Professional Documents

Culture Documents

GE08TI 150-165kW Natural Gas Genset

Uploaded by

Guillermo OchoaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GE08TI 150-165kW Natural Gas Genset

Uploaded by

Guillermo OchoaCopyright:

Available Formats

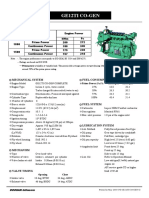

GE08TI GEN-PACK

◎ POWER RATING

Engine

Type of Engine Power

Speed

Operation

rev/min kWm Ps

Prime Power 150 204

1800

Standby Power 165 224

Prime Power 128 174

1500

Standby Power 141 191

Note : -. The engine performance corresponds to ISO 3046, BS 5514 and DIN 6271.

* Without cooling fan, inter cooler inlet water temperature 32℃

-. Ratings are based on ISO 8528.

→ Prime power available at variable load. The permissible average power out put (during 24h period) shell not

exceed 70% of the prime power rating. No overload is permitted.

→ Standby power available in the event of a main power network failure. No overload is permitted.

◎ MECHANICAL SYSTEM ◎ FUEL CONSUMPTION

ㅇEngine Type In-line 4 cycle, water cooled ㅇPrime (Nm3/hr) 1,500 rpm 1,800 rpm

Turbo charged & intercooled (water to air) 25% 13.3 13.9

ㅇCombustion type Stoichiometric, Premixed and spark ignited 50% 17.8 21.8

ㅇCylinder Type Replaceable dry liner 75% 24.3 29.9

ㅇ Number of cylinders 6 100% 31.8 38.5

ㅇBore x stroke 111(4.37) x 139(5.47) mm(in.) ㅇStandby (Nm3/hr) 1,500 rpm 1,800 rpm

ㅇDisplacement 8.071 (492.52) lit.(in3) 25% 12.8 15.7

ㅇCompression ratio 10.5 : 1 50% 20.1 25.4

ㅇFiring order 1-5-3-6-2-4 75% 28.2 34.7

ㅇIgnition timing 13° BTDC 100% 36.0 42.3

ㅇCompression pressure Above 16 kg/cm2(228 psi) at 200rpm

ㅇDry weight Approx. 820 kg (1,808 lb) ◎ FUEL SYSTEM

ㅇDimension 1,415 x 925 x 1,400 mm ㅇCarburetor Impco 200M Varifuel carburetor

(LxWxH) (56 x 37 x 56 in.) ㅇGas regulator Maxitrol RV61

ㅇRotation Counter clockwise viewed from Flywheel ㅇMax. inlet pressure 1.0 psi at the engine inlet

ㅇFly wheel housing SAE NO.2

ㅇFly wheel Clutch NO.11 1/2 ◎ LUBRICATION SYSTEM

ㅇLub. Method Fully forced pressure feed type

◎ MECHANISM ㅇOil pump Gear type driven by crankshaft

ㅇType Over head valve ㅇOil filter Full flow, cartridge type

ㅇNumber of valve Intake 1, exhaust 1 per cylinder ㅇOil pan capacity High level 23 liters ( 6.08 gal.)

ㅇValve lashes at cold Intake 0.30mm (0.0118 in.) Low level 17 liters ( 4.49 gal.)

Exhaust 0.30mm (0.0118 in.) ㅇLub. Oil Refer to Operation Manual

Low ash type(0.5wt%) natural gas

◎ VALVE TIMING engine oil

Opening Close API service grade CD or higher

ㅇIntake valve 16 deg. BTDC 36 deg. ABDC SAE 15W-40

ㅇExhaust valve 46 deg. BBDC 14 deg. ATDC

DOOSAN Infracore Printed in February 2011 PS-GE08TI GEN-PACK-D

GE08TI GEN-PACK

◎ COOLING SYSTEM ◎ ENGINEERING DATA

ㅇCooling method Fresh water forced circulation ㅇWater flow 200 liters/min @1,500 rpm

ㅇWater capacity 18 liters ( 4.76 gal.) 240 liters/min @1,800 rpm

(engine only) ㅇHeat rejection to coolant 32.9 kcal/sec @1,500 rpm

2

ㅇPressure system Max. 0.5 kg/cm ( 7.1 psi) 39.3 kcal/sec @1,800 rpm

ㅇWater pump Centrifugal type driven by belt ㅇHeat rejection to CAC 1.3 kcal/sec @1,500 rpm

