Professional Documents

Culture Documents

Welded Bevel Seal (AFP-1-401D)

Uploaded by

Im ChinithCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welded Bevel Seal (AFP-1-401D)

Uploaded by

Im ChinithCopyright:

Available Formats

Better Air is Our Business ®

Welded Bevel Seal Frame

Extruded Aluminum Frames

for Gasketed HEPA Filter Installations

The patented Bevel Seal frame is a factory welded, extruded aluminum

frame developed specifically for High Efficiency Particulate Air (HEPA)

filter installations. The modular frames can be quickly bolted together

in any combination. Bevel Seal frames are non-directional and can Two-Stage Gasket Compression Prevents Leakage

be installed with filter access from either the air entering or air leaving

side. Standard Bevel Seal frames accommodate 24" x 24" gasketed Gasket Protection Sealing Integrity Assured

HEPA filters in three thicknesses — 2-3/4", 5-7/8" and 11-1/2". The patented Bevel Seal frame The bevel creates sealing

Frames are available for special size filters. The frames are designed features a two-level sealing integrity by providing a graduated

to permit installation of adjacent filters at 3/4" intervals. This design surface connected by a bevel. compression of the sealing gas-

feature maximizes the number of filters that can be installed in a This causes the filter gasket to ket. The outer edge of the gasket

given space and reduces resistance due to frame extrusions. be compressed in two stages is compressed to a greater

as clamping pressure is applied. degree than the inner portion

In the event excessive clamping of the gasket. Having two levels

Cross Section Top View

pressure is applied, the individ- of gasket compression ensures

Visual Control Clamp

ual cells in the gasket material an effective seal will be achieved.

(Adjust Bolt Head Spring

Flush w/Clamp) can be fractured causing the By preventing damage in the

gasket to relax, allowing leakage. recessed sealing surface area

two-stage compression preserves

Ductwork sealing effectiveness should the

cellular structure on the outer

edge of the gasket be destroyed.

Cell Side Bevel Seal Patented Visual Control Filter Clamps

Frame

(Perimeter HEPA Filter Applications Easy Clamp Installation

Media Pack Extrusion) AAF Visual Control clamps are No special tools are required for

Bevel Seal Frame designed to be used with any proper clamp installation. Just

Gasket Bevel conventional gasketed HEPA tighten the bolt head until it is

filter. Located approximately flush with the clamp face to

Cell Side two feet apart, the calibrated, achieve the prescribed compres-

Recessed Sealing spring-loaded clamps maintain sion. Proper clamping pressure

Surface

up to 100 pounds pressure is created indefinitely by the

against the filter at each clamp- calibrated spring. Single filter

ing point. Four clamps are used clamps are used around the

per filter to assure uniform pres- perimeter of the frame bank.

sure against the gasket. The Double clamps are used along

clamps have a 1-1/2" wide main runners to secure a filter

bearing surface. on either side of the T-Section.

Welded Bevel Seal Frame

Bevel Seal Extrusion Sections Visual Control Filter Clamps

Rugged Construction 2 3/ 4 " - 3 3 / 4" - 4 3 / 4" 5 7/ 8" 111/2"

AstroCel II AstroCel I AstroCel I

HEPA filter installations place

great demands on the holding Yellow Red Red

Single

frames. The frames often span Filter

large areas, support many filters Clamps

and accessories, and must be (100#

2" Spring)

lightweight and easy to install.

The frames must provide a barrier Main Runner, T-Section

to particulate as efficient as the

filters themselves.

Double Blue Silver Silver

Bevel Seal frames are construct-

Filter

ed of 6063T5 alloy aluminum 2" Clamps

extrusions. The channel edge (100#

extrusion at the periphery of Spring)

each frame is compatible for 2"

interfacing with walls, floors,

Perimeter Extrusion

ductwork, and other frames. Perimeter Section — Type H

The filter clamp springs are color coded to assure proper clamping pressure depending

on filter thickness and clamp style.

Dimensions: Bevel Seal Frame Bank

(for 24" x 24" AstroCel HEPA Filters)

12.542'

6 12'-61⁄2"

10.479'

5 10'-53⁄4"

8.417'

4 8'-5"

Section

6.354'

3 6'-41⁄4"

4.292'

2 4'-31⁄2"

NOTE: Filter banks larger than four filters in both the height and

2.229' width will be made in two sections. The overall height or width of

1 2'-2 3⁄4" the assembled bank will be 2” greater than indicated above; i.e.,

6 x 6 bank would be 12’-6-1/2” x 12’-8-1/2”.

