Professional Documents

Culture Documents

Leirvik Quarters

Uploaded by

JAY SINGHAMOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leirvik Quarters

Uploaded by

JAY SINGHAMCopyright:

Available Formats

Leirvik sveis innmat v3 16.10.

00 11:03 Side 1

A

p r o u d

h i s t o r y

After 28 years in shipbuilding, Leirvik Sveis started to look into the new oil

industry in the North Sea. Since then we have been the leading supplier of

living quarters modules for offshore platforms.

Our first contract was Beryl “A”, delivered in 1975.

By the time the booming 1980s came along, Leirvik Sveis had acquired substantial

know-how with regard to living quarters and a reputation for being uncompromising

in relation to the quality of our products.

Leirvik Sveis delivered several living quarters and utility modules in the 1980s and the

1990s, including Saga Petroleum’s Snorre LQ. This was the largest aluminium structure

ever built for the offshore industry. Snorre became a pioneer project for Leirvik Sveis,

and has been the basis for our research and development programme on

aluminium used in offshore modules.

Since we started in 1974 most of our contracts have been EPC-related. We are proud

to say they were all delivered on time and with our customers’ stamp of approval.

Today Leirvik Sveis is a company with modern equip-

ment and facilities and 340 highly skilled employees.

Leirvik sveis innmat v3 16.10.00 11:03 Side 2

CUSTOMISED SOLUTION WITH SAFETY IN MIND

Leirvik Sveis has delivered more than twenty accomodation and utility modules

for offshore installations. By developing prefabricated components the company

is able to deliver units to meet the customer's specifications. Compact solutions

first and foremost mean smaller office and cabin sizes and a somewhat lower

level of comfort in the day rooms. This does not mean a lower level of safety,

however. A high level of comfort is characterised by single cabins, spacious offices

and a well-appointed galley. Emphasis is also placed on aesthetics and decora-

tions. Technical systems are concealed for this reason.

The project organisation has the necessary experience to work in accordance

with various specifications regarding comfort and price, but with the same

requirements for safety. Total costs will therefore vary, depending on the lifetime

of the installation, climatic and weather considerations, the level of comfort

desired and other technical solutions.

a

C h o i c e

ALUMINIUM OR STEEL

Aluminium today is known as a safe and suit-

able material for accommodation modules

and a number of other offshore installations.

Conclusive factors in favour of aluminium are

low weight and lower maintenance costs.

Leirvik Sveis has delivered a number of

accommodation modules in aluminium that

have proven to be both safe and durable, for

example Snorre A (1991), Oseberg Øst (1997)

and Snorre B, which will be delivered in 2000.

Leirvik Sveis has developed and patented a

number of standardised aluminium profiles

that make it cost-effective to use this material

in the structures. Fire, safety and strength

have been incorporated so that the complet-

ed structures meet the strictest safety require-

ments.

Steel structures are still relevant where

requirements for low weight are of less

importance and the expected design life on

the field is shorter.

Total costs can be lower for steel structures,

which may therefore be the right choice also

because the customer to a greater extent can

draw on local expertise for subsequent modi-

fications and mainte-

nance. Leirvik Sveis has

its own facilities for

surface treatment which

also includes metallizing.

The fireplace at Oseberg A

Leirvik sveis innmat v3 16.10.00 11:03 Side 3

QUALITY THROUGHOUT THE LIFETIME

After 25 years our products have proved its

durability.

Quality and customers satisfaction are

important issues in our organisation.

All our products are designed and manufac-

tured in accordance with the most stringent

quality assurance standard.

Leirvik Sveis was among the first companies

in Norway obtaining ISO 9001 certification.

Our quality system has adopted our long

experience by continual improvement. By

skill, good facilities and management system

we will obtain and keep customer satisfac-

tion throughout the lifetime of the product.

Q u a l i t y

&

K n o w l e d g e

WOULD YOU USE THE SAME

CONTRACTOR AFTER 25 YEARS?

We delivered our first accommodation module to the Norwegian

sector of the North Sea 25 years ago. It is still in use by Statoil on

Statfjord “A”. Today, 25 years later, we have received an order for

another living quarters module, Kvitebjørn, for the same client.

Since 1974 Leirvik Sveis has been an EPC contractor for 21 modules

in steel or aluminium. Twenty-five years in business have given us

experience as an accommodation module specialist that is envied

by most of our competitors.

LEIRVIK SVEIS CAN OFFER YOU:

Our concept enables us to deliver turnkey products

– weighed and commissioned.

Our total delivery comprises all work from client’s

functional requirements to sailaway. This includes

Project Management, Engineering, Procurement,

Construction and Testing (EPCM) of all systems

The project performance involves a fully integrated in-

house project taskforce, using the most up to date IT

tools, in close co-operation with local suppliers within

all trades.

