Professional Documents

Culture Documents

Rail Projects and Track Installation Supported by Long-Term Track Maintenance Solutions

Uploaded by

shahzilezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rail Projects and Track Installation Supported by Long-Term Track Maintenance Solutions

Uploaded by

shahzilezCopyright:

Available Formats

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

RAIL PROJECTS AND TRACK INSTALLATION

SUPPORTED BY LONG-TERM TRACK

MAINTENANCE SOLUTIONS –

A CASE STUDY OF CURRENT SWISS AND

AUSTRIAN RAILWAY PROJECT AND

MAINTENANCE INITIATIVES

Hubert Rhomberg

MSc (civil engineering)

Board member of the Austrian Transport Institute (OEVG)

Managing Director of Rhomberg Bahntechnik

AusRAIL PLUS 2005

nd th

22 – 24 November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

SUMMARY

As in many other industries total life cycle cost considerations are predominant today in the rail

infrastructure industry.

As a result clear-cut requirements in terms of construction, operation and maintenance of railway

facilities are fundamental for the cost-efficient construction and operation of railway installations. A

design based on these requirements, high quality execution of works and optimised maintenance of

railway installations with an overall life cycle cost (LCC) approach are increasingly important. Due to

ever more stringent safety standards and introduction of new technologies, railway engineering

projects are also becoming more complex and have to be carried out and commissioned in ever-

shorter time spans.

The planning and construction of new infrastructure and renewal of existing assets by competent

Design & Build (D&B) contractors with a proven track record in construction and maintenance offers a

real opportunity for the customer and during operation, systematic maintenance of new and existing

railway installations by specialised companies guarantees the required availability at an economical

price. The experience gained in construction and maintenance, together with a thorough know-how of

managing complex projects and logistics provide thus an ideal basis for a contractor to offer a total

service package in delivering railway technology.

The benefits of railway projects managed by such total services contractor are described, taking the

example of the Lötschberg base tunnel amongst others.

AusRAIL PLUS 2005

nd th

22 – 24 November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

NOTATIONS AND ABBREVIATIONS track and manages multi-disciplinary rail

DB Netz AG Deutsche Bahn Netz AG projects of various magnitude.

German Rail Infrastructure Owner

OEBB „Oesterreichische Bundesbahnen“ 2 REQUIREMENTS TO BE MET BY THE

TRACK

Austrian Federal Railways

SBB “Schweizer Bundesbahnen“ Tracks have to be laid and maintained in such

a manner that the demands by the operator

Swiss Federal Railways and the users in respect to provide a cost

BBW Bahnbau Wels GmbH effective infrastructure are being met. Whether

MDZ “Maschineller DurcharbeitsZug” the track is of ballasted or ballastless design is

only of secondary importance in this respect.

Mechanised maintenance unit

consisting of a ballast regulator, a During the development of DB AG's Track

tamping machine and a track Strategy project [1, 2], the track requirements

stabiliser were compiled by DB AG's own experts

LCC Life Cycle Costs assisted by external specialists and evaluated

as follows:

Mandatory requirements must be met

1 INTRODUCTION, BASICS Tolerated requirements are backed up

with data and are integrated into the

1.1 SUBSTRUCTURE OF TRACK INSTALLATIONS

lifecycle costs or the overall evaluation

(FOUNDATION)

(either via analysis or comparison)

The following deliberations shall be made on Subsidiary requirements criteria are

the premise that the substructure supporting documented, but not further evaluated

the track installations features the required

qualities with regard to stability, load-bearing

capacity and for Alpine conditions – as we

have in Europe - particularly, frost resistance.

The structures, particularly bridges, cut & cover

sections and tunnels shall be designed to

accommodate all track features with the

required dimension and provide a substructure

of sufficient uniform elasticity.

1.2 POINTS AND CROSSINGS

These have deliberately been excluded from

the present considerations, as this subject may

require detailed reflections beyond this very

discussion.

1.3 BASICS OF THIS PRESENTATION

This case study is partly based on DB AG's

report "Track Strategy" [1], a study published in

2003 on DB AG's track strategy [2] as well as

the published excerpts of the "System

Decisions Ballastless Track versus Ballasted

Track for the Swiss Federal Railways" [3].

Further input was drawn from the extensive

experience of Bahnbau Wels (BBW) and

Rhomberg Bahntechnik. BBW is specialised in

the construction and maintenance of railways,

while Rhomberg Bahntechnik has developed

well-proven technologies for laying ballastless

AusRAIL PLUS 2005

nd th

22 – 24 November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

A detailed list of requirements can be found in For the selection and design of the track in

the “DB-AG Track Strategy” Team study.[2]. connection with the lifecycle costs described

below, the following parameters are presented

Next to the mandatory requirements including

as key criteria.

the mandatory fulfilment of speed and load

requisites, the existing regulations, as well as Investment costs

the safety requirements regarding safety in Geometry and design of the earthworks

tunnels, water drainage and environmental and construction works (e.g. smaller radii

protection (noise and vibration emissions) and used when laying ballastless track on new

any tolerated requirements will be evaluated lines)

and added into a matrix in order to define

Maintenance expenditure

priorities.

