Professional Documents

Culture Documents

CJV30 - Electrical Troubleshooting PDF

Uploaded by

aigarsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CJV30 - Electrical Troubleshooting PDF

Uploaded by

aigarsCopyright:

Available Formats

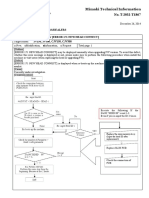

Maintenance Manual > Test Items > Other Test > Determining COM short circuit

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised F/W ver. 1.00 Remark

5.2.1 Determining COM short circuit 1.0

Outline

Check whether the COM circuit generating part has electrical trouble or not.

After turning off the sub and main power switches in order, unplug the power code.

Check if no electric charge is remaining in the PCB.

Refer to the "4.5.2 Electric charge checking when replace the Electrical Parts"

It is very dangerous if sleep mode functions mistakenly during the operation.

Moreover, the PCB may be damaged in case electric charge still remains inside. 1

Also there is a possibility of electric shock because of high power voltage applied the high-pressure part

of the power supply PCB assy. Take care to avoid contact with it.

Procedure

1. Measure a resistance between the test pin TP1 to TP8 and GND 2

on the main PCB ASSY to determine the COM circuit condi-

TP8 tion. Connect the negative terminal of the tester to the GND test

pin (GND1 to 9) and measure the resistance by getting the posi-

tive terminal touch to TP1 to 8.

Measured value of each test pin should be in the range of 17K

ohms to 18K ohms.

3

If the machine cannot be turned on, it is highly possi-

TP1 bility of impedance anomaly of the COM circuit and

short circuit between 42V and GND in the main PCB.

If all the measured value of the TP is shown in the 4

abnormal range, compare with the measured value of

the normal circuit board since it may be variation of

the tester.

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.1 R.1.0 P.1

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Damage of the Print Heads

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised F/W ver. 1.00 Remark

5.2.2 Checking Damage of the Print Heads 1.0

Outline

Check whether the COM line between the print head and the slider PCB has trouble or not.

After turning off the sub and main power switches in order, unplug the power code.

Check if no electric charge is remaining in the PCB.

Refer to the "4.5.2 Electric charge checking when replace the Electrical Parts"

It is very dangerous if sleep mode functions mistakenly during the operation.

Moreover, the PCB may be damaged in case electric charge still remains inside. 1

Also there is a possibility of electric shock because of high power voltage applied the high-pressure part

of the power supply PCB assy. Take care to avoid contact with it.

Procedure

1. Release the locks on both sides of the HDC_FFC ASSY con- 2

nected to CN1 to CN4 on the main PCB ASSY. And then pull

out the HDC_FFC ASSY.

2. Measure a resistance between the test pin TP6 to 13 and GND

TP8,6,11,10

TP9,7,12,13 on the ink slider PCB to determine the value. Connect the nega-

tive terminal of the tester to the GND test pin (TPG 1 to 5) and

4

measure the resistance by getting the positive terminal touch to

TP6 to 13.

Measured value of each test pin should be more than 10M

ohms.

5

If any of the head COM line defect is found, the print

head may be broken. Replace the print heads first.

Connecting the normal main PCB without replacing

the broken head will break the PCB continuously.

6

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.2 R.1.0 P.1

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Damage of the Main PCB ASSY

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised F/W ver. 1.00 Remark

5.2.3 Checking Damage of the Main PCB ASSY 1.0

Outline

Check whether the COM circuit on the main PCB ASSY has trouble or not.

After turning off the sub and main power switches in order, unplug the power code.

Check if no electric charge is remaining in the PCB.

Refer to the "4.5.2 Electric charge checking when replace the Electrical Parts"

It is very dangerous if sleep mode functions mistakenly during the operation.

Moreover, the PCB may be damaged in case electric charge still remains inside. 1

Also there is a possibility of electric shock because of high power voltage applied the high-pressure part

of the power supply PCB assy. Take care to avoid contact with it.