Leirvik sveis innmat v3 16.10.00 11:03 Side 4

Leirvik Sveis, as one of the leading EPC

Contractors for major offshore mod-

ules, has considerable experience with-

in construction and building in steel

and aluminium. Leirvik Sveis can build

and load-out constructions over 5.000

tons.

Our main construction site, approxi-

mately 112.000 m2, consists of produc-

tion halls ranging from 500-4.000 m2.

F a c i l i t i e s

Continuous efforts are made to always

make use of the most modern and up

to date equipment within welding

technology as well as information

technology.

Our company, comprising 3 sites at

Stord, measures a total of approxi-

mately 150.000 m2.

Load-out facilities are excellent and

there are no restrictions on the sail-

away route to the North Sea and the

rest of the world.

You might also like

- Engineering Design Basis (Structural)Document21 pagesEngineering Design Basis (Structural)Kamaraj Bangarusamy100% (1)

- Tarlac - San Antonio - Business Permit - NewDocument2 pagesTarlac - San Antonio - Business Permit - Newarjhay llave100% (1)

- Cameron CatalogDocument53 pagesCameron CatalogJAY SINGHAM0% (1)

- DPWH Cost EstimationDocument67 pagesDPWH Cost EstimationAj Abe92% (12)

- Global Grants Community Assessment FormDocument3 pagesGlobal Grants Community Assessment Formlalitya xavieraNo ratings yet

- KEC International Limited: Pile FoundationDocument49 pagesKEC International Limited: Pile FoundationDinesh Kumar100% (1)

- Guide To Cold Formed Steel FramingDocument14 pagesGuide To Cold Formed Steel Framingjackcan501No ratings yet

- Company Profile LSSGKDocument18 pagesCompany Profile LSSGKrobitNo ratings yet

- Cold Formed Structural SteelDocument14 pagesCold Formed Structural SteelGoran SalimovićNo ratings yet

- How To Guide To Oauth and API SecurityDocument12 pagesHow To Guide To Oauth and API Securitysilviuleahu100% (1)

- 00 Cosmology - Cambridge Lecture Notes PDFDocument82 pages00 Cosmology - Cambridge Lecture Notes PDFJAY SINGHAM100% (1)

- Single Storey Industrial BuildingsDocument40 pagesSingle Storey Industrial BuildingsLahlou DahmaniNo ratings yet

- Lecture Notes (Financial Economics)Document136 pagesLecture Notes (Financial Economics)americus_smile7474100% (2)

- Peb BrochureDocument26 pagesPeb BrochureAbdul MaminNo ratings yet

- Brochure Combined Wall Systems - 2019 - Digital - SingleDocument40 pagesBrochure Combined Wall Systems - 2019 - Digital - SinglelazcanoNo ratings yet

- Audi Navigation System Plus - MMI Operating ManualDocument100 pagesAudi Navigation System Plus - MMI Operating ManualchillipaneerNo ratings yet

- Tensile Membrane Structure PDFDocument25 pagesTensile Membrane Structure PDFAbed Genaim100% (1)

- ABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Document18 pagesABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Zoren Jovillanos EmbatNo ratings yet

- Marine Aluminum-Helideck BrochureDocument17 pagesMarine Aluminum-Helideck Brochurescribbler123100% (1)

- VAT (Chapter 8 Compilation of Summary)Document36 pagesVAT (Chapter 8 Compilation of Summary)Dianne LontacNo ratings yet

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDocument20 pagesTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- Kingspan Structural KSP Multideck Technical Handbook LR 122018 en UKDocument140 pagesKingspan Structural KSP Multideck Technical Handbook LR 122018 en UKdion2110No ratings yet

- FPSO BrochureDocument12 pagesFPSO BrochuredonyaNo ratings yet

- Steel Ladle Calderys Brochure A4Document22 pagesSteel Ladle Calderys Brochure A4Mitone Diaz100% (1)

- Case For SteelDocument24 pagesCase For SteelengkjNo ratings yet

- Light Gauge Steel FrameDocument20 pagesLight Gauge Steel FrameConstro FacilitatorNo ratings yet

- JKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralDocument270 pagesJKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralYamie Rozman100% (1)

- OSNA10 Sheathing MTL Group EN 2019Document6 pagesOSNA10 Sheathing MTL Group EN 2019David RobsonNo ratings yet

- Kee Safety Safety Components Catalog 2016Document52 pagesKee Safety Safety Components Catalog 2016skip5_17No ratings yet