ㅇCooling fan Blower, 660.4mm diameter, 7 blades 2.6 kcal/sec @1,800 rpm

Plastic ㅇIntercooler water flow 302.4 liters/min @1,500 rpm

ㅇLoss power of fan 6.8PS (5kW) @ Eng. Speed 1,500 rpm 362.9 liters/min @1,800 rpm

10.9PS (8kW) @ Eng. Speed 1,800 rpm ㅇAir flow 10.3 m3/min @1,500 rpm

ㅇThermostat Wax – pellet type 12.5 m3/min @1,800 rpm

Opening temp. 71°C ㅇExhaust gas flow 16.5 m3/min @1,500 rpm

Full open temp. 85°C 20.3 m3/min @1,800 rpm

ㅇExhaust gas temp. 540 °C @1,500 rpm

560 °C @1,800 rpm

◎ ELECTRICAL SYSTEM ㅇRadiator air flow 210 m3/min @1,500 rpm, 0.7kPa

ㅇCharging generator 24V x 45A alternator 270 m3/min @1,800 rpm, 1.0kPa

ㅇVoltage regulator Built-in type IC regulator ㅇMax. permissible restrictions

ㅇStarting motor 24V x 4.5kW -.Intake system 220 mmH2O initial

ㅇBattery Voltage 24V 635 mmH2O final

ㅇBattery Capacity 150 AH (recommended) -.Exhaust system 600 mmH2O max.

ㅇIgnition controller 12 or 24V DC ㅇAltitude Capability 1,000 m

(min 8V DC at start, 32V DC max)

◆ CONVERSION TABLE

◎ IGNITION SYSTEM in. = mm x 0.0394 lb/ft = N.m x 0.737

ㅇSpark plug NGK IFR7B-D, 0.4mm air gap PS = kW x 1.3596 U.S. gal = lit. x 0.264

Champion RC78PYP, 0.38mm air gap psi = kg/cm2 x 14.2233 kW = 0.2388 kcal/s

ㅇIgnition controller Altronic CD 1 unit (12 or 24V DC) in3 = lit. x 61.02 lb/PS.h = g/kW.h x 0.00162

ㅇIgnition coil Altronic 501 061 blue epoxy individual hp = PS x 0.98635 cfm = m3/min x 35.336

coil lb = kg x 2.20462 Nm3= SCF × 0.0283

ㅇTrigger system Magnetic pick-up sensor and trigger Kg/hr = Nm3/hr × 0.732 (natural gas)

wheel and Hall-effect Btu/ft3= MJ/m3 × 26.8392 (natural gas)

( 0.75 ~ -0.25mm air gap) kPa = 101.97 mmH2O = 0.01 bar

DOOSAN Infracore Printed in February 2011 PS-GE08TI GEN-PACK-D

GE08TI GEN-PACK

◎ Dimensions : Engine

◎ Dimensions : Gen-pack

Doosan Infracore Co., Ltd.

21st Floor, Doosan Tower, 18-12, Euljiro 6-ga,

Jung-gu, Seoul, Korea

TEL : +82-2-3398-8400 / Fax : +82-2-3398-8509

E-mail : enginesales@doosan.com

Web site : www.doosaninfracore.com

※ Specifications are subject to change without prior notice

DOOSAN Infracore Printed in February 2011 PS-GE08TI GEN-PACK-D

You might also like

- VOLTAR P086TI G-DRIVE SpecificationsDocument186 pagesVOLTAR P086TI G-DRIVE SpecificationsSilver SilverNo ratings yet

- P086ti 1Document2 pagesP086ti 1Serhan AysanNo ratings yet

- P180LE G-DRIVE ENGINE SPECSDocument2 pagesP180LE G-DRIVE ENGINE SPECSNos GoteNo ratings yet

- P158Le-S G-Drive: Power RatingDocument2 pagesP158Le-S G-Drive: Power RatingJavier SilvaNo ratings yet