Procedure

1. Release the locks on both sides of the connector for HDC_FFC 2

ASSY connected to CN1 to CN4 on the main PCB ASSY. And

then pull out the HDC_FFC ASSY.

F13

2. Check the COM circuit referring to [5.2.1].

3. Measure the resistance on both ends of F13 (fuse) to check the 3

blown fuse.

CN4 CN3

Measured value of the fuse should be less than 5 ohms.

CN2 CN1

If ERROR 205 [47V HEAD VOLTAGE] occurs, F13

(fuse) may be blown. 4

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.3 R.1.0 P.1

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Damage of the Ink Slider PCB

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised F/W ver. 1.00 Remark

5.2.4 Checking Damage of the Ink Slider PCB 1.0

Outline

Check whether the IC on the ink slider PCB has electrical trouble or not.

After turning off the sub and main power switches in order, unplug the power code.

Check if no electric charge is remaining in the PCB.

Refer to the "4.5.2 Electric charge checking when replace the Electrical Parts"

It is very dangerous if sleep mode functions mistakenly during the operation.

Moreover, the PCB may be damaged in case electric charge still remains inside. 1

Also there is a possibility of electric shock because of high power voltage applied the high-pressure part

of the power supply PCB assy. Take care to avoid contact with it.

Procedure

1. Remove the six FFCs at CN1 to CN6 on the ink slider PCB. 2

2. Measure a resistance between 3.3V pattern and GND pattern on

U1

the ink slider PCB to determine the condition. Connect the neg-

ative terminal of the tester to the GND test pin (TPG1 to 4) and

measure the resistance by getting the positive terminal touch to

5-7 pin of CN3.

3

CN3 5-7 pin

Measured value of each test pin should be more than 5K ohms.

GND If ERROR 200 or ERROR 50 occurs after the print

heads replaced, U1 (CPLD, E600074) of the ink slider

PCB may be damaged. 4

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.4 R.1.0 P.1

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Conduction of HDC FFC COM Line

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised 2010.11.05 F/W ver. 2.50 Remark

5.2.5 Checking Conduction of HDC FFC COM Line 1.1

Outline

Check whether the HDC FFC COM line has disconnection or poor contact or not.

After turning off the sub and main power switches in order, unplug the power code.

Check if no electric charge is remaining in the PCB.

Refer to the "4.5.2 Electric charge checking when replace the Electrical Parts"

It is very dangerous if sleep mode functions mistakenly during the operation.

Moreover, the PCB may be damaged in case electric charge still remains inside. 1

Also there is a possibility of electric shock because of high power voltage applied the high-pressure part

of the power supply PCB assy. Take care to avoid contact with it.

Signal Test pin on the

ink slider PCB

Test pin on the

main PCB

Normal conduction Nozzle line 2

COM-A TP6 TP1 Less than 3 ohms A*

COM-B TP7 TP2 Less than 3 ohms B*

COM-C TP8 TP3 Less than 3 ohms C*

COM-D TP9 TP4 Less than 3 ohms D*

COM-E TP10 TP5 Less than 3 ohms E* 3

COM-F TP11 TP6 Less than 3 ohms F*

COM-G TP12 TP7 Less than 3 ohms G*

COM-H TP13 TP8 Less than 3 ohms H*

* See below about nozzle lines.

4

4-color ink set 6-color ink set 6-color + white ink set

M Y K C M Lc Y M M Y Lc W

C K Y M C K C Lm C K Lm W

5

A line C line E line G line A line C line E line G line A line C line E line G line

B line D line F line H line B line D line F line H line B line D line F line H line

7-color ink set 8-color ink set

6

M C Y K M C Y K

Lk Lk Lm Lc S W Lm Lc

7

A line C line E line G line A line C line E line G line

B line D line F line H line B line D line F line H line

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.5 R.1.1 P.1

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Conduction of HDC FFC COM Line

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised F/W ver. 1.00 Remark

5.2.5 Checking Conduction of HDC FFC COM Line 1.1

Procedure

1. Check the conduction of HDC FFC COM line as the figure on

the left.

