Professional Documents

Culture Documents

D-702 Product Data 10-15

Uploaded by

Enrique AntonioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D-702 Product Data 10-15

Uploaded by

Enrique AntonioCopyright:

Available Formats

Product Data Sheet 1

Met-L-Chek®

10/2015

D-702 High Temperature

Penetrant Professor Approved

Developer ©2015

Met-L-Chek Company manufactures a complete line of developers used in the fluorescent (Type 1) and vis-

ible (Type 2) dye penetrant inspection process. Met-L-Chek Company high temperature developer, D-702, is

qualified to Mil-I-25135 as a special application developer and is sold under the Met-L-Chek® and Pen-Chek®

trademarks. Met-L-Chek Company products are manufactured under license in The Netherlands by NDT Europa.

D-702 is a special application high temperature inspection developer, form “f”, used with high temperature vis-

ible penetrant VP-302 to enhance detection of surface cracks and porosity on hot surfaces. The use range is 51.6

˚C - 176.6 ˚C (125˚F -350˚F). D-702 is applied after the surface penetrant has been removed. D-702 is applied

by spraying, either from a portable compressed gas spray pack or by conventional spray gun. The developer con-

sists of absorbent powder suspended in a volatile solvent blend. D-702 dries quickly and produces a thin white

film, which is easily removed with water after inspection. This type of developer contains flammable solvents

and should not be used in confined spaces or near open flames or sparks. The use on hot surfaces does not pose a

significant fire hazard in the open air.

D-702 is listed on the approved products list for Mil-I-25135C It is low in Sulfur, Chlorine, Fluorine and other

Halogens, making it safe for use on Titanium and high Nickel alloys found in nuclear components.

D-702 finds wide use in field weld and weld repair inspection. It is used in the inspection of refinery processing

equipment that is at elevated temperatures, speeding up the inspection process time by eliminating the total cool

down required for standard penetrant.

Operator must take precautions when working on hot surface to prevent burns. Protective gloves are recom-

mended.

Guide to METHOD “C” wipe off processing

1. Part must be clean, dry and at a temperature of 52˚-177˚C

(125˚- 350˚F) before penetrant is applied. Test surface tem-

perature by applying a small drop of penetrant on the part

surface. If the color turns brown to black in a minute the High temperature penetrant VP-302 crack indication on

surface is too hot to inspect. Allow to cool until red color D-702 developer film.

persists.

2. Apply VP-302 penetrant using spray or wipe on.

3. Wait a minimum of 1-5 minutes for penetrant to thin and

enter flaws.

4. Using R-502 high temperature remover on wiping media, Portable spray packs

wipe off surface penetrant. for applying

D-702

5. Spray on thin even film of D-702 high temperature de- high temperature

veloper. developer.

6. Wait a minimum of 1-5 minutes before inspection. On

higher temperature surfaces color may begin to fade with

prolonged time. Use illumination of >1100 lux/m2 (>100

foot candles) to inspect.

Product Data Sheet 2

Met-L-Chek®

10/2015

D-702 High Temperature

Developer

Penetrant Professor Approved

Typical Physical Properties Specifications

Form: hazy liquid ASME B & PV code sec V ASTM E-165

Density: 950g/L ASTM E-1417 ISO-3452

Flash Point: > 11.6˚C (>54˚F) Mil-I-25135C, Interim AM-4

Fluorescence: none NAVSEA-250-1500-1, Rev17, ACN-5

Dry Coating: thin white film

Removability with water: complete

Corrosion of aluminum: none Product Availability

Corrosion of carbon steel: none 1 pint (0.473L) metal can

Corrosion of magnesium: none 1 gallon (3.7L) metal can

Corrosion of stainless steel: none 5 gallon (18.9L) metal pail

Corrosion of titanium: none

Chloride content: < 100 ppm (0.01%)

Fluoride content: < 50 ppm (0.005%)

Sulfur content: < 200 ppm (0.02%)

Mercury: none

VOC’s: 0 g/L

Ozone layer depleting substances: none

PCB’s: none

The warranty shelf life of the product is 3 years

from date of batch approval.