- Ge08ti Co Gen-GDocument2 pagesGe08ti Co Gen-GGuillermo OchoaNo ratings yet

- D1146T G-DRIVE: Power RatingDocument2 pagesD1146T G-DRIVE: Power RatingGuillermo OchoaNo ratings yet

- Doosan Daewoo Engine P126TI CDocument2 pagesDoosan Daewoo Engine P126TI CcassiomecNo ratings yet

- 1 PS Ge08tic DDocument2 pages1 PS Ge08tic Debow powerNo ratings yet

- Ge12ti Co Gen-GDocument2 pagesGe12ti Co Gen-GTilok DasNo ratings yet

- Gv180ti Co Gen-FDocument2 pagesGv180ti Co Gen-FSilver SilverNo ratings yet

- Data Sheet SDMO D400Document2 pagesData Sheet SDMO D400AhonakponNo ratings yet

- 26 Ps-P158fe-B LGW 060629Document2 pages26 Ps-P158fe-B LGW 060629Ekhlas SayeedNo ratings yet

- D1146T G-DRIVE: Power RatingDocument2 pagesD1146T G-DRIVE: Power RatingCesar Saavedra SaavedraNo ratings yet

- Dat Ge12tiDocument2 pagesDat Ge12tiheri setyawanNo ratings yet

- GE12TIC Engine Provides 272 Ps Prime Power RatingDocument2 pagesGE12TIC Engine Provides 272 Ps Prime Power Ratingebow powerNo ratings yet

- Brochure Doosan GV222TIDocument4 pagesBrochure Doosan GV222TIGabriel Andres Valencia0% (1)

- P158Le G-Drive: Power RatingDocument2 pagesP158Le G-Drive: Power RatingingcalderonNo ratings yet

- Db58 G-Drive: Power RatingDocument2 pagesDb58 G-Drive: Power RatingDian IdawatiNo ratings yet

- 13 - PS P158le 1 DDocument2 pages13 - PS P158le 1 Dgerencia procesos especialesNo ratings yet

- P158Le G-Drive: Power RatingDocument2 pagesP158Le G-Drive: Power RatingFelipe HernándezNo ratings yet

- GV222TIC Diesel Generator Specs and Performance RatingsDocument2 pagesGV222TIC Diesel Generator Specs and Performance RatingsdaniloreisrochaNo ratings yet

- D1146 G-DRIVE: Power RatingDocument2 pagesD1146 G-DRIVE: Power RatingCesar Saavedra SaavedraNo ratings yet

- Dat Gv180tiDocument2 pagesDat Gv180tiThomasRudyNo ratings yet

- Db33 G-Drive: Power RatingDocument2 pagesDb33 G-Drive: Power RatingDafa' DzakyNo ratings yet

- 3 PS Gv158tic eDocument2 pages3 PS Gv158tic eebow powerNo ratings yet

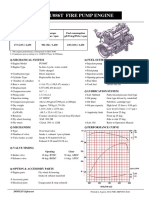

- PU086TI-E1C (Fire Pump)Document2 pagesPU086TI-E1C (Fire Pump)LIU MINNo ratings yet

- Doosan d1146 Pu086 Shop Manual AbDocument186 pagesDoosan d1146 Pu086 Shop Manual AbmaherNo ratings yet

- Pu086T Fire Pump Engine: Power RatingDocument2 pagesPu086T Fire Pump Engine: Power RatingWac MichNo ratings yet

- Pu086 1 1Document2 pagesPu086 1 1عقيد السبئيNo ratings yet

- PU066Document2 pagesPU066Sorin StanescuNo ratings yet

- Pu086ti E1cDocument2 pagesPu086ti E1cLIU MINNo ratings yet

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document4 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)David J SandersNo ratings yet

- 650hp Doosan PU180TI diesel engineDocument2 pages650hp Doosan PU180TI diesel engineAlfonso Alberto ArguelloNo ratings yet

- PU086TDocument3 pagesPU086TSorin StanescuNo ratings yet

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document5 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)Jorge Eraldo Albarran PoleoNo ratings yet

- DWV Series: Power RatingDocument2 pagesDWV Series: Power Ratingquangtruc106No ratings yet