AusRAIL PLUS 2005

nd th

22 – 24 November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

Overall operational Construction and

Risks / Failures Other requirements

model maintenance strategies

Availability Maintainability Safety Drainage

- Guaranteed punctuality - Reduced impact of damage

- Minimal hindrances due Possible alterations (e.g. guidance for a derailed Structure-borne noise

to permanent way - Height and position in wheelset)

- Limited operational the fastenings Damage symptoms and Accustic noise

hindrances caused by - Excessive settlement restoration after noise

- Track equipment

maintenance work derailment - Maintenance

- (Renewal) Investment - Absorbent coatings

- Safe construction processes

Repair of possible fault

Economical - Minimal operational symtoms in respective Impact on the

- Infrastructure costs over hindrances tracks substructure

service life (LCC) - Objective: - Low surface-pressure

- Indirect savings potential Reliable supply of Planning restoration within pressurepressung

by standardisation and components maximum 8 hours without Loading gauge

innovation - Components (e.g. subsequent limitations - Improvements during

individual supply points) conversions (e.g. in tunnels)

- System components

Riding comfort e.g. baseplates) Eddy-current brake

- High quality and long-

lasting track geometry Source: Track Strategy Project (SMP-T)

Figure 1: Summary of requirements and expectations (source: [2])

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

The requirements and criteria were arranged Costs relation to operational hindrances in

according to the following aspects case of scheduled or unscheduled

Overall operational model availability

Construction and maintenance strategies Measures to limit acoustic and structure-

Risk and failure management borne sound (particularly next to track

infrastructure in urban areas)

Requirements arising from the outer field

Operational benefits of geometric profile

(e.g. higher speeds by installing ballastless

tracks on existing routes/ lines)

From the above key criteria, one can subsume

that after direct investment costs, maintenance

and operational hindrance costs are the main

economic parameters for replacement

decisions, and these shall be discussed in

more detail below.

Further parameters determining horizontal and

vertical profile are essentially linked to the

prevailing topography and the overall network

structure and thus have to be analysed

separately on a project specific basis.

3 LIFE CYCLE COSTS (LCC)

The overall life cycle costs of track installations

(from the initial investment in a new track to the

relaying or removal) consist of:

the initial investment or the replacement

investments

the diagnosis and inspection

the unscheduled maintenance and the

associated works carried out immediately

(emergency repairs)

the scheduled maintenance

Investment

Inspection Maintenance

Emergency

Repairs

Figure 2: Interaction of LCC components

3.1 LCC MODEL

The abovementioned cost components shall

be analysed over an entire life cycle or, in case

of a comparison between systems with

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

differing durability, over longer periods of time It shall be noted that on dedicated passenger

and then summarised to a net present value at traffic lines schedules do not usually call for

the time of investment, taking into account operation at night, allowing maintenance to be

inflation and interest rates. carried out without significant operational

hindrances. On freight-only lines, on the other

The model allows therefore a comparison

hand, track possessions for maintenance can

between different track systems (for example:

generally be scheduled to allow for the

ballasted track vs. ballastless track), and can

operational requirements.

be used to represent different maintenance

strategies and comparing these by using Especially on mixed traffic lines, the required

different scenarios. track availability is very high around the clock.

As passenger traffic is normally dense during

As figure 2 shows, there is a high

the day, and freight traffic dense at night,

interdependence between the different

neither during the day nor at night traffic

elements of life cycle costs. As a result pure

volumes are low enough for effective

optimisation of one single component could

maintenance. Maintenance work on this type of

lead to an imbalance of the whole system and

line almost always causes operational

thus have a negative effect on the overall life

hindrances.

cycle costs.

Depending on the operational environment,

3.2 DIAGNOSIS AND INSPECTION

these operational hindrances are taken into

For track infrastructure with high availability account as operational hindrance costs in the

and traffic load requirements, availability is LCC models.

maximised by corresponding diagnosis (e.g.

track inspection train running) and visual 4 TRACK CONSTRUCTION AND

inspections. MAINTENANCE

4.1 MAINTENANCE INTERVALS

3.3 EMERGENCY REPAIRS The objective should be to achieve the longest

possible intervals between systematic track

Emergency repairs are avoided as far as

maintenance cycles.

possible, as the necessary unscheduled ad-

hoc measures are very costly and cause In this respect, it should be remembered that

significant operational hindrance costs with low frequent and often unnecessary tamping of the

efficiency. track wears the ballast and the sleepers down,

which leads to an inferior track stability in the

long run.

3.4 SCHEDULED MAINTENANCE

The average tamping interval ranges between

The objective is to positively impact the total 4 and 7 years in Germany, Switzerland and

life cycle costs by scheduling and preparing Austria.

maintenance intervals based on the actual

track condition.

3.5 OPERATIONAL HINDRANCES

The correlation between gross tonnage and

traffic density on the SBB network [3] shows

that traffic density is higher on passenger lines

than on freight traffic lines for identical traffic

loads. Whereas passenger traffic is

predominated by light trains with high traffic

densities being achieved with comparatively Figure 3: Tamping intervals for ballasted track

depending on the traffic load (source: [3])

low traffic flows, freight trains with generally

heavy axle loads provide high daily traffic loads Figure 3 shows that the tamping interval

with comparatively low traffic densities. depends relatively little on the average daily

traffic load, i.e. the tamping intervals on heavily

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

trafficked lines are only insignificantly shorter quality) due to a lack of elasticity. This leads to

that those on lines with light traffic loads. shorter maintenance intervals, which generally

also means a reduction in the service life of the

The tamping interval is much more dependent

track.

however, on the quality of substructure

(uneven track geometry due to settlements or A remedy to these affects may be the

substructure movements). reinforcement of the ballast bed using sleeper

pads or inserting mats under the ballast, in

Major factors influencing maintenance intervals

particular on bridges.