2.229' 4.292' 6.354' 8.417' 10.479' 12.542'

2'-23⁄4" 4'-31⁄2" 6'-41⁄4" 8'-5" 10'-53⁄4" 12'-61⁄2"

2"

1 2 3 4 5 6

10300 Ormsby Park Place Suite 600 ISO Certified 9001:2000

Louisville, Kentucky 40223-6169

www.aafintl.com AAF has a policy of continuous product research

and improvement and reserves the right to change

design and specifications without notice.

Better Air is Our Business ® Customer Service 888.AAF.2003

Fax 888.223.6500

©2008 AAF International

AFP-1-401D MAR '08 QG 2M

You might also like

- Durco - G4E Sleeveline - Plug ValvesDocument12 pagesDurco - G4E Sleeveline - Plug ValvesOleg ShkolnikNo ratings yet

- Maintenance-free knife gate valveDocument12 pagesMaintenance-free knife gate valvecvfNo ratings yet

- Control+Valve Ecotrol Catalog V1R2+19Jan15 Rev2.CompressedDocument20 pagesControl+Valve Ecotrol Catalog V1R2+19Jan15 Rev2.CompressedLionell LogeshNo ratings yet

- BMV Brochure 4 Page Web - 2019Document4 pagesBMV Brochure 4 Page Web - 2019Velibor StokicNo ratings yet

- FMC Manifolds Ball - ValveDocument4 pagesFMC Manifolds Ball - Valveklich77No ratings yet

- plp_energycat-sec11distoverties-2014Document69 pagesplp_energycat-sec11distoverties-2014Vincent BachellerieNo ratings yet

- BFV WeightDocument8 pagesBFV WeightBhargav PatelNo ratings yet

- Damper-Shutter-Accessories-Product-Guide-1Document26 pagesDamper-Shutter-Accessories-Product-Guide-1Omar KhaterNo ratings yet

- FCC Series 20 High Performance Butterfly ValvesDocument18 pagesFCC Series 20 High Performance Butterfly ValvesBASKARNo ratings yet

- Grooved FittingsDocument2 pagesGrooved FittingsSSS888No ratings yet

- 2008 Viper ACR 1stDocument28 pages2008 Viper ACR 1stLuis YONo ratings yet

- Fibre Optic Inline Closure UCAO 4-9 - P 12.nov.2022Document4 pagesFibre Optic Inline Closure UCAO 4-9 - P 12.nov.2022Catalin DulceataNo ratings yet

- Agrar Ohne PreiseDocument55 pagesAgrar Ohne PreiseBaiuliang BaiuliangNo ratings yet

- Hufcor 633E Cont Hinged F4151EDocument6 pagesHufcor 633E Cont Hinged F4151Edoody.dpujaNo ratings yet

- T - Half Shell Stay Cable Sheaths - enDocument2 pagesT - Half Shell Stay Cable Sheaths - enNaci ÖzsoyNo ratings yet

- Brands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Document8 pagesBrands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Yamil Diaz SantosNo ratings yet

- Diamond Power IR-3Z: Furnace Wall SootblowerDocument4 pagesDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcNo ratings yet

- Catalogo Borboleta RKDocument10 pagesCatalogo Borboleta RKFelipe Ribeiro da CostaNo ratings yet

- Válvulas Concêntricas InterAtiva - InglêsDocument12 pagesVálvulas Concêntricas InterAtiva - Inglêsp7chgzk7h8No ratings yet

- Trunnion Mounted Ball Valves: Flow-TekDocument8 pagesTrunnion Mounted Ball Valves: Flow-TekFrancescoNo ratings yet

- E101 3236 IR 3Z SootblowerDocument4 pagesE101 3236 IR 3Z SootblowerKartika SuryawanNo ratings yet

- PerfectPleat SC M8 - Prod - Mark - SHT - AFP 1 202C NewDocument2 pagesPerfectPleat SC M8 - Prod - Mark - SHT - AFP 1 202C NewRonald SalasNo ratings yet

- Dresser Masoneilan Camflex II 35002 Series Rotary Control Valves 01 2018 PDFDocument20 pagesDresser Masoneilan Camflex II 35002 Series Rotary Control Valves 01 2018 PDFLeyston CaicedoNo ratings yet

- Trunnion Mounted Ball Valves: Flow-TekDocument8 pagesTrunnion Mounted Ball Valves: Flow-TekJuan RodriguezNo ratings yet

