Professional Documents

Culture Documents

Flygt 3045, 50Hz: Technical Specification

Uploaded by

Luis Miguel LimaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flygt 3045, 50Hz: Technical Specification

Uploaded by

Luis Miguel LimaCopyright:

Available Formats

Technical

Specification

Flygt 3045, 50Hz

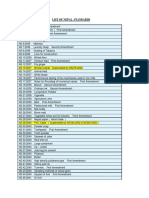

Table of Contents

Table of Contents

C-pump....................................................................................................................................................2

Product description.............................................................................................................................2

Motor rating and performance curves..............................................................................................4

D-pump...................................................................................................................................................6

Product description.............................................................................................................................6

Motor rating and performance curves..............................................................................................8

Dimensions and Weight, C-pump.....................................................................................................10

Drawings............................................................................................................................................10

Dimensions and Weight, D-pump.....................................................................................................12

Drawings............................................................................................................................................12

Flygt 3045, 50Hz Technical Specification 1

C-pump

C-pump

Product description

Usage

A submersible pump for clean water, surface water, or light wastewater containing solids

or fibered material.

Denomination

Type Non explosion proof Explosion proof Pressure class Installation types

version version

Cast iron 3045.181 3045.091 HT — High head F, H, P, S

The pump can be used in the following installations:

F Free standing semi permanent, wet well arrangement where the pump is placed on a

firm surface.

H Semi permanent, wet well quick connection suspended arrangement, incorporating

integral non-return valve.

P Semi permanent, wet well arrangement with pump installed on two guide bars with

automatic connection to discharge.

S Portable semi permanent, wet well arrangement with hose coupling or flange for

connection to discharge pipeline.

Application limits

Feature Description

Liquid temperature Maximum 40°C, (104°F)

Liquid temperature, warm water version Maximum 70°C, (158°F)

Depth of immersion Maximum 20 m (65 ft)

pH of the pumped liquid 5.5 – 14

Liquid density Maximum 1100 kg/m3

2 Flygt 3045, 50Hz Technical Specification

C-pump

Motor data

Feature Description

Motor type Squirrel-cage induction motor

Frequency 50 Hz

Power supply 1-phase or 3-phase

Starting method • Direct on-line

• Star-delta

• Soft starter

Number of starts per hour Maximum 15

Code compliance IEC 60034-1

Rated output variation ±10%

Voltage variation • Continuously running: Maximum ±5%

• Intermittent running: Maximum ±10%

Voltage imbalance Maximum 2%

between phases

Stator insulation class F (+155°C)

Cables

Application Type

Direct-on-line start or Y/D start with two cables Flygt SUBCAB® - a heavy duty 4 cores motor power cable

with two twisted pair screened control cores. Conductor

insulation rating of 90°C, which allows for increased

current. Superior mechanical strength and high abrasion

and tear resistant. Chemical resistant within pH 3-10 and

ozone, oil, and flame resistant. Used up to 70°C water

temperature. Cables < 10 mm2 with unscreened control

cores.

Y/D start Flygt SUBCAB® - a heavy duty 7 cores motor power cable

with two twisted pair screened control cores. Conductor

insulation rating of 90°C, which allows for increased

current. Superior mechanical strength and high abrasion

and tear resistant. Chemical resistant within pH 3-10 and

ozone, oil, and flame resistant. Used up to 70°C water

temperature. Cables < 7G6 mm2 with unscreened

control cores.

Monitoring equipment

• Thermal contacts opening temperature 125° C (257° F)

Materials

Table 1: Major parts except mechanical seals

Denomination Material ASTM EN

Major castings Cast iron, gray 35B GJL-250

Pump housing Cast iron, gray 30B GJL-200

Impeller Plastics, polyamide PA66 - -

Suction cover Stainless steel AISI 304 1,4301

Lifting handle Stainless steel AISI 304 1,4301

Flygt 3045, 50Hz Technical Specification 3

C-pump

Denomination Material ASTM EN

Shaft Stainless steel - 1,4021

Screws and nuts Stainless steel, A2 AISI 304 1.4301, 1.4306,

1.4307, 1.4311

O-rings Fluorinated rubber (FPM) 70° - -

IRH

Oil, part no 901752 Medical white oil of paraffin - -

type. Fulfills FDA 172.878 (a)

Table 2: Mechanical seals

Alternative Inner seal Outer seal

1 Carbon/ Aluminum oxide Silicon carbide/ Silicon carbide

Surface treatment

Priming Finish

Painted with a primer, see internal standard Navy gray color NCS 5804-B07G. Two-component high-

M0700.00.0002 solid top coating, see internal standard M0700.00.0004

for standard painting and M0700.00.0008 for special

painting.

