Professional Documents

Culture Documents

Preparation and Characterization

Uploaded by

SAI ASSOCIATEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparation and Characterization

Uploaded by

SAI ASSOCIATECopyright:

Available Formats

Preparation and Characterization

7. PREPARATION AND CHARACTERIZATION

Different approaches used for preparation of fast dissolving systems like

Lyophilized system, compressed tablet based system and Oral thin wafers/strips.

Oral thin film/wafers are the most convenient and advanced form of oral solid

dosage form due to the efficiency of dissolving within minutes in oral cavity when it

comes in contact of saliva. It neither requires chewing nor water for administration.

It gives quick absorption and instant bioavailability of drugs due to the high blood

flow and permeability of oral mucosa.

7.1 Formulation development of Sublingual wafers of Palonosetron

Various approaches to manufacturing of rapid dissolving wafers are classified as

follows:

A. Casting and drying—(a) solvent casting (b) semi-solid casting

B. Extrusion—(a) hot-melt extrusion (b) solid dispersion extrusion

C. Freeze dried wafers

D. Rolling method

Solvent casting method

This technique is employed to manufacture fast dissolving wafers of size 3x2 cm 2

and 2.5x2.5 cm2. Water soluble polymers are dissolved in the aqueous vehicle. The

drug along with other excipients is dissolved in a suitable solvent, and both are

mixed and stirred. It is finally casted on petridish or plate made up of glass, plastic

or Teflon and dried. Specific types of equipment are used at large scale production

as well as rollers are used for pouring the solution on an inert base. Entrapped air is

removed by vacuum. The final step is drying the wafer, removes the solvent and

helps to obtain the finished product. Wafers are dried after which cutting, stripping

and packaging is done. Due to feasibility and easy to preparation with lower cost,

Solvent casting method used for formulation development of thin wafers of

Palonosetron.

Malhotra College of Pharmacy (MCP), Bhopal Page 30

Preparation and Characterization

7.1.1 Casting process of fast disintegrating oral wafers

Various methods are available for casting of oral wafers. This is fast disintegrating

oral wafers hence on the laboratory scale solvent casting technique was adopted for

formulation of wafers.

7.1.2 Solvent casting technique

Drug (Palonosetron) containing fast dissolving wafers were fabricated by the solvent

casting method. Xanthan gum, Gelatin, Gum acacia, cross carmellose sodium,

Aspartame by solvent casting technique with ice cold distilled water and sublingual

wafers were prepared. Drug solution was sonicated for 30-45 min to solubilize the

drug completely in the solvent. Drug solution was poured into polymeric solution

and ethanol was added for alkaline hydrolysis. Both solutions are uniformly mixed to

get a homogeneous solution on magnetic stirrer at 250-320 rpm. Then this solution

was spread on film former by adjusting the desired temperature on glass moulds of

15cm*5 cm2. Once the wafer sheet was ready, it was cut into desired size of 2.5*2.5

cm2 cm was dried and The dried wafers were carefully removed from the glass plates

and was cut into size required for testing. The wafers were stored in air tight plastic

bags till further use. The composition of sublingual wafers is given in Table 7.1.

7.1.3 Parameter Selection for formulation of oral wafers

1. Size of Wafers

Size of tongue is about 2.5 x 2.5 cm, to provide sufficient space for dissolving in

oral cavity by putting wafers on tongue for swishing or hydrating with saliva, size

2.5 x 2.5 cm were concluded as unit dose of Wafers.

2. Fabrication of wafers casting glass reservoir

Wafers casting glass reservoir is most important glassware which was fabricated

keeping view the following aspect:

1. No. of wafers in one batch

2. Holding capacity of formulation solution for drying

Malhotra College of Pharmacy (MCP), Bhopal Page 31

Preparation and Characterization

3. scrapping-off wafers from Wafers casting glass reservoir

4. Easy to positioned horizontally with gravity for uniform formation of wafers

A 15.0 x 5.0 cm sized Wafers casting glass reservoir was fabricated having depth of

0.5cm. This sized Wafers casting glass reservoir will produce twelve 2.5 x 2.5 cm.

3. Amount of solution for formulation

30.0 ml solution was calculated for further study, because this will produce 200

micrometer depth for solvent evaporation and sufficient numbers of wafers for

further evaluations.

