Professional Documents

Culture Documents

Central Sterile Supply Services Policy KKM PDF

Uploaded by

Gerald TalledoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Central Sterile Supply Services Policy KKM PDF

Uploaded by

Gerald TalledoCopyright:

Available Formats

CENTRAL STERILE SUPPLY

SERVICES POLICY

MEDICAL DEVELOPMENT DIVISION

MINISTRY OF HEALTH MALAYSIA

Central Sterile Supply Services Policy 1

This policy was developed by the Clinical Support Services Unit,

Medical Development Services Section of Medical Development

Division and the Drafting Committee of Operational Policy of Central

Sterile Services Department.

Published in August 2018.

A catalogue record of this document is available from Library and

Resource Unit, Institute for Medical Research, Ministry of Health

Malaysia

MOH/P/PAK/336.17(BP)e ISBN 978-967-0399-72-0

All copyrights reserved

2 Central Sterile Supply Services Policy

ACKNOWLEDGEMENT

Medical Development Division would like to acknowledge the

contributions of the following groups and individuals toward the

development of this document;

An appreciation to Dato’ Dr Hj. Azman bin Hj. Abu Bakar, Deputy

Director General of Health (Medical) for his endless support in

developing this policy.

Matron Hjh Mek binti Jusoh and the Drafting Committee on

Operational Policy of CSSU for their dedication and continuing

support for ensuring that the policy is materialized.

Thanks to others who are directly or indirectly involved in formulating

this policy.

Central Sterile Supply Services Policy 3

CONTENT

PREFACE/FOREWORD

Deputy Director General of Health (Medical) ii

Head of Central Sterile Services unit (CSSU) iii

THE ARTICLES 2

1 INTRODUCTION 2

2 OBJECTIVE 2

3 GENERAL POLICY 2

3.1 Traffic Control 2

3.2 Food and Smoking 3

3.3 Health and Personal Hygiene 4

3.4 Dress Code 5

3.5 CSSU Space and Environment 10

3.6 Safety 12

3.7 Maintenance 14

4 POLICY ON DECONTAMINATION 14

4.1 Objectives 14

4.2 Infrastructure 15

4.3 Equipment in Decontamination Zone 18

4.4 Size and Number of Washer Disinfector 18

4.5 Personnel 19

4.6 Receiving and Handling 19

4.7 Inspection, Repair and Ongoing 20

Maintenance

4.8 Sorting of Instrument 21

4.9 Method of Cleaning 21

4.10 Chemical Disinfection 21

4.11 Porter Services 21

4.12 Counter Services 22

5 POLICY ON PACKAGING 22

5.1 Objectives 22

5.2 Physical Set Up 22

5.3 General Consideration 23

4 Central Sterile Supply Services Policy

6 POLICY ON STERILIZATION 23

6.1 Objective 23

6.2 Purchasing, Commissioning and 24

Maintenance

6.3 Load Monitoring 25

6.4 Efficiency Tests for Sterilization 25

6.5 Malfunction Sterilizer 26

6.6 Record Keeping Sterilizer 27

6.7 Cleaning the Sterilizer 27

6.8 Steam Sterilizer Safety 27

6.9 Ethylene Oxide Sterilization Safety

28

7 POLICY ON STORAGE OF STERILE PRODUCTS 29

7.1 Objectives 29

7.2 Storage and Handling 29

8 POLICY ON TRANSPORTATION AND 30

DISTRIBUTION OF STERILE PRODUCTS

8.1 Objective 30

8.2 General Consideration 30

9 POLICY ON STERILIZATION OF IMPLANTABLE 30

ITEMS

9.1 Objectives 30

9.2 General Consideration 30

10 POLICY ON SHELF LIFE 31

11 POLICY ON PRODUCT RECALL 32

11.1 Objectives 32

11.2 General Consideration 32

12 POLICY ON SINGLE USE ITEMS 33

13 POLICY ON NON-FUNCTIONAL / LOST 33

INSTRUMENTS

14 POLICY ON INCOMPLETE PROCEDURE SETS 33

15 POLICY ON BIOHAZARD CASES 33

16 POLICY ON LOANER INSTRUMENTATION 34

Central Sterile Supply Services Policy 5

17 REFERENCES 35

18 DRAFTING COMMITTEE FOR CENTRAL STERILE 39

SUPPLY SERVICES POLICY

6 Central Sterile Supply Services Policy

PREFACE /

FOREWARD

Central Sterile Supply Services Policy 7

PREFACE

I would like to begin with praise to Allah SWT

for blessing us with wisdom and strength in

completing the Central Sterile Supply Services

Policy.

Central Supply Services Unit (CSSU) is a crucial

part of Clinical Support Service. Despite being

overshadowed by other clinical services,

its presence is indispensible in the Ministry of

Health’s visions to combat the rising incidence

of hospital acquired infections.

CSSU ensures the standardized method of process for supplying sterile

instruments and materials under strict quality control, henceforth

enabling the clinicians at the forefront to focus on the care and safety

of our patients. This policy is written beyond the process and storage

of clinical equipments, but also to armour the CSSU personnel when

dealing with hazardous and infectious wastes.

In recent decades, Malaysian healthcare system too is facing the

effect of global inflations in healthcare costs. Additionally, new and

improved clinical equipment, processes and practices are constantly

evolving, and it is our duty as a care provider to be cognizant with

the latest medical advancement. This is aligned with ministry’s vision

to provide highly efficient, cost-effective, innovative, equitable and

technologically-appropriate healthcare system.

This new Central Sterile Unit Standard Operational Policy is produced

with endless commitments from the committee members and

stakeholders in addressing concerns relating to issues of efficiency

and quality of sterilization service. Therefore, I would like to offer the

committee the highest commendation for embarking such initiatives.

My hope along with the updated guideline is that, CSSU will continue

providing the best care to our patients, as well placing the health

and safety of our personnel at the foremost importance.

Dato’ Dr Hj Azman bin Hj Abu Bakar

Deputy Director General of Health (Medical)

Ministry of Health

ii Central Sterile Supply Services Policy

FOREWARD

First and foremost, I would like to offer my

gratitude to the Medical Development Division

for giving the Central Sterile Services Unit an

opportunity in developing this policy.

The healthcare professionals responsible

for sterilization and disinfection of reusable

medical devices are confronted with ever

increasing range of challenges.

Clinical sterile items must be delivered in

timely and cost-effective manner. Adding on to this challenge, the

instrumentations to accomplish sterilization and monitoring standards

have become increasingly sophisticated.