Ink Slider PCB

1.6Ω The resistance undergoes a little bit change with the

probe location or temperature.

Tester

1

HDC FFC

Main PCB 2

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.5 P.2

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Conduction of HDC FFC Data Line

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised 2010.11.05 F/W ver. 2.50 Remark

5.2.6 Checking Conduction of HDC FFC Data Line 1.1

Outline

Check whether the HDC FFC data line has disconnection or poor contact or not.

After turning off the sub and main power switches in order, unplug the power code.

Check if no electric charge is remaining in the PCB.

Refer to the "4.5.2 Electric charge checking when replace the Electrical Parts"

It is very dangerous if sleep mode functions mistakenly during the operation.

Moreover, the PCB may be damaged in case electric charge still remains inside. 1

Also there is a possibility of electric shock because of high power voltage applied the high-pressure part

of the power supply PCB assy. Take care to avoid contact with it.

Signal IC pin on the

ink slider PCB

IC pin on the

main PCB

Normal conduction Nozzle line 2

SID1+ U8-(10) U46-(2) Less than 22ohms A*

SID1- U8-(9) U46-(3) Less than 22ohms

SID2+ U8-(14) U46-(6) Less than 22ohms B*

SID2- U8-(15) U46-(5) Less than 22ohms

SID3+ U8-(2) U46-(10) Less than 22ohms C* 3

SID3- U8-(1) U46-(11) Less than 22ohms

SID4+ U8-(6) U46-(14) Less than 22ohms D*

SID4- U8-(7) U46-(13) Less than 22ohms

SID5+ U9-(10) U47-(2) Less than 22ohms E*

SID5-

SID6+

U9-(9)

U9-(14)

U47-(3)

U47-(6)

Less than 22ohms

Less than 22ohms F*

4

SID6- U9-(15) U47-(5) Less than 22ohms

SID7+ U9-(2) U47-(10) Less than 22ohms G*

SID7- U9-(1) U47-(11) Less than 22ohms

SID8+ U9-(6) U47-(14) Less than 22ohms H*

SID8- U9-(7) U47-(13) Less than 22ohms 5

*See below about nozzle lines.

4-color ink set 6-color ink set 6-color + white ink set

M Y K C M Lc Y M M Y Lc W

6

C K Y M C K C Lm C K Lm W

A line C line E line G line A line C line E line G line A line C line E line G line 7

B line D line F line H line B line D line F line H line B line D line F line H line

7-color ink set 8-color ink set

M

Lk

C

Lk

Y

Lm

K

Lc

M

S

C

W

Y

Lm

K

Lc

8

A line C line E line G line A line C line E line G line

B line D line F line H line B line D line F line H line

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.6 R.1.1 P.1

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

Maintenance Manual > Test Items > Other Test > Checking Conduction of HDC FFC Data Line

Rev.

Model CJV30/TPC Issued 2009.06.30 Revised F/W ver. 1.00 Remark

5.2.6 Checking Conduction of HDC FFC Data Line 1.1

Procedure

1. Check the conduction of HDC FFC data line as the figure on the

left.

Ink Slider PCB

1.6Ω The resistance undergoes a little bit change with the

probe location or temperature.

Tester

1

HDC FFC

Main PCB 2

3

2. See the figure on the left for the IC pin number.

The mark side is the start of the number.

© 2009 MIMAKI ENGINEERING CO.,LTD. 5.2.6 R.1.1 P.2

TRIAL MODE − a valid license will remove this message. See the keywords property of this PDF for more information.

