Professional Documents

Culture Documents

N Diagnostic PDF

Uploaded by

Zahir KhiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

N Diagnostic PDF

Uploaded by

Zahir KhiraCopyright:

Available Formats

Diagnostic, Orifice,

Bleed Adapters and

Specialty Fittings

The Fitting Authority

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

LOHL6G5TP XHX6G5TP GMA3 F5OG

ORFS Swivel / ORFS / 37° Swivel / 37° Flare / EO Tube / EO Tube / SAE / NPTF Gauge

SAE-ORB SAE-ORB EMA-3 Diagnostic Tip Diagnostic

Diagnostic Tee Port

Tees Adapters

and Plugs

N5 N5 N5 N6

AOHG P5ON HP5ON PD331 EMA3

SAE Adj / NPT Hex Head Plug Hollow Hex Plug PD / SAE-ORB SAE / ORB

Direct

Connect

Diagnostic

Tips

N6 G19 G20 N6* N6*

PDFS341 G5L G65L GLO

PD Fluid Sampling / NPT / SAE-ORB Gauge / ORFS SAE-ORB Gauge / NPT Gauge / ORFS

Direct SAE-ORB ORFS Swivel

SAE-ORB

Connect

Pressure

Sampling

Gauge

Tips

Adapters

N6* N8 N8 N8

G6L GTX G6X MAVE MAV

NPT Gauge / ORFS NPT Gauge / 37° Flare NPT Gauge / 37° Swivel BSPP Gauge / BSPP Gauge / EO

Swivel BSP EO Swivel

Pressure

Gauge

Adapters

N8 N8 N8 N7 N7

G4MXSMO G4MLOSMO PDBTX PDBTL PDBTU

BSPP Gauge / 37° Flare BSPP Gauge / ORFS 37° Swivel / PD ORFS Swivel / PD SAE Flareless / PD

Diagnostic Tip Diagnostic Tip Diagnostic Tip

Swivel

Tube

Adapters

N7 N7 N10* N10* N10*

VKA3 PD345 / PD355 / PD346 / PD366 / MAV 1/4 NPT Series WGTX

EO Swivel / Diagnostic PD365 PD386 Diagnostic Tip / Gauge NPT Gauge / 37° Flare

Tip PD / 37° Flare PD / ORFS

Bulkhead

Diagnostic

Couplings

N10 N9* N9* N9* N9

XHX7 LOHL6 PNLOBA

37° Seat / 37° Flare with ORFS Swivel with Bleed Screw / ORFS

Orifice Orifice / ORFS

ORFS /

Orifice

Port Bleed

Fittings

Adapters

N11 N11 N12

FNLBA P5ONBA HPBA 0109

Bleed Screw / ORFS Bleed Screw / SAE-ORB Bleed Screw / NPT NPTF / PTT 30° Flare

Swivel Parker

Triple

Thread

Fitting

N12 N12 N12 N13

* Standard products available through Parker’s Quick Coupling Division.

N2 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

Introduction

Parker offers a line of specialty-type adapters specifically

designed for diagnostic, fixed flow control and bleeding appli-

cations.

Diagnostic products consist of a line of in-line diagnostic tees,

pressure gauge connectors and diagnostic tips. These prod-

ucts have been developed to work in conjunction with elec-

tronic diagnostic products available from Parker’s Quick Cou-

pling Division and other mechanical pressure and tempera-

ture sensing equipment. Some products can be used for fluid

sampling and bleeding purposes as well.

Parker offers a standard and custom line of fixed flow control

orifice fittings. These products are available as standard in two

Parker product series — ORFS and 37° flare, and as a custom

option in virtually any orifice size, fitting series, size, material

and configuration. Fig. N1 — Parker offers a full line of diagnostic, orifice,

bleed adapters and specialty fittings

Parker’s bleed adapters are designed to remove entrapped

air from a hydraulic system. A common problem in hydraulic

systems is trapped air and the subsequent spillage of hydrau-

lic oil while removing components to bleed air from lines under

pressure. Parker’s bleed adapters provide a quick, clean, and

simple method of bleeding entrapped air from hydraulic systems.

Lastly, Parker offers a limited line of PTT (Parker Triple Thread)

30° flare adapters for transportation markets.

Diagnostic Fittings and

Adapters

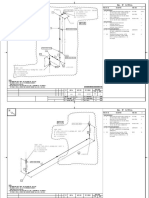

In-Line Diagnostic Tees

Features

• Designed around the two most common hydraulic

tube/hose interfaces: ORFS (Seal-Lok) and 37° flare A

(JIC / Triple-Lok) (see A) 37° Flare

• Available in 16 sizes and end configurations as

standard

• ORFS and 37° flare swivel feature offers unlimited

positioning without displacing port adapter (see B)

• Uses elastomeric sealing: SAE –4 (7/16-20 UNF) port

as universal diagnostic port per SAE J1926-1 / ISO

11926 (see C)

C&D

• Enlarged and lengthened body hex ensures that

B

diagnostic port offers full thread engagement and A

pressure capability (see D) ORFS

• Adaptable to Parker’s line of diagnostic and fluid

sampling tips including: EMA-3, PD and PDFS, as well

as various direct connecting electronic/mechanical

pressure gauges

• Designed to complement Parker’s line of Senso-

Control® electronic diagnostic equipment

• Increased pressure ratings and assembly torque

resistance for diagnostic applications Fig. N2 — Parker’s XHX6G5TP (top) and LOHL6G5TP

(bottom) in-line diagnostic tees

• Additional 20 sizes available in 24° flareless/metric

(EO/EO-2) tube “union style” tee

• 24° flareless/metric rated by size and series as shown

in accompanying tables

• Custom diagnostic tees available upon request.

N3 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

Applications

• In-line pressure and temperature measurements

• In-line oil sampling to evaluate hydraulic contamina-

tion, caused by problems with filtration or internal

components

• In-field diagnostics without removal of port adapters.

Simply remove hose swivel and insert in-line tee.

• Permanent or temporary OEM and MRO diagnostic

applications:

• Where traditional in-port diagnostic tips cannot be

located or easily accessed

• Where OEM diagnostic tips have not been

installed

• Non-traditional diagnostic locations (portable)

• Where port threads are not compatible with

standard diagnostic tips

• To eliminate reducer bushings and couplings typically

required to neck down from larger size connections to

smaller connections; e.g. reductions required for a

gauge, diagnostic tip, bleed adapter, or tube/hose

connection.

System Installation

As with most Parker adapter products, Diagnostic tees are

rated with both a dynamic and static working pressure rating.

A static pressure rating can often be used for in-field or

temporary diagnostic applications so long as the maximum

static pressure rating is not exceeded and the application Fig. N3 — Illustration showing the versatility of Parker’s

diagnostic tee product line

does not exceed 30,000 operating cycles.

Assembly Instructions

The body of the diagnostic tee can be used repeatedly for 10- Assembly Torque

20 remakes at full rated pressure and assembly torque. See Part (+10%-0)

Number in.-lb. ft.-lb.

Tables N2 and N3 for recommended swivel nut assembly

4-4 XHX6G5TP 195 16

torques.