The policies must therefore be in place and implemented to ensure

the safety of healthcare personnel and environment. This policy is

published to guide CSSU operators within the mandated regulations

and voluntary guidelines. It is my sincere hope that all healthcare

workers involved find this booklet informative, beneficial and

invaluable in performing their daily operations effectively.

It is a concise and applicable tool which can be useful for orientation,

training and instructional programmes in healthcare facilities as well

as educational institutions.

Finally, with much pleasure, I present to you the Ministry of Health’s

Central Sterile Supply Services Policy.

Matron Hjh Mek binti Hj Jusoh

Head of Service of CSSU

Ministry of Health

Central Sterile Supply Services Policy iii

iii Central Sterile Supply Services Policy

THE ARTICLES

Central Sterile Supply Services Policy 1

1. INTRODUCTION

Central Sterile Services Unit (CSSU) is an integrated service in

hospitals that performs sterilization and other actions on medical

devices, equipment and consumables. This unit ensures safe

management of decontamination services in the healthcare

through safe, efficient, effective and reliable systems.

This Policy of CSSU is an introductory text developed to provide

guidance and reference for safety of patients and health care

workers. It highlights procedures pertaining to the processes of

decontamination, cleaning, assembly, packaging, sterilization,

storage and distribution of sterile products.

2. OBJECTIVE

The purpose of this document is to provide a framework to

enable the clinical and non-clinical department to understand

the operational and management of CSSU service.

3. GENERAL POLICY

3.1 Traffic Control

3.1.1 Traffic Control shall be strictly enforced in

CSSU.

3.1.2 All doors opening into the main corridor

are to remain closed at all times.

2 Central Sterile Supply Services Policy

3.1.3 The door at the main entrance is the only

door used to enter the CSSU.

3.1.4 Only CSSU personnel are allowed to enter

the unit.

3.1.5 Other personnel that require entry into CSSU

e.g. engineers, technicians, support service

staffs, physicians and administrative

personnel must apply Personal Protective

Equipment (PPE) before being allowed to

enter the Unit.

3.1.6 Limited entry by staff and visitors to the Unit.

3.2 Food and Smoking

3.2.1 Food and beverages are only allowed at the

pantry and shall be restricted from all other areas.

3.2.2 Cooking shall not be allowed.

3.2.3 NO SMOKING in CSSU.

Central Sterile Supply Services Policy 3

3.3 Health and Personal Hygiene

3.3.1 Personal hygiene shall be adhered to and

communicated to all employees:

i. Hair, body and nails shall be cleaned at all

times.

ii. Neither nail polish nor artificial nails shall be

worn.

iii. Fingernails shall be kept short and clean.

3.3.2 All personnel working in CSSU shall be free

from skin diseases, infectious diseases, mental

illness and physical handicaps.

3.3.3 CSSU clinical attire or other garments

that become soiled or wet shall be changed

immediately.

3.3.4 Hair and goatee/beard except eyebrows and

eyelashes shall be completely covered.

3.3.5 Jewellery and wrist watches shall not be

worn.

4 Central Sterile Supply Services Policy

3.4 Dress Code

3.4.1 All personnel working in CSSU shall wear the

CSSU Clinical Attire and change upon leaving.

(Refer Figure 1)

Figure 1: CSSU Clinical Attire

3.4.2 Shoes/clogs worn in the Unit shall be

cleaned, non- skid soles and sturdy.

3.4.3 Visitors entering CSSU shall adhere to CSSU

clinical attire.

3.4.4 Attire shall be changed daily or as needed.

Central Sterile Supply Services Policy 5

3.4.5 The following dress code applies to all

personnel working in the CSSU:

3.4.5.1 Collection (Refer Figure 2)

i. Personnel handling contaminated

medical devices during collection

shall wear:

• Head covers / Surgical cap

• Mask

• Long sleeved apron/long

sleeved water repellent gown

• Rubber Gloves

• Shoes

Figure 2: Collection Dress Code

6 Central Sterile Supply Services Policy

3.4.5.2 Decontamination Zone

(Refer Figure 3)

i. Appropriate PPE should be

worn:

• Long sleeved gowns which shall

be impervious and disposable

• Elbow length latex glove

• Mask

• Protective eye covering / visor

shield

• Boots

ii. The attire shall be removed and

disposed off in the proper

receptacle before leaving.

iii. Head covers / surgical cap and

boots to be changed daily and

as needed.

iv. Boots shall be removed when

leaving the zone.

v. Cover gown shall be backless

and non-permeable.

Central Sterile Supply Services Policy 7

Figure 3: Decontamination Zone Dress Code

3.4.5.3 Packaging Zone (Refer Figure 1)

i.

Personnel working in the

packaging zone shall wear

CSSU clinical attire.

ii.

Personnel working with soft

dressing and linen preparation

shall wear mask.

3.4.5.4 Sterilization Zone (Refer Figure 4)

i. PPE shall be worn by personnel

handling ‘HOT’ medical devices

from the autoclave.

8 Central Sterile Supply Services Policy

ii. Elbow length leather gloves shall

be used during loading and

unloading.

iii. Sweater / cardigan shall not be

used.

Figure 4 : Sterilization dress code

3.4.5.5 Distribution Of Sterile Products

i. Personnel handling sterile

products during distribution

shall wear CSSU clinical attire

(Figure 1).

Central Sterile Supply Services Policy 9

3.5 CSSU Space And Environment

3.5.1 All work surfaces in the CSSU shall be cleaned with

approved germicidal disinfectant at the end of

each work shift.

3.5.2 Lockers shall be provided for all personnel working

in the CSSU.

3.5.3 An area shall be designated for CSSU employees to

change their clothing.

3.5.4 Every zone in the CSSU shall be provided with proper

dedicated air exchange rate to promote maximum

removal of foul air/contaminants from the areas.

3.5.5 The pressure differential scheme shall be strictly

designed and employed to ensure the movement

of air from clean to less clean areas.

3.5.6 Temperature within CSSU shall not be more than

23°C. Temperature in the sterile store shall be

maintained between 20°C – 22°C and the humidity

shall be kept at 50% - 60%.

3.5.7 Proper ventilation system at the plant room must be

provided and the temperature inside the plant room

shall not be more than 35°C to prevent damage to

the machine components.

10 Central Sterile Supply Services Policy

3.5.8 The installation of sterilization equipment shall

adhere to the requirement of noise and vibration

limits as stipulated by the Occupational Safety

and Health Department.

