Professional Documents

Culture Documents

Surface Mine Design and Practice - Engr. Izhar Mithal Jiskani

Surface Mine Design and Practice - Engr. Izhar Mithal Jiskani

Uploaded by

Cristian HOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Mine Design and Practice - Engr. Izhar Mithal Jiskani

Surface Mine Design and Practice - Engr. Izhar Mithal Jiskani

Uploaded by

Cristian HCopyright:

Available Formats

SURFACE MINE DESIGN

AND PRACTICE

Engr. Izhar Mithal Jiskani

Department of Mining Engineering,

Mehran University of Engineering & Technology

Jamshoro, Sindh

SURFACE MINE DESIGN AND PRACTICE

GEOMETRICAL CONSIDERATIONS

INTRODUCTION TO OPEN PIT MINING

The ore deposits being mined by open pit techniques today vary considerably in size,

shape, orientation and depth below surface. The initial surface topographies can vary

from mountain tops to valley floor. In spite of this there are a number of geometry based

design and planning considerations fundamental to them all.

The ore body is mined from top to the down in the series of horizontal layers of uniform

thickness called benches and after a sufficient floor area has been exposed, mining to the

next layer can begin. The process continues until the bottom bench elevation is reached

and the final pit outline achieved. To access different bench a road or ramp must be

created. The width and steepness of this road or ramp depends upon the type of

equipment to be accommodated. Stable slopes must be created and maintained during the

creation and operation of the pit.

Slope angle is an important geometrical parameter which has a significant economic

impact. Open pit mining is very highly mechanized. Each piece of mining machinery has

an associated geometry both related to its own physical size, but also with the space it

requires to operate efficiently. There is a complementary set of drilling, loading and

hauling equipment which requires a certain amount of working space. This space

requirement is taken into account when dimensioning the so called working benches.

From both operating and economic view points certain volumes must or should at least be

removed before others. These volumes have a certain minimum size and an optimum size.

Engr. Izhar Mithal Jiskani 2

SURFACE MINE DESIGN AND PRACTICE

BASIC BENCH GEOMETRY

The basic extraction component is an open pit mine is the “bench”. Bench – nomenclature

is shown in Figure 1.

Fig.1: Bench Nomenclature

FACE: It is an exposed area from where the overburden or mineral/ore is extracted.

CREST: highest point of the face.

TOE: lowest point the face.

BENCH: the step or floor accommodating the mine machinery.

BENCH HEIGHT: each bench has an upper and lower surface separated by a distance

“H” equal to the bench height. The bench height is determined by the size of mining

equipment and formation of the area.

The loose/soft rocks allows, bench height up to shovel reach.

In hard and very strong rock, bench height is usually 10-40 meters.

BENCH SLOPE: the bench slope or the bench face angle is the inclined plane of the

bench made an angle with the horizontal. Or the average angle that a face makes with the

horizontal. The exposed sub-vertical surfaces are known as bench faces. The bench faces

are described by the toe. The crest and he bench face angle ‘ ’. The bench face angle

can vary considerably with rock characteristics, face orientation and the blasting

practices. In most hard rock pits it varies from about 55 O to 80O. A typical initial design

Engr. Izhar Mithal Jiskani 3

SURFACE MINE DESIGN AND PRACTICE

value might be 65O. This should be used with care as the bench face angle can have a

major effect on the overall slope angle.

BENCH FLOOR: The exposed bench lower surface is called as the bench floor.

BENCH WIDTH: The bench width is the distance between the crest and toe measured

along the upper surface.

BANK WIDTH: It is the horizontal projection of the bench face.

There are several types of benches; a working bench is that one which is in process of

being mined. The width being extracted from the working bench is called the cut. The

width of working bench WB is defined as the distance from the crest of the bench floor to

the new toe position after the cut has been extracted as shown in figure 2. After the cut

has been removed, a safety bench or catch bench of width SB remains.

The purpose of leaving safety benches is to:

a) collect the material which slides down from the benches above; and to

b) stop the downward progress of the boulders.

During primary extraction, a safety bench is generally left on every level. The width of

safety bench SB varies with bench height “H”. Generally the width of the safety bench is

of the order 2

3 of the bench height. At the end of mine life, the safety benches are

sometimes reduced to a width of about 1

3 of the bench height.

In addition to leaving the safety benches berms (piles) of broken materials are often

constructed along the crest. These serve the function of forming a ditch between the berm

and the toe of the slope to catch falling rocks.

A safety berm is also left along the outer edge of the bench to prevent trucks and other

machines from backing over. It serves much the same function as a guard rail on bridges

and elevated highways. Normally the pile has a height greater than or equal to the tire

radius. The berm slope is taken to be about 35O, i.e. also called the angle of repose.

The steps which are followed when considering bench geometry are:

i) Deposit characteristics (total tonnage, grade distribution, value etc) dictate a

certain geometrical approach and production strategy.

Engr. Izhar Mithal Jiskani 4

SURFACE MINE DESIGN AND PRACTICE

ii) The production strategy yields daily ore-waste production rates, selective

mining and blending requirements, numbers of working places.

iii) The production requirements leads to a certain equipment set (fleet type and

size).

iv) Each equipment set has a certain optimum associated geometry.

v) Each piece of equipment in the set has an associated operating geometry.

vi) A range of suitable bench geometries results.

vii) Consequences regarding stripping ratios, operating v/s capital costs, slope

stability aspects etc are evaluated.

viii) The best of the various alternatives is selected.

In the past, when the rail bound equipments were being extensively used, great attention

was paid to bench geometry. Today highly mobile rubber tired/crawler mounted

equipments has reduced the detailed evaluation requirements some-what.

Fig. 2: Working Bench

Engr. Izhar Mithal Jiskani 5

SURFACE MINE DESIGN AND PRACTICE

Fig. 2a: Functions of a catch bench

Engr. Izhar Mithal Jiskani 6

SURFACE MINE DESIGN AND PRACTICE

DEVELOPMENT OF ACCESS ROAD: (ORE ACCESS;)

In mining literature, going the initial knowledge about the physical access to the Ore body

is of great importance. For this, the question arises that: “How does one actually begin the

process of Mining?” Obliviously the approach depends upon the topography of the

surrounding ground. To introduce the topic, it is assumed that the ground surface is flat.

The overlying vegetation has been removed as has the soil/sand/gravel overburden. In this

case it will be assumed that the ore body is 700 feet in diameter, 40feet thick, flat dipping

and is exposed by removing the soil overburden. The ore is hard so that drilling and

blasting is required. The bench mining situation is shown in figure: 3.

Figure 3: Geometry of the ore body

A vertical digging face must be established in the ore body before major production can

begin. Further more a “ramp” must be created to allow truck and loader access. A drop

cut is used to create the vertical breaking face and the ramp access at the same time.

To access the Ore body, the “ramp” shown in figure: 4 will be driven it has an 8% grade

and a width of 65 feet.

Although not generally the case, the walls will be assumed vertical. To reach the 40ft

desired depth, the ramp in horizontal projection will be 500ft in length.

Figure 4: Ramp access for example ore body

Engr. Izhar Mithal Jiskani 7

SURFACE MINE DESIGN AND PRACTICE

The volume of access road or ramp volume is the volume of the waste rock mined in

excavating the ramp.

:. Ramp volume = Ramp width (Rw) × Area of ∆abc.

1

Rw horizontal H

2

1 H

Ramp volume (V) = Rw 100 H

2 g

1

Rw H 100 H

2 g

:. Volume of Ramp = V= 50 H2/g × Rw; (ft3)

Example # 01:-

Determine the volume of Ore body by waste rock to develop access road at the

slope of 8%. Depth of cylindrical Ore body is 30 feet and diameter 500 ft, width of ramp

is 65 feet.

Data:

Slope = g = 8%

Depth = H = 30 feet

Diameter = d= 500 feet

Width of ramp = Rw = 65 feet

Solution:

as V = Volume of ramp

H2

and V = 50 × × Rw

g

(30) 2 x 65 2925000

V = 50 × =

8 8

V = 365625 ft3 Ans

.

