Professional Documents

Culture Documents

Process Name: Fork 1,2,3,4

Uploaded by

piyushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Name: Fork 1,2,3,4

Uploaded by

piyushCopyright:

Available Formats

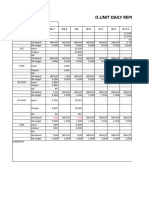

Fork 1,2,3,4

Capacity Analysis Sheet

Part No. - 000032990B12

Part Name - Fork 1,2,3,4

10 20 30 40 50 60 70 80 90 100

Operation Nos.

Type Of Machine

Drilling, Boring, Gange Drilling,

Process name Facing

Broaching Total Length Levelling Tip Milling

Milling

Deburring Polishing

Taping

Deburring

Operation Time

Cycle time (seconds)

No. of parts / cycle 1 1 1 1 1 1 1 1 1 1

Production / Hr #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

No of shifts planned 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

Available hrs for planned shifts (exclude lunch break) 22 22 22 22 22 22 22 22 22 22

Avg. available Hrs /Shift 10.8 10.8 10.8 10.8 10.8 10.8 10.8 10.8 10.8 10.8

Production / Shift #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Day #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Week (6 days) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Month (26 days) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Year (300 days) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Efficiency for capacity analysis 99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52%

Scrap rate 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0%

% OK parts (excluding scrap rate) 100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00%

Capacity for year #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Parts / Vehicle 1 1 1 1 1 1 1 1 1 1

No. of Vehicle sets / Yr #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Yuvraj NXT contracted requirement (Vehicles / year) 96,000 96,000 96,000 96,000 96,000 96,000 96,000 96,000 96,000 96,000

Assumptions for capacity analysis:

Actual Working

Hrs: 10.5

Working days/ month = 26

Working days/ year = 300

Scrap Rate is based on rejections on H1 Line

Takt Time (s):

110 120 130

Inspection

Tip Hardeing Packaging

and Marking

1 1 1

#DIV/0! #DIV/0! #DIV/0!

2.0 2.0 2.0

22 22 22

10.8 10.8 10.8

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

99.52% 99.52% 99.52%

0.0% 0.0% 0.0%

100.00% 100.00% 100.00%

#DIV/0! #DIV/0! #DIV/0!

1 1 1

#DIV/0! #DIV/0! #DIV/0!

96,000 96,000 96,000

You might also like

- Oee TemplateDocument4 pagesOee TemplateJeffrey FullerNo ratings yet

- PTI Post-Tensioning Manual 6th EditionDocument362 pagesPTI Post-Tensioning Manual 6th Editionjackj_1820739838% (12)

- Diff Lock Fork H3: Process NameDocument2 pagesDiff Lock Fork H3: Process NamepiyushNo ratings yet

- Process Name: CR FORK 3025R1Document2 pagesProcess Name: CR FORK 3025R1piyushNo ratings yet

- Cam High Low Gear ShiftingDocument1 pageCam High Low Gear ShiftingpiyushNo ratings yet

- Brake Lever CPTE LH/RH: Process NameDocument2 pagesBrake Lever CPTE LH/RH: Process NamepiyushNo ratings yet

- Fork I-Ii-Iii-Iv Speed H3: Capacity Analysis SheetDocument3 pagesFork I-Ii-Iii-Iv Speed H3: Capacity Analysis SheetpiyushNo ratings yet

- Section Shifter 3 4 - 7709Document2 pagesSection Shifter 3 4 - 7709piyushNo ratings yet

- Shifter Block High Low Range H3: Capacity Analysis SheetDocument6 pagesShifter Block High Low Range H3: Capacity Analysis SheetpiyushNo ratings yet

- GSQT 004 Husqvarna Full Run Test Report Template Revision 0Document3 pagesGSQT 004 Husqvarna Full Run Test Report Template Revision 0Tien Dung Phan100% (1)

- Daily Production Report: Day Sund Date 23-Jul-17Document15 pagesDaily Production Report: Day Sund Date 23-Jul-17mohamadNo ratings yet

- Capex Depreciation: #REF! Projec T'S ReqmtDocument2 pagesCapex Depreciation: #REF! Projec T'S Reqmtjam mallillinNo ratings yet

- Date Description Buy Value Sale Value Contract Note NoDocument15 pagesDate Description Buy Value Sale Value Contract Note NoNikhil BhatiaNo ratings yet