6-4 XHX6G5TP 353 29

8-4 XHX6G5TP 788 66

Specifications 10 XHX6G5TP 975 81

12 XHX6G5TP 1425 119

SAE Products: 37° Flare and ORFS 24° Flareless Metric Parker 2100 175

Specifications 16 XHX6G5TP

Parker Triple-Lok and Seal-Lok EO and EO-2

20 XHX6G5TP 2850 238

37° Flare (JIC): SAE J514/ISO 8434-2 24 XHX6G5TP 3375 281

Industry Standards DIN 2353/ISO 8434-1

ORFS: SAE J1453/ISO 8434-3

37° Flare/ORFS Steel, Cold Drawn barstock Note: Assembly values are for dry,

Material – Machined unlubricated swivel nut connections

– ASTM A108, Type 12L14

Steel, Per DIN 3859 Table N2 — Assembly Torques for

Bodies and Swivel High Strength Nuts

Nuts – ASTM A108, Type C1137

Diagnostic Tees

Cold Formed Swivel

Steel, ASTM A576 Type C-1010/C1008 N/A

Nuts

Assembly Torque

Temperature Range,

Part (+10%-0)

Non-Elastomeric Steel: -40°F to +500°F Steel: -40°F to +500°F

Number in.-lb. ft.-lb.

Seals

4-4 LHL6G5TP 22 2

ORFS Nitrile O-Rings: -30° F to +250° F Nitrile EO-2: -30°F to +212°F

Temperature Range, 6-4 LHL6G5TP 36 3

ORFS Fluorocarbon O-Rings: -15° F to Fluorocarbon EO-2: -15°F to

Elastomeric Seals 8-4 LHL6G5TP 48 4

+400° F +400°F

10 LHL6G5TP 72 6

ORFS: SAE -4 through -24 Light: 6-L through 42-L

Body Sizes Heavy: 6-S through 38-S 12 LHL6G5TP 102 9

37° Flare: SAE -4 through -24

14 LHL6G5TP 114 10

Maximum Rated

See accompanying Tables See accompanying Tables 16 LHL6G5TP 132 11

Working Pressure

20 LHL6G5TP 168 14

Table N1 — Material Specifications of Parker’s Diagnostic Tees 24 LHL6G5TP 216 18

32 LHL6G5TP 432 36

Table N3 — Assembly Torques for

Diagnostic Tees

N4 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

L L

LOHL6G5TP H XHX6G5TP H

Gauge Port Tee Gauge Port Tee

2 1 2 1

ORFS / ORFS Swivel / 37° Flare / 37° Swivel /

SAE-ORB SAE-ORB 3

3

STANDARD STANDARD

Pressure Pressure

END SIZE (x 1,000 PSI) END SIZE (x 1,000 PSI)

TUBE FITTING 1 2 3 H L Static Dynamic TUBE FITTING 1 2 3 H L Static Dynamic

PART # (in.) (in.) UN/UNF (in.) (in.) -S -S PART # (in.) (in.) UN/UNF (in.) (in.) -S -S

4-4 LOHL6GP5TP 1/4 1/4 7/16-20 1-1/16 1.83 10.0 6.0 4-4 LOHL6GP5TP 1/4 1/4 7/16-20 1-1/16 1.83 10.0 6.0

6-4 LOHL6GP5TP 3/8 3/8 7/16-20 1-1/16 1.95 10.0 6.0 6-4 LOHL6GP5TP 3/8 3/8 7/16-20 1-1/16 1.95 10.0 6.0

8-4 LOHL6GP5TP 1/2 1/2 7/16-20 1-1/16 2.18 10.0 6.0 8-4 LOHL6GP5TP 1/2 1/2 7/16-20 1-1/16 2.18 10.0 6.0

10-4 LOHL6GP5TP 5/8 5/8 7/16-20 1-1/8 2.40 10.0 6.0 10-4 LOHL6GP5TP 5/8 5/8 7/16-20 1-1/8 2.40 10.0 6.0

12-4 LOHL6GP5TP 3/4 3/4 7/16-20 1-1/4 2.59 10.0 6.0 12-4 LOHL6GP5TP 3/4 3/4 7/16-20 1-1/4 2.59 10.0 6.0

16-4 LOHL6GP5TP 1 1 7/16-20 1-1/2 2.85 9.5 6.0 16-4 LOHL6GP5TP 1 1 7/16-20 1-1/2 2.85 9.5 6.0

20-4 LOHL6GP5TP 1 1/4 1 1/4 7/16-20 1-3/4 3.07 6.5 5.0 20-4 LOHL6GP5TP 1 1/4 1 1/4 7/16-20 1-3/4 3.07 6.5 5.0

24-4 LOHL6GP5TP 1 1/2 1 1/2 7/16-20 2-1/8 3.22 5.0 4.0 24-4 LOHL6GP5TP 1 1/2 1 1/2 7/16-20 2-1/8 3.22 5.0 4.0

Note: Fluorocarbon O-rings are available upon request.

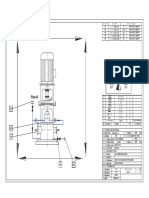

GMA3

Diagnostic Tip S2 H

S3

EO Tube / EO Tube /

M16 x 2.0 Integrated Tip

Tube

O.D. I1

L1

STANDARD

Pressure

TUBE TUBE (x 1,000 PSI)

FITTING O.D. H I1 L1 S2 S3 Static Dynamic

PART # (mm) (mm) (mm) (mm) (mm) (mm) A3C A3C

GMA3/06L 6 49 21 51 14 24 7.2 4.5

GMA3/08L 8 49 21 51 17 24 7.2 4.5

GMA3/10L 10 49 23 53 19 24 7.2 4.5

GMA3/12L 12 50 23 53 22 27 5.8 4.5

GMA3/15L 15 52 25 55 27 30 5.8 4.5

GMA3/18L 18 53 24 57 32 32 5.8 4.5

GMA3/22L 22 55 28 61 36 36 3.6 2.3

GMA3/28L 28 57 28 61 41 41 3.6 2.3

GMA3/35L 35 60 26 69 50 46 3.6 2.3

GMA3/42L 42 64 25 71 60 55 3.6 2.3

GMA3/06S 6 49 25 55 17 24 10.1 9.1

GMA3/08S 8 49 25 55 19 24 10.1 9.1

GMA3/10S 10 49 24 57 22 24 10.1 9.1

GMA3/12S 12 49 24 57 24 24 10.1 9.1

GMA3/14S 14 50 27 63 27 27 10.1 9.1

GMA3/16S 16 52 26 63 30 30 9.1 5.8

GMA3/20S 20 55 26 69 36 36 9.1 5.8

GMA3/25S 25 57 27 75 46 41 9.1 5.8

GMA3/30S 30 60 28 81 50 46 6.1 5.8

GMA3/38S 38 64 29 91 60 55 6.1 4.5

To specify EO-2, add “Z” between tube size and series.

Example: GMA3/28ZLA3C

N5 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

Diagnostic Tee Port Adapters

and Test Points

Adapters are available to enable traditional NPT pressure

gauges to be connected to the 7/16-20 UNF port of the

diagnostic tees. F5OG adapters provide a simple conversion,

while the AOHG adapters provide the same simple conversion

with infinite positioning due to the male ORB adjustable stud.

Direct connecting test points products, available through

Parker’s Quick Coupling Division, provide reliable and safe

testing opportunities. These traditional pressure and tempera-

ture test points (PD and EMA) are the most common diagnostic

test interfaces used in hydraulic applications. The PDFS is

used for fluid sampling applications. Consult Parker’s Quick

Coupling Division for more information on these and many

other diagnostic test point options available through Parker.