4. Temperature and time of drying

Preliminary study suggests that 40+/- 1.0degree centigrade for 12 hrs adequately dry

the wafers.

5. Speed of mixing at magnet stirrer.

250-320 rpm speed for first 30 minutes were optimized for entire study and 5

minutes for all ingredients with same speed were finalized.

7.1.4 Selection and optimization of wafers forming agents

Two wafers forming agents and one co-wafers forming were selected for this

research work. The concentration of wafers forming was important to form a proper

thickness for appropriate packaging and handling of oral wafers.

Concentration of wafers forming agent is optimized on the basis of thickness and

appearance of wafers.

Malhotra College of Pharmacy (MCP), Bhopal Page 32

Preparation and Characterization

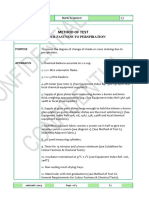

A) Optimization of formulations

Table No 7.1: Selection and Optimization of Wafers Forming Agents

Name of ingredients

(mg for 12 strips) F1 F2 F3 F4 F5 F6 F7 F8 F9

API 6 6 6 6 6 6 6 6 6

Xanthan gum 50 100 150 50 100 150 50 100 150

Gelatin 10 20 30 10 20 30 10 20 30

Gum acacia 25 50 75 25 50 75 25 50 75

Cross carmellose sodium 10 10 10 10 10 10 10 10 10

Methyl Paraben 10 10 10 10 10 10 10 10 10

Aspartame 10 10 10 10 10 10 10 10 10

Citric acid 15 15 15 15 15 15 15 15 15

DM water qs to (ml) 30 30 30 30 30 30 30 30 30

Dose calculations

Width of the plate = 5cm

Length of the plate = 12cm

No. of 2.5 x 2.5 cm2 wafers present whole plate = 12

Each wafer contains 0.5 mg of drug.

12 no. of wafers contains mg of drug? = 0.5×12 = 6mg

The amount of drug added in each plate was approximately equal to 6mg.

7.2 Evaluation of prepared Wafers

7.2.1 Thickness

Three random wafers were selected from each batch and the thickness was measured

at three different places using a vernier caliper.

7.2.2 Weight uniformity

For each formulation, three randomly selected patches were used. For weight

variation test, 10 wafers from each batch were weighed individually by digital

Malhotra College of Pharmacy (MCP), Bhopal Page 33

Preparation and Characterization

electronic balance and the average weight and relative standard deviation was

calculated.

7.2.3 Surface pH Determination

The surface pH of fast dissolving wafers was determined in order to investigate the

possibility of any side effects in vivo. As an acidic or alkaline pH may cause

irritation to the oral mucosa, it is important to keep the surface pH as close to neutral

as possible. The wafer to be tested was placed in a petridish and was moistened with

0.2 ml of distilled water. The electrode of pH meter (Electronic india) was placed on

the surface of wafer to determine the surface pH.

7.2.4 Folding Endurance

This was determined by repeatedly folding one wafers at the same place until it

broke. The number of times the wafers could be folded at the same place without

breaking cracking gave the value of folding endurance.

7.2.5 Percentage of Moisture Content

The wafers were weighed individually and kept in desiccators containing activated

silica at room temperature for 24 hrs. Individual wafers were weighed repeatedly

until they showed a constant weight. The percentage of moisture content was

calculated as the difference between initial and final weight with respect to final

weight.

Initial weight−Final weight

Percentage of Moisture Content = x 100

Initial weight

7.2.6 Drug Content Analysis

The patches (n=3) of specified area were taken into a 10 ml volumetric flask and

dissolved in methanol and volume was made up with 10 ml methanol. Subsequent

dilutions were made and analyzed by UV spectrophotometer at 222nm.

7.2.7 Disintegrating time

The most important criteria of present work are to that dosage form should be

dissolved within few seconds. The incorporation of polymers to minimizes the

Malhotra College of Pharmacy (MCP), Bhopal Page 34

Preparation and Characterization

disintegrating time. In vitro disintegration time was determined by placing the wafer

in a petridish containing 10ml distilled water with swirling every 10 sec. The time at

which the wafer disintegrated was noted.