Options

• Warm liquid version (non-explosion proof versions)

• Zinc anodes

• Other cables

Accessories

Discharge connections, adapters, hose connections, and other mechanical accessories.

Electrical accessories such as pump controller, control panels, starters, monitoring relays,

cables.

Motor rating and performance curves

These are examples of motor rating and curves, for more information contact your local

sales and service representative.

Star-delta starting current is 1/3 of Direct on-line starting current.

4 Flygt 3045, 50Hz Technical Specification

C-pump

HT

P 2 [kW]

1.4

1.2

250

1.0

0.8 252

0.6

H [m]

HT

16

14

12

10

4

250

2

252

0

0 2 4 6 8 10

Q [l/s]

WS005177A

Table 3: 400 V, 50 Hz, 3–phase

Rated Rated Curve/ Revolutions Rated Starting Power factor, Installation

power, kW power, hp Impeller No per minute, current, A current, A cos φ

rpm

1.2 1.6 250 2785 2.8 17 .79 F,P,S

1.2 1.6 252 2785 2.8 17 .79 F,P,S

Table 4: 230 V, 50 Hz, 1–phase

Rated Rated Curve/ Revolutions Rated Starting Power factor, Installation

power, kW power, hp Impeller No per minute, current, A current, A cos φ

rpm

.75 1 252 2825 4.2 19 1 F,P,S

Flygt 3045, 50Hz Technical Specification 5

D-pump

D-pump

Product description

Usage

A submersible pump, with vortex hydraulic, for liquids containing solids and abrasive

media, or light wastewater.

Denomination

Type Non explosion proof Explosion proof Pressure class Installation types

version version

Cast iron 3045.181 3045.091 MT — Medium head F, P, S

The pump can be used in the following installations:

F Free standing semi permanent, wet well arrangement where the pump is placed on a

firm surface.

P Semi permanent, wet well arrangement with pump installed on two guide bars with

automatic connection to discharge.

S Portable semi permanent, wet well arrangement with hose coupling or flange for

connection to discharge pipeline.

Application limits

Feature Description

Liquid temperature Maximum 40°C, (104°F)

Liquid temperature, warm water version Maximum 70°C, (158°F)

Depth of immersion Maximum 20 m (65 ft)

pH of the pumped liquid 5.5 – 14

Liquid density Maximum 1100 kg/m3

Motor data

Feature Description

Motor type Squirrel-cage induction motor

6 Flygt 3045, 50Hz Technical Specification

D-pump

Feature Description

Frequency 50 Hz

Power supply 1-phase or 3-phase

Starting method • Direct on-line

• Star-delta

• Soft starter

Number of starts per hour Maximum 15

Code compliance IEC 60034-1

Rated output variation ±10%

Voltage variation • Continuously running: Maximum ±5%

• Intermittent running: Maximum ±10%

Voltage imbalance Maximum 2%

between phases

Stator insulation class F (+155°C)

Cables

Application Type

Direct-on-line start or Y/D start with two cables Flygt SUBCAB® - a heavy duty 4 cores motor power cable

with two twisted pair screened control cores. Conductor

insulation rating of 90°C, which allows for increased

current. Superior mechanical strength and high abrasion

and tear resistant. Chemical resistant within pH 3-10 and

ozone, oil, and flame resistant. Used up to 70°C water

temperature. Cables < 10 mm2 with unscreened control

cores.

Y/D start Flygt SUBCAB® - a heavy duty 7 cores motor power cable

with two twisted pair screened control cores. Conductor

insulation rating of 90°C, which allows for increased

current. Superior mechanical strength and high abrasion

and tear resistant. Chemical resistant within pH 3-10 and

ozone, oil, and flame resistant. Used up to 70°C water

temperature. Cables < 7G6 mm2 with unscreened

control cores.