NPT Pressure Gauge Conversion Adapters Fig. N4 — Diagnostic tees shown with PD Series nipple

installed in 7/16-20 UNF (SAE-ORB) port

L L

1 2 2 1

C

H

F5OG-S AOHG-S

STANDARD

Pressure

TUBE END SIZE (x 1,000 PSI)

FITTING 1 2 H L Static Dynamic

PART # UN/UNF-2A NPTF (in.) (in.) -S -S

4-1/8 F5OG 7/16-20 1/8-27 9/16 1.00 8.0 6.0

4-1/4 F5OG 7/16-20 1/4-18 3/4 1.16 8.0 6.0

4-1/8 AOHG 7/16-20 1/8-27 5/8 1.41

4-1/4 AOHG 7/16-20 1/4-18 3/4 1.57

Parker’s Quick Coupling Division

Test Point Couplings

D

Features of Parker Quick Coupling Division

D D Diagnostic Test Points

PD:

• Flush face valving, minimizing fluid loss

F

• Industry standard interface

F F

• Push-to-connect

PD EMA3 PDFS

Series Series Series EMA3:

ORB

• M16 x 2 thread-to-connect

TUBE PORT • Connects under pressure

FITTING THREAD D F PERFORMANCE • Industry standard interface

PART # UN/UNF-2A (in.) (in.) RATINGS

PD331* 7/16-20 1.80 0.69 PDFS:

Consult QCD

EMA3/7/16-20 UNF-2A* 7/16-20 1.88 0.67 • For fluid sampling only

Catalog 3800

PDFS341* 7/16-20 1.60 0.69

* A product of Parker’s Quick Coupling Division. Contact QCD at

(763) 544-7781 or at www.parker.com/quickcouplings.

N6 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

BSPP Diagnostic Pressure

Gauge Adapters BSPP pressure

gauge port sealing

Parker’s BSPP direct-connect pressure gauge adapters are with use

available in the most common tube/hose connections — of sealing ring

ORFS, 37° Flare (JIC) and 24° Metric Flareless (DIN 2353).

European pressure gauges often utilize BSPP threads on the

pressure gauges (manometers). Sealing is achieved at the

bottom of the port with a sealing washer as shown in the

illustration on the right.

BSPP Pressure Gauge Adapters

L L

L L

2 1 2 1 2 1 2 1 ORFS 37° Flare EO / EO-2 EO / EO-2

24° Flareless 24° Flareless

H H2 Swivel

H H H

Fig. N5 — BSPP pressure gauge connections

G4MXSMO G4MLOSMO MAVE MAV

(Type A) (Type B) (Type C) (Type D)

STANDARD

H H2 Pressure

END SIZE BODY NUT (x 1,000 PSI)

TUBE FITTING 1 2 L HEX HEX Static Dynamic

PART # TYPE (in.) BSPP (mm) (mm) (mm) S S

4-4G4MXSMO A 1/4 1/4-19 31.0 17 — 5.0 5.0

6G4MXSMO A 3/8 1/4-19 28.0 17 — 5.0 5.0

8-4G4MXSMO A 1/2 1/4-19 31.0 19 — 5.0 5.0

4-4G4MLOSMO B 1/4 1/4-19 26.8 17 — 5.0 5.0

6G4MLOSMO B 3/8 1/4-19 28.2 19 — 5.0 5.0

8-4G4MLOSMO B 1/2 1/4-19 29.8 22 — 5.0 5.0

1 2 Static Dynamic

(mm) BSPP A3C A3C

MAVE06LRA3C C 6 1/4-19 35.5 19 14 4.6 4.6

MAVE08LRA3C C 8 1/4-19 35.5 19 17 4.6 4.6

MAVE10LRA3C C 10 1/4-19 36.0 19 19 4.6 4.6

MAVE06SRA3C C 6 1/2-14 42.5 27 17 9.1 9.1

MAVE08SRA3C C 8 1/2-14 43.0 27 19 9.1 9.1

MAVE10SRA3C C 10 1/2-14 43.5 27 22 9.1 9.1

MAVE12SRA3C C 12 1/2-14 45.0 27 24 9.1 9.1

MAVE06SR1/4A3C C 6 1/4-19 35.5 19 17 9.1 9.1

MAVE08SR1/4A3C C 8 1/4-19 35.5 19 19 9.1 9.1

MAVE10SR1/4A3C C 10 1/4-19 39.0 19 22 9.1 9.1

MAVE12SR1/4A3C C 12 1/4-19 39.0 19 24 9.1 9.1

MAV04LLRA3C D 4 1/4-19 33.0 19 10 1.4 1.4

MAV06LRA3C D 6 1/4-19 37.0 19 14 4.5 4.5

MAV08LRA3C D 8 1/4-19 37.0 19 17 4.5 4.5

MAV10LRA3C D 10 1/4-19 38.0 19 19 4.5 4.5

MAV12LRA3C D 12 1/4-19 38.0 19 22 4.5 4.5

MAV06SRA3C D 6 1/2-14 46.0 27 17 9.1 9.1

MAV08SRA3C D 8 1/2-14 46.0 27 19 9.1 9.1

MAV10SRA3C D 10 1/2-14 47.0 27 22 9.1 9.1

MAV12SRA3C D 12 1/2-14 47.0 27 24 9.1 9.1

Note: MAV supplied as standard with DPR +M nut (EO assembled)

* BSPP Pressure Gauge Connection requires seal. 1/4" replacement seal P/N: M25180.

** BSPP Pressure Gauge Connection requires seal. 1/4" replacement seal P/N: DKI1/4A3CX,

1/2" replacement seal P/N: DKI1/2A3CX.

N7 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

NPT and SAE-ORB Diagnostic

Pressure Gauge Adapters

Traditional or

Parker’s NPT and SAE-ORB direct-connect pressure gauge electronic / digital

adapters are available in the most common North American pressure gauge

tube/hose connections — ORFS and 37° Flare (JIC). North

American pressure gauge manufacturers offer gauges prima-

rily with NPT and some with SAE-ORB port stud options. These

37° flare and ORFS connectors are designed to attach pres-

sure gauges to hose swivel ends or directly to run / branch tees GLO GTX G6L

for in-line diagnostic applications as shown on the right.

NPT / SAE Pressure Gauge Adapters

FF FF FF

2 1 2 1 2 1

H S

H H R5OLO-S

GLO G6L G5L Run Tee

(Type A) (Type B) (Type C)

FF FF FF Hydraulic Hose

2 1 2 1 1 2 Fig. N6 — Typical applications for NPT pressure gauge

adapters. Illustrations show direct hose connections and

H S Run Tee connection.