You might also like

- CJV30 Additional Pages For Service Documents - May2009 PDFDocument32 pagesCJV30 Additional Pages For Service Documents - May2009 PDFaigarsNo ratings yet

- Mimaki Technical Information on Countermeasure for ERROR 171 NEW HEAD CONNECTDocument2 pagesMimaki Technical Information on Countermeasure for ERROR 171 NEW HEAD CONNECTMNo ratings yet

- UJF-3042 - 6042MKII Maintenance Manual D501202 Ver.1.50Document366 pagesUJF-3042 - 6042MKII Maintenance Manual D501202 Ver.1.50Amur ServiceNo ratings yet

- SG Series Printer/Cutters: Sales GuideDocument24 pagesSG Series Printer/Cutters: Sales GuidelobarriospNo ratings yet

- TS300P-1800 Installation Guide D501109 Ver.1.50Document60 pagesTS300P-1800 Installation Guide D501109 Ver.1.50Alexander GonzálezNo ratings yet

- CoPeck User Manual Printer Report SoftwareDocument3 pagesCoPeck User Manual Printer Report SoftwareShree ManjuNo ratings yet

- LEC2-640 PG enDocument51 pagesLEC2-640 PG enAcuña Alonso100% (1)

- Setup Manual: SC-F9300 Series Rev. BDocument68 pagesSetup Manual: SC-F9300 Series Rev. BChapi-Chape Chapi ChapeNo ratings yet

- AuraJet Series II UserManualDocument48 pagesAuraJet Series II UserManualdarkenelNo ratings yet

- Ip-7900-26 Ip-7700-26 Bog en 04 79365 PDFDocument134 pagesIp-7900-26 Ip-7700-26 Bog en 04 79365 PDFSoro FoxNo ratings yet

- Training Manual: Rev. Date DateDocument150 pagesTraining Manual: Rev. Date DateVision COMNo ratings yet

- Service Manual ML-551x 651x Ver1.3 111104 PDFDocument258 pagesService Manual ML-551x 651x Ver1.3 111104 PDFBudau RolandNo ratings yet

- Brother Fax 3750, 8650p, MFC-7750 Service ManualDocument196 pagesBrother Fax 3750, 8650p, MFC-7750 Service ManualRaboni ClaudemirNo ratings yet

- Roland TrueVIS Printer Models Fact SheetDocument1 pageRoland TrueVIS Printer Models Fact SheetBrandonNo ratings yet

- Galaxy Series Machine Install Elevating Capping System InstructionDocument10 pagesGalaxy Series Machine Install Elevating Capping System InstructiondarkenelNo ratings yet

- KIP 7100 User Manual A - 1Document59 pagesKIP 7100 User Manual A - 1Jay TanNo ratings yet

- RSC-1650C, H, HR Service Manual (061208)Document56 pagesRSC-1650C, H, HR Service Manual (061208)JamesNo ratings yet

- 24 JF1631 - 1610 Maintenance Manual D500325 - Ver3.00Document358 pages24 JF1631 - 1610 Maintenance Manual D500325 - Ver3.00alex greekNo ratings yet

- TOPAZRIP Business v9 User Guide PDFDocument138 pagesTOPAZRIP Business v9 User Guide PDFjirayii99No ratings yet

- T08135D ProXL Service ManualDocument271 pagesT08135D ProXL Service ManualAlexandruNo ratings yet

- Errores HP Laserjet 1300 PDFDocument6 pagesErrores HP Laserjet 1300 PDFarkittoNo ratings yet

- Jaguar II Series User Manual: V.4 2011 JulDocument55 pagesJaguar II Series User Manual: V.4 2011 JulDiana ArghirNo ratings yet

- WIT-Color Ultra 9000 High Definition Printer Operations ManualDocument95 pagesWIT-Color Ultra 9000 High Definition Printer Operations ManualHerbert M. ZaycoNo ratings yet

- JV33 - CJV Trouble Shooting of ElectricalDocument1 pageJV33 - CJV Trouble Shooting of ElectricalGarner100% (1)

- UCJV300 - 150 Maintenance Parts List D501318 Ver. 3.10Document80 pagesUCJV300 - 150 Maintenance Parts List D501318 Ver. 3.10Tim GravisNo ratings yet