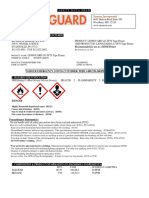

GHS Information

Danger GHS Response Statements:

GHS: Hazard Statements: IF INHALED: Remove person to fresh air and keep comfortable

H225: Highly flammable liquid and vapor. for breathing, get medical advice/attention if you feel

H319: Causes serious eye irritation. unwell.

H336: May cause drowsiness or dizziness IF ON SKIN: Wash with plenty of water. If skin irritation occurs,

get medical advice/attention.

GHS Precautionary Statements: IF IN EYES: Rinse cautiously with water for several minutes.

P102: Keep out of reach of children. Remove contact lenses, if present and easily to do.

P210: Keep away from heat, hot surfaces, sparks, open flames and Continue rinsing, get medical attention.

other ignition sources. No smoking. IF SWALLOWED: Rinse mouth, Do Not induce vomiting, get

P233: Keep container tightly closed. medical attention if feeling unwell.

P261: Avoid breathing fumes/gas/mist/vapors/spray. IF ON CLOTHING: Take off contaminated clothing and wash

P280: Wear protective glove/clothing/eye protection/face before reuse.

protection.

P284: In case of inadequate ventilation wear respiratory Transport:

protection DOT -UN 1219, Isopropanol, class 3, , packing group II, .

Met-L-Chek Company, 1639 Euclid Street, Santa Monica, California, 90404, U.S.A.

Phone: 310-450-1111, Fax: 310-452-4046, Email: info@met-l-chek.com, Web: www.met-l-chek.com

You might also like

- VP-302 Product Data 11-15Document2 pagesVP-302 Product Data 11-15Enrique AntonioNo ratings yet

- VP 30 Product Data 11 15Document2 pagesVP 30 Product Data 11 15marcos crisosto100% (1)

- E 59a Product Data 10 15Document2 pagesE 59a Product Data 10 15marcos crisostoNo ratings yet

- Ldpe 105B + MSDSDocument6 pagesLdpe 105B + MSDSDiana Sarmiento100% (1)

- Fischer Brand PU FoamDocument18 pagesFischer Brand PU FoamClash OfclansNo ratings yet

- MSDS Rored - Hda - 85w-140 - 2013 - 01 - 10Document4 pagesMSDS Rored - Hda - 85w-140 - 2013 - 01 - 10MaroPaneNo ratings yet

- Material Safety Data Sheet For Boss Zinc Galvanised Paint - 400Ml - 84636052Document5 pagesMaterial Safety Data Sheet For Boss Zinc Galvanised Paint - 400Ml - 84636052ojoladapoNo ratings yet

- SS Electropolish E972: Electropolishing Electrolyte For Stainless SteelDocument5 pagesSS Electropolish E972: Electropolishing Electrolyte For Stainless SteelAnonymous gUySMcpSqNo ratings yet

- Arctiko Refrigerant MSDS-1Document3 pagesArctiko Refrigerant MSDS-1jean charles dussexNo ratings yet

- MSDS Turalik 48Document4 pagesMSDS Turalik 48satriaNo ratings yet

- MECHANICsoldering Flux MSDSDocument22 pagesMECHANICsoldering Flux MSDSMECHANIC HONGKONGNo ratings yet

- Green Products Company Safety Data SheetDocument7 pagesGreen Products Company Safety Data SheetbenNo ratings yet

- MSDS Lithium Grease EP2Document4 pagesMSDS Lithium Grease EP2Septian AdityaNo ratings yet

- UT Couplant Gel-MSDSDocument6 pagesUT Couplant Gel-MSDSskynyrd75No ratings yet

- Ficha Tecnica Pegamento 711Document2 pagesFicha Tecnica Pegamento 711MÓNICA PAZOSNo ratings yet

