Professional Documents

Culture Documents

VP-302 Product Data 11-15

Uploaded by

Enrique AntonioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VP-302 Product Data 11-15

Uploaded by

Enrique AntonioCopyright:

Available Formats

Product Data Sheet 1

Met-L-Chek®

11/2015

VP-302 High Temperature

Penetrant

Penetrant Professor Approved ©2015

Met-L-Chek Company manufactures a complete line of penetrants used in the fluorescent (Type 1) and vis-

ible (Type 2) dye penetrant inspection process. Met-L-Chek Company high temperature penetrant, VP-302, is

qualified to Mil-I-25135 as a special application penetrant and is sold under the Met-L-Chek® and Pen-Chek®

trademarks. Met-L-Chek Company products are manufactured under license in The Netherlands by NDT Europa.

VP-302 is a special application high temperature inspection penetrant. The use range is 51.6 ˚C - 176.6 ˚C (125˚F

-350˚F). VP-302 is listed on the approved products list for Mil-I-25135C. It is low in Sulfur, Chlorine, Fluorine

and other Halogens, making it safe for use on Titanium and high Nickel alloys found in nuclear components.

VP-302 finds wide use in field weld and weld repair inspection. It is used in the inspection of refinery processing equip-

ment that is at elevated temperatures, speeding up the inspection process time by eliminating the cool down required

for standard penetrant processing. Protective gloves should be worn while working on hot surfaces to avoid burns.

PENETRANT APPLICATION: Before proceeding with the use of VP-302, it is important to be sure that the temperature of the part

is not too hot. To test this, apply a small amount of penetrant to the area to be tested, and observe it after 10 minutes. If the penetrant

has good red color, you may proceed. But if there is any indication of fading, or of the color turning brown, then the part is too hot and

it must be cooled until the penetrant will function properly without color loss. After making this test, the VP-302 penetrant is applied

to the hot surface to be tested with a brush or other applicator. At this elevated temperature the penetrant thins and penetrates the flaws

rapidly. Penetration time will depend on temperature, but at 93.3˚C (200˚F) two to five minutes is usually sufficient for coarse cracks.

Penetrant should only be applied to a small portion of the part to be tested at one time to minimize excessive dwell time, which can

evaporate part of the penetrant. Inspect a small area at a time, and complete the inspection of the area within 10 minutes. Longer dwell

time may result in the penetrant not functioning properly.

REMOVAL OF EXCESS SURFACE PENETRANT: Remove excess penetrant with a cloth or paper toweling, then clean the sur-

face with a cloth moistened with R-502 remover. The hot surface will then dry rapidly.

DEVELOPER APPLICATION: D-702 developer should be agitated and then applied with a pressurized spray gun, such as a paint

sprayer or “Sure Shot”™ type sprayer. Apply in a thin even coat, making several passes if necessary. If a paint sprayer is not available,

a simple hand pump sprayer, such as is used for household products, and available in supermarkets, may be used, although the developer

coat will not be as smooth or uniform. Be careful not to build up a thick coat, since this may mask defect indications. Flaw indications

form quickly, and appear as red marks on the white developer. After inspection, the D-702 developer coating may be removed by wiping

with a cloth moistened with R-502 remover, or by flushing with water.

High temperature penetrant VP-302 crack indication on

D-702 developer film.

Product Data Sheet 2

Met-L-Chek®

10/2015

VP-302 High Temperature

Penetrant

Penetrant Professor Approved

Typical Physical Properties Specifications

Form: Red viscous liquid ASME B & PV code 07, secV, Art 6

Density: 980 g/L ASTM E-165

Flash Point: > 148.8˚C (> 300˚F) ASTM E-1417

Corrosion of aluminum: none Mil-I-25135C, Interim AM-4

Corrosion of carbon steel: none NAVSEA-250-1500-1, Rev16, ACN-5

Corrosion of magnesium: none

Corrosion of stainless steel: none

Corrosion of titanium: none Product Availability

Chloride content: < 100 ppm (0.01%) 1 pint (0.47L) metal can with dauber

Fluoride content: < 50 ppm (0.005%) 1 gallon (3.7L) plastic jug

Sulfur content: < 100 ppm (0.01%) 5 gallon (18.9L) plastic jug

Mercury: none

VOC’s: 0g/L

Ozone layer depleting substances: none

PCB’s: none

The warranty shelf life of the product is 3 years

from date of batch approval.