H H S

G65L GTX G6X

(Type D) (Type E) (Type F)

S STANDARD

H SWIVEL Pressure

TUBE END SIZE BODY NUT (x 1,000 PSI)

FITTING 1 2 FF HEX HEX Static Dynamic

PART # TYPE (in.) NPT (in.) (in.) (in.) -S -S

4-4 GLO A 1/4 1/4-18 1.25 3/4 — 9.5 6.0

6 GLO A 3/8 1/4-18 1.30 3/4 — 8.0 6.0

8-4 GLO A 1/2 1/4-18 1.20 7/8 — 9.5 6.0

4-4 G6L B 1/4 1/4-18 1.48 3/4 11/16 9.5 6.0

6 G6L B 3/8 1/4-18 1.60 7/8 13/16 8.0 6.0

8-4 G6L B 1/2 1/4-18 1.75 7/8 15/16 9.5 6.0

UN/UNF

4 G5LO C 1/4 7/16-20 1.10 3/4 — 6.0 5.0

6-4 G5LO C 3/8 7/16-20 1.08 3/4 — 6.0 5.0

8-4 G5LO C 1/2 7/16-20 0.78 7/8 — 6.0 5.0

4 G65L D 1/4 7/16-20 1.38 11/16 11/16 6.0 5.0

6-4 G65L D 3/8 7/16-20 1.51 3/4 13/16 6.0 5.0

8-4 G65L D 1/2 7/16-20 1.57 7/8 15/16 6.0 5.0

NPT

2 GTX E 1/8 1/8-27 1.13 9/16 — 10.0 5.0

3 GTX E 3/16 1/8-27 1.13 9/16 — 10.0 5.0

4-4 GTX E 1/4 1/4-18 1.39 3/4 — 10.0 5.0

4 GTX E 1/4 1/8-27 1.19 9/16 — 10.0 5.0

6-2 GTX E 3/8 1/8-27 1.13 5/8 — 10.0 5.0

6 GTX E 3/8 1/4-18 1.41 3/4 — 10.0 5.0

8-4 GTX E 1/2 1/4-18 1.41 13/16 — 8.0 5.0

4-4 G6X F 1/4 1/4-18 9/16 3/4 9/16 9.5 6.0

4 G6X F 1/4 1/8-27 9/16 9/16 9/16 10.0 7.5

6 G6X F 3/8 1/4-18 11/16 3/4 11/16 6.0 5.0

N8 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

Diagnostic Tube / Hose Adapters Bulkhead Diagnostic Couplings

Parker’s diagnostic tube/hose adapters offer direct connec- D

tion to the most common tube and hose interfaces — ORFS, PD Nipple* E

37° Flare (JIC) and 24° Metric Flareless (DIN 2353). The swivel Triple-Lok Bulkhead Nipple

connections are commonly used on tees where periodic PD / Bulkhead 37° Flare

pressure and temperature checks are required. Several bulk-

head connections are also available as well for diagnostic

panels, a common industrial and mobile equipment practice. D E F F

QCD OVERALL EXPOSED HEX

Several of these product series are offered by Parker’s Quick PART # TUBE LENGTH LENGTH SIZE

Coupling Division as designated in the accompanying tables. STEEL SIZE (in.) (in.) (in.)

PD345 4 2.92 2.22 0.81

PD355 5 2.92 2.22 0.81

Bulkhead Application PD365 6 3.00 2.30 0.81

Bulkhead ORFS or 37° Swivel Note: Add -6 to part number to include dust cap;

Locknut Hose Connection e.g., PD345-6. Contact factory for seal option.

PD Nipple* D

E

Seal-Lok Bulkhead Nipple

PD / Bulkhead ORFS

D E F F

QCD OVERALL EXPOSED HEX

Tube Swivel Applications

PART # TUBE LENGTH LENGTH SIZE

In Port STEEL SIZE (in.) (in.) (in.)

PD346 4 2.98 2.27 0.81

PD366 6 3.08 2.37 1.00

Parker Male 37° Swivel Hose 8 3.18 2.47 1.12

PD386

Run Tee Connection

8 R5OX-S

D

MAV 1/4 NPT* C

M16 x 2.0 Diagnostic Tip / A

1/4 NPT Gauge

B

PD38BTX

A B C D

PORT HEX PORT OVERALL

QCD THREAD SIZE THREAD LENGTH

PART # SIZE (in.) SIZE (in.)

MAV1/4NPT-MA3 1/4-18 NPT 0.75 M16 x 2.0 2.22

MAV1/4NPT-MA3-KM** 1/4-18 NPT 0.75 M16 x 2.0 2.22

Parker T Series EO

In-Line or EO-2 Fitting ** Includes dust cap.

WGTX L

Female Bulkhead Connector 2 1

NPT / 37° Flare

F Hex

F L

TUBE END SIZE HEX OVERALL

FITTING 1 2 SIZE LENGTH

PART # (in.) NPT (in.) (in.)

VKA3 Series 4 WGTX 1/4 1/8-27 11/16 1.84

4-4 WGTX 1/4 1/4-18 3/4 2.11

6 WGTX 3/8 1/4-18 13/16 2.06

* A product of Parker’s Quick Coupling Division. Contact QCD for

performance data at (763) 544-7781 or at www.parker.com/

quickcouplings.

N9 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

Tube Swivel Diagnostic Couplings

PDBTX* A

B PDBTL* A

B

Triple-Lok Tube Swivel Nipple Seal-Lok Tube Swivel Nipple

PD Diagnostic Tip / 37° Swivel PD Diagnostic Tip / ORFS Swivel

PD34BTX A B

PD34BTL

A B

QCD OVERALL EXPOSED QCD OVERALL EXPOSED

PART # TUBE LENGTH LENGTH A PART # TUBE LENGTH LENGTH A

(in.) (in.) B (in.) (in.) B

STEEL SIZE STEEL SIZE

PD34BTX 4 1.64 0.94 PD34BTL 4 2.18 1.48

PD36BTX 6 1.66 0.96 PD36BTL 6 2.30 1.60

PD38BTX 8 1.17 0.47 PD38BTL 8 1.12 0.42

PD312BTX 12 1.39 0.69 PD310BTL 10 1.16 0.46

PD36BTX PD36BTL

Note: Tube end nipples are designed to meet the Note: Tube end nipples are designed to meet the

performance standards of the tube or hose fitting performance standards of the tube or hose fitting

connection, which may or may not meet SAE connection, which may or may not meet SAE

J1502 Standards. J1502 Standards.

PDBTU* A

B

Ferulok Tube Swivel Nipple

PD Diagnostic Tip / SAE Flareless

A B

QCD OVERALL EXPOSED

PART # TUBE LENGTH LENGTH

STEEL SIZE (in.) (in.)

PD38BTU 8 1.40 0.70

H

H

SW1

SW1

SW2 SW2

VKA3

M16 x 2.0 Diagnostic G D1 G D1

Tip / EO Swivel

Type A

Type B

STANDARD

TUBE D1 Pressure

FITTING TUBE H (x 1,000 PSI)

PART # O.D. G REF. SW1 SW2 Static Dynamic

STEEL TYPE (mm) Metric (mm) (mm) (mm) A3C A3C

VKA3/06LA3C A 6 M12 x 1.5 55 17 14 7.2 4.5

VKA3/08LA3C A 8 M14 x 1.5 51 17 17 7.2 4.5

VKA3/10LA3C A 10 M16 x 1.5 53 17 19 7.2 4.5

VKA3/12LA3C A 12 M18 x 1.5 53 17 22 5.8 4.5

VKA3/15LA3C B 15 M22 x 1.5 59 17 27 5.8 4.5

VKA3/18LA3C B 18 M26 x 1.5 59 17 32 5.8 4.5

VKA3/22LA3C B 22 M30 x 2 60 17 36 3.6 2.3

VKA3/28LA3C B 28 M36 x 2 64 17 41 3.6 2.3

VKA3/35LA3C B 35 M45 x 2 71 17 50 3.6 2.3

VKA3/42LA3C B 42 M52 x 2 72 17 60 3.6 2.3

VKA3/06SA3C A 6 M14 x 1.5 50 17 17 10.1 9.1

VKA3/08SA3C A 8 M16 x 1.5 52 17 19 10.1 9.1

VKA3/10SA3C A 10 M18 x 1.5 53 17 22 10.1 9.1

VKA3/12SA3C A 12 M20 x 1.5 54 19 24 10.1 9.1

VKA3/14SA3C B 14 M22 x 1.5 59 17 27 10.1 9.1

VKA3/16SA3C B 16 M24 x 1.5 58 17 30 9.1 5.8

VKA3/20SA3C B 20 M30 x 2 65 17 36 9.1 5.8

VKA3/25SA3C B 25 M36 x 2 68 17 46 9.1 5.8 * A product of Parker’s Quick Coupling Division.