- OMM-00107 HS100 Gen1 Sheet Feeder Operations Guide ADocument21 pagesOMM-00107 HS100 Gen1 Sheet Feeder Operations Guide ABruce CampanelliNo ratings yet

- SCT7000 Derniere PDFDocument349 pagesSCT7000 Derniere PDFSerge MaciaNo ratings yet

- OCE 3121,3122 Service ManualDocument908 pagesOCE 3121,3122 Service Manualclient_escopyNo ratings yet

- Epson Stylus Pro 7800/9800: Printer GuideDocument176 pagesEpson Stylus Pro 7800/9800: Printer GuideDiego BgNo ratings yet

- Parts List Xerox 6279Document62 pagesParts List Xerox 6279vladimir242633% (3)

- pumaII PDFDocument54 pagespumaII PDFJuan Sanchez GutierraNo ratings yet

- VersaUV White Gloss Guide PDFDocument76 pagesVersaUV White Gloss Guide PDFJosé Alarcón PalomarNo ratings yet

- Mimaki TS500-1800 Service ManualDocument338 pagesMimaki TS500-1800 Service Manualjosedejesushuescamendez624No ratings yet

- iPR C270C265 - SM - 3Document2,130 pagesiPR C270C265 - SM - 3stefanspa2No ratings yet

- Epson Stylus Pro 7600, 9600 Service ManualDocument325 pagesEpson Stylus Pro 7600, 9600 Service ManualАлекс ВорNo ratings yet

- Puma II Users ManualDocument54 pagesPuma II Users ManualDiana Arghir100% (1)

- VG-640 ZCK0100 and Later Parts CatalogDocument33 pagesVG-640 ZCK0100 and Later Parts CatalogSupremo HaloNo ratings yet

- Service Manual v7 - 1500Document1,699 pagesService Manual v7 - 1500M Fadhil YahyaNo ratings yet

- Operating Instructions Estefold 4210 + 4211Document17 pagesOperating Instructions Estefold 4210 + 4211Alexey KosiyNo ratings yet

- Firmware Model Changing On GCC Cutting Plotter 2 in 1 Main Board PDFDocument2 pagesFirmware Model Changing On GCC Cutting Plotter 2 in 1 Main Board PDFjorge cuetoNo ratings yet

- DCP 6690CW, MFC 6490CW, MFC 6890CDW PDFDocument474 pagesDCP 6690CW, MFC 6490CW, MFC 6890CDW PDFStefanGarnetNo ratings yet

- Canon ImagePROGRF IPF 770 670Document4 pagesCanon ImagePROGRF IPF 770 670Isaac Musiwa BandaNo ratings yet

- Inkjet Printhead Market and Technology Trends 2016Document20 pagesInkjet Printhead Market and Technology Trends 2016cannonsNo ratings yet

- Mutoh Valuejet vj-1604 Maintenance Manual-5Document18 pagesMutoh Valuejet vj-1604 Maintenance Manual-5Javier SarayNo ratings yet

- C911 - C931 - C941 - RSPL - Rev - oDocument67 pagesC911 - C931 - C941 - RSPL - Rev - oWellington TrajanoNo ratings yet

- Printer LinearizationDocument27 pagesPrinter LinearizationpakopcNo ratings yet

- Como Resetear Impresoras EmpsonDocument6 pagesComo Resetear Impresoras EmpsonErick Hidalgo LopezNo ratings yet

- Summa D75 ManualDocument92 pagesSumma D75 ManualMikalae HardenNo ratings yet

- Epson Stylus Pro 9000 Service ManualDocument186 pagesEpson Stylus Pro 9000 Service ManualSean DunhamNo ratings yet

- HP Latex 3000 Printer SMDocument1,069 pagesHP Latex 3000 Printer SMMario BraićNo ratings yet

- SAI Flexi - RIP Output GuidelinesDocument2 pagesSAI Flexi - RIP Output GuidelinesSatyanarayana PVVNo ratings yet