- SigmaweldDocument8 pagesSigmaweldPVFS PVFSNo ratings yet

- Offshore Structural ProductsDocument12 pagesOffshore Structural ProductsBruben Jerome BellsNo ratings yet

- Stoplog DatasheetDocument2 pagesStoplog DatasheetjayusmanNo ratings yet

- Low Temp Cryogenic Storage 2021 DigitalDocument5 pagesLow Temp Cryogenic Storage 2021 DigitalFaisal AwadNo ratings yet

- Storage Calorifier Profile HrsfunkeDocument12 pagesStorage Calorifier Profile HrsfunkePKP MECHNo ratings yet

- 7.1 Manual Tecnico Fabricante Domo CST-CoversDocument12 pages7.1 Manual Tecnico Fabricante Domo CST-CoversJuan Carlos Ortiz ANo ratings yet

- MailerDocument8 pagesMailerGanesh KumarNo ratings yet

- Copper-Nickel Welding and Fabrication - 3Document1 pageCopper-Nickel Welding and Fabrication - 3satnamNo ratings yet

- Metal Roof Deck and Trays BrochureDocument16 pagesMetal Roof Deck and Trays BrochureSaad PervezNo ratings yet

- Corrosion Protection: Arcelormittal Europe - Long Products Sections and Merchant BarsDocument48 pagesCorrosion Protection: Arcelormittal Europe - Long Products Sections and Merchant BarstecnidibujosNo ratings yet

- CaseStudy - AE - Proofex Engage - KSA - June 2011Document3 pagesCaseStudy - AE - Proofex Engage - KSA - June 2011SHAIK ASIMUDDINNo ratings yet

- Deformation-Based Design Method of Aluminium Helideck For Eurocode 9Document6 pagesDeformation-Based Design Method of Aluminium Helideck For Eurocode 9NivethithaNo ratings yet

- Oceans of Opportunities.Document14 pagesOceans of Opportunities.Uhrin ImreNo ratings yet

- 66 DuPont MECS Alloy AcidCoolersDocument2 pages66 DuPont MECS Alloy AcidCoolersMohamed Elayachi100% (1)

- Standard Specification No: Kpc-A-07 Standard Specification For Roof and Wall Cladding FOR PT Kaltim Prima Coal Project at East Kalimantan, IndonesiaDocument12 pagesStandard Specification No: Kpc-A-07 Standard Specification For Roof and Wall Cladding FOR PT Kaltim Prima Coal Project at East Kalimantan, Indonesiabarian karopebokaNo ratings yet

- Tile Pro: Proinso PV RackDocument2 pagesTile Pro: Proinso PV RackFIDELITASSSNo ratings yet

- Nexanaffgs HanggfafdbookDocument116 pagesNexanaffgs HanggfafdbookAnonymous ziG2oaNo ratings yet

- FG0318 AL SFS BrochureDocument12 pagesFG0318 AL SFS BrochureMatt GreeneNo ratings yet

- Projects Oil and Gas BrochureDocument20 pagesProjects Oil and Gas BrochureRussel John RamosNo ratings yet

- Welding 9% Nickel Steel For Liquefied Natural Gas (LNG) ApplicationsDocument11 pagesWelding 9% Nickel Steel For Liquefied Natural Gas (LNG) ApplicationsLiu YangtzeNo ratings yet

- 2100en Surge Arrester Product Programme (English)Document16 pages2100en Surge Arrester Product Programme (English)TurnerNo ratings yet

- Umbilicals: Harsh Environment CablesDocument1 pageUmbilicals: Harsh Environment CableschristpcNo ratings yet

- Western Grandstand Case Study - WebDocument6 pagesWestern Grandstand Case Study - WebannNo ratings yet

- Design Aid To Is 800-2007: Safe Load For Angle StrutsDocument5 pagesDesign Aid To Is 800-2007: Safe Load For Angle StrutsKaran PrabhakarNo ratings yet

- Pipe InsulationDocument2 pagesPipe InsulationZami FurqonNo ratings yet

- Innovative Structural Steel SystemsDocument12 pagesInnovative Structural Steel SystemsCIVILNo ratings yet

- 8803 CS Systems Brochure - EN 1 PDFDocument20 pages8803 CS Systems Brochure - EN 1 PDFAnonymous jW9BkgbQmENo ratings yet

- SCI Steel Buildings BenefitsDocument24 pagesSCI Steel Buildings BenefitsengkjNo ratings yet

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDocument3 pages001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- TWI DVS Welding9Ni JHandFN WeldingCuttingApril2007 Pp103to112 PDFDocument12 pagesTWI DVS Welding9Ni JHandFN WeldingCuttingApril2007 Pp103to112 PDFiTuan Khai TruongNo ratings yet