- PU158TIDocument2 pagesPU158TITrevor BurnettNo ratings yet

- Motor P222FE PDFDocument4 pagesMotor P222FE PDFMarco QuitoNo ratings yet

- 20. SPEC. SHEET SP344CC - CB - 영문Document3 pages20. SPEC. SHEET SP344CC - CB - 영문RYUNo ratings yet

- PDF Hub 6DTAA8.9-G31Document2 pagesPDF Hub 6DTAA8.9-G31Luis YupanquiNo ratings yet

- PU158TI E1G Motor IndustrialDocument2 pagesPU158TI E1G Motor IndustrialANGEL UQUILLASNo ratings yet

- D Á Ð - SC9D310D2 ÀóÂ (Ëó )Document2 pagesD Á Ð - SC9D310D2 ÀóÂ (Ëó )Meme DNo ratings yet

- DWV Series: Power RatingDocument2 pagesDWV Series: Power Ratingquangtruc106No ratings yet

- P126TI-II: Doosan Infracore Generator EngineDocument4 pagesP126TI-II: Doosan Infracore Generator EngineNilthon ChiteNo ratings yet

- Engine Spec Sheet 3 - 6DWD-235A Rev B2Document2 pagesEngine Spec Sheet 3 - 6DWD-235A Rev B2yamahaNo ratings yet

- DOOSAN GENERATOR ENGINE RATINGS AND SPECSDocument5 pagesDOOSAN GENERATOR ENGINE RATINGS AND SPECSWILLIAM ANDRES LEONNo ratings yet

- Doosan Infracore Generator Engine P222le-IiDocument4 pagesDoosan Infracore Generator Engine P222le-IiahmedalgaloNo ratings yet

- PU086TIDocument2 pagesPU086TIFaisal AmininNo ratings yet

- PU222TIDocument2 pagesPU222TISorin StanescuNo ratings yet

- P222le SDocument4 pagesP222le SKazim AlrefaiNo ratings yet

- P222LE-S: Doosan Infracore Generator EngineDocument4 pagesP222LE-S: Doosan Infracore Generator EngineStenlyn LayaNo ratings yet

- Doosan Infracore P126TI Generator Engine Ratings and SpecificationsDocument4 pagesDoosan Infracore P126TI Generator Engine Ratings and SpecificationsPhoenix ForceNo ratings yet

- P126TI-II: Doosan Infracore Generator EngineDocument4 pagesP126TI-II: Doosan Infracore Generator EnginehirararaNo ratings yet

- DP126LA: Doosan Infracore Generator EngineDocument4 pagesDP126LA: Doosan Infracore Generator EnginehirararaNo ratings yet

- Pu066 P-Drive: Mechanical System Fuel SystemDocument2 pagesPu066 P-Drive: Mechanical System Fuel SystemhNo ratings yet

- SP344CBDocument2 pagesSP344CBАнатолий ЗубкоNo ratings yet

- DP180LB: Doosan Infracore Generator EngineDocument4 pagesDP180LB: Doosan Infracore Generator EngineBrandon Atz100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Base Engine Data SheetDocument4 pagesBase Engine Data SheetGuillermo OchoaNo ratings yet

- Doosan DP Engine series 77-828kW for generatorsDocument2 pagesDoosan DP Engine series 77-828kW for generatorsRizka PsNo ratings yet

- D1146T G-DRIVE: Power RatingDocument2 pagesD1146T G-DRIVE: Power RatingGuillermo OchoaNo ratings yet

- P158Le G-Drive: Power RatingDocument2 pagesP158Le G-Drive: Power RatingingcalderonNo ratings yet

- Dat P222leDocument2 pagesDat P222lePowerTechNo ratings yet

- Poster ICGRDocument1 pagePoster ICGRGuillermo OchoaNo ratings yet

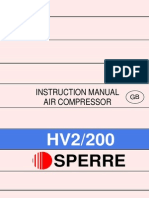

- Instruction Manual Air Compressor: SperreDocument31 pagesInstruction Manual Air Compressor: SperreAnkit Shah100% (2)

- VW Passat B5 21 (38) Charge Air SystemDocument47 pagesVW Passat B5 21 (38) Charge Air SystemJosé Luis OrmeñoNo ratings yet