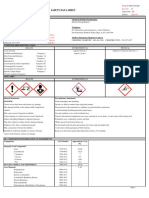

GHS Information

Danger GHS Response Statements:

GHS: Hazard Statements: IF INHALED: Remove person to fresh air and keep comfortable

H351: Suspected of causing cancer. for breathing, get medical advice/attention if you feel

unwell.

GHS Precautionary Statements: IF ON SKIN: Wash with plenty of water. If skin irritation occurs,

P102: Keep out of reach of children. get medical advice/attention.

P261: Avoid breathing fumes/gas/mist/vapors/spray. IF IN EYES: Rinse cautiously with water for several minutes.

P264: Wash skin thoroughly after handling. Remove contact lenses, if present and easily to do.

P280: Wear protective glove/clothing/eye protection/face Continue rinsing, get medical attention.

protection. IF SWALLOWED: Immediately call a poison center/doctor/

P284: In case of inadequate ventilation wear respiratory physician. Do Not induce vomiting

protection IF ON CLOTHING: Take off contaminated clothing and wash

before reuse.

Transport:

DOT- not regulated

IATA- not regulated

See SDS for full health and safety information IMDG- not regulated

Met-L-Chek Company, 1639 Euclid Street, Santa Monica, California, 90404, U.S.A.

Phone: 310-450-1111, Fax: 310-452-4046, Email: info@met-l-chek.com, Web: www.met-l-chek.com

You might also like

- Eastern Sierras RockhoundingDocument8 pagesEastern Sierras RockhoundingNoone Uneedtono100% (2)

- Gold in New Brunswick, CanadaDocument8 pagesGold in New Brunswick, CanadaART'S PLACENo ratings yet

- Table of Bond Work Index by MineralsDocument8 pagesTable of Bond Work Index by MineralsirfanNo ratings yet

- ISO 4386 1 2012, Plain Bearings PDFDocument14 pagesISO 4386 1 2012, Plain Bearings PDFKevin DaveNo ratings yet

- MSDS Hema M-30Document19 pagesMSDS Hema M-30Irvanda ENVIOUSNo ratings yet

- NOTE CHAPTER 4 The Periodic Table of ElementsDocument24 pagesNOTE CHAPTER 4 The Periodic Table of ElementsNur AfiqahNo ratings yet

- Manitou Telehandler MT 1440 MT 1840 H Ha E3 Hydrostatic Euro 3 Repair Manual 647232en 02 2011Document22 pagesManitou Telehandler MT 1440 MT 1840 H Ha E3 Hydrostatic Euro 3 Repair Manual 647232en 02 2011jonathanbond010496aok100% (117)

- VP 30 Product Data 11 15Document2 pagesVP 30 Product Data 11 15marcos crisosto100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- M6 Materials HardwareDocument448 pagesM6 Materials HardwareZac BismonteNo ratings yet

- Common Goals, Shared Action: The European Aluminium Industry'S Sustainability Roadmap Towards 2025Document20 pagesCommon Goals, Shared Action: The European Aluminium Industry'S Sustainability Roadmap Towards 2025Enrique AntonioNo ratings yet

- MSDS of PC 1020 TDocument9 pagesMSDS of PC 1020 TSeno BuminusaNo ratings yet

- Met-L-Chek: Material Safety Data SheetDocument2 pagesMet-L-Chek: Material Safety Data SheetManuel Morivera100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Arthur Israel Vogel - G Svehla - Vogel's Textbook of Macro and Semimicro Qualitative Inorganic Analysis-Longman (1979)Document617 pagesArthur Israel Vogel - G Svehla - Vogel's Textbook of Macro and Semimicro Qualitative Inorganic Analysis-Longman (1979)syifa khairaniNo ratings yet