3.5.9 Each sterilizer processing area shall have exhaust

ventilation to remove heat, moisture and odor.

3.5.10 The installation of Ethylene Oxide (ETO) machine,

sensing device, positive pressure, local exhaust

ventilation and chamber ventilation shall be

provided.

3.5.11 All sources of contamination shall be properly

diluted and discharged.

3.5.12 Exterior shipments cartons shall not be brought into

sterile supply storage or processing areas.

3.5.13 Exhaust fan shall be provided in soft dressing and

linen preparation area. Use of fans is not allowed.

Central Sterile Supply Services Policy 11

3.6 Safety

3.6.1 All new equipments / machines for the unit shall be

properly tested and commissioned.

3.6.2 CSSU Manager shall be responsible in developing,

supervising and maintaining the safety training of

the unit.

3.6.3 CSSU Manager is responsible for notifying the Safety

Officer of any hazard.

3.6.4 All CSSU employees shall report of any defective

equipment, unsafe conditions or hazards to the

CSSU Manager.

3.6.5 Keep electrical cords clear of passage ways. Do not

use electrical extension cords without consent from

the Engineering Department.

3.6.6 All equipment and supplies shall be properly stored.

Do not store heavy items on top of the shelves.

3.6.7 All personal electrical appliances shall have suitably

star-rated and certified safe to be used by the

Energy Commission.

3.6.8 All electrical appliances shall be inspected by the

Engineering Department before use.

12 Central Sterile Supply Services Policy

3.6.9 Scissors, knives, pins, razor blades and other sharp

instruments shall be safely stored for use.

3.6.10 All heat producing machineries shall be switched

off when not in use.

3.6.11 Immediate notification to the concession company

for any ventilation breakdown or illumination sign

warning.

3.6.12 Only authorized personnel shall operate autoclaves

and other high pressure equipments.

3.6.13 To store all combustible supplies at least 44 cm

height from the ceiling.

3.6.14 First Aid Kit shall be readily available and checked

at all times.

Central Sterile Supply Services Policy 13

3.7 Maintenance

3.7.1 The installation of all machines shall allow adequate

space for the maintenance and repair activities.

3.7.2 The maintenance shall be performed from the

unsterilized side of the machine.

3.7.3 Maintenance activities of equipment shall be

performed by certified personnel.

3.7.4 Only new original parts shall be used to replace

any broken/faulty components. Re-used parts

from other machines shall not be permitted at any

circumstances.

4. POLICY ON DECONTAMINATION

4.1 Objectives

4.1.1 To ensure that all soiled medical devices received

in the Decontamination Zone are processed

according to Standard Operating Procedure and

rendered safe for handling.

4.1.2 To protect staffs and patients from any infection risk

of soiled medical devices and equipment.

4.1.3 To eradicate or significantly reduce the number

of microorganisms on soiled medical devices and

equipment.

14 Central Sterile Supply Services Policy

4.1.4 To adhere to standard of decontamination for

cleaning and disinfecting soiled medical devices

and equipment.

4.1.5 To adhere with the standard requirements needed

to achieve safe environment.

4.1.6 To ensure staffs perform and adhere to their

professional duty of care with regards to providing

a safe environment.

4.2 Infrastructure

4.2.1 Decontamination Zone

4.2.1.1 It shall have adequate and designed

electrical supply, water supply, lighting

and ventilation systems.

4.2.1.2 It shall be supplied with negative pressure

air conditioned with a minimum of 10 air

exchanges per hour.

4.2.1.3 The loading area shall be adequate for

staff and trolley maneuverability.

4.2.1.4 The floor shall be made of heavy duty

materials, anti-slippery, anti-dust in

nature with no water accumulation at

any time.

Central Sterile Supply Services Policy 15

4.2.1.5 Walls shall be painted with bright color

anti-fungal paint.

4.2.1.6 Stainless steel double sinks with hot and

cold water supply shall be available.

4.2.1.7 An outlet for air gun shall be available.

4.2.1.8 The drainage system shall be designed

with proper sizing to prevent back flow,

appropriate material to withstand the

water temperature and proper leveling

to prevent flooding.

4.2.1.9 There shall be an in-built outlet for reverse

osmosis water.

4.2.1.10 Each washer shall have individual pipes

with individual socket outlets.

4.2.1.11 An appropriate number of machines

shall be connected to an essential power

supply. Quality of water supply shall

follow the recommended standards.

4.2.1.12 A cart wash area and trolley bay area

shall be made available.

16 Central Sterile Supply Services Policy

4.2.1.13 Detergent store with exhaust fan and

dedicated stainless steel shelf shall be

available.

4.2.1.14 Separate bathrooms for male and

female staff.

4.2.1.15 The main door shall be an automatic

sliding door.

Central Sterile Supply Services Policy 17

4.3 Equipment In Decontamination Zone

4.3.1 Decontamination room shall be equipped with the

following:-

i. Washer disinfector/ decontaminator with

accessories

ii. Ultrasonic washer

iii. Dryer

iv. Collection trolley

v. Stainless steel mobile workstation

vi. Magnifying lamp.

4.4 Size and Number of Washer Disinfector

4.4.1 Estimated size and number of washer disinfector

varies with the application.

4.4.2 Quantity of washer disinfector required is based on

estimated workload divided by actual work load

per basket per week.

Example:

Total workload : 1400 basket / week

Total actual output : 1600 basket / week

No of washer required : 1400 = 0.875 = 1 unit

1600

18 Central Sterile Supply Services Policy

4.5 Personnel

4.5.1 Team leader in decontamination area shall be

headed by a trained nurse with a minimum of 2

years working experience. All staffs involved with

decontamination procedure shall be trained.

4.5.2 All personnel entering the Decontamination Zone

shall be properly attired. (Refer Figure 2)

4.5.3 All personnel assigned to the Decontamination

Zone shall be strictly confined to the designated

area. If needed, the personnel shall bathe and

change into attire accordingly.

4.6 Receiving and Handling

4.6.1 All medical devices returned to CSSU are

considered contaminated and shall be received in

decontamination area.

4.6.2 Delicate and precision instruments shall be handled

with care to avoid damage.

4.6.3 Returned supplies shall be inspected to ensure all

parts of medical instrument are complete.

4.6.4 Notify CSSU Manager for any missing parts or

instruments received.

Central Sterile Supply Services Policy 19

4.6.5 Malfunctioning instruments shall not be used and

to be kept in a separate place.

4.6.6 Users are responsible to return all instruments

regardless opened or disassembled (if applicable)

prior to cleaning and disinfection.