- PSG MPC 307Document32 pagesPSG MPC 307Jose Abraham Grovas VelezNo ratings yet

- Heater Unit: Service NotesDocument16 pagesHeater Unit: Service NotesSerge MaciaNo ratings yet

- varioPRINT 140 130 115 Service Guide Revision 4 FinalDocument109 pagesvarioPRINT 140 130 115 Service Guide Revision 4 FinalJosé LeãoNo ratings yet

- 7800 Fielde ServiceDocument370 pages7800 Fielde Servicemohannad64No ratings yet

- Bipolar Junction Transistor Characterization: Experiment-1Document6 pagesBipolar Junction Transistor Characterization: Experiment-1Tran TuNo ratings yet

- Pw3 - Identify Fault Using Multimeter.Document6 pagesPw3 - Identify Fault Using Multimeter.Nur MazarinaNo ratings yet

- Service Manual - PC/MPC Series Inverter & Charger Repair GuideDocument14 pagesService Manual - PC/MPC Series Inverter & Charger Repair GuideNailson MartinsNo ratings yet

- Current Transformer Testing 18.03.14Document4 pagesCurrent Transformer Testing 18.03.14Venkat Cherukuri50% (2)

- CJV30 Service Documents D500383 - Ver1.20 PDFDocument60 pagesCJV30 Service Documents D500383 - Ver1.20 PDFaigarsNo ratings yet

- Mimaki CJV30 Print & Cut D201875 V1.1Document22 pagesMimaki CJV30 Print & Cut D201875 V1.1pcdocstlNo ratings yet

- CJV30 Service Documents D500383 - Ver1.20 PDFDocument60 pagesCJV30 Service Documents D500383 - Ver1.20 PDFaigarsNo ratings yet

- CJV30 - Mechanical Drawing - D500388 Ver2.30 PDFDocument102 pagesCJV30 - Mechanical Drawing - D500388 Ver2.30 PDFaigarsNo ratings yet

- CJV30 Print and Cut Manual D201875 - Ver1.00 PDFDocument1 pageCJV30 Print and Cut Manual D201875 - Ver1.00 PDFaigarsNo ratings yet

- MIMAKI CJV30-60 Series Service ManualDocument316 pagesMIMAKI CJV30-60 Series Service Manualmsamsoniuk89% (9)

- CJV30 Mechanical Drawing Supplement Version D500388 Ver.2.3b PDFDocument7 pagesCJV30 Mechanical Drawing Supplement Version D500388 Ver.2.3b PDFaigarsNo ratings yet

- CJV30 Installation Guide D500386 - Ver1.30 PDFDocument36 pagesCJV30 Installation Guide D500386 - Ver1.30 PDFaigarsNo ratings yet

- CJV30 Additional Pages For Maintenance Manual Jun2009 PDFDocument12 pagesCJV30 Additional Pages For Maintenance Manual Jun2009 PDFaigarsNo ratings yet

- 3M Series 680CREDocument1 page3M Series 680CREaigarsNo ratings yet

- CJV30 Accesory List D500385 - Ver1.00Document10 pagesCJV30 Accesory List D500385 - Ver1.00aigarsNo ratings yet

- Diferencias Entre STVF7 y WBVFDocument14 pagesDiferencias Entre STVF7 y WBVFFranklin Palacios100% (1)

- Stoeltjes Lift Thyssen Access Flow2Document50 pagesStoeltjes Lift Thyssen Access Flow2Arjan WijnenNo ratings yet

- MSE 405 Spring 2011 HomeworkDocument2 pagesMSE 405 Spring 2011 HomeworkbuttnadsNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document6 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- DC MotorDocument26 pagesDC MotorGerard AlfonsoNo ratings yet

- Comparch Top Level ViewDocument74 pagesComparch Top Level ViewEphraimNo ratings yet

- Ece3002 Vlsi System Deign Cocob 2019Document3 pagesEce3002 Vlsi System Deign Cocob 2019Debasis ChandraNo ratings yet

