Professional Documents

Culture Documents

Mechanical Tubing Cutters Review Outcome PDF

Uploaded by

Khalid ZaeemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Tubing Cutters Review Outcome PDF

Uploaded by

Khalid ZaeemCopyright:

Available Formats

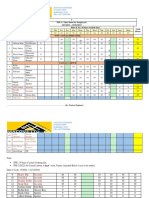

Tubing Under Tension (On rig operations)

Weatherford, Welltec, Baker Hughes, Downhole Electric Cutting RCT Power cutter Tubing Weather Welltec Baker DECT RCT Power

Mechanical Cutting WellCutter Mechanical Pipe Tool (DECT) Considered cutoff Size, in ford cutter

Tool Cutter

Success rate provided by

92% 95% 10 83% 6 92% 10 N/A N/A >90 2 3/8

Vendor 10 10 80-90 6 < 80 3

Success rate from NAM Didn't run in NAM, but

Didn't run in NAM 50% 100% 62% 3 100% 10 >90 2 7/8

record Shell 10 80-90 6 < 80 3

Multible cuts in one run Yes 10 Yes 10 Yes 10 Yes 10 No 3 No 3 Yes 10 N/R 6 N0 3 3 1/2

Monitoring the cut 10 3 3

Yes Yes 10 Yes 10 Yes 10 No No Yes 4

progress & confirming 10 No 3

Dressing run after cut for 10

No No 10 No 10 No 10 Yes 3 Yes 3 No 4 1/2

fishing 10 Yes 3

Cut under Tension Yes 10 Yes 10 Yes 10 Yes 10 Yes 10 Yes 10 Yes 10 N0 3 5

Operation complication Normal 10 Normal 10 Normal 10 Medium, Because of the large 6 1) Mobilization Permits are required. 6 1) Mobilization Permits are required. 3 Low 10 Medium 6 High 3

cutting chips, a junk basket should 2) Require tubing punch upfront 2) Can not transported by Helicopter.

5 1/2

be placed prior to using the DECT. 3) HSE exposure for the crew and the asset.

4) Require tubing punch upfront

Cutting Cost, € 60000 6 50000 6 50000 6 75000 3 50000 6 20000 10 < 40K 10 40-70K 6 > 70 K 3 6

Punch Cost, € 0 10 0 10 0 10 0 10 10000 3 10000, but over all operation cost is low 6 0 10 5K 6 >10 K 3 7

Casing damage risk Low 10 Low 10 Low 10 Low 10 Medium 6 High 3 Low 10 Med 6 High 3 7 5/8

Average NPT, hrs Didn't run in NAM 6 Didn't run in NAM 6 18.5* 6 0.4 10 13 3 1.7 10 <2 10 2-8 6 >8 3 9 5/8

Total score 92 92 88 89 46 61 > 90 90-80 < 80

Tubing under Compression (Rigless Operations)

Success rate provided by Tubing Weather Welltec Baker DECT RCT Power

100% 95% 10 40% 3 100% 10 N/A N/A >90

Vendor 10 10 80-90 6 < 80 3 Size, in ford cutter

Success rate from NAM Didn't run in NAM, but

records Didn't run in NAM 50% 100% 62% 3 100% 10 >90 2 3/8

Shell 10 80-90 6 < 80 3

Multible cuts in one run Yes 10 Yes 10 Yes 10 Yes 10 No 3 No 3 Yes 10 N/R 6 N0 3 2 7/8

Monitoring the cut 10

Yes Yes 10 Yes 10 Yes 10 No 3 No 3 3 1/2

progress & confirming Yes 10 No 3

Dressing run after cut for 10

No No 10 No 10 No 10 Yes 3 Yes 3 No 4

fishing 10 Yes 3

Cut under compression Yes 10 Yes 10 No 3 Yes 10 No 3 Yes 10 Yes 10 N0 3 4 1/2

Operation complication Normal 10 Normal 10 Normal 10 Medium, Because of the large 6 1) Mobilization Permits are required. 6 1) Mobilization Permits are required. 3 Low 10 Medium 6 High 3

cutting chips, a junk basket should 2) Require tubing punch upfront 2) Can not transported by Helicopter.