- QSK19G PerformanceDocument5 pagesQSK19G PerformancetroyNo ratings yet

- QSK19 MCRS Training Revised 05-25-12 - Compatibility ModeDocument184 pagesQSK19 MCRS Training Revised 05-25-12 - Compatibility ModeLe Du88% (8)

- COMPRESOR - Kobelco-Knw-Series-Instruction-Manual-54Document54 pagesCOMPRESOR - Kobelco-Knw-Series-Instruction-Manual-54YERSONNo ratings yet

- Disassembly and Assembly 3500C Marine Engines PDFDocument132 pagesDisassembly and Assembly 3500C Marine Engines PDFlancaster27100% (5)

- 2017-02-22 - Application Installation of GeneratorsDocument60 pages2017-02-22 - Application Installation of GeneratorsSelva Kumar CNo ratings yet

- Damage Brochure MAHLE Original TurbochargersDocument16 pagesDamage Brochure MAHLE Original Turbochargerszhengdong618No ratings yet

- Iso 8178part1a6 ResumenDocument22 pagesIso 8178part1a6 ResumenpicottoNo ratings yet

- Total Service: CharacteristicsDocument4 pagesTotal Service: Characteristicsflorensius suparyantoNo ratings yet

- Sperre Air Compressor HV2-200Document30 pagesSperre Air Compressor HV2-200Tomislav Korencic75% (4)

- Man D2862 (800 - 1000 Kva)Document4 pagesMan D2862 (800 - 1000 Kva)eriscano1100% (3)

- Filtration and separation spectrumDocument9 pagesFiltration and separation spectrumSiti Aisyah ShanazNo ratings yet

- Volvo Penta Tamd74cedcDocument2 pagesVolvo Penta Tamd74cedcElvys Jose Linares BriceñoNo ratings yet

- l2738 Propulsion Tieri PDFDocument960 pagesl2738 Propulsion Tieri PDFcatalintoader1969No ratings yet

- 4 GD Parts List 13-10-523 PDFDocument54 pages4 GD Parts List 13-10-523 PDFSebastian Salazar100% (1)

- Caterpillar Engine FamilyDocument72 pagesCaterpillar Engine FamilyJesus Almanzar Santos100% (1)

- Refrigeration Systems GuideDocument9 pagesRefrigeration Systems GuideericNo ratings yet

- Caterpillar C4.4, C6.6, C7.1 engine test proceduresDocument88 pagesCaterpillar C4.4, C6.6, C7.1 engine test proceduresHotnCrispy Crispy100% (1)

- QSK 45GDocument25 pagesQSK 45Gvassindou67% (3)

- 3126B Serial DCS02760 Arr 2077523 Repair ManualDocument1,196 pages3126B Serial DCS02760 Arr 2077523 Repair Manualviemey1952100% (4)

- ZE-ZA Compressor BrochureDocument16 pagesZE-ZA Compressor BrochureDavid Zelada AlfaroNo ratings yet

- Basic Engine (The Best)Document104 pagesBasic Engine (The Best)MohamedSalah100% (2)

- Volvo Penta - Catalogo MotoresDocument76 pagesVolvo Penta - Catalogo MotoresЕвгенийNo ratings yet

- B Series Engine Familiarization GuideDocument79 pagesB Series Engine Familiarization GuideEdi Ianto100% (2)

- GTA855B engine data sheetDocument4 pagesGTA855B engine data sheetRIGOBERTO LOZANO MOLINANo ratings yet

- ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 Exhaust Manifold Installation InstructionDocument6 pagesISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 Exhaust Manifold Installation Instructionmds9185No ratings yet

- Training Session 1 Gas Turbine Basics: by Jim Noordermeer, P.Eng. Gryphon International Engineering Services IncDocument24 pagesTraining Session 1 Gas Turbine Basics: by Jim Noordermeer, P.Eng. Gryphon International Engineering Services IncM Azri Zulkipli100% (1)

- Mitsubishi Marine Gas SolutionsDocument2 pagesMitsubishi Marine Gas SolutionsAlbertoNo ratings yet

- Turbo Inter CoolerDocument23 pagesTurbo Inter CoolerRanjan MishraNo ratings yet