Materials

Table 5: Major parts except mechanical seals

Denomination Material ASTM EN

Major castings Cast iron, gray 35B GJL-250

Pump housing Cast iron, gray 30B GJL-200

Impeller Plastics, polyamide PA66 - -

Suction cover Stainless steel AISI 304 1,4301

Lifting handle Stainless steel AISI 304 1,4301

Shaft Stainless steel 1,4021

Screws and nuts Stainless steel, A2 AISI 304 1.4301, 1.4306,

1.4307, 1.4311

Flygt 3045, 50Hz Technical Specification 7

D-pump

Denomination Material ASTM EN

O-rings Fluorinated rubber (FPM) 70° - -

IRH

Oil, part no 901752 Medical white oil of paraffin - -

type. Fulfills FDA 172.878 (a)

Table 6: Mechanical seals

Alternative Inner seal Outer seal

1 Carbon/ Aluminum oxide Silicon carbide/ Silicon carbide

Surface treatment

Priming Finish

Painted with a primer, see internal standard Navy gray color NCS 5804-B07G. Two-component high-

M0700.00.0002 solid top coating, see internal standard M0700.00.0004

for standard painting and M0700.00.0008 for special

painting.

Options

• Warm liquid version (non-explosion proof versions)

• Zinc anodes

• Other cables

Accessories

Discharge connections, adapters, hose connections, and other mechanical accessories.

Electrical accessories such as pump controller, control panels, starters, monitoring relays,

cables.

Motor rating and performance curves

These are examples of motor rating and curves, for more information contact your local

sales and service representative.

Star-delta starting current is 1/3 of Direct on-line starting current.

8 Flygt 3045, 50Hz Technical Specification

D-pump

MT

WS005178A

Table 7: 400 V, 50 Hz, 3–phase

Rated Rated Curve/ Revolutions Rated Starting Power factor, Installation

power, kW power, hp Impeller No per minute, current, A current, A cos φ

rpm

1.2 1.6 230 2785 2.8 17 .79 F,P,S

1.2 1.6 234 2785 2.8 17 .79 F,S

Table 8: 230 V, 50 Hz, 1–phase

Rated Rated Curve/ Revolutions Rated Starting Power factor, Installation

power, kW power, hp Impeller No per minute, current, A current, A cos φ

rpm

.75 1 234 2825 4.2 19 1 F,P,S

Flygt 3045, 50Hz Technical Specification 9

Dimensions and Weight, C-pump

Dimensions and Weight, C-pump

Drawings

All drawings are available as Acrobat documents (.pdf) and AutoCad drawings (.dwg).

Contact your local sales and service representative for more information.

All dimensions are in mm.

Figure 1: MT/HT, F-installation Figure 2: MT/HT, P-installation

10 Flygt 3045, 50Hz Technical Specification

Dimensions and Weight, C-pump

Figure 3: MT/HT, S-installation Figure 4: HT, H-installation

Figure 5: HT, P-installation

Flygt 3045, 50Hz Technical Specification 11

Dimensions and Weight, D-pump

Dimensions and Weight, D-pump

Drawings

All drawings are available as Acrobat documents (.pdf) and AutoCad drawings (.dwg).

Contact your local sales and service representative for more information.

All dimensions are in mm.

Figure 6: MT/HT, F-installation Figure 7: MT, P-installation

12 Flygt 3045, 50Hz Technical Specification

Dimensions and Weight, D-pump

Figure 8: MT/HT, P-installation Figure 9: MT/HT, S-installation

Flygt 3045, 50Hz Technical Specification 13

Xylem |’zīləm|

1) The tissue in plants that brings water upward from the roots

2) A leading global water technology company

We're 12,500 people unified in a common purpose: creating

innovative solutions to meet our world's water needs. Developing new

technologies that will improve the way water is used, conserved, and

re-used in the future is central to our work. We move, treat, analyze,

and return water to the environment, and we help people use water

efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with

customers who know us for our powerful combination of leading

product brands and applications expertise, backed by a legacy of

innovation.

For more information on how Xylem can help you, go to xyleminc.com

Xylem Water Solutions AB Visit our Web site for the latest version of this

document and more information

Gesällvägen 33

174 87 Sundbyberg The original instruction is in English. All non-

English instructions are translations of the original

Sweden instruction.

Tel. +46-8-475 60 00 © 2012 Xylem Inc.