5

be placed prior to using the DECT. 3) HSE exposure for the crew and the asset.

4) Require tubing punch upfront

Cutting Cost, € 60000 6 50000 6 50000 6 75000 3 50000 6 20000 10 < 40K 10 40-70K 6 > 70 K 3 5 1/2

0 0 0 0 10000 10000, but over all operation cost is low 6

Punch Cost, € 10 10 10 10 3 6 0 10 5 K 6 >10 K 3

10 10 10 10 6 3

Low Low Low Low Medium High Low 10 Med 6 High 3 7

Casing damage risk

*

Average NPT, hrs Didn't run in NAM 6 Didn't run in NAM 6 18.5 6 0.4 10 13 3 1.7 10 <2 10 2 - 8 6 >8 3 7 5/8

Total score 92 92 78 89 39 61 > 90 90-80 < 80 9 5/8

Abandonment (On rig Operations)

Success rate provided by Tubing Weather Welltec Baker DECT RCT Power

92% 10 95% 10 83% 6 92% 10 N/A N/A >90

Vendor 10 80-90 6 < 80 3 Size, in ford cutter

Success rate from NAM Didn't run in NAM, but

Didn't run in NAM 50% 100% 62% 3 100% 10 >90 2 3/8

records Shell 10 80-90 6 < 80 3

Multible cuts in one run Yes 10 Yes 10 Yes 10 Yes 10 No 3 No, but it's ok based on the success rate 10 Yes 10 N/R 6 N0 3 2 7/8

Monitoring the cut 10 10 10 10 3 3

Yes Yes Yes Yes No No Yes 3 1/2

progress & confirming 10 No 3

Dressing run after cut for 10 10 10 10 10 10

No No No No No No 4

fishing No 10 Yes 3

Cut under Tension Yes 10 Yes 10 Yes 10 Yes 10 Yes 10 Yes 10 Yes 10 N0 3 4 1/2

Operation complication Normal 10 Normal 10 Normal 10 Low, No need for Junk Basket in 10 1) Mobilization Permits are required. 6 1) Mobilization Permits are required. 3 Low 10 Medium 6 High 3

Abandonment operation. 2) Require tubing punch upfront 2) Can not transported by Helicopter.

5

3) HSE exposure for the crew and the asset.

4) Require tubing punch upfront

Cutting Cost, € 60000 6 50000 6 50000 6 75000 3 50000 6 20000 10 < 40K 10 40-70K 6 > 70 K 3 5 1/2

Punch Cost, € 0 10 0 10 0 10 0 10 10000 3 10000, but over all operation cost is low 6 0 10 5 K 6 >10 K 3 6

Casing damage risk Low 10 Low 10 Low 10 Low 10 Accepted 10 Accepted 10 Low 10 Med 6 High 3 7

Average NPT, hrs Didn't run in NAM 6 Didn't run in NAM 6 18.5* 6 0.4 10 13 3 1.7 10 <2 10 2 - 8 6 >8 3 7 5/8

Total score 92 92 88 93 57 82 > 90 90-80 < 80 9 5/8

Movie Not available

* The NPT is not representative as the tool has run in non recommended well conditions Recommended than other alternatives based on costs, operation issues and success ratio

Can be used with precautions or more expensive than alternative ¨green¨.

Not recommended based on either-or track record, costs and operation issues.

Under the field trial and has not commissioned yet

Weatherford, Mechanical Cutting Tool Welltec, WellCutter Baker Hughes, Mechanical Pipe Cutter Downhole Electric Cutting Tool (DECT)

Year Released 2006 2014 2011 2012 2014 2009 2009 2011 2006 2006 2006 2006

Model MCT-A MCT-B 318 WC 358 WC 414 WC 2570MA 2570MA 2571MA DECT001 DECT001 DECT002 DECT002

2 7/8 - 4 4 - 4 1/2 4-jul

Tubing OD, in 2 3/8 & 2 7/8 3 1/2 4 1/2 5 1/2 7 3.5 - 5.0 4.0 - 6.0 4.5 - 7.0 6.0 - 7.625