are a high initial track quality and a high quality

of systematic track maintenance. Tracks embedded in ballast can be regarded

as floating in a floating support. Uneven

Modern high performance machines, able to

settlements will be occurring within the ballast

treat up to 3 to 4 sleepers simultaneously,

bed and on the substructure level under the

have an output of up to 2000m/h and offer the

subsequent traffic loading. For this reason the

highest quality in track geometry and track

use of a dynamic track stabilizer anticipating

stability. This quality can be further improved

the initial train loads and the so-called

when using a stabiliser.

stabilisation tamping have proven to be very

Additionally, special attention has to be paid to effective. Tamping for stabilising the track is

high quality track surveying, which is a carried out a few weeks and then a year after

prerequisite for achieving a high quality and the line has been reopened to traffic. Thus,

durable track geometry on new tracks or during initial faults resulting from uneven settlement of

systematic maintenance. the ballast bed are compensated and the

highest possible initial track quality is achieved.

It is essential, particularly with respect to rail

stresses that the track is delimited Due to the inherent high quality of the track

(geometrically monitored) over its entire there are few dynamic forces acting in the

service life and thus can be reset to its original track, which in turn is supporting the strategy of

alignment during each maintenance operation. long maintenance intervals.

Should this not be the case, the curves of the

track may move either to the inside or to the

4.3 PERMANENT WAY BALLAST

outside during maintenance operations, which

leads to changing rail stresses and inner forces On ballasted track special attention needs to

within the track. be paid to top quality ballast requiring high

edge resistance to be able to direct the forces

acting on the track into the substructure, while

4.2 INITIAL TRACK QUALITY maintaining the elasticity within the ballast bed.

As systematic maintenance, including sleeper

When laying new track or during track tamping, necessitates high stresses on the

renewals, special attention has to be paid to components, frequent maintenance operations

the following factors. have a negative impact on the quality of the

Bearing capacity and stability of the ballast bed material and the bed within which

substructure the sleeper is positioned.

Drainage and for Europe also frost For this reason track tamping should only be

resistance carried out when it is absolutely necessary.

Uniform elastic characteristics of the

substructure

Avoidance of settlements and movements 4.4 MAINTENANCE OF THE RAIL SURFACE

in the substructure After laying the track, the initial quality of the

Sufficient quality of the ballast used rail surface is improved by grinding the rolling

skin while at the same time treating the

It has been found that the service life of track, welding joints. Simultaneously the impurities

and in particular maintenance intervals, are due to the production process (unevenness

negatively impacted by a sub structure that is caused by crushed ballast) are also removed.

too hard (either a ballast bed laid directly on

bridges or on earth construction of too high

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

The grinding also helps produce the rail head 4.6.2 Sleeper pads

cross sections of new rails according to the

specifications. Particularly on high-speed lines, Over the past years, further innovations in the

the initial profile needs to be as accurate as field of permanent way have allowed for the

possible in order to guarantee the required development of improved ballasted track.

wheel-tread conicity. The use of sleeper pads in particular has

These measures have a positive impact on the yielded very positive results with just slightly

service life of the rail and in particular help increased investment costs. These pads can

reduce the incidence of corrugations and rail be installed using existing and well-proven

surface faults. track maintenance machines.

Observations made so far indicate extended

maintenance intervals and possibly also a

4.5 INFRASTRUCTURE ELASTICITY longer overall service life.

Another aspect is the uniform elasticity of As empirical results covering several decades

infrastructure, consisting of substructure and are not available yet , it is impossible to

track. Under standard load conditions, the rail present final conclusions for the time being.

deflection should be 1 to 1.5mm.

Only this deflection allows the rail to optimally

fulfil its longitudinal load-distributing role, which 4.7 EXECUTION OF WORKS WITH SPECIALISED

CONTRACTORS

minimises the load on both the ballast bed and

the substructure and thus reduces the strain on Construction and maintenance operations are

the track and the subgrade. carried out by specialised contractors using the

4.6 ALTERNATIVES TO BALLASTED TRACK

most modern and high capacity machines (e.g.

MDZ units) operated by qualified and very well

trained staff within a framework of medium-

4.6.1 Ballastless track

term operational work programmes.

In the area of tunnel systems, ballastless or

These highly specialised contractors guarantee

concrete tracks are a well-proven and common

highly efficient and state-of-the-art construction

practical alternative to ballasted track.

and maintenance work to the railway

According to studies carried out by DB, infrastructure owners..

ballastless track is – in terms of LCC - also a

Usually the works of these contractors are

cost-efficient alternative in the open primarily

carried out within long-term framework

on lines requiring a high availability around the

contracts, which are essential should the

clock, which in the case of heavily trafficked

contractors be required to invest into

lines require extremely high track reliability.

expensive machinery and train the highly-

Uniform substructure conditions are essential, qualified personnel necessary for the work.

where no settlements or movements would be

expected in the substructure. Current methods 5 GENERAL CONTRACTOR IN RAIL

of construction require higher investments, ENGINEERING

which can only partially be compensated by

5.1 POTENTIAL BENEFITS

lower maintenance cost.