- Daily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateDocument1 pageDaily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateGokul KgsNo ratings yet

- Tops & Dress Division: "A Person Who Never Made A Mistake Never Tried Anything New."Document13 pagesTops & Dress Division: "A Person Who Never Made A Mistake Never Tried Anything New."Megha SharmaNo ratings yet

- Kpi 2024Document8 pagesKpi 2024amatouryamatouryNo ratings yet

- Forecast MIS ReportDocument9 pagesForecast MIS ReportSameer SinghNo ratings yet

- Feuille de Calcul PDC AerauliqueDocument2 pagesFeuille de Calcul PDC Aerauliqueabdessamad CHADDOUNo ratings yet

- GM BreakDownDocument3 pagesGM BreakDowncmena87No ratings yet

- Manpower Plan FormatDocument421 pagesManpower Plan FormatROHAN NAIKNo ratings yet

- Manpower Plan Dated 03.01.2020Document421 pagesManpower Plan Dated 03.01.2020ROHAN NAIKNo ratings yet

- Liquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Document65 pagesLiquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Sanzar Rahman 1621555030No ratings yet

- Ssliquidurea Formaldehyderesinmanufacturingindustry 181201131452Document65 pagesSsliquidurea Formaldehyderesinmanufacturingindustry 181201131452mikaela05No ratings yet

- June OEEDocument57 pagesJune OEEAnthonyNo ratings yet

- PSS Ext JJ FinalDocument1 pagePSS Ext JJ FinalRaj Kumar GiriNo ratings yet

- DPR BWPRP4 Ocean303 12.03.18Document1 pageDPR BWPRP4 Ocean303 12.03.18KRISHNAN ELANGOVANNo ratings yet

- Form Monitoring E2E Motoris 7 AGUSTUS 2021Document5 pagesForm Monitoring E2E Motoris 7 AGUSTUS 2021randaNo ratings yet

- Project Profile For Coir Handicraft or Ornaments Production UnitDocument5 pagesProject Profile For Coir Handicraft or Ornaments Production Unitarka giftsNo ratings yet

- Strengthening To Vadakumelur-Keelur-Pacharapalayam Road at KM 0/0-2/6 (Using Plastic Waste) Including Upkeeping For A Period of 60 MonthsDocument6 pagesStrengthening To Vadakumelur-Keelur-Pacharapalayam Road at KM 0/0-2/6 (Using Plastic Waste) Including Upkeeping For A Period of 60 MonthsveevimalNo ratings yet

- Daily Quality Report - 2019Document395 pagesDaily Quality Report - 2019Thao ChaungocNo ratings yet

- Pt. Era Perkasa Mining: Forecast MonthlyDocument10 pagesPt. Era Perkasa Mining: Forecast MonthlyEric ENo ratings yet

- Copie de Xl0000021 TTRDocument10 pagesCopie de Xl0000021 TTROthmanNo ratings yet

- Grinding Cost Calculation - Summary: Annual Production Quantity Annual Consumption - QuantityDocument6 pagesGrinding Cost Calculation - Summary: Annual Production Quantity Annual Consumption - QuantitynanthaidNo ratings yet

- DPR BWPRP4 Ocean303 14.03.18Document1 pageDPR BWPRP4 Ocean303 14.03.18KRISHNAN ELANGOVANNo ratings yet

- Setco Automotive LTD.: OEE Summary ReportDocument12 pagesSetco Automotive LTD.: OEE Summary ReportDisha ShahNo ratings yet

- REPORTDocument9 pagesREPORTkhelectron3No ratings yet

- Engineering Progress Total ProgressDocument7 pagesEngineering Progress Total ProgressIlyasse EL FAYDYNo ratings yet

- R01-Production ReportDocument1 pageR01-Production ReportISO CERTIFICATION-ROHSNo ratings yet

- GrainsizeDocument18 pagesGrainsizeAli KayaNo ratings yet

- How To Start Business of PP-HDPE Woven Bag, Circular Loom, Plastic BagDocument60 pagesHow To Start Business of PP-HDPE Woven Bag, Circular Loom, Plastic BagNitinNo ratings yet

- Estructura de Costos ServiciosDocument9 pagesEstructura de Costos Serviciosarguello sanchez S.C.No ratings yet

- Frontlit, Backlit & Vinyl Flex Banner Manufacturing For AdvertisingDocument52 pagesFrontlit, Backlit & Vinyl Flex Banner Manufacturing For AdvertisingSusheel GautamNo ratings yet