- Acv 12Document2 pagesAcv 12Ali BabasidiNo ratings yet

- Grid Ceiling Construction GuidanceDocument2 pagesGrid Ceiling Construction GuidancerahuljoagNo ratings yet

- BSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)Document8 pagesBSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)LudiNo ratings yet

- Manifull Control de FlujoDocument4 pagesManifull Control de FlujoGuillermo de la Fuente SantiagoNo ratings yet

- Astm D5417-16Document3 pagesAstm D5417-16Sandra LopesNo ratings yet

- Bypass Blow Valve: Reliable TightDocument2 pagesBypass Blow Valve: Reliable TightAlejo ObregonNo ratings yet

- Keystone Figure 990 and 920 Resilient Seated Butterfly ValvesDocument12 pagesKeystone Figure 990 and 920 Resilient Seated Butterfly ValvesMohd Khairi Mohd NorzianNo ratings yet

- Series Camflex II Rotary Valve Spec Data Gea19376bDocument20 pagesSeries Camflex II Rotary Valve Spec Data Gea19376bPauloNo ratings yet

- SETFt RIP Transformer Outdoor BushingDocument12 pagesSETFt RIP Transformer Outdoor Bushingp m yadavNo ratings yet

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37Document16 pagesKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37el_apache10No ratings yet

- DelVal Series 4 TOBV (Imperial)Document8 pagesDelVal Series 4 TOBV (Imperial)chavasan1No ratings yet

- Bus Insulation and Wildlife Protection Products IndexDocument1 pageBus Insulation and Wildlife Protection Products Indexjorge_moralesmNo ratings yet

- Control Chokes BR PDFDocument16 pagesControl Chokes BR PDFJorge EduardoNo ratings yet

- ALTAIR029 Oil&Gas Industry Brochure ParkerDocument12 pagesALTAIR029 Oil&Gas Industry Brochure Parkerkristian08No ratings yet

- TDS Australia Senatel PowersplitDocument4 pagesTDS Australia Senatel PowersplitFlávia GomesNo ratings yet

- DB 100Document3 pagesDB 100Jaime Valenzuela MarchantNo ratings yet

- Hufcor 632 Paired F4149FDocument6 pagesHufcor 632 Paired F4149Fdoody.dpujaNo ratings yet

- GeoconDocument1 pageGeoconhugoq21hugoNo ratings yet

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37 - IsoDocument18 pagesKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37 - IsoktexNo ratings yet

- Ecoline User Guide 25-300Document8 pagesEcoline User Guide 25-300eduardo roqueNo ratings yet

- Belt RipDocument2 pagesBelt RipChristian Alberto DávilaNo ratings yet

- Inclinometer Casing DatasheetDocument4 pagesInclinometer Casing Datasheetapi-37060950% (1)

- Diaphragm Valve D100Document10 pagesDiaphragm Valve D100Mohd Khairi Mohd Norzian0% (1)

- Figure 990-920 KeystoneDocument12 pagesFigure 990-920 KeystonesiskaNo ratings yet

- SalisburyDocument6 pagesSalisburyjorge_moralesmNo ratings yet

- Plunger Tips - Amp: PurposeDocument2 pagesPlunger Tips - Amp: PurposeAlson LeeNo ratings yet

- Aqualine Liquid FilterDocument2 pagesAqualine Liquid FilterApril LiantoNo ratings yet

- Band-It: Tools and Tool Kits For Reliable Shield TerminationDocument5 pagesBand-It: Tools and Tool Kits For Reliable Shield TerminationPabloNo ratings yet

- Collectors: Water Treatment & Chemical ProcessingDocument7 pagesCollectors: Water Treatment & Chemical ProcessingMagin Idelfonso TorreblancaNo ratings yet

- Cema Components-Handbook - Low PDFDocument44 pagesCema Components-Handbook - Low PDFGM HerbalsNo ratings yet

- Ball Valves - 1523Document6 pagesBall Valves - 1523devil3300No ratings yet

- AVK Wastewater Treatment BrochureDocument24 pagesAVK Wastewater Treatment Brochureفاعل الخيرNo ratings yet

- Henghe Electrical Cutout-FuseDocument7 pagesHenghe Electrical Cutout-Fusejack wuNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Contact Lens Design Tables: Tables for the Determination of Surface Radii of Curvature of Hard Contact Lenses to Give a Required Axial Edge LiftFrom EverandContact Lens Design Tables: Tables for the Determination of Surface Radii of Curvature of Hard Contact Lenses to Give a Required Axial Edge LiftNo ratings yet