Tool OD, in 1 11/16 2 1/2 3 1/8 3 5/8 4 1/4 2 1/8 2 1/8 3 1/4 2 3/4 3.25 3 5/8 4 5/7

2 1/8 2 1/2 3 1/4

Cutting Head OD, in 1 11/16 2 1/2 3 1/8 3 5/8 4 1/4 2 3/4 3 1/4 3 5/8 4 5/7

2 7/8 - 4 4 - 4 1/2 4-jul

Anchoring Range, in 2 3/8 - 2 7/8 3 1/2 5 5 6 1/2 2.99 - 5.3 2.99 - 5.3 4.00- 7.15 4.00- 7.15

Anchoring force, lb 330 each (1000 in total) Proprietary 600 each (1800 in total) 601 each (1800 in total) 602 each (1800 in total) 2200 2200 2200 2200

Max Wall thickness 0 0 0.5 0.5 0.6 0,5 0,68 0,75 0.75" 1 0.875" 0.875"

Compression Yes Yes Yes Yes Yes No No No Yes Yes Yes Yes

Cutting speed, rpm 5-7 12 1800-4200 1800-4200 1800-4200 4200 - 6800 4201 - 6800 4202 - 6800 65 - 67 65 - 67 65 - 67 65 - 67

Max Temp, oF 300 350 284 284 284 400 400 400 300 300 300 300

Max press. Kpsi 20 20 25 25 25 20 20 20 15 15 20 20

Cutting torque, ft.ibf 20 120 Proprietary Proprietary 74 74 74 74

Data Real-time feedback VDC Real-time feedback VDC Real-time feedback VDC Real-time feedback VDC Real-time feedback VDC Real-time feedback VDC, Real-time feedback VDC, Real-time feedback VDC, Real-time feedback VDC Real-time feedback VDC Real-time feedback VDC Real-time feedback VDC

Accelerometer Accelerometer Accelerometer

DC DC DC

AC/DC DC DC DC DC DC DC DC DC DC

750 750 750

Voltage, V 130 250 600 600 600 1000 1000 1000 1000

Maximim Current 2A 2A 5-6 Amps 1,5 1,5 1,5 2 2 2 2

Lab tubing grade For 2 3/8: 4.6 - 5.8 # 9.2 - 12.7 # L80 to 25% Cr Up to P110 Up to P110 Up to P110 13Cr/S135/25Cr/718 Inc 13Cr/S135/25Cr/718 Inc 13Cr/S135/25Cr/718 Inc 13Cr

J55 - P-110 J-55 - P-110

Tubing cut downhole For 2 7/8: 6.5 - 7.8 #

All listed 9.2 and 10.2 # L80 to 25% Cr Yes Yes Yes 13Cr/S135/25Cr/718 Inc 13Cr/S135/25Cr/718 Inc 13Cr/S135/25Cr/718 Inc 13Cr

Borehole fluids WBM / OBM / SALT / AIR Any Any Any ALL ALL ALL Oil/Gas/Water/Mud Oil/Gas/Water/Mud Oil/Gas/Water/Mud Oil/Gas/Water/Mud

Cutting time, min 15 - 60 min 15 - 60 min ~ 1 hr with pads, ~ 10min with cutting arms (pipe weight/material dpeendent) ~7 min ~7 min ~7 min 2 - 5 mins 2 - 5 mins 2 - 5 mins 2 - 5 mins

Length, ft 12 13 17.5 17.5 21 17.75 17,75 17,88 16' - 25' 16' - 25' 16' - 25' 16' - 25'

Tool weight, lb 70 150 419 425 740 143 143 183 170-240lb 170-240lb 170-240lb 170-240lb

Cutting point from bottom of 5 m below CCL 5 m below CCL 5 m below CCL

7 8 3/8 Bottom of the tool 3 3 3 3

tool, in

Blade thickness, mm 4 5 No blade pads 3 mm 3 mm 3 mm 2.2mm 2.2mm 2.2mm 2.2mm

Blade Material Maraging Steel 250 Tungsten Carbide The cutting pads are coated with a proprietary metal matrix compound which Various Various Various Spring Steel Spring Steel Spring Steel Spring Steel