4.6.7 Any single use items received shall be discarded

and not to be processed.

4.6.8 Gross soil shall be removed at the point of use

where immediate containment, transportation

and cleaning may not be feasible.

4.6.9 Personnel shall wear appropriate PPE and follow

good work-practice when handling contaminated

medical devices.

4.6.10 High Filtration Efficiency (HFE) facemask and eye

protection shall be used for any risk of splash or

aerosols.

4.7 Inspection, Repair and Ongoing Maintenance

4.7.1 Every medical device shall be inspected upon

arrival.

4.7.2 All parts of rigid sterilization container systems shall

be cleaned between each use.

20 Central Sterile Supply Services Policy

4.8 Sorting of Instrument

4.8.1 Contaminated medical devices shall be sorted

and prepared for cleaning.

4.8.2 Non-interchangeable component assemblies shall

be kept together to ensure correct reassembly.

4.9 Method of Cleaning

4.9.1 Cleaning shall be accomplished manually,

mechanically or combination of both methods.

4.9.2 The cleaning method or methods selected shall

be effective, not affecting the functionality of the

device and safety.

4.10 Chemical Disinfection

4.10.1 Select appropriate type of disinfectant and follow

manufacturer instructions.

4.10.2 Protective measures for personnel shall be applied

at all times.

4.11 Porter Services

4.11.1 Used medical devices shall be collected and

transported using suitable containers and trolleys.

4.11.2 The transportation carts / trolleys / containers shall

be cleaned and disinfected after used.

Central Sterile Supply Services Policy 21

4.12 Counter Services

4.12.1 All personnel shall wear CSSU clinical attire (Figure

1) during receiving of soiled medical devices.

4.12.2 Soiled medical devices shall be received in suitable

closed containers at the Decontamination Zone.

5. POLICY ON PACKAGING

5.1 Objectives

5.1.1 To provide guidelines for evaluation, selection and

use of packaging materials for item to be sterilized.

5.1.2 Packaging material shall ensure sterility of package

contents until opened for use.

5.2 Physical Set Up

5.2.1 The room shall be equipped with:

i. Air conditioning to maintain positive

pressure

ii. Sufficient lighting

5.2.2 The floor and wall must be able to withstand

frequent cleaning.

5.2.3 Packing table should be constructed of suitable

material (stainless steel material / epoxy coated)

with attached magnifying lamp.

22 Central Sterile Supply Services Policy

5.2.4 Adjustable packing chair with backrest.

5.3 General Consideration

5.3.1 All wrappers shall be double layered.

5.3.2 Medical devices shall be wrapped completely

and packed to provide aseptic opening.

5.3.3 No package shall be above the maximum size of

30cm x 30cm x 50cm nor should it weight more

than 5.5 kilograms.

5.3.4 Chemical Indicators shall be placed for all sets. The

Internal Indicator shall be examined before use.

6. POLICY ON STERILIZATION

6.1 Objectives

6.1.1 To ensure that all medical devices/surgical

instruments which are introduced into the human

body site, traumatic or operation wound shall be

provided sterile.

6.1.2 Sterilization shall be achieved by means of heat,

steam, chemicals and low temperature sterilizers

used under carefully controlled conditions.

Central Sterile Supply Services Policy 23

6.1.3 Each item being processed shall be traceable by

a batch coding system.

6.2 Purchasing, Commissioning and Maintenance

6.2.1 Sterilizers and associated equipment purchased

shall be in accordance with recognized

International Standards and shall meet user

requirement.

6.2.2 The number of sterilizers required will depends on

the cycle time and the chamber size. The minimum

number of sterilizers required to the workload can

be calculated as below:

Number of sterilizers required = Workload

Capacity

6.2.3 It is mandatory for all type of sterilizers to be certified

under the Occupational Safety and Health Act

(OSHA) before use.

6.2.4 Each autoclave shall have a valid design approval

and a certificate of fitness for operation from the

Department of Safety and Health (DOSH) before it

is handed over to the department.

6.2.5 Operating instructions shall be displayed at sterilizer

sites.

6.2.6 The manufacturer shall provide written instructions

for preventive maintenance of the sterilizer. The

24 Central Sterile Supply Services Policy

maintenance shall be carried out by a qualified

individual. Preventive maintenance and repair

records shall be retained for reference.

6.2.7 Every sterilized item shall have a load control

identification that indicates the sterilizer use, the

cycle or load and the date of sterilization. Its

purpose is to readily retrieve items in the event of

a sterilization failure or recall.

6.3 Load Monitoring

6.3.1 All sterilizing processes shall be monitored and

recorded accordingly.

6.3.2 Notify the Supervisor immediately for any

abnormal result.

6.4 Efficieny Tets for Sterilization

6.4.1 Dummy Run shall be done daily for steam

sterilization.

6.4.2 Leak Test shall be done daily and after major

repair.

6.4.3 Bowie Dick Test shall be tested daily in separate

and special cycles.

Central Sterile Supply Services Policy 25

6.4.4 Chemical Indicator

6.4.4.1 A chemical indicator shall be used in each

package to be sterilized.

6.4.4.2 Sterile products shall not be used if the

interpretation of the external process

monitors suggests inadequate processing.

6.4.5 Biological Monitoring

6.4.5.1 All biological monitors are preassembled

by manufacturer.

6.4.5.2 Biological monitoring shall be done once

a week, each load for any transplant and

after major repair (3 times consecutively

daily) on all steam sterilization loads.

6.4.5.3 Biological monitoring shall be done with

every ethylene oxide load.

6.5 Malfunction Strerilizer

6.5.1 CSSU Supervisor shall notify the engineering

personnel.

6.5.2 A recall system shall be initiated immediately if

biological culture is positive.

6.5.3 Stop using the sterilizer until repair is done and

tested negative for three (3) consecutive biological

cultures.

26 Central Sterile Supply Services Policy

6.6 Record Keeping Sterilizer

6.6.1 A maintenance record in either hardcopy or

electronic format shall be kept for each sterilizer.

6.6.2 The record shall be kept according to the Archive

Act.

6.7 Cleaning the Sterilizer

6.6.1 Cleaning and maintenance of the mechanical

part of the sterilizer is the responsibility of

the appointed maintenance company. The

appointed maintenance company shall also

responsible for cleaning the sterilizer service area

which is the enclosed room located directly

behind the sterilizer.

6.6.2 The appointed maintenance company shall

shut off the steam supply valve of high vacuum

sterilizers at night of the cleaning process.