Fax +46-8-475 69 00

http://tpi.xyleminc.com

883445_2.0_en.US_2012-12_TS.3045_50Hz

You might also like

- Flygt D 8058, 60 HZ: LenntechDocument11 pagesFlygt D 8058, 60 HZ: LenntechJOKO WIKARNANo ratings yet

- Especificaciones Tecnicas N 3171Document48 pagesEspecificaciones Tecnicas N 3171Paolo Romario Ordoñez SangaNo ratings yet

- Flygt 3152 50 LDocument32 pagesFlygt 3152 50 LDiego MayorgaNo ratings yet

- Flygt 3153 50 LDocument42 pagesFlygt 3153 50 LNguyễn Văn KiênNo ratings yet

- 6.0 - en-US - 2019-01 - TS - Flygt 3171Document48 pages6.0 - en-US - 2019-01 - TS - Flygt 3171FedeNo ratings yet

- 1.0 en-US 2020-01 TS.3085Document32 pages1.0 en-US 2020-01 TS.3085FedeNo ratings yet

- 5.0 - en-US - 2019-01 - TS - Flygt 3202Document60 pages5.0 - en-US - 2019-01 - TS - Flygt 3202FedeNo ratings yet

- Anexo 12.4 Especificaciones Tecnicas de BombasDocument44 pagesAnexo 12.4 Especificaciones Tecnicas de BombasJhonny Miguel NuñezNo ratings yet

- 1.0 en-US 2020-01 TS.3127Document48 pages1.0 en-US 2020-01 TS.3127ruben estebanNo ratings yet

- Catalogo TsurumiDocument40 pagesCatalogo TsurumiAPOLINAR GARCÍA OTINIANONo ratings yet

- 3127 PDFDocument68 pages3127 PDFAseem Vivek MasihNo ratings yet

- Flygt PumpsDocument56 pagesFlygt PumpsThe_RainmakerNo ratings yet

- XR5 Analog Technical Specification 50kW 7239 (English Rev. 2.0) (1)Document7 pagesXR5 Analog Technical Specification 50kW 7239 (English Rev. 2.0) (1)Thalina DiazNo ratings yet

- Solenoid Valve With Isolating Diaphragm: Type 0780Document6 pagesSolenoid Valve With Isolating Diaphragm: Type 0780Francisco Mones RuizNo ratings yet

- Oil Testing Set SpecificationsDocument10 pagesOil Testing Set SpecificationsAndi MulyanaNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNo ratings yet

- Vickers DCV With Manual LatchDocument12 pagesVickers DCV With Manual LatchIon Logofătu AlbertNo ratings yet

- Evotron TS Eng PDFDocument6 pagesEvotron TS Eng PDFAlin PopaNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 744Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 744Francisco Mones RuizNo ratings yet

- Brochure VARIPURE 20160519 EN PDFDocument8 pagesBrochure VARIPURE 20160519 EN PDFMhs EngineerNo ratings yet

- Manual de Instalacion Osko XR5 - Rayos X Convencional Analogico Data SheetDocument6 pagesManual de Instalacion Osko XR5 - Rayos X Convencional Analogico Data SheetLeandro Pabon Villarreal100% (1)

- Rocsan-Lix NT Eng 50hzDocument10 pagesRocsan-Lix NT Eng 50hzAntonio StrahijaNo ratings yet

- Transformers Oil Filtration MachineDocument4 pagesTransformers Oil Filtration MachinePintu BeheraNo ratings yet

- TLL13X Fozmula Liquid Level Sensor Data 8-6-33R2Document1 pageTLL13X Fozmula Liquid Level Sensor Data 8-6-33R2moisesNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- Summary Fan Data Sheet: Technical Data Performance ChartDocument1 pageSummary Fan Data Sheet: Technical Data Performance ChartDanish QaziNo ratings yet

- CW-3000 Industrial Chiller User ManualDocument7 pagesCW-3000 Industrial Chiller User ManualMalick SyNo ratings yet

- 测试仪合集Document24 pages测试仪合集jackNo ratings yet

- 10MFP ParkerDocument8 pages10MFP ParkerJoel PalaciosNo ratings yet

- 2/2-Way Solenoid Valve, Servo-Assisted With Servo Diaphragm: Type 280Document4 pages2/2-Way Solenoid Valve, Servo-Assisted With Servo Diaphragm: Type 280Francisco Mones RuizNo ratings yet