VKA3/30SA3C B 30 M42 x 2 74 17 50 6.0 5.8 Contact QCD for performance data at (763) 544-7781

VKA3/38SA3C B 38 M52 x 2 81 17 60 6.0 4.5 or at www.parker.com/quickcouplings.

N10 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

L

Orifice Fittings XHX7 Orifice

In-Line Orifice Connector 2 1

These compact and cost effective orifice adapters allow OEMs

to pre-set, at the factory, a specified orifice in specific hydraulic 37° Flare / Female 37° Seat

Orifice

tube or hose lines. Costly flow control valves can be eliminated C

or minimized in a system by selecting the proper orifice sizes

STANDARD

at the factory. OEMs can also be assured that end users are not Pressure

END

adjusting the factory established flow and speed characteris- SIZE (x 1,000 PSI)

C

tics of the hydraulic system. 1&2 HEX ORIFICE L

TUBE FITTING Static Dynamic

PART # (in.) (in.) (in.) (in.) -S -S

Orifice 1/4 9/16 .015 1.10 10.0 5.0

4 XHX7-S .015 Orifice

4 XHX7-S .031 Orifice 1/4 9/16 .031 1.10 10.0 5.0

4 XHX7-S .047 Orifice 1/4 9/16 .047 1.10 10.0 5.0

4 XHX7-S .062 Orifice 1/4 9/16 .062 1.10 10.0 5.0

4 XHX7-S .078 Orifice 1/4 9/16 .078 1.10 10.0 5.0

4 XHX7-S .094 Orifice 1/4 9/16 .094 1.10 10.0 5.0

6 XHX7-S .015 Orifice 3/8 11/16 .015 1.18 10.0 5.0

6 XHX7-S .031 Orifice 3/8 11/16 .031 1.18 10.0 5.0

6 XHX7-S .047 Orifice 3/8 11/16 .047 1.18 10.0 5.0

6 XHX7-S .062 Orifice 3/8 11/16 .062 1.18 10.0 5.0

Orifice 6 XHX7-S .078 Orifice 3/8 11/16 .078 1.18 10.0 5.0

Features: 6 XHX7-S .094 Orifice 3/8 11/16 .094 1.18 10.0 5.0

• 37° flare and ORFS configurations as standard 8 XHX7-S .015 Orifice 1/2 7/8 .015 1.32 8.5 5.0

8 XHX7-S .031 Orifice 1/2 7/8 .031 1.32 8.5 5.0

• Three standard body sizes available: 1/4" 3/8", and 1/2 7/8 .047 1.32 8.5 5.0

8 XHX7-S .047 Orifice

1/2" 1/2 7/8 .062 1.32 8.5 5.0

8 XHX7-S .062 Orifice

• Available in commonly accepted pre-set orifice sizes 8 XHX7-S .078 Orifice 1/2 7/8 .078 1.32 8.5 5.0

as shown on accompanying tables 8 XHX7-S .094 Orifice 1/2 7/8 .094 1.32 8.5 5.0

• Designed for permanent or temporary installation

• Can be installed in-line into hydraulic system by simply

connecting between hose swivel and adapter

• Orifice size is permanently stamped on body LOHL6 Orifice L

• Additional differentiation can be provided as a custom

In-Line Orifice Connector 2 1

option (special color plating, hex notch, etc.)

ORFS Swivel / ORFS

• Can eliminate costly flow control valves Orifice

C

• Standard construction consists of zinc yellow dichro-

mate plated steel STANDARD

• Custom orifice fittings available upon request in END Pressure

SIZE C (x 1,000 PSI)

multitudes of sizes, materials, configurations, and

orifice sizes TUBE FITTING 1 & 2 HEX ORIFICE L Static Dynamic

PART # (in.) (in.) (in.) (in.) -S -S

Applications: 4 LOHL6-S .015 Orifice 1/4 5/8 .015 1.33 12.0 9.2

4 LOHL6-S .031 Orifice 1/4 5/8 .031 1.33 12.0 9.2

• Fixed rotation speed for hydraulic motors

4 LOHL6-S .047 Orifice 1/4 5/8 .047 1.33 12.0 9.2

• Fixed speed on cylinder extend or retract 4 LOHL6-S .062 Orifice 1/4 5/8 .062 1.33 12.0 9.2

4 LOHL6-S .078 Orifice 1/4 5/8 .078 1.33 12.0 9.2

Direct Port Orifice Fittings: 1/4 5/8 .094 1.33 12.0 9.2

4 LOHL6-S .094 Orifice

Available as a custom product, Parker also offers a line of 6 LOHL6-S .015 Orifice 3/8 3/4 .015 1.44 12.0 9.2

orifice adapters that will replace a traditional port adapter. 6 LOHL6-S .031 Orifice 3/8 3/4 .031 1.44 12.0 9.2

6 LOHL6-S .047 Orifice 3/8 3/4 .047 1.44 12.0 9.2

6 LOHL6-S .062 Orifice 3/8 3/4 .062 1.44 12.0 9.2

6 LOHL6-S .078 Orifice 3/8 3/4 .078 1.44 12.0 9.2

6 LOHL6-S .094 Orifice 3/8 3/4 .094 1.44 12.0 9.2

8 LOHL6-S .015 Orifice 1/2 7/8 .015 1.67 12.0 9.2

8 LOHL6-S .031 Orifice 1/2 7/8 .031 1.67 12.0 9.2

8 LOHL6-S .047 Orifice 1/2 7/8 .047 1.67 12.0 9.2

8 LOHL6-S .062 Orifice 1/2 7/8 .062 1.67 12.0 9.2

8 LOHL6-S .078 Orifice 1/2 7/8 .078 1.67 12.0 9.2

8 LOHL6-S .094 Orifice 1/2 7/8 .094 1.67 12.0 9.2

N11 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

Bleed Adapters Bleeding Hydraulic Systems with Parker

Bleed Adapters

Entrapped air is a major contributor to inefficient opera-

tion. Typically, bleeding hydraulic systems is done by Whenever possible, the bleed adapter should be mounted at the

“cracking” a connection to “bleed off” the entrapped air. highest point within the hydraulic system. The trapped air can be

This practice is not recommended, especially in larger relieved while the system is running at low pressure. To bleed,

size fittings where high forces can exist. Parker’s bleed loosen the bleed screw 1/2 turn counterclockwise. After the

adapters are especially beneficial in applications where hydraulic fluid begins to run freely from the bleed screw, the bleed

elastomeric seals (O-rings) can be extruded and/or dam- screw should be re-tightened.

aged during bleeding such as with Parker’s Seal-Lok

fittings. Bleed Screw Tightening Torque: 35-40 in.-lbs.