6.6.3 CSSU staff shall be responsible for direct cleaning

of all sterilizers.

6.8 Steam Sterilization Safety

6.8.1 All new equipment shall be tested jointly by

the supplier and the representative from the

Engineering Department, appointed maintenance

company personnel, and department personnel

before it is put into use.

Central Sterile Supply Services Policy 27

6.8.2 Autoclaves shall be operated only by trained and

certified personnel.

6.8.3 A preventive maintenance shall be carried out

by an appointed maintenance company for all

sterilizing equipment. They shall be responsible for

all repairs.

6.8.4 Timing cycle shall follow recommendation by

manufacturer for a specific product.

6.8.5 Time and temperature settings shall not be

changed unless a manufacturer of an item

recommends different parameters.

6.9 Ethylene Oxide Sterilization Safety

6.9.1 Operated only by trained staff.

6.9.2 An appointed maintenance company shall be

responsible for the activation of the emergency

plan in the event of an ethylene oxide spillage or

leakage.

6.9.3 Ethylene oxide tanks shall be stored in a controlled

ventilated area at a temperature that does not

exceed 37.7°C.

28 Central Sterile Supply Services Policy

7. POLICY ON STORAGE OF STERILE PRODUCTS

7.1 Objectives

To have proper storage and handling of sterile products.

7.2 Storage and Handling

7.2.1 Staff assigned to the sterile store shall be free from

upper respiratory tract infection (URTI) and skin

diseases.

7.2.2 Staff shall be trained in handling sterile items.

7.2.3 Storage systems

7.2.3.1 Basic systems for storing sterile products

shall be opened shelving or closed

shelving.

7.2.3.2 Open shelving shall be 25cm from the

floor, 5cm from outside walls and 44cm

from ceiling.

Central Sterile Supply Services Policy 29

8. POLICY ON TRANSPORTATION AND DISTRIBUTION

OF STERILE PRODUCTS

8.1 Objectives

To maintain sterility and prevent damage of sterile

products.

8.2 General Consideration

8.2.1 To have dedicated carts/trolley for delivery

of sterile items and shall be kept clean at all

times.

8.2.2 Sterile products shall be transported and

protected from contamination and damage.

8.2.3 Supply of sterile products shall be transported

via dedicated or scheduled route.

9. POLICY ON STERILIZATION OF IMPLANTABLE ITEMS

9.1 Objectives

To control and ensure effective management of

instrument and implantable items for quality service.

9.2 General Consideration

9.2.1 Sterile implantable items shall be supplied by the

manufacturer.

30 Central Sterile Supply Services Policy

9.2.2 If the implantable items are not sterile, it should

be sterilized according to the manufacturer’s

recommendation.

9.2.3 An implantable item shall be monitored and

quarantined until results of Biological Indicator (BI)

reads negative.

9.2.4 Detailed protocols should be available from the

manufacturer, regarding handling and sterilization

of implant.

10. POLICY ON SHELF LIFE

10.1 The shelf life of a packaged sterile item is EVENT-

RELATED.

10.2 Stock shall be rotated according to the principle

FIRST IN, FIRST OUT (FIFO).

10.3 The integrity of the pack shall be inspected before

being released to the user.

10.4 Sterile products shall be labeled, ‘STERILE UNLESS

OPENED, DAMAGED OR WET’.

10.5 Quality Audit of sterile products shall be done by

CSSU personnel as scheduled.

Central Sterile Supply Services Policy 31

11. POLICY ON PRODUCT RECALL

11.1 Objectives

To ensure complete removal from central inventory

of all products and equipment that may be unsafe as

established by notification/ alert or internal surveillance.

11.2 General Consideration

11.2.1 Positive Biological Indicator (BI) results shall be

immediately reported to the Supervisor.

11.2.2 The CSSU manager shall determine the cause

of sterilization failure and arrange for corrective

action.

11.2.3 Retrieve all unused items from affected loads.

11.2.4 Malfunction sterilizers shall not be used until

repaired and BI tests are negative.

11.2.5 The CSSU manager shall keep a record of all

incidents.

32 Central Sterile Supply Services Policy

12. POLICY ON SINGLE USE ITEMS

12.1 A device designated for ‘single use’ SHALL NOT be

reprocessed.

13. POLICY ON NON-FUNCTIONAL / LOST INSTRUMENTS

13.1 Damaged or spoilt and lost surgical instruments

shall be accompanied by Breakages and Lost

Form signed by the Supervisor.

13.2 The user shall lodge a police report if an instrument

or sets are found lost.

14. POLICY ON INCOMPLETE PROCEDURE SETS

14.1 Sterile product opened and found to be

incomplete, SHALL NOT BE USED and returned to

CSSU.

15. POLICY ON BIOHAZARD CASES

15.1 All surgical instruments used shall be double

bagged and labelled Biohazard.

Central Sterile Supply Services Policy 33

16. POLICY ON LOANER INSTRUMENTATION

16.1 Arrangements can be made with the vendor

or other healthcare facilities. Request for the

loaner of instruments shall be directed to the

responsible personnel only.

16.2 All items shall be delivered directly to CSSU

decontamination area.

16.3 CSSU shall not be responsible for any items

not listed on the vendor’s inventory list.

16.4 CSSU shall monitor proper count of the items

borrowed and returned.

34 Central Sterile Supply Services Policy

REFERENCES

Central Sterile Supply Services Policy 35

36 Central Sterile Supply Services Policy

REFERENCES

1. Malaysian Standard of Sterilization Process Book

– Second Edition 2011 (MSSA).

2. American Society for Healthcare Central Service Professionals

Training Manual for Health Care Central Service Technicians:

American Hospital Associate, 2001.

3. ANSI/ AAMI ST 79:2006

4. ANSI/ AAMI/ISO 15880:2003

5. Central Service, Policy and Procedure Manual Version 5.

6. Comprehensive Guide to Steam Sterilization and Sterility

Assurance in Health Care Facilities.

7. Marimargaret Reicher, RN, MA and Jack H. Yong, PhD

Sterilization Technology, an Aspen Publication, Second

Edition 1997.

8. NJ Department of Health Central Service Standards

Subchapter 8, Central Service.

9. Sterilization Process Monitoring the Children’s Hospital,

University of Colorado, Denver, USA.

10. 2005 Association for the Advancement of Medical

Instrumentation.