- MSDS Copper CathodeDocument8 pagesMSDS Copper CathodeREIG Ingatlan KftNo ratings yet

- Msds Seikisui Thermobreak Ek-Ks-1Document5 pagesMsds Seikisui Thermobreak Ek-Ks-1Nuril AniwindiraNo ratings yet

- SDS (Ups) Silicone Mould Release Paintable - enDocument4 pagesSDS (Ups) Silicone Mould Release Paintable - enhugocupuNo ratings yet

- 492 MSDSDocument5 pages492 MSDSsrinivignaNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetfaridkhanNo ratings yet

- Material Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationruksfarhanNo ratings yet

- Techseal Silver SL GDocument11 pagesTechseal Silver SL GAnh Quang NgoNo ratings yet

- Synthetic Food Grade Lubricant (NSF Certified, Category H1, REGISTRATION NO.132479)Document2 pagesSynthetic Food Grade Lubricant (NSF Certified, Category H1, REGISTRATION NO.132479)mayurghule19No ratings yet

- MSDS PFC - 225 SealerDocument4 pagesMSDS PFC - 225 SealerchindyNo ratings yet

- Product 42 HW02NDocument7 pagesProduct 42 HW02Nshesmine92No ratings yet

- MSDS - SiliconeFluid200 350Document7 pagesMSDS - SiliconeFluid200 350Rafael Saldanha LopesNo ratings yet

- Asphalt PG 58-28: Material Safety Data SheetDocument3 pagesAsphalt PG 58-28: Material Safety Data SheetSen HuNo ratings yet

- Met-L-Chek: Material Safety Data SheetDocument2 pagesMet-L-Chek: Material Safety Data SheetManuel Morivera100% (1)

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationUkesh Wangpa NegiNo ratings yet

- Complete Top-of-Wall Firestopping Solution!: CP 672 CP 672Document4 pagesComplete Top-of-Wall Firestopping Solution!: CP 672 CP 672Gökhan GülhanNo ratings yet

- MSDS PFC - 225Document4 pagesMSDS PFC - 225chindyNo ratings yet

- SDS - 34 - Epilux 9 HB Phenolic Coating Part A - 00 - 174Document4 pagesSDS - 34 - Epilux 9 HB Phenolic Coating Part A - 00 - 174john rajNo ratings yet

- NavGuard II AU SDS v1.0Document4 pagesNavGuard II AU SDS v1.0Aaron HeapsNo ratings yet

- SKF Grease LGMT 2Document5 pagesSKF Grease LGMT 2Agung P WibowoNo ratings yet

- SDS - 34 - Epilux 9 HB Phenolic Coating Part B - 00 - 175Document4 pagesSDS - 34 - Epilux 9 HB Phenolic Coating Part B - 00 - 175john rajNo ratings yet

- Section 1: Identification: Modine Manufacturing Company 10225 Elizabeth PlaceDocument4 pagesSection 1: Identification: Modine Manufacturing Company 10225 Elizabeth PlaceAlfredo Merizalde AvilesNo ratings yet

- MSDS Turalik XT 46Document4 pagesMSDS Turalik XT 46satriaNo ratings yet

- Dynalub Lubricant 510 Eng R0 SafetyDocument4 pagesDynalub Lubricant 510 Eng R0 Safetysteelpro1No ratings yet

- Helling Engl KATALOGDocument42 pagesHelling Engl KATALOGSuphi Yüksel100% (1)

- Hm-604 Fluorescent PenetrantDocument3 pagesHm-604 Fluorescent PenetrantivanNo ratings yet

- Minimum Oil Circuit BreakerDocument4 pagesMinimum Oil Circuit BreakergshdavidNo ratings yet

- SKF Grease LGWA 2Document6 pagesSKF Grease LGWA 2Agung P WibowoNo ratings yet

- 711 PB 07-2010Document2 pages711 PB 07-2010Angel BarretoNo ratings yet

- VP 31a Product Data Met L CheckDocument2 pagesVP 31a Product Data Met L CheckTopoilServNo ratings yet