Force to break blade 1,500 lbf 35,000 lbf Not applicable, fail safe mechanism that collapse the tool shutdown/loss of 200lbs 200lbs 200lbs 200lbs

communication

CCL CCL CCL

Locating device CCL CCL or GR Yes Yes Yes CCL/NOGO CCL/NOGO CCL/NOGO CCL/NOGO

Yes Yes Yes All Tractor Types All Tractor Types All Tractor Types All Tractor Types

Tractor deployable Yes Yes Yes Yes Yes

(GE/SLB/Aker/Welltec) (GE/SLB/Aker/Welltec) (GE/SLB/Aker/Welltec) (GE/SLB/Aker/Welltec)

Other E-line n/a n/a Yes Yes Yes Yes Yes Yes Multi/Mono/Coax Multi/Mono/Coax Multi/Mono/Coax Multi/Mono/Coax

Any Any Any

Transportation No limitations No limitations Any Any Any Air/Helicopter/etc Air/Helicopter/etc Air/Helicopter/etc Air/Helicopter/etc

You might also like

- PPE No 1 (2023)Document3 pagesPPE No 1 (2023)IsraelNo ratings yet

- Risk Assessment in Shipping CompaniesDocument18 pagesRisk Assessment in Shipping Companiesleopradeep100% (4)

- Bgl-Fm-Qa-10b Monthly Rejection Tracking & AnalysisDocument66 pagesBgl-Fm-Qa-10b Monthly Rejection Tracking & AnalysisMohit SinghNo ratings yet

- GN 589 Lifting Points Continued: Safety InstructionsDocument1 pageGN 589 Lifting Points Continued: Safety InstructionsAlbertoNo ratings yet

- FT GeotextilesDocument2 pagesFT GeotextilesElber Ramiro Olivares BareñoNo ratings yet

- Process Name: Fork 1,2,3,4Document2 pagesProcess Name: Fork 1,2,3,4piyushNo ratings yet

- Values Jan Feb Mar Apr May Jun Waste (Bur X Esp) M HA HA Quantex Quantex Quantex Quantex DrillingDocument4 pagesValues Jan Feb Mar Apr May Jun Waste (Bur X Esp) M HA HA Quantex Quantex Quantex Quantex DrillingAkemi LuceroNo ratings yet

- FA Checking Result Ver 1Document5 pagesFA Checking Result Ver 1khuonmau ducNo ratings yet

- Plugs SummaryDocument3 pagesPlugs SummaryRaed fouadNo ratings yet

- 6-Lobe Pin Countersunk Self TapperDocument1 page6-Lobe Pin Countersunk Self Tapperkenichihattori01No ratings yet

- DPR BWPRP4 Ocean303 12.03.18Document1 pageDPR BWPRP4 Ocean303 12.03.18KRISHNAN ELANGOVANNo ratings yet

- Critical Path Method: ID Task Name ES EF LS LF Slack Predecessors O M P DurationDocument3 pagesCritical Path Method: ID Task Name ES EF LS LF Slack Predecessors O M P DurationMaking IronNo ratings yet

- CBA of TanksDocument25 pagesCBA of TanksNithinNo ratings yet

- Ring Frame End Breakage DistributionDocument17 pagesRing Frame End Breakage DistributionMohandas BalasubramaniamNo ratings yet

- 10CDCF LM-1600406 (PFGD)Document2 pages10CDCF LM-1600406 (PFGD)Sohaib AhmadNo ratings yet

- Victaulic Firelock Fittings: 1.0 Product DescriptionDocument4 pagesVictaulic Firelock Fittings: 1.0 Product Descriptionmido2112No ratings yet

- Optimization of Doubling at Draw Frame FDocument6 pagesOptimization of Doubling at Draw Frame FHamid MovahedNo ratings yet

- Category Item Bobot (%)Document2 pagesCategory Item Bobot (%)Jusuf Jaya KusumaNo ratings yet

- Thebault Dop01 Teboply Ext GBDocument2 pagesThebault Dop01 Teboply Ext GBDumitrache IulianNo ratings yet