- Quotation of PVC-U Drainage Pipe Sell3 Final2Document5 pagesQuotation of PVC-U Drainage Pipe Sell3 Final2Im ChinithNo ratings yet

- Test Report OD63mm PN12.5 PE100Document6 pagesTest Report OD63mm PN12.5 PE100Im ChinithNo ratings yet

- Rifeng Project References2020 压缩版Document38 pagesRifeng Project References2020 压缩版Im ChinithNo ratings yet

- Certificated 1507-065 For 12-PPWSA-15Document2 pagesCertificated 1507-065 For 12-PPWSA-15Im ChinithNo ratings yet

- Bodycote SCG - H1000PCDocument1 pageBodycote SCG - H1000PCIm ChinithNo ratings yet

- Quotation of PVC-U Drainage Pipe Sell3 FinalDocument3 pagesQuotation of PVC-U Drainage Pipe Sell3 FinalIm ChinithNo ratings yet

- LESSO PVC-U Drainage Pipe and Fittings 2014.4Document59 pagesLESSO PVC-U Drainage Pipe and Fittings 2014.4Im Chinith100% (2)

- Manufacturing Quality Manual: Cert. No. NQ767/04 Cert. No. TH04/0500Document17 pagesManufacturing Quality Manual: Cert. No. NQ767/04 Cert. No. TH04/0500ChhomNo ratings yet

- Pre FilterDocument8 pagesPre FilterIm ChinithNo ratings yet

- PEX Plumbing SystemDocument4 pagesPEX Plumbing SystemIm ChinithNo ratings yet

- Rifeng PP R System EmailDocument18 pagesRifeng PP R System EmailIm ChinithNo ratings yet

- Varicel V (AFP-1-258H)Document4 pagesVaricel V (AFP-1-258H)Im ChinithNo ratings yet

- Gas Piping SystemDocument4 pagesGas Piping SystemIm ChinithNo ratings yet

- ISO15874 by SGS-PPR Pipes & Fittings-RehomeDocument15 pagesISO15874 by SGS-PPR Pipes & Fittings-RehomeIm ChinithNo ratings yet

- PVC Drainage System CatalogueDocument13 pagesPVC Drainage System CatalogueIm ChinithNo ratings yet

- Iso4427 by Sgs-Hdpe Pipes-RehomeDocument4 pagesIso4427 by Sgs-Hdpe Pipes-RehomeIm ChinithNo ratings yet

- Biocel I: Better Air Is Our BusinessDocument2 pagesBiocel I: Better Air Is Our BusinessIm ChinithNo ratings yet

- AAF Air Filter Selection Guide: en enDocument1 pageAAF Air Filter Selection Guide: en enIm ChinithNo ratings yet

- PCXSMT1604B R410A Inv Light Commercial Series Standard PDFDocument16 pagesPCXSMT1604B R410A Inv Light Commercial Series Standard PDFIm ChinithNo ratings yet

- Biocel IaDocument2 pagesBiocel IaIm ChinithNo ratings yet

- PPR WF Technical HandbookDocument60 pagesPPR WF Technical HandbookAhmedMahir100% (2)

- Astrocel I: Better Air Is Our BusinessDocument8 pagesAstrocel I: Better Air Is Our BusinessmohdzamryNo ratings yet

- Wiring Design: 1. GeneralDocument5 pagesWiring Design: 1. GeneralIm ChinithNo ratings yet

- PCXSMT1603A R410A Light Commercial Series StandardDocument28 pagesPCXSMT1603A R410A Light Commercial Series StandardWai Lwin Ko0% (1)

- Home Central Air ConditioningDocument16 pagesHome Central Air ConditioningIm Chinith100% (1)

- Daikin Inverter Sky Air Malay PDFDocument16 pagesDaikin Inverter Sky Air Malay PDFIm ChinithNo ratings yet

- Remote Controller: System OverviewDocument18 pagesRemote Controller: System OverviewIm ChinithNo ratings yet

- Controls: 1. Outline of Application ControlDocument11 pagesControls: 1. Outline of Application ControlIm ChinithNo ratings yet

- Technical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Document56 pagesTechnical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Im Chinith100% (1)

- Technical Support Engineer - JDDocument2 pagesTechnical Support Engineer - JDKshitiz SagarNo ratings yet

- ESP-report 22633 (31-33)Document23 pagesESP-report 22633 (31-33)1322 - Prasad KumbharNo ratings yet