- Spectra GT30 Gas Turbine Flame SensorDocument2 pagesSpectra GT30 Gas Turbine Flame SensorServinorca, C.A.No ratings yet

- Endress-Hauser Liquiphant S FTL71 ENDocument4 pagesEndress-Hauser Liquiphant S FTL71 ENsureyaNo ratings yet

- 10MFP Carrito de FiltracionDocument8 pages10MFP Carrito de FiltracionIanNo ratings yet

- EPOWER Centrifugal Pumps Compliant with EN 733 StandardDocument1 pageEPOWER Centrifugal Pumps Compliant with EN 733 StandardVu DangNo ratings yet

- Datasheet Flygt 2201 321 SH 50hz En-UsDocument2 pagesDatasheet Flygt 2201 321 SH 50hz En-UsDavinsson RivasNo ratings yet

- FAR Series Outdoor Auto Circuit RecloserDocument11 pagesFAR Series Outdoor Auto Circuit RecloserJoe ChuengNo ratings yet

- PFC PhaseCap Premium PBDocument3 pagesPFC PhaseCap Premium PBGerardoNo ratings yet

- Grundfos - SEG 40 31 2 50BDocument17 pagesGrundfos - SEG 40 31 2 50BMarina CoskovicNo ratings yet

- Submersible Drainage Pump XJ 25: SpecificationDocument2 pagesSubmersible Drainage Pump XJ 25: SpecificationDavid SoaresNo ratings yet

- Data Sheet 5SJ4101-8HG40: ModelDocument4 pagesData Sheet 5SJ4101-8HG40: ModelFaiz 3BNo ratings yet

- Oil Test Set KIT: Delta Roto Tech Make Oil Test Kits Are ISO 9001:2015 Certified Test KitsDocument2 pagesOil Test Set KIT: Delta Roto Tech Make Oil Test Kits Are ISO 9001:2015 Certified Test KitsMaa Win PowersNo ratings yet

- Alc 830Document4 pagesAlc 830parth sapariaNo ratings yet

- Automatic Autoclave ControllerDocument2 pagesAutomatic Autoclave ControllerNumanNo ratings yet

- Wilo-Datasheet International en 2537343 Siboost-Smart-3-Helix-Ve1003Document7 pagesWilo-Datasheet International en 2537343 Siboost-Smart-3-Helix-Ve1003sanaaNo ratings yet

- 500kVA K600C Rigsafe Diesel Generator Flyer PDFDocument2 pages500kVA K600C Rigsafe Diesel Generator Flyer PDFMd MkNo ratings yet

- Azbil, MagneW3000 FLEX Electromagnetic Flowmeter ConverterDocument16 pagesAzbil, MagneW3000 FLEX Electromagnetic Flowmeter ConverterRangga Taufiqurahman100% (1)

- Caterpillar XQ80 Towable Diesel Generator SetDocument5 pagesCaterpillar XQ80 Towable Diesel Generator SetMacAllister MachineryNo ratings yet

- Vibronic Point Level Detection Liquiphant FTL50HDocument5 pagesVibronic Point Level Detection Liquiphant FTL50HPham Thien TruongNo ratings yet

- P7810C Pressuretrol® Controller: FeaturesDocument12 pagesP7810C Pressuretrol® Controller: FeaturesNebur MtzaNo ratings yet

- Inverter Rooftop KendalDocument36 pagesInverter Rooftop Kendalmarielena BarazarteNo ratings yet

- LG180CDocument3 pagesLG180CMohamed ElsagerNo ratings yet

- Flygt 3153 PDFDocument38 pagesFlygt 3153 PDFMarcelo DelgadoNo ratings yet

- 7PA Auxiliary Relays Technical SpecificationsDocument7 pages7PA Auxiliary Relays Technical SpecificationssoltaniNo ratings yet

- EmsDocument3 pagesEmsmanoj nirgudeNo ratings yet

- Stingray 6048 SpecsDocument1 pageStingray 6048 SpecsUnurbat ByambajavNo ratings yet

- Flipper Solenoid Valve With Isolating Diaphragm For Analytical ApplicationsDocument4 pagesFlipper Solenoid Valve With Isolating Diaphragm For Analytical ApplicationsFrancisco Mones RuizNo ratings yet