Parker’s bleed adapters are designed specifically for Warning: When bleeding hydraulic fluid, operate the system

installation directly to ORFS (O-Ring Face Seal) type below 500 psi. To avoid injury, ensure that all persons are clear

fittings or into SAE/NPT manifolds and valves where of the path of discharge. Another recommended practice is to

bleeding is often required. attach a section of hose over the bleed screw/adapter to direct oil

away from the area and to reduce oil spillage.

Features

• Bleed hydraulic systems without “cracking” 1) Seal-Lok Bleed Adapter

hydraulic connections 2) (Sizes -8 thru -24)

• Uses standard automotive bleed screw design For use with

Seal-Lok Fittings

• Bleed screw is permanently crimped into body

housing, for blowout prevention

1)

• In-port options with SAE and NPT male studs

• Tube/hose connection options to male and female

ORFS

• Zinc Yellow Chromate plated steel construction 2)

Pipe Thread Bleed Adapter

1/4 NPT

For use with Pipe Thread

Ports

ORFS Bleed Adapters

1)

L Ref. Notes:

L F 1) Standard automotive

Ø.30 Ø.30 bleedscrew.

(ref) (Ref.) 2) Locking crimp prevents

screw from being completely

1 1 unthreaded. 2)

3/8 Hex 3/8 Hex Straight Thread Bleed Adapter

H Size 4 (7/16-20 UNF)

ORFS Tube Nut For use with SAE Straight

Thread Ports

PNLOBA FNLBA

ORFS Tube Nut sold separately

STANDARD Port Bleed Adapters

END Pressure

TUBE SIZE (x 1,000 PSI) L (Ref.) L (Ref.)

FITTING 1 F H L Static Dynamic Ø .30 Ø .30 LL (Ref.)

(Ref.) LL (Ref.)

PART # (in.) (in.) (in.) (in.) -S -S (Ref.)

4 PNLOBA 1/4 - 11/16 1.90 12.0 9.2

3/8 - 3/4 1.97 12.0 9.2 1 1

6 PNLOBA

8 PNLOBA 1/2 - 7/8 2.07 12.0 9.2

10 PNLOBA 5/8 - 1 1/16 2.19 11.0 6.0 3/8 Hex H

3/8 Hex H

12 PNLOBA 3/4 - 1 1/4 2.27 11.0 6.0

16 PNLOBA 1 - 1 1/2 2.35 9.5 6.0 4 P5ONBA 1/4 HPBA

20 PNLOBA 1 1/4 - 1 3/4 2.41 8.0 6.0

24 PNLOBA 1 1/2 - 2 1/8 2.48 6.5 5.0 STANDARD

8 FNLBA 1/2 1.63 15/16 2.07 12.0 9.2 Pressure

10 FNLBA 5/8 1.63 1 1/8 2.17 11.0 6.0 TUBE END SIZE BODY L LL (x 1,000 PSI)

12 FNLBA 3/4 1.63 1 3/8 2.21 11.0 6.0 FITTING HEX H REF. REF. Static Dynamic

16 FNLBA 1 1.63 1 5/8 2.21 9.5 6.0 PART # 1 (in.) (in.) (in.) (in.) -S -S

20 FNLBA 1 1/4 1.63 1 7/8 2.21 8.0 6.0 4 P5ONBA 7/16-20 UN/UNF-2A 11/16 11/16 2.05 1.62 10.0 6.0

24 FNLBA 1 1/2 1.63 2 1/4 2.21 6.5 5.0 1/4 HPBA 1/4-18 NPTF 11/16 11/16 2.20 1.86 10.0 6.0

N12 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

4300 Catalog Diagnostic, Orifice, Bleed Adapters

and Specialty Fittings

L

Parker Triple Thread (PTT) 0109 LL

Adapters Parker Triple Thread Fitting 2 1

NPTF / PTT

C

0109 Adapter “32” Series (PTT)

Hose Swivel

STANDARD

Dynamic

LL Pressure

TUBE END SIZE C AFTER (x 1,000 PSI)

FITTING 1 2 HEX L ASSY

(in.) (in.) (in.) S SS B

PART # (in.) NPTF

0109-12-16 1 (1 5/16-14) 3/4-14 1 3/8 1.84 1.36 3.0

0109-16-16 1 (1 5/16-14) 1-11 1/2 1 3/8 2.03 1.46 3.0

0109-20-20 1 1/4 (1 5/8-14) 1 1/4-11 1/2 1 3/4 2.22 1.63 3.0

0109-24-24 1 1/2 (1 7/8-14) 1 1/2-11 1/2 2 2.50 1.91 3.0

Parker Triple Thread (PTT) adapters are considered the

original three-piece hydraulic flared fittings. The connec-

tion was pioneered by Arthur Parker, the founder of Parker

Hannifin Corporation, as an improved fitting design over

traditional two-piece flared fittings. Its use was widespread

as a primary hydraulic connection for various aircraft, indus-

trial and mobile applications. The PTT 30° flare three-piece

design paved the progress towards the standardized 37°

connection (through the Joint Industrial Council – JIC) and

later to current standardization initiatives of SAE and ISO.

Its popularity has been diminished by the more common

and standardized 37° flare connection, but even today

certain transportation customers utilize PTT hose adapters

for OEM and MRO applications.

Features:

• 30° flare connection

• Hose adapter connection only (no sleeve for tube

connections)

• Metal-to-metal seal

• SAE 12L14 steel with zinc yellow dichromate Parker

plating and friction control system

• Four 0109 PTT sizes available as standard

• Custom sizes, configurations, and materials avail-

able upon request

Applications:

• Diesel engine manufacturers

• Transportation air conditioning lines

Mates with Parker Hose Products Division “32” swivel end

configuration in 20 and 22 Series fittings.

N13 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

www.parker.com/tfd

You might also like

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Pipe Fittings and Port Adapters 3Document1 pagePipe Fittings and Port Adapters 3armin_kunosic9871No ratings yet

- Pipe Fitting Dimensions CatalogueDocument22 pagesPipe Fitting Dimensions CatalogueMuhammad AfzaalNo ratings yet

- Pipe Fittings and Port Adapters 2Document1 pagePipe Fittings and Port Adapters 2armin_kunosic9871No ratings yet

- O-Rings and Seals: 90° ElbowsDocument6 pagesO-Rings and Seals: 90° ElbowsHuy NguyễnNo ratings yet

- Parker Catalogue (Fittings, Adaptors, Tube Clamps, Valves) PDFDocument508 pagesParker Catalogue (Fittings, Adaptors, Tube Clamps, Valves) PDFMohamed ElsemanNo ratings yet

- ADAPTERS ParkerDocument61 pagesADAPTERS ParkerIon StingaciNo ratings yet

- JDocument28 pagesJBaso Syahrul AkramNo ratings yet

- PAUT Solution For Flange-Pipe WeldDocument25 pagesPAUT Solution For Flange-Pipe WeldAbderrahmane79No ratings yet

- Pipe Fittings & Port AdaptersDocument28 pagesPipe Fittings & Port AdaptersRO-AM-BDNo ratings yet

- RYCO Adaptors FittingsDocument131 pagesRYCO Adaptors FittingsGeorge BNo ratings yet

- Parker Fittings CatalogDocument72 pagesParker Fittings CatalogAlmir RodriguesNo ratings yet

- BSPP Adapters FemaleFemaleDocument2 pagesBSPP Adapters FemaleFemaleIvan IvanNo ratings yet