- Aluminium Extrusion Plant. Aluminium Extruded Profiles. Extruded Sections-816300 PDFDocument70 pagesAluminium Extrusion Plant. Aluminium Extruded Profiles. Extruded Sections-816300 PDFjinendra50% (2)

- Manhour Productivity RatesDocument7 pagesManhour Productivity RatesSpeedster Exhalted100% (1)

- DPR BWPRP4 Ocean303 02.04.18Document1 pageDPR BWPRP4 Ocean303 02.04.18KRISHNAN ELANGOVANNo ratings yet

- QA ReportDocument28 pagesQA ReportVikas SharmaNo ratings yet

- Project Profile For Coco Log Making UnitDocument6 pagesProject Profile For Coco Log Making UnitRamanjaneyulu PoludasuNo ratings yet

- Als Dmea Q3 Cy 2023Document91 pagesAls Dmea Q3 Cy 2023Nilo ZolinaNo ratings yet

- Pdfanddoc 638378 PDFDocument56 pagesPdfanddoc 638378 PDFVimal Anbalagan100% (1)

- Capacity Analysis Sheet: Process NameDocument4 pagesCapacity Analysis Sheet: Process NamepiyushNo ratings yet

- Green and Ampt Infiltration Cumulative Infiltration: Time, T (HR)Document7 pagesGreen and Ampt Infiltration Cumulative Infiltration: Time, T (HR)Ika CahyantiNo ratings yet

- Form Monitoring E2E Motoris 4 AGUSTUS 2021Document5 pagesForm Monitoring E2E Motoris 4 AGUSTUS 2021randaNo ratings yet

- Pipette and Sieve Grain Size Analysis Data Sheets: Raw Data PageDocument18 pagesPipette and Sieve Grain Size Analysis Data Sheets: Raw Data PageRed RedNo ratings yet

- Rebar Accomplishment (As of October 30,2020)Document43 pagesRebar Accomplishment (As of October 30,2020)Kris Camille MoralesNo ratings yet

- Production Report FormatDocument2 pagesProduction Report FormatIshah ahamed KaziNo ratings yet

- Production of Pearl Caustic Soda-653343 PDFDocument62 pagesProduction of Pearl Caustic Soda-653343 PDFhardajhbfNo ratings yet

- DPR BWPRP4 Ocean303 01.04.18Document1 pageDPR BWPRP4 Ocean303 01.04.18KRISHNAN ELANGOVANNo ratings yet

- Fastenet JUN-JUL 2022Document140 pagesFastenet JUN-JUL 2022Joao Pedro Rendeiro Correia de SousaNo ratings yet

- Copy and Paste Income Statement Below in A2 Cell in Blue!!!Document3 pagesCopy and Paste Income Statement Below in A2 Cell in Blue!!!Jc TambauanNo ratings yet

- Stoppages Study FormatDocument2 pagesStoppages Study Formatsachinsharma31No ratings yet

- Section Shifter 3 4 - 7709Document2 pagesSection Shifter 3 4 - 7709piyushNo ratings yet

- Gajanan Precision Pvt. LTD.: Packaging ReportDocument1 pageGajanan Precision Pvt. LTD.: Packaging ReportpiyushNo ratings yet

- Shifter Block High Low Range H3: Capacity Analysis SheetDocument6 pagesShifter Block High Low Range H3: Capacity Analysis SheetpiyushNo ratings yet

- List of OperationsDocument4 pagesList of OperationspiyushNo ratings yet

- Capacity Analysis Sheet: Process NameDocument4 pagesCapacity Analysis Sheet: Process NamepiyushNo ratings yet

- For in If and Elif and Elif and Else: "Enter A String"Document2 pagesFor in If and Elif and Elif and Else: "Enter A String"piyushNo ratings yet

- OstlDocument8 pagesOstlpiyushNo ratings yet

- OstlDocument8 pagesOstlpiyushNo ratings yet

- CG Exp-10Document4 pagesCG Exp-10piyushNo ratings yet

- Experiment No:1 Aim:WAP To Demonstrate Strings in Python:: Name:Pratiksha D. Laldas SE Comps A Roll No:53 Batch A3Document5 pagesExperiment No:1 Aim:WAP To Demonstrate Strings in Python:: Name:Pratiksha D. Laldas SE Comps A Roll No:53 Batch A3piyushNo ratings yet