- Chemical Safety Data Sheet: Section 1: Chemical Product & Company IndentificationDocument7 pagesChemical Safety Data Sheet: Section 1: Chemical Product & Company IndentificationSyerifaizal Hj. MustaphaNo ratings yet

- Polyurethane PaintDocument9 pagesPolyurethane PaintCaNo ratings yet

- MSDS 143-261Document5 pagesMSDS 143-261Nurul Arifatul AminNo ratings yet

- Air Current MSDs FSDocument9 pagesAir Current MSDs FSa k bNo ratings yet

- Sds - 35 - Epilux 555 HB Cte Part A - 00Document4 pagesSds - 35 - Epilux 555 HB Cte Part A - 00jagannathmohanta290No ratings yet

- EC Safety Data Sheet: 1. Name of Product, Characterization and Company NameDocument3 pagesEC Safety Data Sheet: 1. Name of Product, Characterization and Company NamemitramgopalNo ratings yet

- LG TP70 Tape Primer SDSDocument4 pagesLG TP70 Tape Primer SDSscibduser001No ratings yet

- Msdsduco Primer DP-12111 HV Grey P429C IvsmDocument4 pagesMsdsduco Primer DP-12111 HV Grey P429C IvsmAjiWidyartaNo ratings yet

- Safety Data Sheet: Sodium HydroxideDocument6 pagesSafety Data Sheet: Sodium HydroxideSandeep ShettyNo ratings yet

- MSDS Food Grade Multi Purpose GreaseDocument7 pagesMSDS Food Grade Multi Purpose Greaseayu laksitaNo ratings yet

- 1052 Emulsion Bulk (5.1)Document3 pages1052 Emulsion Bulk (5.1)tarek aneesNo ratings yet

- Work Place Hazardous MaterialDocument56 pagesWork Place Hazardous MaterialMartahanManurungNo ratings yet

- SDSHandoutDocument3 pagesSDSHandoutangel crus crusNo ratings yet

- D-100 Hoja de Datos TecnicosDocument2 pagesD-100 Hoja de Datos TecnicosPilar Medrano MenaNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- Supercritical Carbon Dioxide: In Polymer Reaction EngineeringFrom EverandSupercritical Carbon Dioxide: In Polymer Reaction EngineeringMaartje F. KemmereNo ratings yet

- ReliabilityDocument2 pagesReliabilityEnrique AntonioNo ratings yet

- Release Note TESTEK (0120)Document2 pagesRelease Note TESTEK (0120)Enrique AntonioNo ratings yet

- Emma Remote ControlDocument12 pagesEmma Remote ControlEnrique AntonioNo ratings yet

- AJR Scan-II Series A B Scan Ultrasonic Thickness GaugeDocument3 pagesAJR Scan-II Series A B Scan Ultrasonic Thickness GaugeEnrique AntonioNo ratings yet

- Mentor Flex ManualDocument80 pagesMentor Flex ManualEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Policy On Proficiency Testing RequirementsDocument22 pagesPerry Johnson Laboratory Accreditation, Inc.: Policy On Proficiency Testing RequirementsEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Policy On Measurement UncertaintyDocument8 pagesPerry Johnson Laboratory Accreditation, Inc.: Policy On Measurement UncertaintyEnrique AntonioNo ratings yet

- Ultramate SeriesDocument1 pageUltramate SeriesEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Calibration Scopes of Accreditation PolicyDocument20 pagesPerry Johnson Laboratory Accreditation, Inc.: Calibration Scopes of Accreditation PolicyEnrique AntonioNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Measurement Traceability PolicyDocument12 pagesPerry Johnson Laboratory Accreditation, Inc.: Measurement Traceability PolicyEnrique AntonioNo ratings yet

- Ustai Able Evelop ENT Ndic TOR: S N D M I A S 2015Document15 pagesUstai Able Evelop ENT Ndic TOR: S N D M I A S 2015Enrique AntonioNo ratings yet