7.2.8 In vitro dissolution study

The in vitro dissolution test was performed using the USPXXX dissolution

apparatus II (Paddle type). The dissolution studies were carried out at 37±0.5°C;

with stirring speed of 50 rpm in 900 ml phosphate buffer (pH 6.8). Wafers size

required for dose delivery (2.5×2.5 cm 2) was used. Five ml aliquot of dissolution

media was collected at time intervals of 1, 2, 5, 10 and 15 minutes and replaced with

equal volumes of phosphate buffer (pH 6.8). The collected samples were filtered

through 0.45 μm membrane filter and the concentration of the dissolved

Palonosetron was determined using UV-Visible spectrophotometer at 222nm. The

results were presented as an average of three such concentrations.

7.9 Stability studies

Stability studies were carried out with optimized formulation which was stored for a

period of one, two and three months at 40±2oC temperature and 75±5% relative

humidity for a period 3 months. The % Assay of formulation was determined by

U.V. spectrophotometer using calibration curve method. The % assay of wafers was

found to slightly decrease at higher temperature.

Malhotra College of Pharmacy (MCP), Bhopal Page 35

You might also like

- Numerology Decoder PDFDocument3 pagesNumerology Decoder PDFChris Walker100% (3)

- Gratuity Affidavit FormatDocument3 pagesGratuity Affidavit FormatSAI ASSOCIATE100% (1)

- Internoise-2015-437 - Paper - PDF Sound Standard Gas TurbineDocument8 pagesInternoise-2015-437 - Paper - PDF Sound Standard Gas TurbinePichai ChaibamrungNo ratings yet

- Demystifying Interventional Radiology A Guide For Medical StudentsDocument195 pagesDemystifying Interventional Radiology A Guide For Medical StudentsMo Haroon100% (1)

- Developmental Psychology-Revised 2018Document51 pagesDevelopmental Psychology-Revised 2018Aadya PoddarNo ratings yet

- International Case StudyDocument14 pagesInternational Case StudyPriyanka Khadka100% (1)

- Evaluation of The Suspending Property of Khaya Snegalensis Gum in Co-Trimoxazole SuspensionsDocument6 pagesEvaluation of The Suspending Property of Khaya Snegalensis Gum in Co-Trimoxazole SuspensionsridwanridwanNo ratings yet

- Rada 2018Document10 pagesRada 2018AdewaleNo ratings yet

- Design and Evaluation of Matrix Tablets for Extended Release of Diltiazem HydrochlorideDocument9 pagesDesign and Evaluation of Matrix Tablets for Extended Release of Diltiazem HydrochlorideSiva PrasadNo ratings yet

- C07 - Colour Fastness To PerspirationDocument5 pagesC07 - Colour Fastness To PerspirationChandru TGNo ratings yet

- Research PaperDocument6 pagesResearch PaperNitin BansalNo ratings yet

- Jar Test ExperimentDocument13 pagesJar Test Experimentfatin najwaNo ratings yet

- Design of Novel Oral Films As Drug Delivery SystemDocument7 pagesDesign of Novel Oral Films As Drug Delivery SystemReza-ul JalilNo ratings yet

- Acm 003Document5 pagesAcm 003Roan BNo ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression MethodDocument5 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression Methodanto_pharma7784No ratings yet

- Disintegration TestDocument13 pagesDisintegration TestVesh Chaurasiya100% (1)

- 1481 D0752025 PDFDocument6 pages1481 D0752025 PDFANo ratings yet

- Central Water Standard Operating Procedure Coagulant Jar TestDocument7 pagesCentral Water Standard Operating Procedure Coagulant Jar Testعراقي iraqiNo ratings yet

- Aulia Indra Gunawan 202114010Document12 pagesAulia Indra Gunawan 202114010miftahulhusna030503No ratings yet

- 9 To 11 FinalDocument19 pages9 To 11 FinalSusmita GhoshNo ratings yet

- SDS PAGE de ProteinasDocument11 pagesSDS PAGE de Proteinasana cristinaNo ratings yet

- Isolation and Evaluation of Binding Property of Sago Starch in Paracetamol TabletDocument7 pagesIsolation and Evaluation of Binding Property of Sago Starch in Paracetamol TabletGusti Ketut KusumaNo ratings yet