In Germany, Switzerland and Austria, the

Only by using the comparatively high

laying and upgrading of lines are frequently

operational hindrance costs in the LCC is the

outsourced to general contractors.

long-term cost-efficiency of ballastless track

achieved. This is of great importance The benefits to the customer derive from risk

particularly on mixed traffic lines, which are minimisation by awarding the contract to a total

being used by passenger traffic during the day services contractor which provides the

and dense freight traffic at night. following:

No planning and functionality risk, due to

centralised planning and execution by the

general contractor

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

A high level of schedule reliability for the maintenance intervals and maintenance

construction and commissioning of the schedules. This maintenance was not only

entire railway installation. restricted to the ballastless track itself but

The complex logistical and construction included complete maintenance of the system

site safety issues, especially for tunnel like signalling, air conditioning, catenary

projects, are centralised. equipment, high and low voltage equipment,

cabeling, etc., in principal you can say,

Use of synergies between different areas everything around the track in that tunnel.

within the general contractor for railway

technology

Reliable budgeting by avoidance or

minimisation of supplements.

By doing so BLS AG achieved a twofold goal:

The customer incurs fewer risks regarding

additional costs and delays, as project a) they could test and evaluate the

management acts as an interface between prospective bidders competence as an

traditionally separate project areas. overall contractor

A prerequisite for the works being carried out b) by introducing the

by a total services contractor for railway availability/maintenance cost approach

technology is a concise and complete they created a bench mark for internal

formulation of the requirements, the definition maintenance procedures.

of the interfaces and responsibilities of the

general contractor, the customer and third

parties. Last but not least, one major reason for BLS

AG to use one general contractor for the whole

“tunnel equipment” was the fact that the real

5.2 EXAMPLE LÖTSCHBERG BASE TUNNEL challenge for the realisation of this project was

the solution of the logistics issue, mainly the

Based on intensive studies with regard to Total transport of all equipment into the tunnel in a

Life Cycle Cost of Swiss Federal Railways and timely manner and assuring the smooth

experience with slab-track technology in sequence of installation.

general it was a very logical decision that the

BLS AG (Bern – Lötschberg – Simplon AG) 5.2.1 The project

had the Swiss and European most prestigious

railway project - the Lötschberg-Tunnel The 35 km long Lötschberg base tunnel will be

connecting the north side and the south side of the first high speed line through the Swiss Alps

the Alps in Switzerland when it goes into service in 2007. The base

tunnel reduces the crown height of the total

a) subcontracted to an experienced Lötschberg line from today's 1240m to 825m

General Contractor namely above sea level.

Zschokke/Rhomberg, a Swiss/Austrian

consortium and

b) have selected the ballastless track

technology for the project itself by

defining clearly the minimum speed,

availability/minimum train frequency

and reaction time to occurring

unforeseen event.

As BLS AG was well aware of the Total Life

Cycle Cost issue, in their tender documents

they clearly challenged the prospective bidders

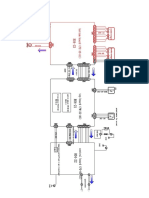

by not only asking for pure investment cost for Figure 4 : Diagramm of the Lötschberg base tunnel

the whole project but asked the bidders to bid

firmly as an option also for maintenance cost

over a period of 10 years including

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

5.2.2 The project organisation Power supply installations: lighting,

installations of low voltage supplies for the

construction phase

Communications for the construction

phase: 2-way radio, data links and

telephone

Containers: for operational centres

Data-telephone: phone,

telecommunication and loudspeaker

systems

High-voltage: transformers, switch &

control gear, safety installations

Subject organisation chart highlights the

complexity of the project and the individual Mechanic equipment: building ventilation,

work packages to be covered by the general lifting equipment, signs and boards,

contractors. It can easily be seen that the signals, lock-gates and other metal

ballastless track work package is only a part of constructions

the whole, in terms of money, approximately Low-voltage: emergency power supplies,

15% of the total project value only. lighting, low-voltage installations

Safety equipment: colour-light signals,

5.2.3 Basic principles for the railway system tunnel atmosphere, fire-fighting equipment,

installations video, fire-, gas- and moisture detectors

Installation of components which are well- Cubicles: for connecting passageways

proven and not merely tested systems: and operational centres

Only reliable systems are also safe Sliding doors: as closures for connecting

systems passageways and operational centres

Strive for simple systems Tunnel surveillance system: monitoring

As few systems as possible of all tunnel installations for the control

centre

Create back-up systems where necessary

Safety equipment: installations for railway

Use systems of modular design

engineering, signalling, FSS system, point

Take into account the special problems of motors

long single-track tunnels (safety, access,

atmospheric conditions etc.) The Railway Engineering Co-ordination is in

overall charge, acting as project management:

Use the suppliers' expert knowledge

Co-ordination and control of the design

5.2.4 Comprehensive co-ordination planning of all railway technology

disciplines

The following railway engineering fields must Construction supervision in the

be planned, co-ordinated and executed

execution phase of all railway technology

Track: track structure slab, ballasted and fields

ballastless track Co-ordination of installation planning

Overhead contact system: catenary and

Project supervision (services, deadlines,

earthing wire, radio system

costs) and reporting

Cable: laying of all cables, overhead line

Interface management

equipment feeder and earthing,

telecommunication and high-voltage Quality management

cables Modifications and documentation

Ventilation: ventilation for regular

operation and the construction phase 5.2.5 Statistical data

The most important installations in the tunnel

are:

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

Track from mid 2003 Approval of execution projects

57 km September Beginning of construction at Raron

Catenary 25, 2003 site

60 km January 7, Delivery of the control containers in

2004 the assembly depot, beginning of

Catenary supports production in the plants

1500 units

November Handing over of the first section

Sliding doors in connecting 2004 Raron-Lötschen (Western tube) for

passages the installation of railway

175 units infrastructure and equipment

January 2005 Commencement of installation of

Transformer stations

ballastless track

21 units

as of March Start of trial runs in the Eastern

Electrical cabinets 2006 tube between Visp and Ferden

1200 units January 2007 Beginning of acceptance

Control equipment containers procedures and commissioning by

in the operations control centers (20“) BLS AlpTransit AG

134 units May 31, 2007 Hand over of the Lötschberg base

tunnel to the Swiss Federation and

Cables laid the operator (BLS Lötschbergbahn

1390 km AG)

Video cameras December 9, Beginning of scheduled traffic

133 units 2007

Fire detectors

3200 units The contract sum of the railway infrastructure

Central fire alarm systems of this project amounts to a total of approx. 480

20 units million Euros.