- Sustainability Performance ReportDocument6 pagesSustainability Performance ReportEnrique AntonioNo ratings yet

- Common Goals, Shared Action: The European Aluminium Industry'S Sustainability Roadmap Towards 2025Document20 pagesCommon Goals, Shared Action: The European Aluminium Industry'S Sustainability Roadmap Towards 2025Enrique AntonioNo ratings yet

- The Current State of Citizen Science As A Tool For Ecological Research and Public EngagmentDocument7 pagesThe Current State of Citizen Science As A Tool For Ecological Research and Public EngagmentEmiliano CalabazaNo ratings yet

- ISO 4386 1 2012, Plain Bearings PDFDocument14 pagesISO 4386 1 2012, Plain Bearings PDFKevin DaveNo ratings yet

- ThermAppTH Prices 2017Document2 pagesThermAppTH Prices 2017Enrique AntonioNo ratings yet

- Ensayos en Los Acoplantes - NDT ItaliaDocument8 pagesEnsayos en Los Acoplantes - NDT ItaliaEnrique AntonioNo ratings yet

- Thermal Applications and Examples - IndustrialDocument4 pagesThermal Applications and Examples - IndustrialEnrique AntonioNo ratings yet

- Manual IRISDocument81 pagesManual IRISEnrique AntonioNo ratings yet

- Hygienic Attest ZINGA-English TranslationDocument2 pagesHygienic Attest ZINGA-English TranslationEnrique AntonioNo ratings yet

- Approval Czech Railway (EN)Document1 pageApproval Czech Railway (EN)Enrique AntonioNo ratings yet

- ThermAppTh Brochure Jul2017Document4 pagesThermAppTh Brochure Jul2017Enrique AntonioNo ratings yet

- FGA300 V User's GuideDocument172 pagesFGA300 V User's GuideEnrique AntonioNo ratings yet

- Thermal Camera Applications - GeneralDocument1 pageThermal Camera Applications - GeneralEnrique AntonioNo ratings yet

- Brochure Ceta S 1Document2 pagesBrochure Ceta S 1Enrique AntonioNo ratings yet

- Brochure Ceta S 1Document2 pagesBrochure Ceta S 1Enrique AntonioNo ratings yet

- Panametrics Zirconium Oxide Oxygen Analyzer: SensingDocument4 pagesPanametrics Zirconium Oxide Oxygen Analyzer: SensingEnrique AntonioNo ratings yet

- Panametrics Smart Oxygen Analyzer: Sensing & Inspection TechnologiesDocument4 pagesPanametrics Smart Oxygen Analyzer: Sensing & Inspection TechnologiesEnrique AntonioNo ratings yet

- Panametrics - O2X1 Manual PDFDocument37 pagesPanametrics - O2X1 Manual PDFCamilo MartinezNo ratings yet

- O2X1 Panametrics Oxygen Transmitter DatasheetDocument4 pagesO2X1 Panametrics Oxygen Transmitter DatasheetdingNo ratings yet

- Jsa PVC, CPVC, Teflon, PVDFDocument7 pagesJsa PVC, CPVC, Teflon, PVDFM. MagnoNo ratings yet

- Adsorbents Purification Olefin Polymer Streams BrochureDocument12 pagesAdsorbents Purification Olefin Polymer Streams BrochureMaría Belén JaureguiNo ratings yet

- Robond ProhesionDocument4 pagesRobond ProhesionHerul VetonkNo ratings yet

- Indian Medicine ListsDocument294 pagesIndian Medicine ListsAmjad ShareefNo ratings yet

- Alpine Drill BeadsDocument2 pagesAlpine Drill BeadsAlex K.100% (1)

- MSDS Lubline High Temp MC2495 XRT Grease NLGI 2Document6 pagesMSDS Lubline High Temp MC2495 XRT Grease NLGI 2EloNo ratings yet