- Eldon Replacement 2016xxDocument55 pagesEldon Replacement 2016xxAnonymous SDeSP1No ratings yet

- Brochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTDocument8 pagesBrochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTArturo lopez abucharNo ratings yet

- M1-Ce TRK1-103Document9 pagesM1-Ce TRK1-103Yves VillagraciaNo ratings yet

- MGI CORPORATE BROCHURE CompressedDocument43 pagesMGI CORPORATE BROCHURE CompressedmiplbuildsysNo ratings yet

- SRWF Hvac CatalogueDocument12 pagesSRWF Hvac CataloguejengandxbNo ratings yet

- Steel Sandwich Panels in Marine Applications: Pentti KUJALA Alan KlanacDocument10 pagesSteel Sandwich Panels in Marine Applications: Pentti KUJALA Alan KlanacMarko AnticNo ratings yet

- Civil Miniproject AishwaryaDocument22 pagesCivil Miniproject Aishwaryavikas kadamNo ratings yet

- Reefer Rack Steel ConstructionDocument13 pagesReefer Rack Steel ConstructionFay NandaNo ratings yet

- 02 Value Benefits of Steel ConstructionDocument7 pages02 Value Benefits of Steel ConstructionOlay KwongNo ratings yet

- P124 Fire Resistance Web Infilled ColumnsDocument32 pagesP124 Fire Resistance Web Infilled Columnsanil97232No ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Marinco AsiaDocument2 pagesMarinco AsiaJAY SINGHAMNo ratings yet

- Zentech, Incorporated: Consulting EngineersDocument8 pagesZentech, Incorporated: Consulting EngineersJAY SINGHAMNo ratings yet

- Bostrig 125 Type P-VFD Power CableDocument2 pagesBostrig 125 Type P-VFD Power CableJAY SINGHAMNo ratings yet

- Cosmic Mystery PDFDocument5 pagesCosmic Mystery PDFJAY SINGHAMNo ratings yet

- New Form 2550 M Monthly VAT Return P 1 2 1Document3 pagesNew Form 2550 M Monthly VAT Return P 1 2 1The ApprenticeNo ratings yet

- List of Approved Journals For Promoting Purposes at The University of JordanDocument3 pagesList of Approved Journals For Promoting Purposes at The University of JordanZaid MarwanNo ratings yet

- Heirs of Tancoco v. CADocument28 pagesHeirs of Tancoco v. CAChris YapNo ratings yet

- Applicant Details : Government of Tamilnadu Application Form For Vehicle E-Pass For Essential ServicesDocument1 pageApplicant Details : Government of Tamilnadu Application Form For Vehicle E-Pass For Essential ServicesŠářoĵ PrinceNo ratings yet

- Guidelines For New Students - 2022Document14 pagesGuidelines For New Students - 2022Ria Faye PaderangaNo ratings yet

- UN-HABITAT Quick Quide Urban Mobility Plans For Review - Fri 01-Feb-2013Document59 pagesUN-HABITAT Quick Quide Urban Mobility Plans For Review - Fri 01-Feb-2013tarekyousryNo ratings yet

- Andaman & Nicobar: Port BlairDocument4 pagesAndaman & Nicobar: Port BlairDevan BhallaNo ratings yet

- Octopus 900 Instructions For UseDocument18 pagesOctopus 900 Instructions For UseAli FadhilNo ratings yet

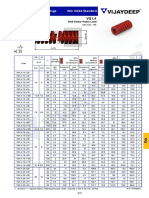

- Rectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadDocument3 pagesRectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadbashaNo ratings yet

- Business Works Student User GuideDocument14 pagesBusiness Works Student User GuideAkram UddinNo ratings yet

- High-Definition Multimedia Interface SpecificationDocument51 pagesHigh-Definition Multimedia Interface SpecificationwadrNo ratings yet

- Good Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaDocument2 pagesGood Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaADBGADNo ratings yet

- Ultra Wideband TechnologyDocument21 pagesUltra Wideband TechnologyAzazelNo ratings yet

- Electrical NTPCDocument24 pagesElectrical NTPCSenthil KumarNo ratings yet

- Review of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)Document12 pagesReview of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)RHIAN B.No ratings yet

- Exchange Rates JBDocument9 pagesExchange Rates JBboss9921No ratings yet

- News/procurement-News: WWW - Sbi.co - inDocument15 pagesNews/procurement-News: WWW - Sbi.co - inssat111No ratings yet

- Ljubljana European Green Capital 2016Document56 pagesLjubljana European Green Capital 2016Kann_dandy17No ratings yet

- 11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsDocument6 pages11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsCorrado BisottoNo ratings yet

- Es 590Document35 pagesEs 590Adnan BeganovicNo ratings yet