- Miranda: Compaction Test ReportDocument1 pageMiranda: Compaction Test ReportJuan Carlos Miranda ColqueNo ratings yet

- Assumptions: Cell LockDocument21 pagesAssumptions: Cell LockUmar YaqoobNo ratings yet

- DIN 906 - 1983hexagon Socket Pipe PlugsDocument4 pagesDIN 906 - 1983hexagon Socket Pipe PlugsChris StefanouNo ratings yet

- Daily Progress Report Jetty South Beach KMT 010423Document1 pageDaily Progress Report Jetty South Beach KMT 010423Haris SutiyonoNo ratings yet

- Stasticalfns CWDocument6 pagesStasticalfns CWArpit KurlNo ratings yet

- Gap Flush - Filled ReportDocument7 pagesGap Flush - Filled ReportajayNo ratings yet

- Technical Specification 18Document2 pagesTechnical Specification 18sarvan shivaNo ratings yet

- Standards and Measurements of Agronomy SOP Nomor SOP: AA-SOP-OP-1101 (NURSERY)Document3 pagesStandards and Measurements of Agronomy SOP Nomor SOP: AA-SOP-OP-1101 (NURSERY)Ulin HsbNo ratings yet

- DPR BWPRP4 Ocean303 14.03.18Document1 pageDPR BWPRP4 Ocean303 14.03.18KRISHNAN ELANGOVANNo ratings yet

- Ramset Anchoring Chemicals Reo502 PDFDocument1 pageRamset Anchoring Chemicals Reo502 PDFSuci YatiningtiyasNo ratings yet

- 14-Sieve Analysis of Aggregates Fine Agg.Document6 pages14-Sieve Analysis of Aggregates Fine Agg.Khizar HayatNo ratings yet

- Soil ReportDocument8 pagesSoil ReportAleem NawazNo ratings yet

- A1. Columns LCCDocument1 pageA1. Columns LCCRiffathNo ratings yet

- MMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateDocument1 pageMMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateshrikantNo ratings yet

- Cruci Si Reductii - RoDocument4 pagesCruci Si Reductii - Roioan cristian cotorobaiNo ratings yet

- Partograph Poster A3 - 25july2019 (English)Document1 pagePartograph Poster A3 - 25july2019 (English)renuNo ratings yet

- Tampa Cost of Living ChartsDocument1 pageTampa Cost of Living ChartsTampaEDCNo ratings yet

- GD016-0028A Monitoring Cutting Edge AllmakesDocument1 pageGD016-0028A Monitoring Cutting Edge AllmakesRio aji RiyantoNo ratings yet

- Time Study: BY Kaustav MukherjeeDocument12 pagesTime Study: BY Kaustav Mukherjeevikingspirit999No ratings yet

- Kurva SDocument4 pagesKurva SDiana MeiraniNo ratings yet

- Data Procedure B: The Effect of A Dielectric Between The Plates. A Measurement of The Dielectric Constant of PaperDocument4 pagesData Procedure B: The Effect of A Dielectric Between The Plates. A Measurement of The Dielectric Constant of PaperDavid Antonio Suarez MartinezNo ratings yet

- Concrete CubesDocument7 pagesConcrete CubesMohammed AbbasNo ratings yet

- DPR BWPRP4 Ocean303 10.04.18Document1 pageDPR BWPRP4 Ocean303 10.04.18KRISHNAN ELANGOVANNo ratings yet

- Presentasi PM Performance MHA KDC Weekly - Week 11 2024Document17 pagesPresentasi PM Performance MHA KDC Weekly - Week 11 2024aidil adhaNo ratings yet

- MB Spec EO Service Oils 2012.1Document2 pagesMB Spec EO Service Oils 2012.1Mia Anggraini100% (1)

- Diff Lock Fork H3: Process NameDocument2 pagesDiff Lock Fork H3: Process NamepiyushNo ratings yet

- Master C/O 2/O 3/O C/E 1/E 2/E 3/E Qualification of OfficersDocument1 pageMaster C/O 2/O 3/O C/E 1/E 2/E 3/E Qualification of Officersmuhamad nurul aminNo ratings yet