- BT503 - Past Papers PDFDocument83 pagesBT503 - Past Papers PDFJawad100% (1)

- 99-6632 Series Megaseal™ SC/HSN: General Description Product Code InformationDocument2 pages99-6632 Series Megaseal™ SC/HSN: General Description Product Code InformationHectorNo ratings yet

- Alloy 4047 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 4047 Weld Data Sheet: Typical ApplicationsMarcoAntonioNo ratings yet

- Cast It2000Document5 pagesCast It2000jkpolino85No ratings yet

- Chemistry Project CBSE 2016-17 Joymalya Biswas Roll Number: 23Document26 pagesChemistry Project CBSE 2016-17 Joymalya Biswas Roll Number: 23affiliate30dayNo ratings yet

- 1.2 Chemical Reagents and Laboratory Supplies 1Document4 pages1.2 Chemical Reagents and Laboratory Supplies 1Justine Mel Concepcion IlardeNo ratings yet

- 1-3 Cold Welding, EtcDocument50 pages1-3 Cold Welding, EtcNguyễn Hồng Thanh100% (2)

- 1 Mass ConcreteDocument38 pages1 Mass ConcreteJayel GuintoNo ratings yet

- Construction Materials: Assignment ReportDocument7 pagesConstruction Materials: Assignment ReportKiệt ĐỗNo ratings yet

- Boiler Water Quality RequirementsDocument10 pagesBoiler Water Quality RequirementsAbdul Qadir JamaludinNo ratings yet

- Carbon Dioxide Adborption Into Promoted Potassium Carbonate SolutionsDocument13 pagesCarbon Dioxide Adborption Into Promoted Potassium Carbonate SolutionsLucia RojasNo ratings yet

- Growing Mushrooms The Easy WayDocument22 pagesGrowing Mushrooms The Easy WayRamamohan Vallala100% (1)

- Vancomycin SolutionDocument1 pageVancomycin SolutionjamalNo ratings yet

- Dosage Calculation Med SurgDocument2 pagesDosage Calculation Med SurgAubrey Silencio BalahayNo ratings yet

- Rando HD 32: Safety Data SheetDocument6 pagesRando HD 32: Safety Data SheetNguyen Thuy Thuy LinhNo ratings yet

- Candle LabDocument5 pagesCandle LabHarrison Lee50% (2)

- Silicone Fluid: Performance Test ResultsDocument36 pagesSilicone Fluid: Performance Test ResultsSouradeep MukherjeeNo ratings yet

- Mixtures Solutions & Mechanical Mixtures'-2Document17 pagesMixtures Solutions & Mechanical Mixtures'-2Mariam AmgadNo ratings yet

- Saw Wen Yi - Test 1Document2 pagesSaw Wen Yi - Test 1wudi zheNo ratings yet

- The Influence of Chromium Content On Wear and Corrosion Behavior of Surface AlloyedDocument10 pagesThe Influence of Chromium Content On Wear and Corrosion Behavior of Surface AlloyedBurag HamparyanNo ratings yet

- Ascorbic Acid 47863 LRAD1702Document4 pagesAscorbic Acid 47863 LRAD1702Irowati PurwaningsihNo ratings yet

- ASTM E1131 - Standard Test Method For Compositional Analysis by ThermogravimetryDocument6 pagesASTM E1131 - Standard Test Method For Compositional Analysis by ThermogravimetrysiaNo ratings yet

- Ref: Introduction To Acids, Bases and Salts: Classification of MatterDocument5 pagesRef: Introduction To Acids, Bases and Salts: Classification of MatterAhmed shakilNo ratings yet

- Techno-Economical Evaluation of Coupling Ionizing Radiation and Biological Treatment Process For The Remediation of Real Pharmaceutical WastewaterDocument12 pagesTechno-Economical Evaluation of Coupling Ionizing Radiation and Biological Treatment Process For The Remediation of Real Pharmaceutical WastewaterMarita ElvinaNo ratings yet