11. EN285 European Standard : Steam Sterilizers, 1996 : Brussels.

12. ISO 15883 Part 1-4 : Washer Disinfectors, 2003 : Geneva.

13. Health Technical Memoradum 2030 (HTM 2030).

Central Sterile Supply Services Policy 37

38 Central Sterile Supply Services Policy

DRAFTING

COMMITTEE

Central Sterile Supply Services Policy 39

40 Central Sterile Supply Services Policy

DRAFTING COMMITTEE FOR CENTRAL STERILE

SUPPLY SERVICES POLICY

Advisors

• Y. Bhg. Dato’ Dr. Hj Azman bin Hj Abu Bakar

Deputy Director General of Health (Medical)

• Y.Bhg. Datin Sri Dr. Asmah binti Samat

Deputy Director of Medical Development Division

Chairperson

• Matron Hjh Mek binti Jusoh

Head of Service of CSSU

Coordinator/ Secretariat

• Dr. Selvamalar Selvarajan

Senior Principal Assistant Director

Medical Development Division

• Dr. Suriana Aishah binti Zainal

Senior Principal Assistant Director

Medical Development Division

• Dr. Zuhaida binti Che Embi

Senior Principal Assistant Director

Medical Development Division

• Dr. Muhammad Al-Amin bin Safri

Senior Assistant Director

Medical Development Division

• Dr. Nazmir Ikmal bin Najibuddin

Senior Assistant Director

Medical Development Division

Central Sterile Supply Services Policy 41

• Nur Baidura binti Bakeri

Administrative Assistant

Medical Development Division

Drafting Members

• Dr. Zubaidah binti Abdul Wahab

Senior Consultant Medical Microbiology

Hospital Sungai Buloh

• Tn. Hj. IR Rosmahadi bin Ali

Deputy Director

Engineering Services Division

• Matron Hjh Mek binti Jusoh

State Matron

Jabatan Kesihatan Negeri Kelantan

• Pn. Kamariah binti Jusoh

Malaysian Sterile Service Association

• Pn. Siti Salmiah binti Mohamad Bazid

Malaysian Sterile Service Association

• Pn. Yeo Siau Ling

Malaysian Sterile Service Association

• Pn. Rahijah binti Abdul Rahman

Malaysian Sterile Service Association

• Pn. Yeoh Saw See

Malaysian Sterile Service Association

• Pn. Noormah binti Hj. Hashim

Malaysian Sterile Service Association

42 Central Sterile Supply Services Policy

• Pn. Halimaton Adauyah binti Nan Abidin

Malaysian Sterile Service Association

• Pn. Munirah binti Abdullah

Sister

Hospital Tengku Ampuan Rahimah

REVIEW PANEL

This document was reviewed by:

Dr. Abdul Hakim bin Abdul Rashid

Senior Assistant Director

Medical Development Division

Central Sterile Supply Services Policy 43

You might also like

- Aorn Recomentation Practices PDFDocument15 pagesAorn Recomentation Practices PDFWandi HuseinNo ratings yet

- Checklists For Central Sterile Supply Departments: CIS Self-Study Lesson PlanDocument5 pagesChecklists For Central Sterile Supply Departments: CIS Self-Study Lesson PlanAtahiNo ratings yet

- EtO Gas Sterilization Vs Steam SterilizationDocument3 pagesEtO Gas Sterilization Vs Steam SterilizationVer BautistaNo ratings yet

- Cis222 PDFDocument4 pagesCis222 PDFjerimiah_manzonNo ratings yet

- CIS Self-Study Lesson Plans: Surgical Instrumentation For Gynecological ProceduresDocument3 pagesCIS Self-Study Lesson Plans: Surgical Instrumentation For Gynecological Proceduresjerimiah_manzonNo ratings yet

- CSSD CPT ManualDocument3 pagesCSSD CPT Manualthirsal2003No ratings yet

- 41 Sterilization Validation Key Steps To Dose Auditing 1Document2 pages41 Sterilization Validation Key Steps To Dose Auditing 1Vivian CerdasNo ratings yet

- Cis Self-Study Lesson Plan: Vascular and Cardiovascular Surgical InstrumentsDocument4 pagesCis Self-Study Lesson Plan: Vascular and Cardiovascular Surgical Instrumentsjerimiah_manzonNo ratings yet

- Supplies & Consumables in CSSDDocument119 pagesSupplies & Consumables in CSSDjerimiah_manzonNo ratings yet

- Cis Self-Study Lesson Plan: Care and Handling of Sharp InstrumentsDocument4 pagesCis Self-Study Lesson Plan: Care and Handling of Sharp Instrumentsjerimiah_manzonNo ratings yet

- Urology Overview: Part II: CIS Self-Study Lesson PlanDocument5 pagesUrology Overview: Part II: CIS Self-Study Lesson Planjerimiah_manzonNo ratings yet

- How To SterilizeDocument27 pagesHow To SterilizeTanzeil_Rehman_4731No ratings yet

- Cis Self-Study Lesson Plan: Instruments For Total Knee ArthroplastyDocument3 pagesCis Self-Study Lesson Plan: Instruments For Total Knee Arthroplastyjerimiah_manzonNo ratings yet

- SterilizationDocument33 pagesSterilizationFitri AnggraeniNo ratings yet

- CSSDDocument35 pagesCSSDAzmi Tok-tokNo ratings yet

- Steam SterilizationDocument2 pagesSteam SterilizationHumayun KhanNo ratings yet

- QP-022 Sterilization Process ValidationDocument2 pagesQP-022 Sterilization Process Validationesraa asemNo ratings yet

- Process Failures HO RoseDocument14 pagesProcess Failures HO RoseHilario AlinabonNo ratings yet

- Cis Self-Study Lesson Plan: Otolaryngological InstrumentationDocument4 pagesCis Self-Study Lesson Plan: Otolaryngological Instrumentationjerimiah_manzonNo ratings yet

- HLD SterilizationDocument40 pagesHLD Sterilizationzahisma89No ratings yet

- Why Should A Hospital Have CSSDDocument12 pagesWhy Should A Hospital Have CSSDANOOPVA100% (1)

- CRCST Self-Study Lesson PlanDocument4 pagesCRCST Self-Study Lesson Planjerimiah_manzonNo ratings yet

- Medical Sterilization Methods - LemoDocument52 pagesMedical Sterilization Methods - LemoPedro GomesNo ratings yet

- Cis 209Document4 pagesCis 209jerimiah_manzonNo ratings yet

- CSSDDocument18 pagesCSSDMehak KapoorNo ratings yet

- Legal Aspects in HospitalDocument32 pagesLegal Aspects in HospitalDr. Rakshit Solanki0% (1)