- Sujathapaper 1Document12 pagesSujathapaper 1Catherine chaimaNo ratings yet

- Research Article Fast Disintegrating Combination Tablets of Omeprazole and DomperidoneDocument9 pagesResearch Article Fast Disintegrating Combination Tablets of Omeprazole and DomperidoneMuhamad Nur ArifinNo ratings yet

- Hasil Penelitian PvaDocument7 pagesHasil Penelitian PvaEga TrikuntiantiNo ratings yet

- Aloe Vera GelDocument8 pagesAloe Vera GelUday MahajanNo ratings yet

- Ujian BikarDocument4 pagesUjian BikarHana AiceNo ratings yet

- GelCode Blue Stain ReagentDocument4 pagesGelCode Blue Stain ReagentAhammed Abu DilNo ratings yet

- JDDR 139Document11 pagesJDDR 139Earthjournal PublisherNo ratings yet

- SDS-PAGE Protein SeparationDocument7 pagesSDS-PAGE Protein SeparationNoor JanahiNo ratings yet

- Tds 4Document4 pagesTds 4Neha YadavNo ratings yet

- Introduction To Bosentan PPRDocument7 pagesIntroduction To Bosentan PPRkulbhushan singhNo ratings yet

- Available Online Through: ISSN: 0975-766XDocument8 pagesAvailable Online Through: ISSN: 0975-766XAshish TripathiNo ratings yet

- Spe 198351 MSDocument9 pagesSpe 198351 MSAli AliievNo ratings yet

- Ikebe2005 - Origen y Relación de La Concentración de Glucosa Extraída Con El Área de Superficie TrituradaDocument7 pagesIkebe2005 - Origen y Relación de La Concentración de Glucosa Extraída Con El Área de Superficie TrituradaYarisa Villar BonilloNo ratings yet

- SecnidazoleDocument4 pagesSecnidazolemimibarasa06No ratings yet

- Water Treatment - AmbesaDocument8 pagesWater Treatment - AmbesaAmbesiwe Amatshawe RauzelaNo ratings yet

- Formulation and Evaluation of Montelukast Sodium and Levocetirizine Dihydrochloride Sublingual TabletsDocument5 pagesFormulation and Evaluation of Montelukast Sodium and Levocetirizine Dihydrochloride Sublingual TabletsNeerajNo ratings yet

- Technical-Grade Low-Viscosity CMC (CMC-L VT)Document5 pagesTechnical-Grade Low-Viscosity CMC (CMC-L VT)MilosTrbojevicNo ratings yet

- Spherical Crystallization of Zaltoprofen for Enhanced PropertiesDocument7 pagesSpherical Crystallization of Zaltoprofen for Enhanced PropertiesAditya RizqullohNo ratings yet

- JYPharm 4 157Document7 pagesJYPharm 4 157Mari Ana BuendiaNo ratings yet

- JURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19Document3 pagesJURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19AnditapitalokaNo ratings yet

- Cambridge Ordinary LevelDocument12 pagesCambridge Ordinary LevelIqraNo ratings yet

- Lab 4.isolation of PlasmidDocument7 pagesLab 4.isolation of PlasmidJane MargarethaNo ratings yet

- End TermDocument9 pagesEnd TermEducation PecNo ratings yet

- Formulation and Evaluation of Fast Dissolving Tablets ofDocument12 pagesFormulation and Evaluation of Fast Dissolving Tablets ofSofiah YahyaaNo ratings yet

- Etoposide JurnalDocument6 pagesEtoposide JurnalShalie VhiantyNo ratings yet

- FTEC103L-Total Yeast and Molds Count PDFDocument6 pagesFTEC103L-Total Yeast and Molds Count PDFian reyNo ratings yet

- Development and Stability Evaluation of Enteric Coated Diclofenac Sodium Tablets Using SuretericDocument6 pagesDevelopment and Stability Evaluation of Enteric Coated Diclofenac Sodium Tablets Using SuretericTiara Anindita NugrohoNo ratings yet

- Formulation and Evaluation of Ocular Inserts of Acyclovir PDFDocument8 pagesFormulation and Evaluation of Ocular Inserts of Acyclovir PDFcilamanantaNo ratings yet

