1-03.7) Thai Oil Refinery Explosion - (1999) - Aug. 2017mkkamarajNo ratings yet

- ADIS - P-4 (@1-02) Process Safety Management - (70) - Aug. 2017Document70 pagesADIS - P-4 (@1-02) Process Safety Management - (70) - Aug. 2017mkkamarajNo ratings yet

- ADIS - P-4 (@1-03.0) Major Industrial Disasters - General - Aug. 2017Document21 pagesADIS - P-4 (@1-03.0) Major Industrial Disasters - General - Aug. 2017mkkamarajNo ratings yet

- The Seveso Disaster (1976) : by A.K. GuptaDocument29 pagesThe Seveso Disaster (1976) : by A.K. GuptamkkamarajNo ratings yet

- Flixborough Disaster (1974) : A.K. GuptaDocument24 pagesFlixborough Disaster (1974) : A.K. GuptamkkamarajNo ratings yet

- HSSE ALERT Terminal Diwali PrecautionsDocument1 pageHSSE ALERT Terminal Diwali PrecautionsmkkamarajNo ratings yet

- ADIS - P-4 (@1-01) Safety in Chemical Industry - (34) - Dec. 2014Document34 pagesADIS - P-4 (@1-01) Safety in Chemical Industry - (34) - Dec. 2014mkkamarajNo ratings yet

- Cslplasma Online Health Questionnaire Instructions March2023Document4 pagesCslplasma Online Health Questionnaire Instructions March2023Ivel RhaenNo ratings yet

- Daf Abse2 BlockdiagramDocument34 pagesDaf Abse2 BlockdiagramMircea Gilca100% (2)

- SIGRADEDocument2 pagesSIGRADErajpre1213No ratings yet

- 02 - Alto Saxophone - Marcha Radetzky (JOC)Document2 pages02 - Alto Saxophone - Marcha Radetzky (JOC)Manuel LópezNo ratings yet

- Operating Systems: DeadlockDocument22 pagesOperating Systems: DeadlockOwner JustACodeNo ratings yet

- Labov Stratification 16march2023Document1 pageLabov Stratification 16march2023Chaima Benchourak03No ratings yet

- BrochureDocument3 pagesBrochurealhumdulilahNo ratings yet

- Quarter 2 Answer Sheet - Mathematics 9: Pre-Assessment: Write The Letter of Your Answer. (Page 1)Document8 pagesQuarter 2 Answer Sheet - Mathematics 9: Pre-Assessment: Write The Letter of Your Answer. (Page 1)John Vinz ÜvNo ratings yet

- L 2Document15 pagesL 2Serch Estrada CastellónNo ratings yet

- Machine Learning Based Gate Opening and ClosingDocument40 pagesMachine Learning Based Gate Opening and ClosingMadduri NithamNo ratings yet

- Terrain-Avoidance (Pull-Up) Maneuver: Tool KitDocument4 pagesTerrain-Avoidance (Pull-Up) Maneuver: Tool KitLuis HernandezNo ratings yet

- 170 Python ProjectsDocument15 pages170 Python Projectsrajeswari.bommanaboinaNo ratings yet

- Aip 2023 San Diego Elementary School 121172 Leo Robedillo FinalDocument10 pagesAip 2023 San Diego Elementary School 121172 Leo Robedillo Finalruskyjeth16No ratings yet

- Structural DynamicsDocument79 pagesStructural DynamicsJunnaz BalacuitNo ratings yet

- 4 91 1 Air ServiceDocument32 pages4 91 1 Air ServiceAntony MorenoNo ratings yet

- Tcs Book FinalDocument16 pagesTcs Book FinalAbinash MohantyNo ratings yet

- Drude Theory of MetalsDocument13 pagesDrude Theory of MetalsShochin Chandra DasNo ratings yet

- Logical PositivismDocument30 pagesLogical Positivismangela danzalanNo ratings yet

- 29 Hydraulic PowerDocument114 pages29 Hydraulic PowerVitty PhanNo ratings yet

- Pick - Place PDFDocument44 pagesPick - Place PDFABDOPORSNo ratings yet

- 2.2.8 Doctor Blade: A. Berni, M. Mennig, H. SchmidtDocument4 pages2.2.8 Doctor Blade: A. Berni, M. Mennig, H. SchmidtMan Roland 709No ratings yet

- Pemilihan Bibit SaperDocument30 pagesPemilihan Bibit SaperRosa Trihertamawati100% (1)

- Advanced Structural Dynamics and Acoustics 13811 Advanced Structural PDFDocument13 pagesAdvanced Structural Dynamics and Acoustics 13811 Advanced Structural PDFJitendra ItankarNo ratings yet

- Powercore Model Tec-10 Installation ManualDocument12 pagesPowercore Model Tec-10 Installation ManualmikeNo ratings yet

- D14 Updated 24 Dec 2007 PDFDocument14 pagesD14 Updated 24 Dec 2007 PDFVinayak SanghaniNo ratings yet

- GED102 Module 3 Project: Group Members: Raynard Yu John Luis Arce Miguel Agustin Galang Paul Cauman Renz Eugene GurionDocument6 pagesGED102 Module 3 Project: Group Members: Raynard Yu John Luis Arce Miguel Agustin Galang Paul Cauman Renz Eugene GurionqwertasdfgNo ratings yet

- Organising - DPP 01 (Of Lecture 02) - (Kautilya) (1) KDDDDocument5 pagesOrganising - DPP 01 (Of Lecture 02) - (Kautilya) (1) KDDDAshutosh SauganNo ratings yet

- Amway BrandingDocument2 pagesAmway BrandingSophia PhoebeNo ratings yet

- ELEC4810: Introduction To Biosensors and Bioinstrumentation: Lecture Notes - Set #10Document17 pagesELEC4810: Introduction To Biosensors and Bioinstrumentation: Lecture Notes - Set #10Kwan ChanNo ratings yet

- Thesis Writing and ResearchDocument5 pagesThesis Writing and ResearchAlverastine AnNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Theory and Calculation of Heat Transfer in FurnacesFrom EverandTheory and Calculation of Heat Transfer in FurnacesRating: 3 out of 5 stars3/5 (4)

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Geotechnical Engineering Calculations and Rules of ThumbFrom EverandGeotechnical Engineering Calculations and Rules of ThumbRating: 4 out of 5 stars4/5 (17)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsFrom EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNo ratings yet

- Basic Digital Signal Processing: Butterworths Basic SeriesFrom EverandBasic Digital Signal Processing: Butterworths Basic SeriesRating: 5 out of 5 stars5/5 (1)