- c40402 Sterile ContainerAESCULAPDocument108 pagesc40402 Sterile ContainerAESCULAPIfan RizkyNo ratings yet

- 21 - SafetyDocument54 pages21 - SafetySEI my nameNo ratings yet

- CSSDDocument17 pagesCSSDRifky Octavio PNo ratings yet

- CSSD SupervisorDocument6 pagesCSSD SupervisorNuman KhanNo ratings yet

- CISDocument4 pagesCISjerimiah_manzonNo ratings yet

- APSIC Sterilization Guidelines 2017Document119 pagesAPSIC Sterilization Guidelines 2017CSSD RSUDMWNo ratings yet

- CSSD RCRD KeepingDocument4 pagesCSSD RCRD KeepingsattichenNo ratings yet

- Basics of Steam SterilizationDocument6 pagesBasics of Steam SterilizationroberifinNo ratings yet

- Technician Manual 3840Document104 pagesTechnician Manual 3840Jorge Valenzuela100% (1)

- General Chapters - 1035 - Biological Indicators For SterilizationDocument6 pagesGeneral Chapters - 1035 - Biological Indicators For SterilizationKoeys KuswandaNo ratings yet

- Lesson 124Document5 pagesLesson 124jerimiah_manzonNo ratings yet

- Chemicals Used For Cleaning & Manual Cleaning Processes - FINAL 2Document45 pagesChemicals Used For Cleaning & Manual Cleaning Processes - FINAL 2jerimiah_manzonNo ratings yet

- Lesson 122Document4 pagesLesson 122jerimiah_manzonNo ratings yet

- CSSD - Sep 1st 2016 Final 3 in 1-1Document16 pagesCSSD - Sep 1st 2016 Final 3 in 1-1SundaraBharathiNo ratings yet

- Doctorss Manual PDFDocument154 pagesDoctorss Manual PDFMohilary GautamNo ratings yet

- Sterilization Methods and PrinciplesDocument11 pagesSterilization Methods and PrinciplesChanthini VinayagamNo ratings yet

- JNJ - SSI - Instrument Reprocessing, 2019 PDFDocument76 pagesJNJ - SSI - Instrument Reprocessing, 2019 PDFDEBBYNo ratings yet

- 5.hospital Waste Management - ppt1Document22 pages5.hospital Waste Management - ppt1Pankaj PatelNo ratings yet

- CSSDDocument32 pagesCSSDRAHUL100% (1)

- CSSDDocument4 pagesCSSDjerimiah_manzon100% (1)

- Flash SterilizationDocument0 pagesFlash SterilizationTanya GoriNo ratings yet

- SterilizationDocument126 pagesSterilizationj.k.kumar100% (7)

- Recommended Practices For Cleaning and Care of Surgical Instruments and Power EquipmentDocument46 pagesRecommended Practices For Cleaning and Care of Surgical Instruments and Power EquipmentRex Lagunzad FloresNo ratings yet

- Sterile Processing - Infection Prevention For Support Services and The Care Environment - Table of Contents - APICDocument74 pagesSterile Processing - Infection Prevention For Support Services and The Care Environment - Table of Contents - APICsalamon2tNo ratings yet

- Medical Waste ManagementDocument50 pagesMedical Waste ManagementNisa ShiningNo ratings yet

- Sterilization: Click To Edit Master Subtitle StyleDocument43 pagesSterilization: Click To Edit Master Subtitle Stylesalinderkaur100% (1)

- Hospital WasteDocument9 pagesHospital WasteBudhiraja ShiviNo ratings yet

- Decontamination ProcedureDocument2 pagesDecontamination ProcedureSB HudginsNo ratings yet

- Diseases That Needs Isolation PrecautionsDocument1 pageDiseases That Needs Isolation Precautionsjerimiah_manzonNo ratings yet

- How To Use Laminar Air FlowDocument9 pagesHow To Use Laminar Air Flowrahma ajusNo ratings yet

- Contamination Control Strategy DevelopmentDocument75 pagesContamination Control Strategy DevelopmentArnaldo García100% (6)

- Sa GCP 2020 FinalDocument71 pagesSa GCP 2020 FinalNeneng Aini KaruniawanNo ratings yet

- Infection Control PDFDocument52 pagesInfection Control PDFahmadzikrulmuhtadinNo ratings yet

- 06 BLOOD STATION - DOH-BSF-LTO - ATO-AT-rev1-172020-24pgs-DC2018-0039ADocument24 pages06 BLOOD STATION - DOH-BSF-LTO - ATO-AT-rev1-172020-24pgs-DC2018-0039AGerald TalledoNo ratings yet

- Central Sterile Supply Services Policy KKM PDFDocument53 pagesCentral Sterile Supply Services Policy KKM PDFGerald TalledoNo ratings yet

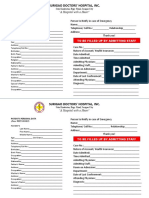

- Surigao Doctors' Hospital, Inc. C: "A Hospital With A Heart."Document4 pagesSurigao Doctors' Hospital, Inc. C: "A Hospital With A Heart."Gerald TalledoNo ratings yet

- Narrative ReportDocument3 pagesNarrative ReportGerald TalledoNo ratings yet

- Hospital Daily Census ReportDocument1 pageHospital Daily Census ReportGerald TalledoNo ratings yet

- Card DexDocument1 pageCard DexGerald TalledoNo ratings yet

- Cardex Nursing Endorsement SheetDocument1 pageCardex Nursing Endorsement SheetGerald TalledoNo ratings yet

- Patient Daily Census NameDocument1 pagePatient Daily Census NameGerald TalledoNo ratings yet

- X X R R: Surigao Doctors' Hospital, Inc. Surigao Doctors' Hospital, IncDocument2 pagesX X R R: Surigao Doctors' Hospital, Inc. Surigao Doctors' Hospital, IncGerald TalledoNo ratings yet

- X X R R: Surigao Doctors' Hospital, Inc. Surigao Doctors' Hospital, IncDocument1 pageX X R R: Surigao Doctors' Hospital, Inc. Surigao Doctors' Hospital, IncGerald TalledoNo ratings yet

- Patient Personal Data FormDocument1 pagePatient Personal Data FormGerald TalledoNo ratings yet

- Surigao Doctors' Hospital, Inc.: Cfac of Stool & Vomitous Monitoring DataDocument2 pagesSurigao Doctors' Hospital, Inc.: Cfac of Stool & Vomitous Monitoring DataGerald TalledoNo ratings yet