Example # 02:-

Repeat example # 01 for Depth (H) = 40 ft and Ramp width (Rw) = 60 ft.

H2

Solution: - V = 50 × × Rw

g

(40) 2 x 60

V = 50 ×

8

V = 600000 ft3 Ans

Engr. Izhar Mithal Jiskani 8

SURFACE MINE DESIGN AND PRACTICE

DEVELOPMENT OF ACCESS ROAD: (ramps)

i) In waste rock (Fig. 5a)

.

ii) Ramp in ore body (Fig. 5b)

.

iii) Ramp starting in waste and ending in ore (Fig. 5c)

Engr. Izhar Mithal Jiskani 9

SURFACE MINE DESIGN AND PRACTICE

Engr. Izhar Mithal Jiskani 10

SURFACE MINE DESIGN AND PRACTICE

THE PIT EXPANSION PROCESS

When the drop cut has reached the desired grade, the cut is expanded laterally. Figure: 6

shows the steps. Initially Fig: 6.A; the operating space is very low/limited; therefore the

trucks must turn and stop at the top of the ramp and then back down the ramp towards the

loader. When the pit bottom has been expanded sufficiently as shown in fig: 6.B; the

truck can turn around on the pit bottom. Latter, as the working area becomes quite larger

as shown in fig. 6.C; several loaders can be used at the same time. The optimum face

length assigned to a machine varies with the size and type. It is of the range 200-500 feet.

Once access has been established the cut is winded until the entire bench/level has been

extended to the bench limits. There are three approaches which will be discussed here;

they are as follows:

1. Frontal Cuts

2. Parallel Cuts – Drive by

3. Parallel Cuts – Turn & Back

The first two apply where there is a great deal of working area available, for example “at

the pit bottom”. The mining of the more narrow benches on the sides of the pit is covered

under the third approach.

Figure: 6 A

Step I

Engr. Izhar Mithal Jiskani 11

SURFACE MINE DESIGN AND PRACTICE

Figure: 6 B

Step II

Figure: 6 C

Step III

Figure 6: Detailed steps in the development of a new production level

FRONTAL CUTS:

The frontal cut is shown diagrammatically in figure – 7.

The shovel faces the bench face and begins digging forward straight ahead and to the

side. A niche is cut in the bank wall. For the case shown, double spotting of the trucks is

used. The shovel first loads to the left and when the truck is full he proceeds to the other

truck on the right. The swing angle varies from 1100 (maximum) to an angle of 100

(minimum). The average swing angle is about 600; hence the loading operation is quite

effective. There must be room for trucks to position them around the shovel. The shovel

Engr. Izhar Mithal Jiskani 12

SURFACE MINE DESIGN AND PRACTICE

penetrates to the point that the face. It then moves parallel to itself and takes another

frontal cut as shown in fig: 7.1;

With a long face and sufficient bench width, more than one shovel can work the same

face, as shown in fig. 7.2.

1. DRIVE BY CUTS :- (parallel cuts-drive by)

Another possibility when the mine geometry allows is the parallel cut with drive by. This

is diagrammatically shown in figure 8. The shovel moves across and parallel to the

digging face. For this case bench access for the haul units must be available from both the

directions. It is highly efficient for both the trucks and the loader. Although the average

swing angle is greater than for the frontal cut, the trucks do not have to back up to the

shovel and the spotting is simplified.

2. TURN AND BACK:- (Parallel cuts-turn and back)

The expansion of the pit at the upper levels is generally accomplished by using parallel

cuts. Due to space limitations there is only access to the ramp from one side of the shovel.

This means that the trucks approach the shovel from the rear. Then, they stop, turn, and

back into the load position.

Sometimes there is a room for double spotting of the trucks (fig: 9.1) but sometimes for

only single spotting as shown in figure 9.2.

Engr. Izhar Mithal Jiskani 13

SURFACE MINE DESIGN AND PRACTICE

DETERMINATION OF THE MINIMUM OPERATING ROOM

REQUIRED FOR PARALLEL CUTS

In determing the width of operating room required for the parallel cut operations; to

accommodate the large trucks and shovels involved in loading, the dimension being

sought is “the width of working bench WB”. The working bench is that bench mined. The

width of working bench “WB” is synonymous with the term “operating room” and is

defined as the distance from the crest of the bench providing the floor for the loading

operations to the bench toe being created as the parallel cut is being advanced. The

minimum amount of operating room varies depending upon whether single or double

spotting of trucks is used with the latter obviously requiring some what more. The

minimum width of the working bench (wb) is equal to the width of the minimum required

safety bench plus the width of the cut.

This is expressed as; “WB = SB + WC”

The easiest way of demonstrating the principles involved is by way of an example: For

this, the following assumptions will be made:

Beach height = 40 feet

A safety beam is required.

The minimum clearance b/w the outer truck tire and safety berm = 5 feat.

Single spotting is used.

Bench face angle = 700

Loading is done with a 9yd3 Shovel.

Haulage is done by 85 ton capacity Trucks.

Truck width = 16 feet

Tire Rolling radius = 4 feat.

The general arrangement of working bench (in x-sectional view) is shown in figure 10.

Engr. Izhar Mithal Jiskani 14

SURFACE MINE DESIGN AND PRACTICE

Figure 10:

.

Figure 10.1: Simplified representation of berm.

kl

The design shows that:-

Working bench width = 102 feet

Cut width = 60 feet

Safety bench width = 42 feet.

The basic calculations (justifications) behind these calculations are presented as follows.

Engr. Izhar Mithal Jiskani 15

SURFACE MINE DESIGN AND PRACTICE

Step # 01:- Highest of the berm should be at least same as the radius of the

truck tire, i.e.; = 4 feet.

Step # 02:- The distance b/w the crept and centre line of the truck = Tc = 21:

Width of Berm = 8 feet.

Clearance distance b/w safety berm and the wheels of truck = 5 feet

and; the total width of truck = 16 feet.

Step # 03:- The distance b/w the centre line of the Shovel and centre line of the

truck is also called as “Dumping radius” denoted by B; B = 45.5

feet.

Step # 03b:- The Maximum duping height (A) is more than sufficient to clear

the truck;

A = 28 feet.

Step # 03c:- Distance b/w the centre line of Shovel and toe = G ;

G= 35.5 feet

Step # 04:- The desired working bench dimensions become ;

Total minimum width of working bench = WB = TC +B+G;

:. WB = 21 feet + 45.5 feet + 35.5 feet.

WB = 102 feet

Note: All the parameters and /or dimensions used above, depends upon the size of the

machinery which is used.

WIDTH OF CUT :- (Wc)

The corresponding width of cut is:-

WC = 0.90 × 2 × G = 0.90 × 2 × 35.5 feet

WC = 63.9 feet

Engr. Izhar Mithal Jiskani 16

SURFACE MINE DESIGN AND PRACTICE

Note: This is applied to the width of the pile of broken material. Therefore, to allow for

swell and throw of the material during blasting. The design cut width should be less than

this value. Thus a value of 60 feet has been assumed.

WIDTH OF SAFETY BENCH :- (SB)

Knowing the width of working bench, and width of cut, the resulting safety bench has a

width of; SB = WB – WC ;

:. SB = 102-60 = 42 feet.

SB = 42 feet.

Note: This is of the order of the bench height (40ft) which is a rule of thumb, sometimes

employed.

Engr. Izhar Mithal Jiskani 17

SURFACE MINE DESIGN AND PRACTICE

CUT SEQUENCINGS:

Let us consider a pit consisting of four benches as shown in fig: 11

Fig. 11: Initial Geometry of the pit:

After the initial geometry of the bench is completed; the mining of first bench is started as

shown in figure: 12.

Fig. 12: Mining of bench # 01

The above figure shows that while performing the cut mining operation of bench # 01, the

overall slope angle was “θ01”.

After the mining of bench # 01, the next bench (i.e.: Bench # 02) is mined, as shown in

fig. 13:

Engr. Izhar Mithal Jiskani 18

SURFACE MINE DESIGN AND PRACTICE

Fig: 13:- Cut mining from bench # 02

Where

θ = individual slope angle.

and θ01 = overall slope angle (while mining Bench # 01) of pit.