- SUBMERSIBLE PUMP 63 GPM at 9 MDocument4 pagesSUBMERSIBLE PUMP 63 GPM at 9 MRamil LazNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- XT 50 QT 2Document32 pagesXT 50 QT 2Luis Miguel LimaNo ratings yet

- Crossfire CF125 Owners ManualDocument59 pagesCrossfire CF125 Owners ManualLuis Miguel LimaNo ratings yet

- ALFA ROMEO 33 - p4 - SwitchDocument38 pagesALFA ROMEO 33 - p4 - SwitchGolub MarkoNo ratings yet

- 102 Spbu2Document28 pages102 Spbu2Luis Miguel LimaNo ratings yet

- 16v Motronic PDFDocument19 pages16v Motronic PDFbreaky1110% (1)

- Workshop Manual Full 1.7 IEDocument211 pagesWorkshop Manual Full 1.7 IELibros18100% (1)

- Iphone 11 Pro Info PDFDocument2 pagesIphone 11 Pro Info PDFAlberto QuintavoNo ratings yet

- ALFA ROMEO 33 - p4 - SwitchDocument38 pagesALFA ROMEO 33 - p4 - SwitchGolub MarkoNo ratings yet

- Manuals from Manualslib.com Search EngineDocument151 pagesManuals from Manualslib.com Search EngineLuis Miguel LimaNo ratings yet

- Airpods Max G03403838 InfoDocument12 pagesAirpods Max G03403838 InfoRogerio SousaNo ratings yet

- DIREZIONE ASSISTENZA COMPLETE CAR MANUALDocument378 pagesDIREZIONE ASSISTENZA COMPLETE CAR MANUALwi$ardNo ratings yet

- l-33) Manual Supplement: Pa3335Oooos W O O MARCH 1988Document28 pagesl-33) Manual Supplement: Pa3335Oooos W O O MARCH 1988bazinga64No ratings yet

- Owner'S Manual-: EGL MotorDocument46 pagesOwner'S Manual-: EGL MotorLuis Miguel LimaNo ratings yet

- Workshop Manual Full 1.7 IEDocument211 pagesWorkshop Manual Full 1.7 IELibros18100% (1)

- Iphone 12 Pro Max Ios14 InfoDocument4 pagesIphone 12 Pro Max Ios14 InfoRui Moraes BarbosaNo ratings yet

- Iphone 11 Pro Info PDFDocument2 pagesIphone 11 Pro Info PDFAlberto QuintavoNo ratings yet

- Iphone Se 2nd Gen Ios13 InfoDocument2 pagesIphone Se 2nd Gen Ios13 Infovijay gopal0% (1)

- Cebora PDFDocument36 pagesCebora PDFLuis Miguel LimaNo ratings yet

- Manual 614110 Aura85 Esp Port PDFDocument40 pagesManual 614110 Aura85 Esp Port PDFLuis Miguel LimaNo ratings yet

- Instruction Manual For Wire Welding Machines: 1 InstallationDocument6 pagesInstruction Manual For Wire Welding Machines: 1 InstallationLuis Miguel LimaNo ratings yet

- Smart Battery Case Iphone11 Iphone11pro Iphone11pro Max UA03404146 UgDocument12 pagesSmart Battery Case Iphone11 Iphone11pro Iphone11pro Max UA03404146 UgRogerio SousaNo ratings yet

- Manual 614110 Aura85 Esp Port PDFDocument40 pagesManual 614110 Aura85 Esp Port PDFLuis Miguel LimaNo ratings yet

- 4M06 Series: Powerkit EngineDocument2 pages4M06 Series: Powerkit EngineLuis Miguel LimaNo ratings yet

- BMW F650GS CatalogueDocument5 pagesBMW F650GS CatalogueLuis Miguel LimaNo ratings yet

- Absmixbroch PDFDocument11 pagesAbsmixbroch PDFLuis Miguel LimaNo ratings yet

- 741mjza0s PDFDocument12 pages741mjza0s PDFLuis Miguel LimaNo ratings yet

- Sunny Roo Solar Power Inverter ManualDocument17 pagesSunny Roo Solar Power Inverter ManualLuis Miguel LimaNo ratings yet

- Hyundai Getz Body Electric PDFDocument144 pagesHyundai Getz Body Electric PDFLuis Miguel Lima67% (3)