- D-702 Product Data 10-15Document2 pagesD-702 Product Data 10-15Enrique AntonioNo ratings yet

- E 59a Product Data 10 15Document2 pagesE 59a Product Data 10 15marcos crisostoNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationkei iswandaNo ratings yet

- 1400b Product Data MLC 709Document2 pages1400b Product Data MLC 709marcos crisostoNo ratings yet

- Air Current MSDs FSDocument9 pagesAir Current MSDs FSa k bNo ratings yet

- Module 2 - Workplace Hazardous Materials Information System (Whmis)Document56 pagesModule 2 - Workplace Hazardous Materials Information System (Whmis)BabbooNo ratings yet

- Work Place Hazardous MaterialDocument56 pagesWork Place Hazardous MaterialMartahanManurungNo ratings yet

- Bonderite C-Ak 5948DPM Eu Aero-EnDocument2 pagesBonderite C-Ak 5948DPM Eu Aero-EnjjonasNo ratings yet

- VP 31a Product Data Met L CheckDocument2 pagesVP 31a Product Data Met L CheckTopoilServNo ratings yet

- Msdsduco Primer DP-12111 HV Grey P429C IvsmDocument4 pagesMsdsduco Primer DP-12111 HV Grey P429C IvsmAjiWidyartaNo ratings yet

- Section 1: Identification: Modine Manufacturing Company 10225 Elizabeth PlaceDocument4 pagesSection 1: Identification: Modine Manufacturing Company 10225 Elizabeth PlaceAlfredo Merizalde AvilesNo ratings yet

- Ferrous Chloride Solution PDFDocument5 pagesFerrous Chloride Solution PDFzamburittiNo ratings yet

- Sds - 35 - Epilux 555 HB Cte Part A - 00Document4 pagesSds - 35 - Epilux 555 HB Cte Part A - 00jagannathmohanta290No ratings yet

- Eter Spray - STARTING FLUIDDocument6 pagesEter Spray - STARTING FLUIDJESA CONSTRUCCIONESNo ratings yet

- Ficha Tecnica Pegamento 711Document2 pagesFicha Tecnica Pegamento 711MÓNICA PAZOSNo ratings yet

- MSDS Copper CathodeDocument8 pagesMSDS Copper CathodeREIG Ingatlan KftNo ratings yet

- Eagle PaintDocument8 pagesEagle Paintfhinojoza34No ratings yet

- Pu Ral 7035Document4 pagesPu Ral 7035Srikanth GantaNo ratings yet

- Green Products Company Safety Data SheetDocument7 pagesGreen Products Company Safety Data SheetbenNo ratings yet

- Msds Oli NG Lube Sae40Document4 pagesMsds Oli NG Lube Sae40Eko WibowoNo ratings yet

- Metacaulk C70Document6 pagesMetacaulk C70OpalaNo ratings yet

- STICKTITE® 271A Easy Pastilles PDFDocument5 pagesSTICKTITE® 271A Easy Pastilles PDFAlexis GonzalezNo ratings yet

- 711 PB 07-2010Document2 pages711 PB 07-2010Angel BarretoNo ratings yet

- SDS - 34 - Epilux 9 HB Phenolic Coating Part A - 00 - 174Document4 pagesSDS - 34 - Epilux 9 HB Phenolic Coating Part A - 00 - 174john rajNo ratings yet

- 228 R Solvent - 2015Document5 pages228 R Solvent - 2015Nabil NnNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationUkesh Wangpa NegiNo ratings yet

- SDS - 31 - Epilux 4 Clear Lacquer Part A - 00 - 159Document4 pagesSDS - 31 - Epilux 4 Clear Lacquer Part A - 00 - 159john rajNo ratings yet

- Arctiko Refrigerant MSDS-1Document3 pagesArctiko Refrigerant MSDS-1jean charles dussexNo ratings yet