θ02 = overall slope angle of pit (while mining bench # 02)

It is observed that; the overall slope angle “θ0” always keep varying as we will advance

the mining from the upper to the lower benches.

i.e.:- θ01 ≠ θ02

It is essential to consider (know) the value of “θ0” for slope stability designs.

Engr. Izhar Mithal Jiskani 19

SURFACE MINE DESIGN AND PRACTICE

PIT SLOPE GEOMETRY

There are a number of “slopes” which enter into “pit design”. Care is taken so that there is

no confusion as to how they are calculated and what they mean. One slope has already

been introduced. That is the ‘bench face angle” (shown in figure). It is defined as the

angle made with the horizontal of the line connecting the Toe to the crest “this def:” will

be maintained through this piece of literature.

Now consider the slope consisting of “5” such benches (shown in figure). The angle made

with the horizontal of the line connecting the lowest most toes to the upper most crests is

defined as the overall pit slope.

5x50 (Y)

θ overall tan

1

50.4O

4x35 5x50

tan75O

Height of each bench = y = 50 feet.

Horizontal distance = x = 35 feet

Distance under slope = x’ =?

Bench face angle = 750 = θ

:. tan y

x'

y 50 50

x' 13.4 '

tanθ tan75 3.732

Since we have 5 benches,

i.e.: - 5 slopes, X= (4*x) + (5*x’).

X = (4 x 35) + (5 x 13.4) = 140 + 67 X = 207’

Y = 5 x 50 Y = 250’

:. Overall pit slope angle = θ overall

y 250

θ overall tan 1 tan 1

x 207

θ overall 50.4O

Engr. Izhar Mithal Jiskani 20

SURFACE MINE DESIGN AND PRACTICE

INTRODUCING RAMP IN PIT SLOPE GEOMETRY

An access ramp with a width of 100 feet; introduced at the half way up bench 3, the

overall pit slope becomes;

y

θ overall tan 1

x

where, Y = 250’

5x50

and X 4x35 O

100'

tan75

:. X = 307 feet.

250

θ overall tan 1 39.18

O

307

θ overall 39.2 O

It can be seen that the presence of the ramp n a give section has an enormous impact on

the overall slope angle.

Fig. 15: Overall slope angle with ramp included.

Engr. Izhar Mithal Jiskani 21

SURFACE MINE DESIGN AND PRACTICE

INTER-RAMP SLOPE ANGLES AFTER RAMP INCLUDED

The ramp breaks the overall slope angles “ θ overall” into 2 portions as shown in following

figure; each of these 2 portions can be described by slope angles. These angles are called

as “the Inter ramp (Between the ramps)” angles.

θIR1 θIR 2 tan 1 y

x

Y 50 50 24 Y 124feet

50 25

X 2x35 2 O

O

tan75 tan75

X 70 26.8 6.7 103.5

125

θIR1 θIR 2 tan 1 50.38

O

103.5

θIR1 θIR 2 50.4O

Figure 16: Inter ramp slope angles after ramp included

The inter-ramp wall height is 125 ft for each segment. Generally the inter ramp wall

heights and angles for different slope segments would not be the same. From a slope

stability view point each inter-ramp segment would be examined separately.

Engr. Izhar Mithal Jiskani 22

SURFACE MINE DESIGN AND PRACTICE

INTRODUCING WORKING BENCHES IN PIT SLOPE

GEOMETRY

While active mining is underway, some working benches are included in the overall

slope. The fig. ; shows a working bench 125ft in width included as bench 2.

The overall slope angle “ θ overall” now becomes;

θ overall tan 1 y

x

50

As; Y 250' , X 4x35 ' 5 O

'125'

tan75

X 140' 67' 125' X 332 feet

250

θ overall tan 1 36.98

O

332

Fig. 17: Overall slope angle with working bench included

Engr. Izhar Mithal Jiskani 23

SURFACE MINE DESIGN AND PRACTICE

INTER-RAMP SLOPE ANGLES AFTER WORKING BENCH

INCLUDED

The working bench is treated in the same way as a ramp in terms of interrupting the slope.

Therefore from following figure, two inter-ramp angles are shown:-

θIR 2 tan 1 y ; As; Y = 250 – 50 = 200 feet and

x

50

θIR 2 tan 1

200 X 3 x 35 4 O

tan75

158.6'

X 105 53.6 158.6'

θIR 2 51.58O or 51.6 O

As; for the above inter ramp angles, the inter ramp heights are,

H1= 50’ and H2 = 2’

Fig. 18: Inter-ramp slope angles after working bench included

Engr. Izhar Mithal Jiskani 24

SURFACE MINE DESIGN AND PRACTICE

PLANNAR FAILURE

Fig. 19: Perspective

view of plannar

failure.

Fig. 20: Dimensions and forces in a rock slope with a potential failure plane.

As figure 20 shows the dimensions and forces in a rock slope with potential failure plane.

The Mohr-coulomb failure criterion has been used.

The following definitions apply:

i= average slope angle from horizontal in degrees,

ß = the angle of discontinuity from the horizontal (degrees),

W =block weight;

Engr. Izhar Mithal Jiskani 25

SURFACE MINE DESIGN AND PRACTICE

R = resisting force;

C = cohesion,

φ =friction angle.

Wcosß= normal force

Wsinß= driving force

A= Area of the failure plane.

The factor of safety ‘F’ is defined by the following equation:

Total force available to resist sliding

F

Force tending to induce sliding

For the case shown in Fig:”20”

cA Wcos β tanφ

F

Wsin β

If there is water present then;

cA Wcos β - U tanφt

F

Wsin β V

where,

U= water pressure along potential failure surface,

φ a = friction angle (affected by water),

V= force along potential sliding plane.

Engr. Izhar Mithal Jiskani 26

SURFACE MINE DESIGN AND PRACTICE

Example # 01:-

The average planned slope angle i = 700, the orientation of the potential failure plane ß =

500 and the friction angle φ = 300. The thickness of he plane is 1ft; the cohesion is 1600

lb/ft3. The unit weight of the rock is 160 lb/ft3, and height of the wall is 100ft.

Sol:-

frictional force

S.F

Sliding force

Frictional force cA Wcosβ tanφ

Fig. 21 (a)

i 70, β 50

A 70 0 50 0 A 20 0

C 50 0

B 180 0 A C 180 0 70 0

B 110 0

Fig. 21 (b)

1 2 sin A sin C

b

2 sin B (a)

1 2 sin B sin C

a

2 sin A (b)

1 2 sin A sin C

c

2 sin C (c)

H 100

sin B

as, b b

Engr. Izhar Mithal Jiskani 27

SURFACE MINE DESIGN AND PRACTICE

100 100

b 0

130.54feet

or sin50 0.766

Putting the above value in eqn (a).

130.54 2 sin 20 sin0 50

0 0

1

2 sin 110

1 0.262

17040.692

2 0.9396

0.279

2375.62 ft 2

(V) Volume of (triangle ABC) sliding block = thickness of sliding block

2375.62 1ft

V 2375.62 1ft 3

(W) Weight of sliding block is = volume × unit weight

W V γ 2375.62 160lb/ft 3

W 380099.2lbs

As

cA Wcosβcosβ

F

Wsinβ

A= Area of the failure plane, and

A= length of failure plane × thickness

A= b × 1ft= 130.54ft × 1ft

A= 130.54ft2

Wcosβ 380099.2 cos50 0 244323.05lb

Wsinβ 380099.2 sin50 291172.88lb

c 1600lb/ft 2

Tanφ Tan30 0 0.577

F

1600 130.54 244323.05 0.577

291172.88

349838.4

F

291172.88

F 1.2

Engr. Izhar Mithal Jiskani 28

SURFACE MINE DESIGN AND PRACTICE

By using “graphical simplification” of the S.F;

X 2 i β β φ 2 70 50 50 30

X Slope angle function 2 400

or X 40

Y slope height function γγH/

Y 160 100 /1600

Y 10

Now by using slope design chart for plane

failure the safety factor for X= 40 and Y= 10

is;

S.F = 1.6

Engr. Izhar Mithal Jiskani 29

SURFACE MINE DESIGN AND PRACTICE

Example 02:

Determine the limiting pit slope angle (i) using the following data:

Inclination of failure plane β50

0

i.