Rooms with automatic fire

extinguishing systems

110 units 6 CONCLUSION

Emergency tunnel lights 6.1 POTENTIAL BENEFITS

2 500 units

Telephone switchboards The case study for defining the track strategy

16 units for Deutsche Bahn (DB) concluded that well-

defined and managed technical, functional and

Phones performance requirements in terms of

427 units construction, operation and maintenance

Direction and information signs underpin the commercial success of a project

3000 units and the subsequent cost-effective operation of

Double floors in centres and rooms a railway infrastructure.

5500 m² Combined with high quality execution of works

and an optimised maintenance regime, overall

lifecycle cost (LCC) calculations reinforce

increasingly key decisions in respect to the

5.2.6 Project milestones

development and realisation of rail

July 19, 2001 Publication of 3 "prototype" tender infrastructure projects on an international

lots

scale.

September 4, Publication of 8 main tender lots

2001

The planning and construction of new

infrastructure and/or renewal of existing assets

March 15, Tender closure date for main lots by competent Design & Build or total services

2002

contractors offer a real opportunity to deliver

June 25, 2002 Award of main lots complex programmes of work on behalf of the

July 2002 Beginning of project works of main customer in Germany, Switzerland and Austria

lots

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

Hubert Rhomberg Rail Projects and Track Installation supported

by Long-Term Track Maintenance Solutions –

Rhomberg Bahntechnik A Case Study of Current Swiss and Austrian

Railway Project and Maintenance Initiatives

with the least amount of risk and a measured ballastless versus ballasted track for the Swiss

amount of opportunity. Federal Railways); ETR 6/2005 pages 348-354

Principles in regard to achieving the optimum [4] Ablinger P, Ganzheitliches Prozessdesign im

intervals of track maintenance cycles may Bereich der Bahntechnik (Overall process

apply to infrastructure requirements elsewhere, design in the area of railway technology);

whereby materials are being installed to design Eisenbahningenieur 9/2001, page 14

by the appropriate techniques to allow for the [5] Ablinger P, Vermessen und Einrichten von

asset to perform to its maximum service life. Festen Fahrbahnen – Systemkonzept

Experience gained in both construction and (Surveying and installation of ballastless track –

system concept) ; Eisenbahningenieur 9/2001,

maintenance, together with bringing innovation

page 15 – 21

together with a thorough knowledge of

[6] Ablinger P, Rhomberg H, Kleboth C,

managing complex projects proves to provide

Spezifische Anforderungen an die Herstellung

the right background and sufficient benefits for des Füllbetons bei Festen Fahrbahnen (Specific

a total services package being delivered on requirements on the production of filling

behalf of a railway infrastructure owner. concrete for ballastless tracks);

Eisenbahningenieur 9/2001, pages 22 – 30

6.2 WHAT DOES THAT MEAN FOR [7] Knittel S, PLASMA – das Vermessungssystem

AUSTRALIA? zur effektiven und ökonomischen

Qualitätsbeurteilung von Bahngleisen (PLASMA

The principles of designing, constructing and – the surveying system for efficient and

maintaining a railway infrastructure may not economical quality appraisal of railway tracks) ;

differ greatly to systems being delivered Eisenbahningenieur 7/2004 pages 55-57

elsewhere in the world. [8] Foege T, Flatscher T, Feste Fahrbahn Rheda

The demands by the operator and the users in 2000® auf der NBS Nürnberg Ingolstadt

respect to provide a cost effective railway (Ballastless track Rheda 2000 ® on the new

infrastructure will need to be met line Nuremberg Ingolstadt); ETR 1/2/2005

unconditionally. pages 44 – 54

From the operator to the maintainer and from [9] Zuppiger J, Orsenigo V, Bahntechnik im

the client to the contractor, all have to have Lötschberg-Basitunnel (Railway technology in

sufficient know how and understanding of the the Lötschberg base tunnel); Der

Eisenbahningenieur 8/2004, pages xx –xx

system as a whole. Only then can they share

the tasks and the risks to fulfil the challenging

requirements of a high competitive The literature as well as further information can

environment, in a perfect manner.. be downloaded to a large extent from the

website:

LITERATURE http://www.bahntechnik.com/Englisch/news.html

[1] Koriath H, Hamprecht A, Huesmann H, Ablinger

P; Objektivierung der Systementscheidung

Schotteroberbau versus Feste Fahrbahn bei

der DB-AG (Making an objective system

decision regarding ballasted versus ballastless

Track), ETR 3/2003 pages 113-122

[2] DB Systemtechnik Projektteam

Fahrbahnstrategie, Systementscheidung

Schotteroberbau oder Feste Fahrbahn, ,

(DB Systems Technology Project Team Track

Strategy, System decision ballasted or

ballastless track), published by IFV Bahntechnik

e.V. 10857 Berlin Salzufer 17-19/SG20; second

printing 2003 (www.ifv-bahntechnik.de)