- Pipe FittingsDocument26 pagesPipe Fittingsmajid fardniaNo ratings yet

- I Metric BSPDocument85 pagesI Metric BSPArun JaisonNo ratings yet

- Seal-Lok O-Ring Face Seal FittingsDocument36 pagesSeal-Lok O-Ring Face Seal FittingsZackyD03No ratings yet

- Seal-Lok O-Ring Face Seal Tube FittingsDocument34 pagesSeal-Lok O-Ring Face Seal Tube Fittingsarmin_kunosic9871No ratings yet

- Hydraulic Flanges & Components & Dual Seal Flanges: Visual IndexDocument20 pagesHydraulic Flanges & Components & Dual Seal Flanges: Visual IndexHuy NguyễnNo ratings yet

- CN3 4 1 7 - ADocument2 pagesCN3 4 1 7 - AAugusto RezendeNo ratings yet

- Mini - General Purpose Regulators - R07, R46Document2 pagesMini - General Purpose Regulators - R07, R46Miguel Camacho BalabarcaNo ratings yet

- Norma JIC 37Document36 pagesNorma JIC 37guguimirandaNo ratings yet

- O RingsDocument10 pagesO RingsFernando Padilla100% (1)

- Parker Adaptors Hydraulic Flanges & Components & Dual Seal FlangesDocument44 pagesParker Adaptors Hydraulic Flanges & Components & Dual Seal Flangesjadan tupuaNo ratings yet

- Parker Pneumatic Sensors PDFDocument25 pagesParker Pneumatic Sensors PDFyouri59490No ratings yet

- NG-01 - 8.02.13 Pressure Regulating ValveDocument2 pagesNG-01 - 8.02.13 Pressure Regulating ValveAlexsandro TorezinNo ratings yet

- Diagnostic Orifice Bleed Adapters & Specialty FittDocument14 pagesDiagnostic Orifice Bleed Adapters & Specialty FittPartsGopher.comNo ratings yet

- Parker Pipe - Fitting - and - Adapters PDFDocument47 pagesParker Pipe - Fitting - and - Adapters PDFPeter SNo ratings yet

- RA FittingsDocument16 pagesRA FittingsDejanNo ratings yet

- Conn To 740-A-001/TP-001 INLET 4 in RFFE 150 F3 G6 B7 E 579304990 N 2119665795 EL +107278 4"NPD 2Document9 pagesConn To 740-A-001/TP-001 INLET 4 in RFFE 150 F3 G6 B7 E 579304990 N 2119665795 EL +107278 4"NPD 2DANLIN ENGINEERSNo ratings yet

- 0900 SensDocument32 pages0900 Sensxally hernandez sorianoNo ratings yet

- Parker RHDDocument46 pagesParker RHDDuygu GerçekNo ratings yet

- Vent Lines of Booster PumpsDocument1 pageVent Lines of Booster PumpsRiadh RiadhNo ratings yet

- AG - Hyfdraulic Fittings Guideline - 2017 05 09Document14 pagesAG - Hyfdraulic Fittings Guideline - 2017 05 09CAT CYLINDERNo ratings yet

- Glass Expansion Catalogue - Issue 9 2014 PDFDocument59 pagesGlass Expansion Catalogue - Issue 9 2014 PDFPalika MedinaNo ratings yet

- SD6 Valve DetailsDocument1 pageSD6 Valve DetailsVEERAMANINo ratings yet

- R1620 EASY TEST – Complete hydraulic test point systemDocument8 pagesR1620 EASY TEST – Complete hydraulic test point systemakangucaiNo ratings yet

- Instrumentation Thread FittingsDocument9 pagesInstrumentation Thread FittingsDiego PillajoNo ratings yet

- Parker PDFDocument32 pagesParker PDFJean DuboisNo ratings yet

- Breather & Filler Breather Product Range: Innovative Fluid PowerDocument22 pagesBreather & Filler Breather Product Range: Innovative Fluid PowerSai RamNo ratings yet

- MAG welding procedure for butt welding S355 steel platesDocument2 pagesMAG welding procedure for butt welding S355 steel platesdayalram100% (1)

- EFCG9_Tube_Fittings_4300_2_Triple-Lok_and_Triple-Lok2_37Flare_Tube_FittingDocument40 pagesEFCG9_Tube_Fittings_4300_2_Triple-Lok_and_Triple-Lok2_37Flare_Tube_FittingDavid BaylissNo ratings yet

- JIS HYD FittingsDocument8 pagesJIS HYD FittingsVipuchit SirikhemapornNo ratings yet

- Check Valve Type NRV and NRVH: Data SheetDocument14 pagesCheck Valve Type NRV and NRVH: Data SheetBao Nguyen Nguyen HuuNo ratings yet

- S850Anew ComparisonDocument1 pageS850Anew ComparisonStefan HorvathNo ratings yet

- F - Brass Inserts PLDocument12 pagesF - Brass Inserts PLecto8totoNo ratings yet

- Parker Ermeto CatalogueDocument66 pagesParker Ermeto CataloguewakaNo ratings yet

- Adapters: Pipe FittingsDocument18 pagesAdapters: Pipe FittingsLeonNo ratings yet

- PT-36 Cut Data 04-13-06 PDFDocument92 pagesPT-36 Cut Data 04-13-06 PDFAnonymous 1I6K0ttrRNo ratings yet

- Pressure Senders: Pressure Sender & Adapter KitsDocument2 pagesPressure Senders: Pressure Sender & Adapter KitsJohn GarnetNo ratings yet

- EO and EO-2 Metric Bite Type Fittings: The Fitting AuthorityDocument62 pagesEO and EO-2 Metric Bite Type Fittings: The Fitting AuthorityZahir KhiraNo ratings yet

- Instrument Thread FittingsDocument10 pagesInstrument Thread FittingsFabio MolinaNo ratings yet

- FP06P Data SheetDocument1 pageFP06P Data Sheetcuatrillizos2015No ratings yet

- Extron Electronics TPX 88 and TPX A Compatibility ChartDocument1 pageExtron Electronics TPX 88 and TPX A Compatibility ChartToday's NameNo ratings yet

- Sae Adapters CatalogueDocument230 pagesSae Adapters CataloguehaggNo ratings yet

- p546 - Line Differential DistanceDocument15 pagesp546 - Line Differential DistancesaiNo ratings yet

- LG-6001 Lead Gage: Operation ManualDocument24 pagesLG-6001 Lead Gage: Operation ManualSukumarNo ratings yet

- ProductSerieSheet 4SRPV enDocument4 pagesProductSerieSheet 4SRPV enSyamsul SetyawanNo ratings yet

- Genie Hyd&elec - Diagram PDFDocument94 pagesGenie Hyd&elec - Diagram PDFManuel casanovaNo ratings yet

- 02 Datasheet Pressure TransmitterDocument2 pages02 Datasheet Pressure TransmitterFadlila MuhammadNo ratings yet

- Did CatalogDocument347 pagesDid CatalogJorge Eliecer RodriguezNo ratings yet

- SKF Power Transmission ProductsDocument286 pagesSKF Power Transmission ProductsZahir KhiraNo ratings yet

- Realtech High Alumina Ceramic LinerDocument2 pagesRealtech High Alumina Ceramic LinerZahir KhiraNo ratings yet

- Realtech Ceramic Pipe and BendDocument2 pagesRealtech Ceramic Pipe and BendZahir KhiraNo ratings yet