- Hospital Daily Census ReportDocument1 pageHospital Daily Census ReportGerald TalledoNo ratings yet

- Cardex Nursing Endorsement SheetDocument1 pageCardex Nursing Endorsement SheetGerald TalledoNo ratings yet

- Oxygen Tag Oxygen Tag: Surigao Doctors' Hospital, Inc. Surigao Doctors' Hospital, IncDocument1 pageOxygen Tag Oxygen Tag: Surigao Doctors' Hospital, Inc. Surigao Doctors' Hospital, IncGerald TalledoNo ratings yet

- Surigao Doctors' Hospital, Inc.: "A Hospital With A Heart"Document1 pageSurigao Doctors' Hospital, Inc.: "A Hospital With A Heart"Gerald TalledoNo ratings yet

- "A Hospital With A Heart" "A Hospital With A Heart": Charge To The Account of Charge To The Account ofDocument1 page"A Hospital With A Heart" "A Hospital With A Heart": Charge To The Account of Charge To The Account ofGerald TalledoNo ratings yet

- Surigao Doctors' Hospital, Inc.: "A Hospital With A Heart"Document2 pagesSurigao Doctors' Hospital, Inc.: "A Hospital With A Heart"Gerald TalledoNo ratings yet

- Cardex Nursing Endorsement SheetDocument1 pageCardex Nursing Endorsement SheetGerald TalledoNo ratings yet

- Surigao Doctors' Hospital, Inc. Laundry Surigao Doctors' Hospital, Inc. LaundryDocument2 pagesSurigao Doctors' Hospital, Inc. Laundry Surigao Doctors' Hospital, Inc. LaundryGerald TalledoNo ratings yet

- Surigao Doctors' Hospital, Inc.: Vital Signs Monitoring SheetDocument11 pagesSurigao Doctors' Hospital, Inc.: Vital Signs Monitoring SheetGerald TalledoNo ratings yet

- Ivf TagDocument1 pageIvf TagGerald TalledoNo ratings yet

- Referral Slip BlueDocument2 pagesReferral Slip BlueGerald TalledoNo ratings yet

- Star Health Corporate BrochureDocument4 pagesStar Health Corporate BrochureRajendiran SundaravelNo ratings yet

- Thesis Topic Selection Review 04.03Document12 pagesThesis Topic Selection Review 04.03VinayakNo ratings yet

- WHLP Grade 2 Q3 W8Document8 pagesWHLP Grade 2 Q3 W8Revilyn NimoNo ratings yet

- As-Is Annual Preventive Maintenance Plan (V6)Document1 pageAs-Is Annual Preventive Maintenance Plan (V6)Muhammad Faizan SiddiquiNo ratings yet

- Template Inventory of Roads With The LGU JurisdictionDocument4 pagesTemplate Inventory of Roads With The LGU JurisdictiongreteNo ratings yet

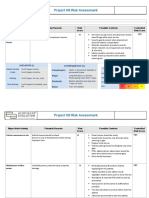

- Hirac (Light-Fittings Installation)Document5 pagesHirac (Light-Fittings Installation)tana100% (2)

- Hazard Indentificaction and Risk Assessment: Name of Project:-Documents NoDocument4 pagesHazard Indentificaction and Risk Assessment: Name of Project:-Documents Noaman anand100% (2)

- Safe : Observation CategoriesDocument1 pageSafe : Observation CategoriesFaris WahedNo ratings yet

- Eligible Candidaets List For MBBS CLC 2020Document63 pagesEligible Candidaets List For MBBS CLC 2020Ishika JohriNo ratings yet

- How To Live To Be 2oo: What Is The Lesson About?Document7 pagesHow To Live To Be 2oo: What Is The Lesson About?M.SHOURYA VARDHANNo ratings yet

- U07754QOSM - Project O & M Manual Vinyl FlooringDocument19 pagesU07754QOSM - Project O & M Manual Vinyl FlooringRithesh ShettyNo ratings yet

- Patient SafetyDocument8 pagesPatient SafetyKelly J Wilson0% (1)

- COVID 19 Death Summary 12-11-2020Document1 pageCOVID 19 Death Summary 12-11-2020Live 5 NewsNo ratings yet

- GunnellDocument1 pageGunnellapi-533856782No ratings yet

- Manual Operador CAT529 PDFDocument326 pagesManual Operador CAT529 PDFHeidi Cuevas VenegasNo ratings yet

- Barangay Health Board ResulotionDocument3 pagesBarangay Health Board ResulotionSHEBA RAE ESPERANZA100% (1)

- Penulisan Resep Yang Baik Dan BenarDocument2 pagesPenulisan Resep Yang Baik Dan BenarEdward KurniawanNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakaBang UsopNo ratings yet

- DM No. 2020-0282Document1 pageDM No. 2020-0282kristalsanzNo ratings yet

- Mid-Upper Arm Circumference (Muac) Measuring Tapes: BackgroundDocument2 pagesMid-Upper Arm Circumference (Muac) Measuring Tapes: BackgroundDIMAMIANo ratings yet

- Project HS Risk AssessmentDocument9 pagesProject HS Risk AssessmentParasNo ratings yet

- Grammar Tests Upper Intermediate Determiners ...Document4 pagesGrammar Tests Upper Intermediate Determiners ...silvia0% (1)

- Resume John Doerschuk JRDocument3 pagesResume John Doerschuk JRapi-454540037No ratings yet

- Lingualized Occlusion-A Case ReportDocument4 pagesLingualized Occlusion-A Case ReportSkAliHassanNo ratings yet

- Concept of Buddha: Spa, Belgium LatinDocument14 pagesConcept of Buddha: Spa, Belgium LatinSatish SharmaNo ratings yet

- VWR Analog and Digital Multi-Tube Vortexer Instruction ManualDocument109 pagesVWR Analog and Digital Multi-Tube Vortexer Instruction ManualWai YanNo ratings yet

- Expository EssayDocument2 pagesExpository EssaySherida GibbsNo ratings yet

- Results Based Budgeting (RBB) Technical GuidelinesDocument4 pagesResults Based Budgeting (RBB) Technical GuidelinesTavongasheMaddTMagwatiNo ratings yet

- Steelmaster 1200WF: Technical Data SheetDocument4 pagesSteelmaster 1200WF: Technical Data SheetHarmandeep BhattiNo ratings yet

- Training CodesDocument10 pagesTraining CodesFarrukh EjazNo ratings yet