- SKF Grease LGMT 2Document5 pagesSKF Grease LGMT 2Agung P WibowoNo ratings yet

- Air Filter CleanerDocument4 pagesAir Filter CleanerempmedicNo ratings yet

- ExxonMobil Chalmette Refining LLC MSDS RFCCU Equilibrium CatalystDocument11 pagesExxonMobil Chalmette Refining LLC MSDS RFCCU Equilibrium CatalystGeauxGreenNo ratings yet

- Opticlean V Liquid Detergent Ld-V003Document6 pagesOpticlean V Liquid Detergent Ld-V003Anonymous 5PsGXCNo ratings yet

- WF 209Document6 pagesWF 209AmenNo ratings yet

- 241 MSDSDocument7 pages241 MSDSPete DechaNo ratings yet

- MSDS PFC - 225 SealerDocument4 pagesMSDS PFC - 225 SealerchindyNo ratings yet

- Safety Data Sheet: N-Butyl AlcoholDocument6 pagesSafety Data Sheet: N-Butyl AlcoholDeny AlsanNo ratings yet

- Carbothane 134 HG - Urethane Converter 811 MSDS Part BDocument6 pagesCarbothane 134 HG - Urethane Converter 811 MSDS Part BAyman JadNo ratings yet

- Desengrasante HS RPW-49Document2 pagesDesengrasante HS RPW-49Lenni Tatiana Corrales FernándezNo ratings yet

- MD-TempMSDS R120160722Document7 pagesMD-TempMSDS R120160722Sruthi SomanNo ratings yet

- Carboline 635 Part ADocument12 pagesCarboline 635 Part AOthelloBeneventiNo ratings yet

- Msds Krytox LVP Grease Artno 80005031 enDocument5 pagesMsds Krytox LVP Grease Artno 80005031 enRomiNo ratings yet

- MSDS Rored - Hda - 85w-140 - 2013 - 01 - 10Document4 pagesMSDS Rored - Hda - 85w-140 - 2013 - 01 - 10MaroPaneNo ratings yet

- Pu Golden Yellow - Part BDocument4 pagesPu Golden Yellow - Part BSrikanth GantaNo ratings yet

- Oil - Pertamina Meditran Sae40Document4 pagesOil - Pertamina Meditran Sae40dk_moehammedNo ratings yet

- Material Safety Data Sheet: WWW - Smartlab.co - IdDocument8 pagesMaterial Safety Data Sheet: WWW - Smartlab.co - IdHilman SyehbastianNo ratings yet

- Pu Black - Part ADocument4 pagesPu Black - Part ASrikanth GantaNo ratings yet

- SDS Cold Galvanize SprayDocument10 pagesSDS Cold Galvanize Sprayfarhahnadiah.mokhtarNo ratings yet

- MSDS, Uncharged VRB ElectrolyteDocument7 pagesMSDS, Uncharged VRB ElectrolytedeaNo ratings yet

- Bonderite C-NE 5088Document2 pagesBonderite C-NE 5088Agustin MantegazzaNo ratings yet

- Msds 51910419745 Titan SilverDocument6 pagesMsds 51910419745 Titan SilverAnonymous fXWzyInNo ratings yet

- SDS - 43 - BR Acrylic Pu Enl Partb - 00 - 204Document4 pagesSDS - 43 - BR Acrylic Pu Enl Partb - 00 - 204john rajNo ratings yet

- Safety Data Sheet: Revised: AEDocument7 pagesSafety Data Sheet: Revised: AERoberto VargasNo ratings yet

- Safety Data Sheet: Eco-GPE™ - Part A 1. Product Identification Eco-GPE™ - Part ADocument8 pagesSafety Data Sheet: Eco-GPE™ - Part A 1. Product Identification Eco-GPE™ - Part AJORGEMANUELNo ratings yet

- ITW Performance Polymers - Devcon Material Safety Data SheetDocument6 pagesITW Performance Polymers - Devcon Material Safety Data SheetNazirAhmadBashiriNo ratings yet