- Neoway N58 Product Specifications V2.0.20201110153004Document33 pagesNeoway N58 Product Specifications V2.0.20201110153004Phạm Trọng NhânNo ratings yet

- Adafruit Arduino Lesson 6 Digital Inputs PDFDocument10 pagesAdafruit Arduino Lesson 6 Digital Inputs PDFSilviaNo ratings yet

- Multilin 469Document260 pagesMultilin 469darkelnoNo ratings yet

- Keysight Technologies DSO1000A/B Series: Portable OscilloscopesDocument14 pagesKeysight Technologies DSO1000A/B Series: Portable Oscilloscopesmarciovirtuatec1013No ratings yet

- Application Note: Guidance On Selecting and Handling Coaxial RF Connectors Used With Rohde & Schwarz Test EquipmentDocument19 pagesApplication Note: Guidance On Selecting and Handling Coaxial RF Connectors Used With Rohde & Schwarz Test EquipmentMạnh Huy BùiNo ratings yet

- Max 8798Document31 pagesMax 8798Reynaldo PerezNo ratings yet

- XILINX XC SeriesDocument41 pagesXILINX XC SeriesAnil Kumar YernintiNo ratings yet

- 2SB647 / 2SB647A PNP General Purpose Transistors: Lead (PB) - FreeDocument5 pages2SB647 / 2SB647A PNP General Purpose Transistors: Lead (PB) - FreeWilliam JimenezNo ratings yet

- Skin and Brain Implantable Inset-Fed Antenna at ISM Band For Wireless Biotelemetry ApplicationsDocument6 pagesSkin and Brain Implantable Inset-Fed Antenna at ISM Band For Wireless Biotelemetry ApplicationsMr. MERLIN GILBERT RAJ S 1154No ratings yet

- Hardware Course Outline: Lesson 1: Computer Safety and Work HabitsDocument4 pagesHardware Course Outline: Lesson 1: Computer Safety and Work HabitsDanilo Sasi SantosNo ratings yet

- Build Your Own Vibrato Popular Electronics December 1957 Archivedby Cigar Box NationDocument9 pagesBuild Your Own Vibrato Popular Electronics December 1957 Archivedby Cigar Box NationjondvalNo ratings yet

- CAPE Unit 2 Paper 2 2013Document14 pagesCAPE Unit 2 Paper 2 2013CAPE Past PapersNo ratings yet

- Operational AmplifierDocument17 pagesOperational AmplifierDan AdrianNo ratings yet

- Technical Documents: FUJI IGBT Modules U4-120 SeriesDocument14 pagesTechnical Documents: FUJI IGBT Modules U4-120 SeriesМихаилNo ratings yet

- Diagram Guardall Board With Relay Board Use For VerexDocument1 pageDiagram Guardall Board With Relay Board Use For VerexHeather WallaceNo ratings yet

- FAS - Amps Models Axe III Ares12.05Document44 pagesFAS - Amps Models Axe III Ares12.05王云哲No ratings yet

- Nvi BhuDocument2 pagesNvi Bhumeghna vNo ratings yet

- Dasung Paperlike HD Quick Start Guide 2020Document2 pagesDasung Paperlike HD Quick Start Guide 2020Sose ManukNo ratings yet

- MEG250A Manual Ver A3 PDFDocument42 pagesMEG250A Manual Ver A3 PDFTom BoeremaNo ratings yet

- Kenwood RXD 302,352,372, Ls n302, n352Document32 pagesKenwood RXD 302,352,372, Ls n302, n352Piter De AzizNo ratings yet

- GBVD Model Generalizes Butterworth-Van Dyke Circuit for FBARsDocument2 pagesGBVD Model Generalizes Butterworth-Van Dyke Circuit for FBARsByron FischerNo ratings yet

- SVX9000Document13 pagesSVX9000Biswadeep GhoshNo ratings yet

- DDCArv_Ch3Document36 pagesDDCArv_Ch3rabiatul adawiyahNo ratings yet