Angle of internal friction φ35

0

ii.

Cohesion = C 7800 kg m

3

iii.

iv. γ 2.5 tons m 3

v. Height of slope = 150m

Solution:

γH 2.5 150 375

Y

c 7800 7.8

Y 48.07

From the slope design chart, at Y=48 and S.F = 1.0, X=18

:.

We know that X 2 i

18 2 i 50 50 35 2 13i 750

Now, squaring both sides

18 2 2 2 15i 750

324 4 15i 750

324 60i 3000

60i 324 3000 3324

3324

i 55.4 0

60

i 55.4 0

Engr. Izhar Mithal Jiskani 30

SURFACE MINE DESIGN AND PRACTICE

Slope design chart for plane failure including various

safety factors (Hoek, 1970a)

Engr. Izhar Mithal Jiskani 31

SURFACE MINE DESIGN AND PRACTICE

Example 03:

Determine the height of slope using the following data.

Slope angle i 65

0

i.

Inclination of failure plane β50

0

ii.

Angle of internal friction 35

0

iii.

Cohesion c 7800 kg m

2

iv.

Unit wt: of rock γ 2.5t m ;

3

v.

vi. Safety factor = S.F = 1.4;

Sol:

X 2 i β β φ 2 65 50 50 35

2

15 15 2 255 2 15

X 30 0

By using the graph of “slope design chart for plane failure including various safety

factors”

At X 30 and S.F 1.4

0

The value of Y=16

H

Y ,

:. As c

Y c 16 7800

H 49.92m

γ 2.5

H 49.92m

Engr. Izhar Mithal Jiskani 32

SURFACE MINE DESIGN AND PRACTICE

CIRCULAR FAILURE

Fig. 22 (a):

Plane failure in rock with highly

ordered structure, such as state

Fig. 22 (b): Free body diagram

As we know that;

ΣM 0

Mw Mc 0.; Mw w d

Engr. Izhar Mithal Jiskani 33

SURFACE MINE DESIGN AND PRACTICE

length of Arc ‘AB’ in fig:22(b); Rθ

Area of Arc ‘AB’= length × thickness

[For simplicity, here we have considered the value of thickness of Arc as Unit]

Area of Arc ‘AB’ = Rθ 1

Mc = (Area of Arc) × (cohesion) × (R)

Rθ C R

Mc CR 2 θ

as, Mw+Mc= 0

wd CR 2 θ 0

wd CR 2 θ

CR 2 θ

or S.F

wd

If the portion is in equilibrium state,

it is stable, and will not slip down.

Engr. Izhar Mithal Jiskani 34

SURFACE MINE DESIGN AND PRACTICE

Example:

A cutting in saturated clay inclined at a slope of 1 vertical and 1.5 horizontal and has a

vertical height of 10.0 m. the bulk unit weight of soil is 18.5 KN/m3 and its un-drained

cohesion is 40 KN/m2. Determine the safety factor against immediate shear failure along

the slip circle as shown in figure.

Soln:

1 vertical Slope

1.5 horizontal Slope

λ 18.5 KN m 3

C 40 KN m 2

From fig: 23, consider “ Δ afo ” to find out ‘ θ 1 ’

Figure 23

5m

θ 1 Tan 1

16.7m

θ 1 16.7 0

According to Pythagoras theorem,

2 2 2

Hyp perp Base

R 2 5 16.7 25 278.9 303.0

2 2

R 303.9

R 17.43m

φ 1 ?; since given slope of cutting plane “ad” is 1 vertical and 1.5 horizontal;

1

φ 1 Tan 1

1.5

Thus, φ 1 33,7

0

from figure 23; it is clear that:

Engr. Izhar Mithal Jiskani 35

SURFACE MINE DESIGN AND PRACTICE

φ 90 0 φ 1 θ 1

90 0 33.7 0 16.7 0 39.6 0

φ 39.6 0

Now we consider right angled “oec”

6.7

cosθ 2

17.43

θ 2 cos 1 0.384

θ 2 67.4 0

φ 3 180 0 90 0 67.4

φ 3 22.6

From Δ obe we get 2 , as follows,

6.7

φ 2 sin 1 φ 2 22.6

0

17.43

φ 3 180 φ 1 φ 2 180 0 33.7 0 22.6 0

0

0

φ 3 180 56.3 φ 3 123.71

0

0

as φ 90 φ 1 θ 1 90 0 33.7 0 16.7 0

0

φ 84.10

Ψ 180 0 θ φ 180 0 84.10 39.6

Ψ 180 0 123.7 0

Ψ 56.30

1 sinθ sinφ

Δaod Δ 1 R2

Area of 2 sinΨ

Δ1

1

17.43

2

sin 84.10 sin 39.6 0

2 sin 56.3 0

Δ 1 115.85m 2

In order to find the area of bcd , we must know any one side of bcd . Let’s find “DB”

for sake of ease.

OD R

DB R OD and

sinφ sinΨ

Engr. Izhar Mithal Jiskani 36

SURFACE MINE DESIGN AND PRACTICE

OD

Rsinφ 17.43 sin 39.6 0

13.36m

sinΨ sin 56.30

DB 17.43 13.36 DB 4.07m

1 sinφ 2 sinφ 3

Δ 2 4.07

2

2 sinφ 1

Δ 2 4.77m 2

Now area of polygon oabc=Ap

Ap 120.62m 2

1

aoc R 2 0

(as) Area of sector 2 180

As

1

2

π

17.43 84.10 0

180

As 222.86m 2

Now, Area of slip mass (A)= As-Ap

A 222.86 120.62

A 102.24m 2

Volume of slip mass= V A t 102.24 1

V 102.24m 3

Weight of slip mass= W V γ

W 102.24 18.5

W 1891.44KN

CR 2 θ

S.F

Wd

S.F

40 17.43 80.10 π

2

180

0

1891.44 6.54

S.F 1.44

Engr. Izhar Mithal Jiskani 37

SURFACE MINE DESIGN AND PRACTICE

STRIPPING RATIO

Figure 24 (a)

Vm = Vol. of mining

Vc = Vol. of cone

VT = Vol. of truncated portion

:. Vm = Vc- VT

Fig. 24 (b)

Engr. Izhar Mithal Jiskani 38

SURFACE MINE DESIGN AND PRACTICE

As we know that;

1 2

πr h

Vol: of cone= 3

2

And Vol: of cylinder = πr h

:. Volume of circular ore body; Vo

2

Vo= πr h ……… (1)

Volume of (small) truncated tip of cone; VT

1

VT πr 2 Δh

3 …… (2) (:.) Height of small cone is ∆h). and Δh γtanθ

as height of big cone, is Hc;

and Hc h Δh

Hc h γtanθ

or

:. Vol: of bigger cone, Vc

1 1

Vc πR 2 Hc πr 2 h Δh

3 3

1

or Vc πR 2 h γtanθ (3)

3

:. Mined Vol: Vm VC VT

1 1

Vm πr 2 H c πr 2 Δh (4)

3 3

Vol: of waste: Vw Vm V0

2

Where, Vol: of Ore V0 πr h

:. Vol: of waste Vw Vm V0 (5)

SR

Vol : of waste m 3

:. Stripping Ratio

Vol : of ore. m 3

Vw Ww

SR (6) SR

V0 or W0

Engr. Izhar Mithal Jiskani 39

SURFACE MINE DESIGN AND PRACTICE

Example:

A cylindrical ore body with radius of 50m and Depth of 250m is to be excavated by

developing a cone. Slopes of the sides of the cone with the horizontal are 550. Unit

weight of the ore is 3.1 tons/m3 and that of the waste rock is 2.6 tons/m3.determine the

stripping ratio (SR).