- BMW F650GS SchematicDocument13 pagesBMW F650GS SchematicLuis Miguel LimaNo ratings yet

- AWG CatalogDocument444 pagesAWG CatalogFire NowNo ratings yet

- Battery terminals, cables, covers and accessoriesDocument5 pagesBattery terminals, cables, covers and accessoriesMatt KimminsNo ratings yet

- h07rn F Bs en 50525 2 21 Flexible Rubber CableDocument6 pagesh07rn F Bs en 50525 2 21 Flexible Rubber CableManny DummyNo ratings yet

- Understand Heat Energy Transfer MethodsDocument15 pagesUnderstand Heat Energy Transfer MethodsMahamud elmogeNo ratings yet

- Diptesh ProjectDocument188 pagesDiptesh ProjectDiptesh DashNo ratings yet

- Nasa-Std 8739 - 3Document93 pagesNasa-Std 8739 - 3Andrian GirscanNo ratings yet

- 4 Pole DesignDocument102 pages4 Pole Designashutosh2009100% (1)

- SymbolsDocument5 pagesSymbolsmurad6a9No ratings yet

- ACSR Some Equal Standards-Indian StandardDocument20 pagesACSR Some Equal Standards-Indian StandardHabib EmamiNo ratings yet

- Katalog KmiDocument4 pagesKatalog Kmisheila fitriaNo ratings yet

- Bs 6004 624 y Twin and Earth PVC CableDocument3 pagesBs 6004 624 y Twin and Earth PVC CableharmlesdragonNo ratings yet

- C - C (CR) Series New CatalogueDocument5 pagesC - C (CR) Series New CatalogueJohan CastroNo ratings yet

- EEB 231 - 2019 Lectures # 1 - 15 AugustDocument32 pagesEEB 231 - 2019 Lectures # 1 - 15 AugustLast BofeloNo ratings yet

- Cables - Cable For Petrochemical Plants IEEESTANDARD1242Document10 pagesCables - Cable For Petrochemical Plants IEEESTANDARD1242cadtil100% (1)

- Insulation Resistance Test and Polarization Index TestDocument5 pagesInsulation Resistance Test and Polarization Index Testnagar_maheshNo ratings yet

- An'rgrkv: Wig "CO ZW 41cit4aDocument10 pagesAn'rgrkv: Wig "CO ZW 41cit4aShubham BaderiyaNo ratings yet

- FT N304 Outdoor Single Core Termination CDTO-1CDocument3 pagesFT N304 Outdoor Single Core Termination CDTO-1CKarin FernandoNo ratings yet

- Electricity and Magnetism Fundamentals CourseDocument6 pagesElectricity and Magnetism Fundamentals CourseChristopher MabilinNo ratings yet

- 114 Elc G KGP 22 23 50 - 01 06 2023Document23 pages114 Elc G KGP 22 23 50 - 01 06 2023ADEE G GRCNo ratings yet

- Multi-band Low-loss Power Tappers up to 2500 MHzDocument3 pagesMulti-band Low-loss Power Tappers up to 2500 MHzJoao CarameloNo ratings yet

- Copper Busbar Design GuideDocument136 pagesCopper Busbar Design GuideOscar SchmüthNo ratings yet

- Clasificacion de Temperatura en Cables y TerminalesDocument7 pagesClasificacion de Temperatura en Cables y TerminalesMaxNo ratings yet

- RME Reviewer 2Document60 pagesRME Reviewer 2Rodel PelimianoNo ratings yet

- Power Cable Failure Modes and Fault Loca PDFDocument5 pagesPower Cable Failure Modes and Fault Loca PDFtaufiqishak09No ratings yet

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla VietorNo ratings yet

- Insulation Resistance IR Values PDFDocument14 pagesInsulation Resistance IR Values PDFRodel D DosanoNo ratings yet

- Texcan - Building Wire CatalogueDocument28 pagesTexcan - Building Wire CataloguelemolathNo ratings yet

- Article 430 Motors GuideDocument4 pagesArticle 430 Motors GuideambuenaflorNo ratings yet

- List of NSDocument22 pagesList of NSPujan NeupaneNo ratings yet

- Generator Technical Operation & Maintenance ManualDocument68 pagesGenerator Technical Operation & Maintenance ManualRaul BalboaNo ratings yet