[3] Steinegger R, Lang TP, Güldenapfel P,

Ablinger P, Systementscheidung Feste

Fahrbahn versus Schotteroberbau für die

Schweizerische Bundesbahn (System decision

AusRAIL PLUS 2005

22nd – 24th November 2005, Sydney

You might also like

- Ballast Less Track DesignDocument8 pagesBallast Less Track DesignSanjoy SanyalNo ratings yet

- City of Syracuse Comprehensive Plan 2025Document55 pagesCity of Syracuse Comprehensive Plan 2025nurpeek100% (1)

- MAI ProfileDocument31 pagesMAI Profileyashpote027No ratings yet

- SB6.1 Guideline STRDocument137 pagesSB6.1 Guideline STRmorralla123No ratings yet

- SB3.15 Guideline ICA PDFDocument259 pagesSB3.15 Guideline ICA PDFBianca ZahariaNo ratings yet

- Bridges - EN - AcelorMittalDocument52 pagesBridges - EN - AcelorMittalstavros_stergNo ratings yet

- ABC-Draft - 03 Dated 18.07.13Document96 pagesABC-Draft - 03 Dated 18.07.13Ratul RanjanNo ratings yet

- Transmission and Distribution Substations: Company ProfileDocument15 pagesTransmission and Distribution Substations: Company ProfileAnonymous MDkp0hnb3lNo ratings yet

- Arcelor Mittal - Bridges PDFDocument52 pagesArcelor Mittal - Bridges PDFShamaNo ratings yet

- Slab Tracks in Germany - Implementation and ExperienceDocument16 pagesSlab Tracks in Germany - Implementation and ExperienceAkshay WahalNo ratings yet

- Life-Cycle Considerations in The Selection and Use of Bridge Expansion JointsDocument8 pagesLife-Cycle Considerations in The Selection and Use of Bridge Expansion Joints정주호No ratings yet

- Catálogo VARIOKIT PERI PDFDocument44 pagesCatálogo VARIOKIT PERI PDFHenry MorenoNo ratings yet

- Acobri Efficient and Economic Design of Composite BridgesDocument10 pagesAcobri Efficient and Economic Design of Composite BridgestyukgombaNo ratings yet

- Catálogo VARIOKIT PERI PDFDocument44 pagesCatálogo VARIOKIT PERI PDFHenry MorenoNo ratings yet

- MAI Profile 21.2.24Document33 pagesMAI Profile 21.2.24yashpote027No ratings yet

- Technical Journal: Plan Design EnableDocument16 pagesTechnical Journal: Plan Design EnableAkshay SakhujaNo ratings yet

- State of The Art Report On Soil Improvment Methodes and ExperiencesDocument54 pagesState of The Art Report On Soil Improvment Methodes and Experiencesmojijan100% (1)

- Highway Structures: Approval Procedures & General Design Section 2 Other Procedural DocumentsDocument13 pagesHighway Structures: Approval Procedures & General Design Section 2 Other Procedural DocumentsΔημητρηςΣαρακυρουNo ratings yet

- D4.6-Design Guide and Technology Assessment of The Transmission Mitigation MeasuresDocument42 pagesD4.6-Design Guide and Technology Assessment of The Transmission Mitigation MeasuresAnghel Cristian GabrielNo ratings yet

- Earthing and Bonding - Crossrail Learning LegacyDocument20 pagesEarthing and Bonding - Crossrail Learning LegacyNilo AbrilNo ratings yet

- Engineering Failure Analysis: D. Rechena, V. Infante, L. Sousa, R. Baptista TDocument13 pagesEngineering Failure Analysis: D. Rechena, V. Infante, L. Sousa, R. Baptista TAngel FajmNo ratings yet

- Bridges: With Rolled SectionsDocument52 pagesBridges: With Rolled SectionsFRANCISCO CUBA H.No ratings yet

- Rail Bridges and TunnelsDocument2 pagesRail Bridges and TunnelsAnirudra BhattacharyaNo ratings yet

- Approach For The Life-Cycle Management of Structures Including Durability Analysis and Maintenance PlanningDocument8 pagesApproach For The Life-Cycle Management of Structures Including Durability Analysis and Maintenance PlanningPPPnewsNo ratings yet

- PRECO English PDFDocument119 pagesPRECO English PDFAmal HajarNo ratings yet

- A5 CornicDocument9 pagesA5 CornichakimNo ratings yet

- Nam Tran Electrical Engineer 0913484565Document3 pagesNam Tran Electrical Engineer 0913484565Huu NamNo ratings yet

- Safety ReportDocument22 pagesSafety Reportrayudu vvs50% (4)

- Rob PPT FinalDocument24 pagesRob PPT FinalAyan GuhaNo ratings yet

- Crossrail Sprayed Concrete LiningsDocument20 pagesCrossrail Sprayed Concrete LiningsDEBASIS BARMANNo ratings yet

- CH3 - Railway Transport Planning StudiesDocument63 pagesCH3 - Railway Transport Planning Studiesct constructionNo ratings yet

- SB6.1 Guideline STR PDFDocument137 pagesSB6.1 Guideline STR PDFBianca ZahariaNo ratings yet

- Reliability Engineering and System Safety: Sara Bressi, Jo Ao Santos, Massimo LosaDocument17 pagesReliability Engineering and System Safety: Sara Bressi, Jo Ao Santos, Massimo LosaMarcellina ChyntiaNo ratings yet

- Modular Precast Concrete Bridges CBDG PDFDocument42 pagesModular Precast Concrete Bridges CBDG PDFBalty ShedyNo ratings yet