- PD 26904Document3 pagesPD 26904Lam Khê PhạmNo ratings yet

- Excavadora Hidraulica 336eDocument15 pagesExcavadora Hidraulica 336eOscar LosadaNo ratings yet

- Strategi Penguatan Audit Tata Kelola dan Manajemen Resiko TI Start UpDocument7 pagesStrategi Penguatan Audit Tata Kelola dan Manajemen Resiko TI Start UpAndini VatiadyNo ratings yet

- Chapter 1 - Introduction To System AdministrationDocument27 pagesChapter 1 - Introduction To System AdministrationAbdul KilaaNo ratings yet

- Manual IFQ Monitor en Rev 08-2022Document50 pagesManual IFQ Monitor en Rev 08-2022Gerald StiflerNo ratings yet

- Grade 9 - Term 3 Math Rubrics 9aDocument3 pagesGrade 9 - Term 3 Math Rubrics 9aSabahath KhanNo ratings yet

- Ee6602 Embedded Systems LT P C 3 0 0 3Document94 pagesEe6602 Embedded Systems LT P C 3 0 0 3Jebas ManovaNo ratings yet

- Subject: Use of Multi-Core Processors Date: XXX AC No: AC 20-193 Initiated By: AIR-622Document17 pagesSubject: Use of Multi-Core Processors Date: XXX AC No: AC 20-193 Initiated By: AIR-622rdpereir100% (1)

- Online FDP - Civil Engg-VIT ChennaiDocument2 pagesOnline FDP - Civil Engg-VIT ChennaiDharmesh DharmaNo ratings yet

- Data Mining Model For Predicting Student Enrolment PDFDocument8 pagesData Mining Model For Predicting Student Enrolment PDFShuya HideakiNo ratings yet

- Technology and Society Unit 3Document21 pagesTechnology and Society Unit 3me niksyNo ratings yet

- Wireless Po en A1 Unfolded 0758-1029-82 v1500Document1 pageWireless Po en A1 Unfolded 0758-1029-82 v1500Ghulam MujtabaNo ratings yet

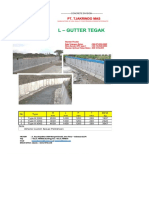

- Brosur L-Gutter TJMDocument4 pagesBrosur L-Gutter TJMPandu HarisurawanNo ratings yet

- IS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Document1 pageIS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Deputy Executive Engineeer RWS & S Nrpm100% (2)

- LogDocument823 pagesLogVõ Hoàng Như PhúcNo ratings yet

- OS Chapter 3Document52 pagesOS Chapter 3Afza FatimaNo ratings yet

- Introduction To MultimediaDocument217 pagesIntroduction To MultimediaMajestyNo ratings yet

- SSP 370 Crafter Electrical SystemDocument84 pagesSSP 370 Crafter Electrical SystemJavier GarciaNo ratings yet

- Design and Performance of Multi-Hull Ships and BoatsDocument3 pagesDesign and Performance of Multi-Hull Ships and BoatsAndrés VillarNo ratings yet

- Booked Train Ticket Confirmation for 15205 CHITRAKOOT EXPDocument1 pageBooked Train Ticket Confirmation for 15205 CHITRAKOOT EXPMohd Kousar RazaNo ratings yet

- 2016 - 07 - 05 Com-Sea - 0 - 0Document232 pages2016 - 07 - 05 Com-Sea - 0 - 0Satyamraju PNo ratings yet

- C-11, C-13 Dissassembly - Assembly 2006 PDFDocument80 pagesC-11, C-13 Dissassembly - Assembly 2006 PDFAhmer Camdzic100% (2)

- Hotel Property Management System SRSDocument17 pagesHotel Property Management System SRSUmair HassanNo ratings yet

- Sem 5 and 6 BSC Computer ScienceDocument5 pagesSem 5 and 6 BSC Computer ScienceKalyani ChilukuriNo ratings yet

- Practical Training Report Content Sample 3 - KTacDocument13 pagesPractical Training Report Content Sample 3 - KTacauni fildzah0% (1)

- Unit4: Adapted Collider (LHC) Is The Largest Acce Erator and Collides Particle Beams On Questions ofDocument2 pagesUnit4: Adapted Collider (LHC) Is The Largest Acce Erator and Collides Particle Beams On Questions ofThắm NguyễnNo ratings yet

- Array List Example Storing Student ObjectsDocument3 pagesArray List Example Storing Student ObjectsNurul AinniNo ratings yet

- RMC 150 DatasheetDocument20 pagesRMC 150 DatasheetIthanLeonardoNo ratings yet