- Material LogDocument5 pagesMaterial LogRafi ullah khanNo ratings yet

- Udt YARINDODocument88 pagesUdt YARINDOWanda SafiraNo ratings yet

- Sahib Enterprise - PDIR Report-DM011102C000810091Document3 pagesSahib Enterprise - PDIR Report-DM011102C000810091surender vimalNo ratings yet

- Construction of Patenga Container Terminal (PCT) Package - 2A (Revision - O2)Document4 pagesConstruction of Patenga Container Terminal (PCT) Package - 2A (Revision - O2)Engr.Estiaq AhmedNo ratings yet

- Iran Choque: Compaction Test ReportDocument1 pageIran Choque: Compaction Test ReportJuan Carlos Miranda ColqueNo ratings yet

- Aplicatie 4Document35 pagesAplicatie 4AndreeaPopescuNo ratings yet

- XR Industrial - Gage R&RDocument1 pageXR Industrial - Gage R&Rlatasardina09No ratings yet

- 04 Ranking de Fundamentos I Sem 2024 Al 6 de MarzooDocument3 pages04 Ranking de Fundamentos I Sem 2024 Al 6 de Marzoocarvamen09No ratings yet

- NP Pressure Pipe SystemDocument11 pagesNP Pressure Pipe SystemMustafa AlluhaibiNo ratings yet

- 2tech Data - MF PET (300 601-td-0219)Document4 pages2tech Data - MF PET (300 601-td-0219)Ismacahyadi Mohamed JaisNo ratings yet

- Presented By: NewilnDocument10 pagesPresented By: NewilnSundara PandianNo ratings yet

- THIELE Grade80 A5 EnglishDocument53 pagesTHIELE Grade80 A5 EnglishAlberth Mauricio Casteblanco GomezNo ratings yet

- PENILAIAN SKP 2021 LT 1Document6 pagesPENILAIAN SKP 2021 LT 1DediNo ratings yet

- Packer SettingDocument10 pagesPacker SettingKhalid ZaeemNo ratings yet

- Setting ToolDocument41 pagesSetting ToolKhalid ZaeemNo ratings yet

- Gas Lift ValvesDocument9 pagesGas Lift ValvesKhalid Zaeem100% (1)

- When To Use The Data Converter ObjectDocument18 pagesWhen To Use The Data Converter ObjectKhalid ZaeemNo ratings yet

- TCP30234Document1 pageTCP30234Khalid ZaeemNo ratings yet

- TCP30227Document1 pageTCP30227Khalid ZaeemNo ratings yet

- TCP30281Document1 pageTCP30281Khalid ZaeemNo ratings yet

- Sand Management GuideDocument3 pagesSand Management GuideKhalid ZaeemNo ratings yet

- Section 4 - Basic Hydraulics PDFDocument25 pagesSection 4 - Basic Hydraulics PDFKhalid ZaeemNo ratings yet

- Coiled Tubing I: Halliburton Energy Institute Duncan, OklahomaDocument1 pageCoiled Tubing I: Halliburton Energy Institute Duncan, OklahomaKhalid ZaeemNo ratings yet

- PS41518Document1 pagePS41518Khalid ZaeemNo ratings yet

- TCP30228Document1 pageTCP30228Khalid ZaeemNo ratings yet

- Basic Bottomhole Assemblies (Bhas) : Section 13Document10 pagesBasic Bottomhole Assemblies (Bhas) : Section 13Khalid ZaeemNo ratings yet

- Round I Rules - WE & CWIDocument2 pagesRound I Rules - WE & CWIKhalid ZaeemNo ratings yet

- Coiled Tubing Technical Data: Section 18Document10 pagesCoiled Tubing Technical Data: Section 18Khalid ZaeemNo ratings yet

- PS64666Document2 pagesPS64666Khalid ZaeemNo ratings yet

- PS64692 PDFDocument2 pagesPS64692 PDFKhalid ZaeemNo ratings yet

- Depth Control PDFDocument11 pagesDepth Control PDFKhalid Zaeem100% (1)

- TRSCSSSV Check List Cemented CompletionDocument4 pagesTRSCSSSV Check List Cemented CompletionKhalid ZaeemNo ratings yet