- Conveying and Storing in Cement IndustryDocument32 pagesConveying and Storing in Cement IndustryZahir KhiraNo ratings yet

- Rexnold Take Up Unit PDFDocument28 pagesRexnold Take Up Unit PDFZahir KhiraNo ratings yet

- Installation Components: TubingDocument31 pagesInstallation Components: TubingZahir KhiraNo ratings yet

- General Lubrication Products: Fittings & AccessoriesDocument1 pageGeneral Lubrication Products: Fittings & AccessoriesZahir KhiraNo ratings yet

- Material Handling Equipment SteelDocument114 pagesMaterial Handling Equipment SteelZahir Khira100% (1)

- QCX - General - Cement PDFDocument4 pagesQCX - General - Cement PDFZahir KhiraNo ratings yet

- Operators Guide KobelcoDocument30 pagesOperators Guide KobelcoZahir KhiraNo ratings yet

- Centrifugal Fans - Flakt (India) Limited PDFDocument8 pagesCentrifugal Fans - Flakt (India) Limited PDFZahir KhiraNo ratings yet

- Drum BrakesDocument7 pagesDrum BrakesZahir KhiraNo ratings yet

- Grease Fitting PDFDocument20 pagesGrease Fitting PDFleonardsiregarNo ratings yet

- Standard Features: Your One-Stop Source For Material Handling Control SolutionsDocument2 pagesStandard Features: Your One-Stop Source For Material Handling Control SolutionsZahir KhiraNo ratings yet

- 3.5 Fans & BlowersDocument8 pages3.5 Fans & BlowersPrasad GangavathuNo ratings yet

- Brochure Axicooler GBDocument10 pagesBrochure Axicooler GBEko SusantoNo ratings yet

- Multi-Line and Progressive Systems: Product CatalogueDocument36 pagesMulti-Line and Progressive Systems: Product CatalogueZahir KhiraNo ratings yet

- Chapter-Fans and BlowersDocument21 pagesChapter-Fans and BlowersRathish RaghupathyNo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Cranes AccidentsDocument16 pagesCranes AccidentsGogyNo ratings yet

- Ringspann Elecon CatlogDocument30 pagesRingspann Elecon CatlogZahir Khira100% (2)

- Howden Axial Fans HC Centrifugal Fans PDFDocument116 pagesHowden Axial Fans HC Centrifugal Fans PDFSurya Kiran KNo ratings yet

- Industrial Process Fans: Installed Power Up To 4,000 KWDocument2 pagesIndustrial Process Fans: Installed Power Up To 4,000 KWZahir KhiraNo ratings yet

- Freewheel Clutches: Ringspann CorporationDocument16 pagesFreewheel Clutches: Ringspann CorporationZahir KhiraNo ratings yet

- Fläkt Woods' Document Collector - User GuideDocument7 pagesFläkt Woods' Document Collector - User GuideZahir KhiraNo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Freewheel Clutches: Ringspann CorporationDocument16 pagesFreewheel Clutches: Ringspann CorporationZahir KhiraNo ratings yet

- Stieber Clutches Maincatalog en 2010Document92 pagesStieber Clutches Maincatalog en 2010Alice SunNo ratings yet

- KOYO One-Way Clutches GuideDocument19 pagesKOYO One-Way Clutches GuideZahir KhiraNo ratings yet

- Canalta SCOF Product ManualDocument11 pagesCanalta SCOF Product ManualBowo Edhi WibowoNo ratings yet

- China Steel SpecificationDocument45 pagesChina Steel SpecificationMohit KohliNo ratings yet

- 300KG LD PP Hdpe Waste Washing Plant - 2018Document3 pages300KG LD PP Hdpe Waste Washing Plant - 2018Pervez Ahmad Khan100% (1)

- Vacuum Pump Manual (English)Document12 pagesVacuum Pump Manual (English)nguyen lam An100% (1)

- How To Order ThermowellsDocument23 pagesHow To Order ThermowellsJoão LuizNo ratings yet

- Jola GB AbleDocument16 pagesJola GB AbleRoberto C RuizNo ratings yet

- Instructions Manual: Rotatory SieveDocument53 pagesInstructions Manual: Rotatory SieveBogdan PistolNo ratings yet

- CanadOil High Yield SteelDocument2 pagesCanadOil High Yield SteelsuparnaNo ratings yet

- 2021 Airtool CatalogDocument140 pages2021 Airtool CatalogKaruNo ratings yet

- Glass Balcony Fittings Catalog (Form Cathy) PDFDocument64 pagesGlass Balcony Fittings Catalog (Form Cathy) PDFDamons Foo OoipinNo ratings yet

- Metal FabricationsDocument10 pagesMetal FabricationsGhayas JawedNo ratings yet

- Style Alpha FC: Installation InstructionsDocument2 pagesStyle Alpha FC: Installation InstructionsAjiCiangsanaNo ratings yet

- Is-5131 Dividing Breeching With ControlDocument9 pagesIs-5131 Dividing Breeching With ControlCharls JamesNo ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4No ratings yet

- Aaon - Coils Brochure (2020)Document8 pagesAaon - Coils Brochure (2020)Trever TomesNo ratings yet

- Full Name Contact No. CityDocument335 pagesFull Name Contact No. CitySatyam TejiNo ratings yet

- Automatic Tap Water ControlingDocument38 pagesAutomatic Tap Water ControlingAngel AngalinaNo ratings yet

- Hazid Latest 1Document9 pagesHazid Latest 1Aleksei SukhovNo ratings yet

- Raw Mill Vertical Roller Mill PDFDocument58 pagesRaw Mill Vertical Roller Mill PDFManpreetSaran92% (12)

- 1 - Comilla Lot1-05 BOQ CantonmentDocument34 pages1 - Comilla Lot1-05 BOQ CantonmentjgnmoqjidncpobeimuNo ratings yet

- Conceptual Cost Estimating Manual - John S. PageDocument350 pagesConceptual Cost Estimating Manual - John S. PageiponputraNo ratings yet

- Extrusion of PlasticsDocument130 pagesExtrusion of PlasticsShubham Chaudhary100% (1)

- Colour coding pipelines for identificationDocument4 pagesColour coding pipelines for identificationNaizil Kareem100% (1)

- Plumbing Sanitary Bill of Quantities HSR Marketing Office BengaluruDocument6 pagesPlumbing Sanitary Bill of Quantities HSR Marketing Office BengaluruSachin KothvalNo ratings yet

- AIS Pipe Hangers and Supports Picture Index CatalogDocument9 pagesAIS Pipe Hangers and Supports Picture Index CatalogArtur MkrtchyanNo ratings yet

- L&T Ball Valves: 3-Piece DesignDocument8 pagesL&T Ball Valves: 3-Piece DesignmahaveenNo ratings yet

- Telescoping Guide Rhs and Chs Aug13 sj0510-1Document2 pagesTelescoping Guide Rhs and Chs Aug13 sj0510-1Richard GrahamNo ratings yet

- Pressure Boosting Technology 2008Document112 pagesPressure Boosting Technology 2008Paul DanielNo ratings yet

- BA 80-99 Use of Rock Bolts (DMRB Vol 2, Section 1, Part 7, 1999)Document69 pagesBA 80-99 Use of Rock Bolts (DMRB Vol 2, Section 1, Part 7, 1999)sandycastleNo ratings yet

- Torque Turn PDFDocument1 pageTorque Turn PDFAdi CiptadiNo ratings yet