Data: Δh γtanθ

γ 50m Δh 50tan55

h 250m Δh 71.4m

γ ore 3.1 tons m 3 H C h Δh 250 71.4

H C 321.4m

γ wast 2.6tons/m 3

H C RTan θ

Solution

HC

R

1 Tan55 0

VC πR 2 H c

3 R 321.4

Tan55 0

VC 17044879.24m 3

R 225.04m

1

VT πγ 2 Δh

3

VT 186924.76m 3

Vm VC VT 17044879.24 186924.76

Vm 16857954.48m 3

Vore πγ 2 h π 50 2 250 VO 1963495.4m 3

VW Vm VO 16857954.48 1963495.4

VW 14894459.08m 3

W waste Vw γ w 14894459.08 2.6

S.R

W ore Vo γ o 1963495.4 3.1

38725593.61

S.R

6086835.74

S.R 6.36

Engr. Izhar Mithal Jiskani 40

SURFACE MINE DESIGN AND PRACTICE

DETERMINATION OF “SR” BY AREA METHOD

Ao =Area of sections (i), (ii) and (iii)

1

50 50 1250ft 2

Area of Sec: (i) = 2

Area of Sec: (ii) = 100 50 5000ft 2

Area of Sec: (iii) = 100 150 15000ft 2

A O 21250 2 5000 15000

A O 27500ft 2

1

Aw 1 100 100 5000ft 2

2

since Aw 1 Aw 2

Aw Aw 1 Aw 2 5000 5000

Aw 10000ft 2

Aw 10000

S.R 0.36

Ao 275000

S.R 0.36

Now consider the bench of 25ft thickness.

Engr. Izhar Mithal Jiskani 41

SURFACE MINE DESIGN AND PRACTICE

Ao1 100 25 2500ft 2

Ao 2

50 2 50 2 25 70.71 25

Ao 2 1767.75ft 2

Ao Ao1 2Ao 2 2500 21767.75

Ao 6035.5ft 2

Aw 2Aw 1 2Aw 2

Aw 1 100 2

100 2 25.10000 25 150000ft

1

Aw 2 25 25 312.5ft 2

2

Aw 2 250000 2 312.5

500000 625

Aw 500625ft 2

A = ½(b1 + b1) × h = b1h

Engr. Izhar Mithal Jiskani 42

SURFACE MINE DESIGN AND PRACTICE

PIT LIMITS

The minable material becomes that lying

within the pit boundaries. A vertical section

taken through such a pit is shown in figure

A:

The size and shape of the pit depends upon

economic factors and design/production

constraints.

With an increase in price, the pit would expand in size assuming all other factors

remained constant.

The “pit” existing at the end of mining is called the “final pit” or the ultimate pit. In b/w

the birth and death of an open pit mine, there are a series of intermediate pits. This

includes a series of procedures based upon:

Hand Methods,

Computer Methods, and

Computer assisted hand methods

The above mentioned methods are used for developing the pit limits. Within the pit

materials of differing values are found. Economics criteria are applied to assign

destination for these materials based on their value (i.e. mill, waste dump, loach dump,

stock pile etc). Once the pit limits have been determined and rules established for

classifying the in pit materials, then the ore reserves (tonnage and grade) can be

calculated.

The Net Value Calculation:-

The term cut-off grade refers to the “grades” for which the destination of pit material

changes. It should be noted that “grades” were used rather than “grade” since there may

be several possible – destinations. The simplest case is that in which there are two

destinations: the mill or the waste dump. One cut of grade is needed for many operations

today; there are many possible destinations: the mill or leach dump and the waste dump.

Engr. Izhar Mithal Jiskani 43

SURFACE MINE DESIGN AND PRACTICE

Each of the decisions:-

Mill or leach?

Leach or waste?

requires a cut-off grade.

Cut-off Grade:-

The grade at which the mineral resources can’t longer be processed at a profit.

Break-even cut-off grade:-

The grade at which the net value is zero; is called Break-even cut-off grade.

Determination of pit limits, on the basis of net value:

Example:

Determine the pit limits of an open pit mine as shown in figure: setting price of 1m3 of

Ore is US$ 1.9 and mining cost of 1m3 of waste is US$ 1.0.

Sol:

For Strip # 01:-

Vo 1 5 1.25 1

Vol: of ore (Strip 1) Vo 1 6.25m

3

1

Vw 1 6.364 1.25 1 1.25 1.25

2

Vol: of waste (Strip 1) Vw 1 8.74m

3

Engr. Izhar Mithal Jiskani 44

SURFACE MINE DESIGN AND PRACTICE

Vw 1

Ins (S.R)

Vo 1

S.R 1.4

Ins

Value of ore = Vo1* Selling price of 1/m3 of ore

6.25 1.9

= Value of ore 11.875US dollars

Cost of mining of waste =

Vw 1 Mining cost of 1m 3 waste

8.74 1.0

Cost of mining of waste = 8.74 US dollars

Net value = value – cost

= 11.875 – 8.74

N.V = 3.14 US $. → for strip # 01

Calculate for strip, 2, 3 and 4.

For Strip #02:-

Vol. of ore, Vo 2 5 1.25 1

Vo 2 6.25m 3

Vol. of waste, Vw 2 6.614 1.25 1 1 1.25 2

2

Vw 2 10.3m 3

Vol. of ore Vo 2 1.9 6.25 1.9

Vol. of ore 11.875US $

Cost of mining waste 10.3 1 10.3US $

Vw 2 10.3

SR (ins) 1.65

Vo 2 6.25

N.V Value cost 11.875 10.3

N.V 1.58US dollars

For Strip# 03

Vo 3 6.25m 3

Vw 3 8.864 1.25 1 1 1.25

2

2

Vw 3 11.86m 3

S.R ins 11.86 S.R ins 1.9

6.25

Engr. Izhar Mithal Jiskani 45

SURFACE MINE DESIGN AND PRACTICE

Value of ore 6.25 1.9 11.875 US dollars

Cost of waste 11.86 1 11.86 US dollars

N.V 11.875 - 11.86

N.V 0.015 US dollars

For Strip # 04:-

Vo 4 6.25

Vw 4 10.114 1.25 1 1 1.25 2

2

Vw 4 12.6425 0.78125

Vw 4 13.424m 3

Vw 4 13.424

S.R Ins 2.14

Vo 4 6.25

Cost of mining waste 13.424 1 13.424 $

Price/value of ore 6.25 1.9 11.875 $

N.V 11.875 - 13.424

N.V -1.55US dollars

As can be seen that the net value changes from (+) to (-) as the pit is expanded, sometimes the N. V

become zero, so that this pit position is termed as “Break-even”, which is the location of final pit wall.

Now for overall volume of waste we have;

1

Δw 9.9 9.9

2

49m 2 thickness 1

overall vol : of waste 49m 3

& overall vol : of ore 9.9 5 1 1 5 5 1

2

49.5 12.5 1m

overall vol : of ore 62m 3

overall strippig ratio Vw 49 0.79 0.8

Vo 62

overall value of ore 62 1.9 117.8 US dollars

overall mining cost of waste 49 1 49.00 US dollars

N - value (overall) 117.8 - 49.00

N.V 68.8 US dollars

Engr. Izhar Mithal Jiskani 46

SURFACE MINE DESIGN AND PRACTICE

Example

Copper ore is milled to produce a copper concentrate. This mill concentrate is slipped and

transported to a smatter and the resulting blister copper is eventually refined.

In this example, the following data will be assumed.

Mill recovery rate = 80%

Mill concentrate grade = 20%

Smelting loss = 10 lbs/st of concentrate

Refining loss = 5 lbs/st of blister copper.

The ore is containing 0.55%, All the costs and revenues will be calculated in terms of 1

ton of ore. Note that ore short ton= 2000 lbs.

Solution:-

Step # 01:- Complete the amount of saleable copper (lb/s per st of ore)

a) Contained copper (cc) is :-

0.55

cc 2000lb/st * 11.00lbs

100

b) Copper recovered by mill (RM/st of ore)

80

RM 11lbs 8.8lbs

100

c) Concentration ratio (r):- the ratio of concentration is defined as

lbs of cu/st of concentrate

r

lbs of " cu" recovered/st of ore

2000 20 100 400

r 45.45

8.8 8.8

r 45.45

d) Copper recovered by smelter :- (R.S)

As, smelting loss = 10 lbs/st of concentrate.\

Economic Block Models:-

The block model representation of ore bodies rather than section representation and the

storage of the information on high speed computers have offered some new possibilities

in open pit mines.