- DBPPCTF 01jul11Document20 pagesDBPPCTF 01jul11Michael DavisNo ratings yet

- Ij Es Vnim 14aDocument15 pagesIj Es Vnim 14aNguyễn LaNo ratings yet

- DesignofPort-AndIndustrialPavements April 2014Document6 pagesDesignofPort-AndIndustrialPavements April 2014Wibawa WorksNo ratings yet

- Design and Optimization of Roller in Belt Conveyor System For Weight ReductionDocument4 pagesDesign and Optimization of Roller in Belt Conveyor System For Weight ReductionSamir KulkarniNo ratings yet

- Whole Life Costing of Bridge Deck ReplacementDocument9 pagesWhole Life Costing of Bridge Deck Replacementtony13touchNo ratings yet

- Austroads Bridge Design Code - Progress Report: R. Wedgwood, Be, Mengsc, MieaustDocument12 pagesAustroads Bridge Design Code - Progress Report: R. Wedgwood, Be, Mengsc, MieaustGAluffiNo ratings yet

- Suspension BridgeDocument56 pagesSuspension Bridgeritesh chauhanNo ratings yet

- Bridge Erection Techniques and Construction EquipmDocument2 pagesBridge Erection Techniques and Construction EquipmAbderrahmane SaidNo ratings yet

- Rolling Stock Supplement 2012 PDFDocument14 pagesRolling Stock Supplement 2012 PDFAgung SedajuNo ratings yet

- Bridgeconstructionpartner 01 2014Document36 pagesBridgeconstructionpartner 01 2014Harianto RamadhanNo ratings yet

- Basis of Design RevaDocument13 pagesBasis of Design RevaDave ThompsonNo ratings yet

- BBR 016 RigidCatenaryDocument4 pagesBBR 016 RigidCatenarykunalkhubaniNo ratings yet

- Railway Infra JournalDocument20 pagesRailway Infra JournalFalak SherNo ratings yet

- DesignofPort-AndIndustrialPavements April 2014Document6 pagesDesignofPort-AndIndustrialPavements April 2014Paola RosalesNo ratings yet

- Together With Chapter 3: Load Requirements in These SpecificationsDocument1 pageTogether With Chapter 3: Load Requirements in These Specificationspravin bharatiNo ratings yet

- Ibdas: Integrated Bridge Design and Analysis SystemDocument12 pagesIbdas: Integrated Bridge Design and Analysis SystemChun Fai ChoNo ratings yet

- Tech Ulsab EnglDocument28 pagesTech Ulsab EnglJony M. TemnikarNo ratings yet

- 2006 Bridge Pircher PDFDocument10 pages2006 Bridge Pircher PDFReenu VermaNo ratings yet

- Bus Stop Steel FinalDocument33 pagesBus Stop Steel FinalanuarNo ratings yet

- Bahan Kuliah PJJ Ext 3Document20 pagesBahan Kuliah PJJ Ext 3Andisa Zerty SeptianiNo ratings yet

- Noise Technical Measures CatalogueDocument63 pagesNoise Technical Measures CatalogueAdela TomaNo ratings yet

- Fibre Reinforced Concrete in Structural Applications (Paper)Document11 pagesFibre Reinforced Concrete in Structural Applications (Paper)Heri SiswantoNo ratings yet

- Lightweight Composite Monocoque Heavy Goods Vehicle TrailerDocument4 pagesLightweight Composite Monocoque Heavy Goods Vehicle TrailerMatthew TurnerNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- Accelerated Bridge Construction: Best Practices and TechniquesFrom EverandAccelerated Bridge Construction: Best Practices and TechniquesRating: 2 out of 5 stars2/5 (4)

- Handbook of Optimization in the Railway IndustryFrom EverandHandbook of Optimization in the Railway IndustryRalf BorndörferNo ratings yet

- 1 Introduction To Ballastless Track EditedDocument26 pages1 Introduction To Ballastless Track Editedshahzilez0% (1)

- Journal Pre-Proofs: Transportation GeotechnicsDocument35 pagesJournal Pre-Proofs: Transportation GeotechnicsshahzilezNo ratings yet

- 1.1 GeneralDocument22 pages1.1 GeneralshahzilezNo ratings yet

- Measurement: Liang Gao, Bolun An, Tao Xin, Ji Wang, Pu WangDocument14 pagesMeasurement: Liang Gao, Bolun An, Tao Xin, Ji Wang, Pu WangshahzilezNo ratings yet

- Geotechnical Engineering-I: As Per KTU SyllabusDocument68 pagesGeotechnical Engineering-I: As Per KTU SyllabusshahzilezNo ratings yet

- Case Study Elasticity For The Slab Track in The Gotthard Base Tunnel, (CH) EN PDFDocument8 pagesCase Study Elasticity For The Slab Track in The Gotthard Base Tunnel, (CH) EN PDFshahzilezNo ratings yet

- Journal Pre-Proofs: Transportation GeotechnicsDocument35 pagesJournal Pre-Proofs: Transportation GeotechnicsshahzilezNo ratings yet

- 1.1 General BackgroundDocument21 pages1.1 General BackgroundshahzilezNo ratings yet

- MOS NotesDocument12 pagesMOS NotesshahzilezNo ratings yet

- Case Study Elasticity For The Slab Track in The Gotthard Base Tunnel, (CH) EN PDFDocument8 pagesCase Study Elasticity For The Slab Track in The Gotthard Base Tunnel, (CH) EN PDFshahzilezNo ratings yet