- Formulation Development and Evaluation of Medicated Jelly With Cuminum Cyminum Extract and Its Comparative Study Using Different Jelling AgentsDocument7 pagesFormulation Development and Evaluation of Medicated Jelly With Cuminum Cyminum Extract and Its Comparative Study Using Different Jelling AgentsBaru Chandrasekhar RaoNo ratings yet

- Research Project On GelatinDocument86 pagesResearch Project On GelatinRitesh RanganiNo ratings yet

- Development and in Vitro-In Vivo Evaluation of Gastro Retentive Drug Delivery of Nizatidine Using Natural and Semi - Synthetic PolymersDocument17 pagesDevelopment and in Vitro-In Vivo Evaluation of Gastro Retentive Drug Delivery of Nizatidine Using Natural and Semi - Synthetic PolymersShyamlaNo ratings yet

- Jar Test Procedures CHEMKIMIADocument8 pagesJar Test Procedures CHEMKIMIASY LeeNo ratings yet

- Enteric Coated Aspirin Tablet Formulation DevelopmentDocument72 pagesEnteric Coated Aspirin Tablet Formulation Developmentronak_panchal_21No ratings yet

- Saquinavir Sodgganga PDFDocument104 pagesSaquinavir Sodgganga PDFSiva PrasadNo ratings yet

- Overcoming Poor Solubility of Dimenhydrinate: Development, Optimization and Evaluation of Fast Dissolving Oral FilmDocument5 pagesOvercoming Poor Solubility of Dimenhydrinate: Development, Optimization and Evaluation of Fast Dissolving Oral FilmKhoa DuyNo ratings yet

- Development and Validation of High Performance Thin Layer Chromatographic Method For Determination of Rebamipide From Its Tablet Dosage FormDocument5 pagesDevelopment and Validation of High Performance Thin Layer Chromatographic Method For Determination of Rebamipide From Its Tablet Dosage FormPinak PatelNo ratings yet

- ES ISO 6885.2012 Grasas y Aceites. Valor de P-AnisidinaDocument12 pagesES ISO 6885.2012 Grasas y Aceites. Valor de P-AnisidinadcardonasterNo ratings yet

- Formulation and Evaluation of Fast Disintegrating Tablet of Diclofenac SodiumDocument6 pagesFormulation and Evaluation of Fast Disintegrating Tablet of Diclofenac SodiumfiafinaNo ratings yet

- EPA 413.1 Grasas y AceitesDocument3 pagesEPA 413.1 Grasas y AceitesdcardonasterNo ratings yet

- Preparation and Development of Diclofenac Loaded Aloevera Gel Nanoparticles For Transdermal Drug Delivery SystemsDocument4 pagesPreparation and Development of Diclofenac Loaded Aloevera Gel Nanoparticles For Transdermal Drug Delivery SystemsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1627668785jmpas May-June 2021Document5 pages1627668785jmpas May-June 2021anisskhoirunsNo ratings yet

- Kim1 ELISA Kit for Human Kidney Injury DetectionDocument8 pagesKim1 ELISA Kit for Human Kidney Injury DetectionTPNo ratings yet

- Spray Drying Techniques for Food Ingredient EncapsulationFrom EverandSpray Drying Techniques for Food Ingredient EncapsulationNo ratings yet

- Gim - 2 8 Page - 5 Photo ChangeDocument1 pageGim - 2 8 Page - 5 Photo ChangeSAI ASSOCIATENo ratings yet

- Grid Connected PV System Using Single and Three Phase Neutral Point Clamped MLIDocument1 pageGrid Connected PV System Using Single and Three Phase Neutral Point Clamped MLISAI ASSOCIATENo ratings yet

- Egssunz Dqekj Tsu: Lo-Jheku /kuukyky Tsu TH Ekekth Ifjokj Okys LKXJ Okyksa Ds Lqiks DH LqiqDocument1 pageEgssunz Dqekj Tsu: Lo-Jheku /kuukyky Tsu TH Ekekth Ifjokj Okys LKXJ Okyksa Ds Lqiks DH LqiqSAI ASSOCIATENo ratings yet

- FLGKSJ Ftys DK, SFRGKFLD, Oa Lkal-Frd V/ U : 'Kks/K&Izca/KDocument8 pagesFLGKSJ Ftys DK, SFRGKFLD, Oa Lkal-Frd V/ U : 'Kks/K&Izca/KSAI ASSOCIATENo ratings yet