- AJR Scan-II Series A B Scan Ultrasonic Thickness GaugeDocument3 pagesAJR Scan-II Series A B Scan Ultrasonic Thickness GaugeEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Policy On Proficiency Testing RequirementsDocument22 pagesPerry Johnson Laboratory Accreditation, Inc.: Policy On Proficiency Testing RequirementsEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Calibration Scopes of Accreditation PolicyDocument20 pagesPerry Johnson Laboratory Accreditation, Inc.: Calibration Scopes of Accreditation PolicyEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Policy On Measurement UncertaintyDocument8 pagesPerry Johnson Laboratory Accreditation, Inc.: Policy On Measurement UncertaintyEnrique AntonioNo ratings yet

- Release Note TESTEK (0120)Document2 pagesRelease Note TESTEK (0120)Enrique AntonioNo ratings yet

- Emma Remote ControlDocument12 pagesEmma Remote ControlEnrique AntonioNo ratings yet

- ReliabilityDocument2 pagesReliabilityEnrique AntonioNo ratings yet

- Mentor Flex ManualDocument80 pagesMentor Flex ManualEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Measurement Traceability PolicyDocument12 pagesPerry Johnson Laboratory Accreditation, Inc.: Measurement Traceability PolicyEnrique AntonioNo ratings yet

- Ultramate SeriesDocument1 pageUltramate SeriesEnrique AntonioNo ratings yet

- Ustai Able Evelop ENT Ndic TOR: S N D M I A S 2015Document15 pagesUstai Able Evelop ENT Ndic TOR: S N D M I A S 2015Enrique AntonioNo ratings yet

- Ensayos en Los Acoplantes - NDT ItaliaDocument8 pagesEnsayos en Los Acoplantes - NDT ItaliaEnrique AntonioNo ratings yet

- Sustainability Performance ReportDocument6 pagesSustainability Performance ReportEnrique AntonioNo ratings yet

- The Current State of Citizen Science As A Tool For Ecological Research and Public EngagmentDocument7 pagesThe Current State of Citizen Science As A Tool For Ecological Research and Public EngagmentEmiliano CalabazaNo ratings yet

- Thermal Applications and Examples - IndustrialDocument4 pagesThermal Applications and Examples - IndustrialEnrique AntonioNo ratings yet

- ThermAppTH Prices 2017Document2 pagesThermAppTH Prices 2017Enrique AntonioNo ratings yet

- Brochure Ceta S 1Document2 pagesBrochure Ceta S 1Enrique AntonioNo ratings yet

- Approval Czech Railway (EN)Document1 pageApproval Czech Railway (EN)Enrique AntonioNo ratings yet

- Manual IRISDocument81 pagesManual IRISEnrique AntonioNo ratings yet

- ThermAppTh Brochure Jul2017Document4 pagesThermAppTh Brochure Jul2017Enrique AntonioNo ratings yet

- Hygienic Attest ZINGA-English TranslationDocument2 pagesHygienic Attest ZINGA-English TranslationEnrique AntonioNo ratings yet

- FGA300 V User's GuideDocument172 pagesFGA300 V User's GuideEnrique AntonioNo ratings yet

- Panametrics Zirconium Oxide Oxygen Analyzer: SensingDocument4 pagesPanametrics Zirconium Oxide Oxygen Analyzer: SensingEnrique AntonioNo ratings yet

- Panametrics - O2X1 Manual PDFDocument37 pagesPanametrics - O2X1 Manual PDFCamilo MartinezNo ratings yet

- Brochure Ceta S 1Document2 pagesBrochure Ceta S 1Enrique AntonioNo ratings yet

- Thermal Camera Applications - GeneralDocument1 pageThermal Camera Applications - GeneralEnrique AntonioNo ratings yet

- O2X1 Panametrics Oxygen Transmitter DatasheetDocument4 pagesO2X1 Panametrics Oxygen Transmitter DatasheetdingNo ratings yet