Engr. Izhar Mithal Jiskani 47

SURFACE MINE DESIGN AND PRACTICE

ORE GRADE ESTIMATION

by the constant distance weighting techniques

a) Inverse Distance Techniques:-

The formula to calculate the ore grade by inverse distance technique is :

n

Σ

gi

di

i 1

Σ i di

n

i 1

Where,

gi= given grade of ore at a point.

g= estimated grade of ore.

di= distance b/w known point and point of estimation.

Example:

Calculate the estimated grade of ore at point “C”, using inverse distance technique.

Known grades of an ore at points C1-C6 ore shown in fig: [in brackets]

Sol:

Engr. Izhar Mithal Jiskani 48

SURFACE MINE DESIGN AND PRACTICE

First let’s estimate the value of distances d1, d2...d6 by using Pythogona’s theorem.

d 1 200 2 200 2 8000 d 1 282.84m

d 2 300 2 100 2 100000 d 2 316.23m

d 3 100 2 200 2 50000 d 3 223.6m

d 4 200 2 200 2 80000 d 4 282.84m

d 5 200 2 100 2 50000 d 5 223.6m

d 6 100 2 300 2 100000 d 6 316.23m

As we know that;

g1 g 2 g 6

d d d

1 2 6

g

1 1 6

d d d

1 2 6

0.409 0.165 0.258 1.365 0.023 0.644

282.84 316.23 223.6 282.84 223.6 316.23

g

1282.84

1

316.23

1

223.6

1

282.84

1

223.6

1

316.23

0.0100

g g 4.484 10 1

0.0223

:. The estimated grade of ore =g

g = 0.45 %

b) Inverse Distance Squared weighting Technique:-

Using this technique, the grade of ore is found, by using following equations.

n

gi

Σ di

i 1

2

g n

1

Σ di

i 1

2

Using the data of previous example; calculate the grade of ore by squared weighting

technique.

Engr. Izhar Mithal Jiskani 49

SURFACE MINE DESIGN AND PRACTICE

2

d 1 282.84m - - - - - - - - - - d 1 79998.4656m 2

2

d 2 316.23m - - - - - - - - - - d 2 100001.4129m 2

2

d 3 223.6m - - - - - - - - - - d 3 49996.96m 2

2

d 4 282.84m - - - - - - - - - - d 4 79998.4656m 2

2

d 5 223.6m - - - - - - - - - - d 5 49996.96m 2

2

d 6 316.23m - - - - - - - - - - d 6 100001.4129m 2

g1 g 2

g 5 2 g 6 2

d d

2 2

d5 d6

g

1 2

1 1

2

2

1 2 1 2

d1 d 2 d5 d6

3.5885 10 5

g

8.5003 10 5

g 0.422%

Engr. Izhar Mithal Jiskani 50

SURFACE MINE DESIGN AND PRACTICE

ORE RESERVE ESTIMATION

by Triangular Method

From above figure:

Area of rectangle abcd= x 3 x 1 y 2 y 3

1

ΔA 1 x 2 x 1 y 2 y1

Area of 2

1

ΔA 2 x 3 x 2 y 2 y 3

Area of 2

1

ΔA 3 x 3 x 1 y1 y 3

Area of 2

Area of ΔA Area of abcd - ΔA 1 ΔA 2 ΔA 3

x 3 x 1 y 2 y 1

1

x 3 x 1 y 2 y 3 x 3 x 2 y 2 y 3 1

2

x 3 x 1 y 1 y 3

Example:

Calculate the above of ΔA by using ore reserve estimation:

Easting (x)m Northing (y)m

1100 1200

1500 1200

1100 800

Solution:-

Let

Engr. Izhar Mithal Jiskani 51

SURFACE MINE DESIGN AND PRACTICE

x 1 1100 m, y1 1200m

x 2 1500m, y 2 1200m

x 3 1100 m, y 3 800m From given table.

And we know that;

1 x 3 x 1 y 2 y 3 x 3 x 2

A x 3 x 1 y 2 y 3

2 y 2 y 3 x 3 x 1 y 1 y 3

1 1100 1100 1200 1200 1100 1500

A 1100 1100 1200 800

2 1200 8001100 1100 1200 800

1

0 0 16000 0

2

1

160000

2

A 80,000m 2

OR

1

ΔA bh

2

1

400 400

2

1 160000

2

ΔA 80,000m 2

Engr. Izhar Mithal Jiskani 52

SURFACE MINE DESIGN AND PRACTICE

Example:

Calculate the ore reserves in area, as shown in following figure. Density of the ore is

given as 2.5 tons/m3

Solution:-

As we know that:

ΔA Area of abcd - ΔA 1 ΔA 2 ΔA 3

500 700 1 700 200 1 400 300 1 500 300

2 2 2

350000 205000

ΔA 145000m 2

C1 C 2 C 3

Average thickness of ore = 3

3 5 4 12

t av: 4m

2 3

t av: 4m

Vol: of ore in Triangular area= ΔA t av:

Vol. of ore = 145000×4m

Vol. of ore = 580000m3.

;. Ore reserves = 580000×2.5

Ore reserves = 1450000

Engr. Izhar Mithal Jiskani 53

SURFACE MINE DESIGN AND PRACTICE

Calculation Of Thickness Of Ore In A Drill Hole

Length of “t” Grade (%) Length × grade

ore body (m) “g” (t×g)

t 1 0.6 g 1 0.59 t 1g 1

t 2 1.4 g 2 0.48 t 2g 2

t 3 1.4 g 3 0.6 t 3g 3

t 4 1.4 g 4 0.56 t 4g 4

t 5 1.3 g 5 0.32 t 5g 5

Σ tigi

i 1

n

- - - - - - - (1)

Σ ti

:. Average thickness = (tav:) i 1

t av:

0.6 0.59 1.4 0.48 1.4 0.6 1.4 0.56 1.3 0.32

0.6 1.4 1.4 1.4 1.3

3.066

t av:

6.1

t av: 0.503m

Calculation Of Reserves Using Weight Age Average

Thickness:

Calculate the reserves of ore shown in above fig: having a density of 1.35 tons/m 3 by

using the weight age average thickness, when; t1=40m, t2=60m, t3=50m

Solution: the weight age average thickness is calculated as:

Engr. Izhar Mithal Jiskani 54

SURFACE MINE DESIGN AND PRACTICE

t 1 θ1 t 2 θ 2 t 3 θ 3

60

tw (1)

3

from above fig :

800 300

φ tan 1 tan 2.5

1

400 200

68.2 0

500 300

φ1 tan 1 tan 0.5

1

600 400

φ1 26.56 0

800 500

φ 2 tan 1 tan 1.5

1

600 400

φ 2 56.31 0

θ1 φ φ1 68.2 0 26.56 0 41.64 0

θ 3 φ1 φ 2 26.56 0 56.310 82.87 0

θ 2 180 0 φ1 φ 3 180 0 41.64 0 82.87 0

θ1 55.49 0

Substitute the values of t1, t2, t3, θ 1, θ 2, θ 3 in equation 1

(40 x 41.64) (60 x 55.49) (50 x 82.87)

60

tw

3

9138.5

tw 60

3

152.3

tw

3

tw = 50.77 m

∆ A = Area of abcd – [∆A1, ∆A2, ∆A3]

∆ A = (400 x 500) – [ (½ x 500 x 200) + (½ x 300 x 200) + (½ x 400 x 200) ]

∆ A = 200000 – 120000

∆ A = 80000 m2

Volume of A = A x tw = 80000 x 50.77

:. Volume of A = 4061600 m3

:. Ore reserves = Volume x density

= 4061600 m3 x 1.35 t/m3

= 5483160 tons

Engr. Izhar Mithal Jiskani 55

SURFACE MINE DESIGN AND PRACTICE

Example:

In a level terrain, determine the max height of high wall that dragline can strip without re-

handling, using the following data:

Dumping radius =(Rd)= 47m,

Outside diameter of tub = (Et) = 11m,

Spoil angle of repose ( ) =370

High wall angle = ( φ ) = 8740

Pit width =(w) = 15m

Sean thickness = (T) = 1.22 m

Swelling factor = (Ps) = 30 %

Solution:

As we know that

Rd = Re + So

.: Re = Rd – So -------> 1 and So = 0.75 Et.