- Grid Connected PV System Using Single and Three Phase Neutral Point Clamped MLIDocument1 pageGrid Connected PV System Using Single and Three Phase Neutral Point Clamped MLISAI ASSOCIATENo ratings yet

- Tax Invoice - Plating-207Document1 pageTax Invoice - Plating-207SAI ASSOCIATENo ratings yet

- Hindi Typing Application 2021Document2 pagesHindi Typing Application 2021SAI ASSOCIATENo ratings yet

- 2021 Typing 1Document2 pages2021 Typing 1SAI ASSOCIATENo ratings yet

- Polyphase Boost Converter Integration With Lithium Ion BatteryDocument2 pagesPolyphase Boost Converter Integration With Lithium Ion BatterySAI ASSOCIATENo ratings yet

- Tax Invoice - Plating-207Document1 pageTax Invoice - Plating-207SAI ASSOCIATENo ratings yet

- Grid Connected PV System Using Single and Three Phase Neutral Point Clamped MLIDocument1 pageGrid Connected PV System Using Single and Three Phase Neutral Point Clamped MLISAI ASSOCIATENo ratings yet

- Grid Connected PV System Using Single and Three Phase Neutral Point Clamped MLIDocument1 pageGrid Connected PV System Using Single and Three Phase Neutral Point Clamped MLISAI ASSOCIATENo ratings yet

- 2021 Typing 1Document2 pages2021 Typing 1SAI ASSOCIATENo ratings yet

- Hindi Typing Application 2021Document2 pagesHindi Typing Application 2021SAI ASSOCIATENo ratings yet

- Polyphase Boost Converter Integration With Lithium Ion BatteryDocument2 pagesPolyphase Boost Converter Integration With Lithium Ion BatterySAI ASSOCIATENo ratings yet

- Gim - 2 8 Page - 5 Photo ChangeDocument1 pageGim - 2 8 Page - 5 Photo ChangeSAI ASSOCIATENo ratings yet

- Egssunz Dqekj Tsu: Lo-Jheku /kuukyky Tsu TH Ekekth Ifjokj Okys LKXJ Okyksa Ds Lqiks DH LqiqDocument1 pageEgssunz Dqekj Tsu: Lo-Jheku /kuukyky Tsu TH Ekekth Ifjokj Okys LKXJ Okyksa Ds Lqiks DH LqiqSAI ASSOCIATENo ratings yet

- Idea Cellular Limited: Input Form For Full & Final Settlement & Clearance - FinanceDocument2 pagesIdea Cellular Limited: Input Form For Full & Final Settlement & Clearance - FinanceSAI ASSOCIATENo ratings yet

- Employee DetailsDocument1 pageEmployee DetailsSAI ASSOCIATENo ratings yet

- Acknowledgment For JoiningDocument1 pageAcknowledgment For JoiningSAI ASSOCIATENo ratings yet

- Details For Medical Insurance.Document1 pageDetails For Medical Insurance.SAI ASSOCIATENo ratings yet

- Name of Applicant: Surname Middle FirstDocument3 pagesName of Applicant: Surname Middle FirstSAI ASSOCIATENo ratings yet

- Hind QoatationDocument3 pagesHind QoatationSAI ASSOCIATENo ratings yet

- Izi (,E-Vsd NK Ksa GSRQ) : XKMZ, PD W VKWFQL Ds Ikl) Tcyiqj E-Iz - DH GKSDJ 'KifkiwozdDocument2 pagesIzi (,E-Vsd NK Ksa GSRQ) : XKMZ, PD W VKWFQL Ds Ikl) Tcyiqj E-Iz - DH GKSDJ 'KifkiwozdSAI ASSOCIATENo ratings yet

- Affidavit on leave encashment detailsDocument1 pageAffidavit on leave encashment detailsSAI ASSOCIATENo ratings yet

- Grid Connected PV System Using Single and Three Phase Neutral Point Clamped MLIDocument1 pageGrid Connected PV System Using Single and Three Phase Neutral Point Clamped MLISAI ASSOCIATENo ratings yet

- Paymenthistoryredirecturl NIT PDocument2 pagesPaymenthistoryredirecturl NIT PSAI ASSOCIATENo ratings yet