- Research ArticleDocument15 pagesResearch ArticleshahzilezNo ratings yet

- Local Scour Protection MethodDocument1 pageLocal Scour Protection MethodshahzilezNo ratings yet

- Mos Comprehnsice MCQDocument18 pagesMos Comprehnsice MCQshahzilezNo ratings yet

- Ballastless Track StudyDocument7 pagesBallastless Track StudyshahzilezNo ratings yet

- ABSTRACTDocument1 pageABSTRACTshahzilezNo ratings yet

- Local Scour Protection MethodDocument1 pageLocal Scour Protection MethodshahzilezNo ratings yet

- Rail Projects and Track Installation: Supported by Long-Term Track Maintenance SolutionsDocument23 pagesRail Projects and Track Installation: Supported by Long-Term Track Maintenance SolutionsshahzilezNo ratings yet

- ABSTRACTDocument1 pageABSTRACTshahzilezNo ratings yet

- ABSTRACTDocument1 pageABSTRACTshahzilezNo ratings yet

- Rheda 2000Document20 pagesRheda 2000Yongliang LiuNo ratings yet

- Ballastless TrackDocument13 pagesBallastless TrackshahzilezNo ratings yet

- Railway Case StudyDocument21 pagesRailway Case StudyshahzilezNo ratings yet

- Local Scour Protection MethodDocument1 pageLocal Scour Protection MethodshahzilezNo ratings yet

- Local Scour Protection MethodDocument1 pageLocal Scour Protection MethodshahzilezNo ratings yet

- OSHA Fixed Ladders DesignDocument7 pagesOSHA Fixed Ladders Designken910076No ratings yet

- Telemecanique Mini Control Relays TechnicalDocument12 pagesTelemecanique Mini Control Relays Technicalfelipeintegra100% (1)

- Travelling Allowance On Retirement/ Death, While in Service: 1. DefinitionsDocument2 pagesTravelling Allowance On Retirement/ Death, While in Service: 1. DefinitionsSuv ZeromNo ratings yet

- Train TicketDocument2 pagesTrain TicketKalyan SunnyNo ratings yet

- 8DA10 SiemensDocument32 pages8DA10 SiemensSathit Buapanommas100% (2)

- Various Allowances Referred To 7th CPCDocument73 pagesVarious Allowances Referred To 7th CPCGiri KumarNo ratings yet

- Alternator: From Wikipedia, The Free EncyclopediaDocument7 pagesAlternator: From Wikipedia, The Free EncyclopediaS M NaveedNo ratings yet

- Nef Int Wordlist FrenchDocument40 pagesNef Int Wordlist FrenchNeven VlahovićNo ratings yet

- Amtrak Case StudyDocument8 pagesAmtrak Case Studyapi-302845667No ratings yet

- EOT CraneDocument5 pagesEOT CraneNaveen NagisettiNo ratings yet

- Garden Rail - N°281 - 2018-01Document56 pagesGarden Rail - N°281 - 2018-01Valery GagichNo ratings yet

- Hyderabad TrainsDocument1 pageHyderabad Trainsstealthypa1No ratings yet

- EOI Gandhingar StationDocument18 pagesEOI Gandhingar StationNaveen AlleNo ratings yet

- Sunmar MatrixMetal Products PhotosDocument8 pagesSunmar MatrixMetal Products PhotosSelva GaneshNo ratings yet

- Military Geography-The Balkan PeninsulaDocument224 pagesMilitary Geography-The Balkan PeninsulaMoonsferatu75% (4)

- Route 17 Bus ScheduleDocument2 pagesRoute 17 Bus SchedulebobbobingsonNo ratings yet

- MonorailDocument13 pagesMonorailAMIT0048No ratings yet

- Monopolistic Behaviour in Indian RailwaysDocument52 pagesMonopolistic Behaviour in Indian RailwaysChandra Sen BhatiaNo ratings yet

- IntroductionDocument2 pagesIntroductionNikki Angela Lirio BercillaNo ratings yet

- Taipei GuideDocument34 pagesTaipei GuidejohnlohNo ratings yet

- India Railway Zonal Map, Indian Railway Zones PDFDocument3 pagesIndia Railway Zonal Map, Indian Railway Zones PDFAnonymous V4WLj1f6No ratings yet

- Panama Canal - Compliance Check-ListDocument5 pagesPanama Canal - Compliance Check-ListDragan JerčićNo ratings yet

- Jojopearlie Project ProposalDocument24 pagesJojopearlie Project ProposalSusan O'TugaNo ratings yet

- Melbourne CityLink BookDocument77 pagesMelbourne CityLink BookDaniel Alfonso Sirait50% (2)

- Chap 1 .Ppt. 2012Document68 pagesChap 1 .Ppt. 2012Philimond SegieNo ratings yet

- CR, Er, Ecr, Ecor, NR, NCR, Ner, NFR, NWR, SR, SCR, Ser, Secr, SWR, WR, WCR and Metro Railway/KolkataDocument3 pagesCR, Er, Ecr, Ecor, NR, NCR, Ner, NFR, NWR, SR, SCR, Ser, Secr, SWR, WR, WCR and Metro Railway/Kolkatapmali2No ratings yet

- ContouringDocument45 pagesContouringAhmad KhaledNo ratings yet

- Aerial Interdiction Air Power and The Land Battle in Three American WarsDocument444 pagesAerial Interdiction Air Power and The Land Battle in Three American WarsBob Andrepont100% (1)

- ARC200Document3 pagesARC200Seyed Amir Ali MousavianNo ratings yet