Re = 47 – (0.75 Et)

Re = 47 – (0.75 ×11)

Re = 47 – 8.25

Re = 38.75 m

Ps W

Re Hcotφ cotθ H1 tanθ T

100 4

30 15 0

38.75 Hcot74 0 cot37 0 H1 tan37 1.22

100 4

0.287H 1.3271.3H 2.825 1.22

0.287H 1.7251H 3.748 1.619

38.75 2.0121H 2.13

2.012H 38.75 2.13

36.62

H

2.012

H 18.2

Engr. Izhar Mithal Jiskani 56

You might also like

- Blasting Technology - Blast DesignDocument36 pagesBlasting Technology - Blast DesignBenjamin Amoah100% (1)

- Surface Firing PatternsDocument6 pagesSurface Firing PatternsTamani Moyo0% (1)

- Surpac Quick Start Tutorial 2Document56 pagesSurpac Quick Start Tutorial 2dimitrijeilic75% (4)

- Electrical Measurements, Types of Electrical Instruments & Different Types of Voltmeter and AmeterDocument9 pagesElectrical Measurements, Types of Electrical Instruments & Different Types of Voltmeter and AmeterIzhar Jiskani50% (2)

- OpenPitOpt PDFDocument150 pagesOpenPitOpt PDFJose JoelNo ratings yet

- Geology, Its Main Branches, Relationship With Other Sciences & Role in Mining EngineeringDocument5 pagesGeology, Its Main Branches, Relationship With Other Sciences & Role in Mining EngineeringIzhar Jiskani57% (7)

- Opencast Mining Lec 1Document36 pagesOpencast Mining Lec 1Gaurav SinhaNo ratings yet

- Blasting PDFDocument76 pagesBlasting PDFJuan Pablo Romero Rivera78% (9)

- Resource EstimationDocument32 pagesResource EstimationRohit KumarNo ratings yet

- Underground Mining Methods Choice of MethodsDocument8 pagesUnderground Mining Methods Choice of MethodsSheshu BabuNo ratings yet

- Selection and Design of Blasting Techniques For SelectiveDocument8 pagesSelection and Design of Blasting Techniques For SelectiveMostafaOmidNo ratings yet

- Surface Mine Design and PracticeDocument60 pagesSurface Mine Design and PracticeUriel Placido Jacho Pacha100% (1)

- Lecture 7 2010 Open Pit Planning and DesignDocument38 pagesLecture 7 2010 Open Pit Planning and DesignFelichi Dacumos BalajadiaNo ratings yet

- Surface MiningDocument39 pagesSurface MiningShiva Aeronautical Engr100% (4)

- Thesis - Stope Mine OptimisationDocument100 pagesThesis - Stope Mine OptimisationCarlos A. Espinoza MNo ratings yet

- Mining MethodsDocument56 pagesMining MethodsRakesh Roushan100% (1)

- Underhand Stoping-SpDocument14 pagesUnderhand Stoping-SpNARESH CHOUDHARYNo ratings yet

- Opencast Mining MethodDocument7 pagesOpencast Mining MethodjaypadoleNo ratings yet

- Mining MethodsDocument78 pagesMining Methodsفردوس سليمانNo ratings yet

- Mine Planning & DesignDocument89 pagesMine Planning & DesignVenkateshwer Reddy AV88% (16)

- Best Practice in Mine PlanningDocument7 pagesBest Practice in Mine PlanningAnonymous nz1HcVTNo ratings yet

- Reserve EstimationDocument26 pagesReserve EstimationSanjay Singh75% (4)

- PWC Basics of Mining 6 Som A Future of MiningDocument45 pagesPWC Basics of Mining 6 Som A Future of MiningRobert Villanueva Sedano100% (1)

- 2012 Surface Mining MethodDocument67 pages2012 Surface Mining Methodgirmay kasayeNo ratings yet

- Igneous Rocks Classification, Composition, Formation, Texture & Uses)Document3 pagesIgneous Rocks Classification, Composition, Formation, Texture & Uses)Izhar JiskaniNo ratings yet

- Ultimate Pit Design Using Surpac: Mentored ByDocument40 pagesUltimate Pit Design Using Surpac: Mentored ByjunaifaNo ratings yet

- StrippingRatios and PitLimitsDocument12 pagesStrippingRatios and PitLimitsmekuchta100% (1)

- Mine Design GuidelinesDocument7 pagesMine Design GuidelinesShaiter Naseff100% (1)

- Olya - Radost - Baby - Bear - Eng Dukke Bamse SødDocument34 pagesOlya - Radost - Baby - Bear - Eng Dukke Bamse Sødnettegregersen100% (1)

- Fundamental of Mine Planning and DesignDocument51 pagesFundamental of Mine Planning and DesignKotesh DharavathNo ratings yet

- Open Pit DesignDocument17 pagesOpen Pit Designyogesh shindeNo ratings yet

- Drill and Blast Performance Evaluation ADocument8 pagesDrill and Blast Performance Evaluation AAUGEN AMBROSENo ratings yet

- Surface Mining MethodsDocument15 pagesSurface Mining MethodsMatthew Butler50% (2)

- Stages in The Life of A MineDocument5 pagesStages in The Life of A MineIzhar Jiskani86% (7)

- Open Pit Mine Planning and Design (MN)Document3 pagesOpen Pit Mine Planning and Design (MN)Izzan Ferdi Andrian100% (2)

- Underground Ring Design PDFDocument49 pagesUnderground Ring Design PDFАнхбаяр БатболдNo ratings yet

- Grade Estimation Using SurpacDocument58 pagesGrade Estimation Using SurpacBoukaré OuédraogoNo ratings yet

- Determination of A Mining Cutoff Grade Strategy Based On An Iterative Factor PDFDocument5 pagesDetermination of A Mining Cutoff Grade Strategy Based On An Iterative Factor PDFRenzo MurilloNo ratings yet

- Geostats ENG 042111 PDFDocument387 pagesGeostats ENG 042111 PDFOmar RamírezNo ratings yet

- Project On Mutual Fund Akhilesh MishraDocument142 pagesProject On Mutual Fund Akhilesh Mishramishra.akhilesh459737983% (262)

- Open Pit MiningDocument13 pagesOpen Pit MiningIndy Pao Tafur60% (5)

- Room-And-pillar Panel Design MethodDocument6 pagesRoom-And-pillar Panel Design MethodDaniel SantanaNo ratings yet

- C O - P M: Anadian PEN IT InesDocument62 pagesC O - P M: Anadian PEN IT InesJorge Gastelum Piña100% (5)

- Mining Method NotesDocument48 pagesMining Method NotesSimba100% (1)

- Coal Mining MethodsDocument10 pagesCoal Mining MethodsFarhan AliNo ratings yet

- Underground MiningDocument97 pagesUnderground Miningtamanimo100% (3)

- Mine VentilationDocument3 pagesMine VentilationIzhar Jiskani100% (1)

- Surface Mining and Design PDFDocument44 pagesSurface Mining and Design PDFMartin JanuaryNo ratings yet

- Education Mine Planning and Automation Docs48Document54 pagesEducation Mine Planning and Automation Docs48elangelang99No ratings yet

- An Integrated Mine PlanDocument8 pagesAn Integrated Mine PlanVachist WangelNo ratings yet

- Ore Dilution Vs Mine To MillDocument9 pagesOre Dilution Vs Mine To MillMiguel Torres100% (1)

- MINE3230 Mine Planning Sample ExamDocument9 pagesMINE3230 Mine Planning Sample Exam2685866100% (3)

- Libro B2.2Document106 pagesLibro B2.2Passport Colombia100% (1)

- NIETO-Mining Cutoff Grade Strategy To Optimise NPVDocument7 pagesNIETO-Mining Cutoff Grade Strategy To Optimise NPVOlegario SosaNo ratings yet