- Infinity Management and Engineering College Sagar (M.P.)Document1 pageInfinity Management and Engineering College Sagar (M.P.)SAI ASSOCIATENo ratings yet

- Infinity College Sagar student project on managementDocument1 pageInfinity College Sagar student project on managementSAI ASSOCIATENo ratings yet

- Automatic Optimization and Elastic ConstantsDocument15 pagesAutomatic Optimization and Elastic ConstantsFebriman ZendratoNo ratings yet

- University of DelhiDocument4 pagesUniversity of DelhiNamasteNo ratings yet

- Perret Mahindra SeminarDocument32 pagesPerret Mahindra SeminarBeowulf StarkNo ratings yet

- BJT Mkwi4201 Bahasa InggrisDocument3 pagesBJT Mkwi4201 Bahasa Inggrisnatalia walunNo ratings yet

- How To Prepare For The CFA Exam - QuoraDocument10 pagesHow To Prepare For The CFA Exam - QuoraaduragbeNo ratings yet

- Data Sheet: PhotodiodesDocument22 pagesData Sheet: PhotodiodesDavid Nasael VERGARANo ratings yet

- Commentary On The Raven's 2 Progressive Matrices Tests and ManualDocument14 pagesCommentary On The Raven's 2 Progressive Matrices Tests and ManualSinityNo ratings yet

- Hph203 Lecture 03-1Document38 pagesHph203 Lecture 03-1Chengetai ManyaraNo ratings yet

- Sets ProbabilityDocument33 pagesSets ProbabilityGaithNo ratings yet

- Clamper and ClipperDocument16 pagesClamper and ClipperSouvik ChatterjeeNo ratings yet

- Avian 48 Guide PDFDocument8 pagesAvian 48 Guide PDFEng-Mohamed Zakria ElbadryNo ratings yet

- Quantum Chemistry: Dr. Rohul Hayat Adnan Department of Chemistry UTMDocument7 pagesQuantum Chemistry: Dr. Rohul Hayat Adnan Department of Chemistry UTMNazratul NajwaNo ratings yet

- Brochure - DT - SO - SORTEX B MultiVision - BSBDDocument12 pagesBrochure - DT - SO - SORTEX B MultiVision - BSBDAlexandruNo ratings yet

- A Social Network Analysis of ICTD Conferences (2006-2017) : Information Technology For DevelopmentDocument24 pagesA Social Network Analysis of ICTD Conferences (2006-2017) : Information Technology For DevelopmentRjendra LamsalNo ratings yet

- GRADE 9 Course Outlines 1ST QUARTERDocument12 pagesGRADE 9 Course Outlines 1ST QUARTERDahyun KimNo ratings yet

- WEG Pump Genius 50059602 Brochure enDocument20 pagesWEG Pump Genius 50059602 Brochure enGabriel AraújoNo ratings yet

- Test Specification: iUBT435 - Anatomy and PhysiologyDocument3 pagesTest Specification: iUBT435 - Anatomy and PhysiologyVicki TseNo ratings yet

- Final Project: Compiled Chapter Test: Icaro, Joanne Bernadette GDocument18 pagesFinal Project: Compiled Chapter Test: Icaro, Joanne Bernadette GJoanne IcaroNo ratings yet

- SSC 211 ED Activity 4.1Document4 pagesSSC 211 ED Activity 4.1bernard bulloNo ratings yet

- Exam 2020-2021Document8 pagesExam 2020-2021Rawan ToubarNo ratings yet

- Clinical and Forensic Interviewing Sattler JeromeDocument9 pagesClinical and Forensic Interviewing Sattler Jeromeraphael840% (1)

- I Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendDocument11 pagesI Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendSahariar Bin ShafiqueNo ratings yet

- Slab Design: 6,000MM X 4900MMDocument21 pagesSlab Design: 6,000MM X 4900MMJohnPhilip2000 GeraldizoNo ratings yet

- Grade 4 DLL Quarter 2 Week 9 (Sir Bien Cruz)Document38 pagesGrade 4 DLL Quarter 2 Week 9 (Sir Bien Cruz)FUMIKO SOPHIANo ratings yet

- Contribution of Science and Technology To National DevelopmentDocument2 pagesContribution of Science and Technology To National DevelopmentAllan James DaumarNo ratings yet