- Panametrics Smart Oxygen Analyzer: Sensing & Inspection TechnologiesDocument4 pagesPanametrics Smart Oxygen Analyzer: Sensing & Inspection TechnologiesEnrique AntonioNo ratings yet

- Steel Lecture Notes 1 PDFDocument6 pagesSteel Lecture Notes 1 PDFMary Grace BorinagaNo ratings yet

- Laeticia Rodrigues - P21008 - MetullurgyDocument2 pagesLaeticia Rodrigues - P21008 - MetullurgyLAETICIA RODRIGUESNo ratings yet

- A Concise Guide To Ceramic Manufacturing ProcessesDocument78 pagesA Concise Guide To Ceramic Manufacturing ProcessesUmarNo ratings yet

- Electric IronDocument21 pagesElectric IronRanbirNo ratings yet

- A Study On Employee Satisfaction in Avatar Gold and Diamonds, EdappalDocument74 pagesA Study On Employee Satisfaction in Avatar Gold and Diamonds, EdappalAkNo ratings yet

- Short Term Financial Management 3rd Edition Maness Test BankDocument38 pagesShort Term Financial Management 3rd Edition Maness Test Bankjanelevotraw1983100% (15)

- Strength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeDocument6 pagesStrength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeJason BorejszoNo ratings yet

- Resultados - Aceite - Gloria IllapuDocument3 pagesResultados - Aceite - Gloria IllapuDavid Chapoñan PascoNo ratings yet

- Anion Ide: Monoatomic: Change Ending ToDocument24 pagesAnion Ide: Monoatomic: Change Ending TodjkedslNo ratings yet

- Centaurus Metals Limited (Asx: CTM) : Will Thomson and Chip Russell, Managing PartnersDocument11 pagesCentaurus Metals Limited (Asx: CTM) : Will Thomson and Chip Russell, Managing Partnerscarlosmarco87No ratings yet

- Watt Density & Sheath SelectionDocument13 pagesWatt Density & Sheath SelectionJim ElliottNo ratings yet

- OSMB Technical Handbook Iss3Document92 pagesOSMB Technical Handbook Iss3shrikant mishraNo ratings yet

- Catalogo Soldadura Por Resistencia PDFDocument58 pagesCatalogo Soldadura Por Resistencia PDFwebs.usuarioNo ratings yet

- Azulcocha 43-101 - Feb2008 - ReportDocument65 pagesAzulcocha 43-101 - Feb2008 - Reportwalter sanchez vargasNo ratings yet

- Technical Specification Documents What Is Stainless Steel?Document1 pageTechnical Specification Documents What Is Stainless Steel?Mongia MoghiNo ratings yet

- Astm A286Document1 pageAstm A286akmlogaNo ratings yet

- A Reexamination of The Mount Bischoff Cassiterite Sulfide Skarn, Western TasmaniaDocument18 pagesA Reexamination of The Mount Bischoff Cassiterite Sulfide Skarn, Western Tasmaniakimberly salomeNo ratings yet

- Utility of Complex Metric TitrationDocument8 pagesUtility of Complex Metric Titrationcyper zoonNo ratings yet

- Principles of Brazing TechnologyDocument14 pagesPrinciples of Brazing TechnologyErivaldo ConstantNo ratings yet

- Chapter 5 - Minerals and Energy Resources: CBSE Notes Class 10 Social Science GeographyDocument5 pagesChapter 5 - Minerals and Energy Resources: CBSE Notes Class 10 Social Science GeographyEKLABAY SONINo ratings yet

- UTP Bestseller PDFDocument28 pagesUTP Bestseller PDFdaha333No ratings yet

- Chemical Composition - Is 2062 - Anx - BDocument2 pagesChemical Composition - Is 2062 - Anx - BTuhin Subhra Mondal100% (4)

- CE 4109: Design of Steel StructuresDocument50 pagesCE 4109: Design of Steel StructuresAfif AdnanNo ratings yet