- Role of Geology in Mining IndustryDocument2 pagesRole of Geology in Mining IndustryIzhar Jiskani81% (21)

- Ventsim - Deswik İmportDocument11 pagesVentsim - Deswik İmportkemalllNo ratings yet

- The MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDocument1 pageThe MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDiegoAlvarezHuguezNo ratings yet

- GATE 2016 2018 Mining Engineering Question Paper and Answer KeyDocument61 pagesGATE 2016 2018 Mining Engineering Question Paper and Answer KeySantanu Dutta100% (1)

- Blast Design in Surface MinesDocument35 pagesBlast Design in Surface MinesSujib BarmanNo ratings yet

- Importance of Mine Surveying in Mining IndustryDocument3 pagesImportance of Mine Surveying in Mining IndustryIzhar Jiskani88% (16)

- Stripping Ratio ConsiderationsDocument18 pagesStripping Ratio ConsiderationsFranz Diaz100% (2)

- Ultimate Pit DesignDocument20 pagesUltimate Pit DesignRohit KumarNo ratings yet

- Open Pit DesignDocument24 pagesOpen Pit DesignJhon Andrés Toapanta CastellanosNo ratings yet

- Rock BurstDocument2 pagesRock BurstIzhar Jiskani100% (1)

- The Application of Geostatistics in Coal Estimation and Classification Abstract FINALDocument127 pagesThe Application of Geostatistics in Coal Estimation and Classification Abstract FINALAde Prayuda100% (1)

- Types of Mining: Stripping Ratio Mass of Burden/mass of MineralDocument6 pagesTypes of Mining: Stripping Ratio Mass of Burden/mass of MineralHILLARY FRANCIS SHENJERENo ratings yet

- Earth SCIENCEDocument7 pagesEarth SCIENCEJohn Gabriel BuliNo ratings yet

- Dedication This Term Paper Is Dedicated To God Almighty The Author and Finisher of Our FaithDocument10 pagesDedication This Term Paper Is Dedicated To God Almighty The Author and Finisher of Our FaithHorsfall NathanielNo ratings yet

- Lecture 2 Stages in The Life of A Mine, Types of MiningDocument7 pagesLecture 2 Stages in The Life of A Mine, Types of MiningHILLARY FRANCIS SHENJERENo ratings yet

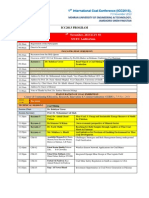

- ICC2013 ProgramDocument5 pagesICC2013 ProgramIzhar JiskaniNo ratings yet

- Lakhra Coal Mine ReportDocument4 pagesLakhra Coal Mine ReportIzhar Jiskani25% (4)

- Formation of Coal & Theories Associated With Coal FormationDocument2 pagesFormation of Coal & Theories Associated With Coal FormationIzhar Jiskani100% (2)

- Coal Mining MethodsDocument2 pagesCoal Mining MethodsIzhar JiskaniNo ratings yet

- Rank of CoalDocument2 pagesRank of CoalIzhar Jiskani0% (1)

- Volcanoes, Its Eruption, Types, Geographical Distribution & ProductsDocument3 pagesVolcanoes, Its Eruption, Types, Geographical Distribution & ProductsIzhar JiskaniNo ratings yet

- Erosion & Agents of ErosionDocument2 pagesErosion & Agents of ErosionIzhar JiskaniNo ratings yet

- Interior of EarthDocument2 pagesInterior of EarthIzhar JiskaniNo ratings yet

- DC Generator, Basic Principle of Operation, Construction & Working PrincipleDocument3 pagesDC Generator, Basic Principle of Operation, Construction & Working PrincipleIzhar Jiskani62% (13)

- Formation of Sedimentary RocksDocument2 pagesFormation of Sedimentary RocksIzhar Jiskani100% (1)

- TransformerDocument2 pagesTransformerIzhar JiskaniNo ratings yet

- RudaliDocument43 pagesRudaliShahruk KhanNo ratings yet

- 1-11-Take A Part Tens To AddDocument1 page1-11-Take A Part Tens To Addapi-338595937No ratings yet

- Super Student PDFDocument68 pagesSuper Student PDFsuperstudents01No ratings yet

- Proyecto ICARO TestCaseDocument20 pagesProyecto ICARO TestCasePol MorenoNo ratings yet

- SL2100 Hardware Manual GE4 1 5Document156 pagesSL2100 Hardware Manual GE4 1 5Javi Katz100% (1)

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Pengaruh Pemenuhan Nutrisi Dan Tingkat Kecemasan Terhadap Pengeluaran Asi Desa Sumber RembangDocument12 pagesPengaruh Pemenuhan Nutrisi Dan Tingkat Kecemasan Terhadap Pengeluaran Asi Desa Sumber RembangZainul MalikNo ratings yet

- ANSYS Advantage V4 I1 2010Document52 pagesANSYS Advantage V4 I1 2010j_c_garcia_d100% (1)

- 3.5 Pressure Drop: ΔP = 8f (L/di)Document2 pages3.5 Pressure Drop: ΔP = 8f (L/di)fadi713No ratings yet

- FARIT THREE CAHYA BIN BUDIMAN ResumeDocument1 pageFARIT THREE CAHYA BIN BUDIMAN ResumeMohammad SufriNo ratings yet

- International Human Resource ManagementDocument18 pagesInternational Human Resource ManagementAmritMohantyNo ratings yet

- Web Design StruchtureDocument7 pagesWeb Design StruchtureCenk Nihat DemirtaşNo ratings yet

- E-Store Project Software Requirements SpecificationDocument14 pagesE-Store Project Software Requirements SpecificationShwetha KulloliNo ratings yet

- Internal Noise - Confined Within The Psychological and Sociological Nature ofDocument12 pagesInternal Noise - Confined Within The Psychological and Sociological Nature ofDianna Lynn MolinaNo ratings yet

- Chathum Dinal Dickkumbura: Visa Expired: 20 Salary Expectation: 4,500 AEDDocument2 pagesChathum Dinal Dickkumbura: Visa Expired: 20 Salary Expectation: 4,500 AEDraoof ahmedNo ratings yet

- Diagnosis For in Vehicle NetworksDocument26 pagesDiagnosis For in Vehicle NetworksSayyedNo ratings yet

- Analysis of Switched-Capacitor Common-Mode Feedback CircuitDocument12 pagesAnalysis of Switched-Capacitor Common-Mode Feedback Circuitjulio perezNo ratings yet

- 683 Illustrated Parts Catalog - BellDocument305 pages683 Illustrated Parts Catalog - BellLuan BothaNo ratings yet

- 7 Pillars of Spill ManagmentDocument1 page7 Pillars of Spill ManagmentAndy Mdl100% (2)

- EncryptionstDocument41 pagesEncryptionstSamer SamaraNo ratings yet

- Basic Course in Biomedical Research - AnnouncementsDocument1 pageBasic Course in Biomedical Research - AnnouncementsTANAY AGARWALNo ratings yet

- Jayabrata Mukherjee Review Paper PDFDocument10 pagesJayabrata Mukherjee Review Paper PDFEshona ChakrabortyNo ratings yet

- Alternator Synchronous Generator - Definition and Types of Alternator - Electrical4uDocument7 pagesAlternator Synchronous Generator - Definition and Types of Alternator - Electrical4uM Kumar MarimuthuNo ratings yet

- Onič, Tomaž - Pinter, Harold-Harold Pinter On International Stages-Peter Lang GMBH, Internationaler Verlag Der Wissenschaften (2014)Document216 pagesOnič, Tomaž - Pinter, Harold-Harold Pinter On International Stages-Peter Lang GMBH, Internationaler Verlag Der Wissenschaften (2014)Renata NemitzNo ratings yet

- TLE TE 10 - Q3 - ICT CSS - Module and ActivityDocument10 pagesTLE TE 10 - Q3 - ICT CSS - Module and Activitypetergomez0119No ratings yet

- Ques 1:-ORIGIN: Rajasthani School of Miniature Painting FlourishedDocument4 pagesQues 1:-ORIGIN: Rajasthani School of Miniature Painting FlourishedLoveleen ChopraNo ratings yet