- PS78560Document2 pagesPS78560Khalid ZaeemNo ratings yet

- PS78541Document1 pagePS78541Khalid ZaeemNo ratings yet

- Guide Rope LubricationDocument30 pagesGuide Rope LubricationRavi MahadeokarNo ratings yet

- Program Book ICPAM 2014Document48 pagesProgram Book ICPAM 2014AstoriaDtefanNo ratings yet

- SWB A5 m01 FinalDocument19 pagesSWB A5 m01 Finalharshal161987No ratings yet

- Septic TanksDocument6 pagesSeptic TanksJustin MusopoleNo ratings yet

- Staple Cotton Spinning SystemsDocument24 pagesStaple Cotton Spinning Systemsagga1111No ratings yet

- PadajucebrtveDocument11 pagesPadajucebrtveMonk3y MNo ratings yet

- PSD CEU 180Sept11-Corrosion PDFDocument17 pagesPSD CEU 180Sept11-Corrosion PDFSam ChoiNo ratings yet

- Is 1448PT 32Document23 pagesIs 1448PT 32RAKESH SRIVASTAVANo ratings yet

- SyllabusDocument2 pagesSyllabusprajari ghoshNo ratings yet

- Electrical EstimateDocument1 pageElectrical EstimateJoel JusayNo ratings yet

- Training Report On Manufacturing of SugarDocument33 pagesTraining Report On Manufacturing of SugarShivam Mittal50% (6)

- Jotun Facade New 21 - tcm132 91545Document5 pagesJotun Facade New 21 - tcm132 91545dnytan12345No ratings yet

- Lab 6 Ceramics and GlassDocument7 pagesLab 6 Ceramics and GlassJawad AhmadNo ratings yet

- Permalife Full CatalogDocument76 pagesPermalife Full Catalogarchitecturalelement0% (1)

- ATLAS OF ISOTHERMAL TRANSFORMATION AND COOLING TRANSFORMATION DIAGRAMS - CompressedDocument430 pagesATLAS OF ISOTHERMAL TRANSFORMATION AND COOLING TRANSFORMATION DIAGRAMS - CompressedYENIFER PLATA LOPEZNo ratings yet

- DIN 17100 ST 37-2 SteelDocument2 pagesDIN 17100 ST 37-2 SteelSiddiqui Abdul KhaliqNo ratings yet

- Copper (II) OxideDocument5 pagesCopper (II) OxideWill Aguilar MamaniNo ratings yet

- 150 66-RP4Document92 pages150 66-RP4MJZENo ratings yet

- Hl500pin ManualDocument1 pageHl500pin ManualMarious NavNo ratings yet

- Cutback Bitumen Medium Curing MCDocument3 pagesCutback Bitumen Medium Curing MCEng Venance MasanjaNo ratings yet

- HMPP Hempaline Bro - WEBDocument6 pagesHMPP Hempaline Bro - WEBvpjagannaathNo ratings yet

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoNo ratings yet

- Buckling and Postbuckling of Beams, Plates, and ShellsDocument8 pagesBuckling and Postbuckling of Beams, Plates, and Shellslalo198No ratings yet

- Polymers PPT PDFDocument47 pagesPolymers PPT PDFShivani RajeevNo ratings yet

- 9E Reactions of Metals andDocument18 pages9E Reactions of Metals and陳信羽No ratings yet

- Effect of PH On FlotationDocument10 pagesEffect of PH On FlotationInnocent Achaye100% (1)

- Small-Scale Soapmaking A Handbook 1986 PDFDocument80 pagesSmall-Scale Soapmaking A Handbook 1986 PDFTarak Raj Kumar100% (3)

- Gold Leaf TechniqueDocument4 pagesGold Leaf TechniqueBapake MariaNo ratings yet

- Owner'S Manual: Z100 / Z300 Z500 Z700Document16 pagesOwner'S Manual: Z100 / Z300 Z500 Z700A de LegaspiNo ratings yet

- Stabilised Mud Block Production With Mardini Block PressDocument16 pagesStabilised Mud Block Production With Mardini Block PressMahesh ConstructionNo ratings yet