- CG Exp-7Document3 pagesCG Exp-7piyushNo ratings yet

- Ostl EXP 5BDocument8 pagesOstl EXP 5BpiyushNo ratings yet

- Ostl 1Document11 pagesOstl 1piyushNo ratings yet

- Experiment No.04: Neel Sanjay Bhatt Se Comps-A Roll NO.07Document3 pagesExperiment No.04: Neel Sanjay Bhatt Se Comps-A Roll NO.07piyushNo ratings yet

- Experiment No.03: Neel Sanjay Bhatt Se Comps-A Roll NO.07Document3 pagesExperiment No.03: Neel Sanjay Bhatt Se Comps-A Roll NO.07piyushNo ratings yet

- CG Exp-1 Case Study2Document4 pagesCG Exp-1 Case Study2piyushNo ratings yet

- Pratiksha D.Laldas SE Computer A Roll No. 53 Exiperiment No: 05 Aim: Implementation of Polygon Filling Algorithm. 1. Boundary-Fill Algorithm CodeDocument8 pagesPratiksha D.Laldas SE Computer A Roll No. 53 Exiperiment No: 05 Aim: Implementation of Polygon Filling Algorithm. 1. Boundary-Fill Algorithm CodepiyushNo ratings yet

- CG Exp-9Document6 pagesCG Exp-9piyushNo ratings yet

- Neel Sanjay Bhatt SE Computer A Roll No:-07Document8 pagesNeel Sanjay Bhatt SE Computer A Roll No:-07piyushNo ratings yet

- Name: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParametersDocument8 pagesName: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParameterspiyushNo ratings yet

- Experiment No.02: Pratiksha D. Laldas SE Computer A Roll NO.53Document4 pagesExperiment No.02: Pratiksha D. Laldas SE Computer A Roll NO.53piyushNo ratings yet

- Experiment No: 6A: Neel Sanjay Bhatt Roll No:-07 SE Computer ADocument11 pagesExperiment No: 6A: Neel Sanjay Bhatt Roll No:-07 SE Computer ApiyushNo ratings yet

- Neel Sanjay Bhatt Roll No:-07 Div:ADocument7 pagesNeel Sanjay Bhatt Roll No:-07 Div:ApiyushNo ratings yet

- Ostl EXP 5BDocument8 pagesOstl EXP 5BpiyushNo ratings yet

- Name: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParametersDocument8 pagesName: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParameterspiyushNo ratings yet

- ISO 26262-10-2012-Road Vehicles Functional Safety Guideline On ISO 26262Document100 pagesISO 26262-10-2012-Road Vehicles Functional Safety Guideline On ISO 26262Cycy Hm100% (1)

- FS2 Episode 6-10Document24 pagesFS2 Episode 6-10Ian Dante ArcangelesNo ratings yet

- Eticket - Rohit Gupta 5892137278569Document3 pagesEticket - Rohit Gupta 5892137278569Rohit GuptaNo ratings yet

- Alfian Dwi Nugroho S.T: Geodetic EngineeringDocument1 pageAlfian Dwi Nugroho S.T: Geodetic EngineeringAlfian Dwi NugrohoNo ratings yet

- Physics 12 ADocument22 pagesPhysics 12 ASatyam RajNo ratings yet

- Rehan Overseas - Just Another WordPress SiteDocument1 pageRehan Overseas - Just Another WordPress SiteRaunaq SinghNo ratings yet

- Ieltsliz Com Ielts Writing Task 1 Line Graph Model Score 9 PDFDocument13 pagesIeltsliz Com Ielts Writing Task 1 Line Graph Model Score 9 PDFMD MAHBUBUL HAQUENo ratings yet

- Mathcad License 3.1Document1 pageMathcad License 3.1ncatalin94100% (1)

- Tiny Tweaks James WedmoreDocument31 pagesTiny Tweaks James WedmoreErise Global100% (1)

- Assessment Ers5900Document7 pagesAssessment Ers5900Asma AsmaNo ratings yet

- How Energy Efficiency Fails in The Building Industry: Knut - Sorensen@hf - Ntnu.noDocument22 pagesHow Energy Efficiency Fails in The Building Industry: Knut - Sorensen@hf - Ntnu.nomuhammad muhramNo ratings yet

- IQ3 Metal Detector User Guide PDFDocument144 pagesIQ3 Metal Detector User Guide PDFLuis Fernando Garrido MolinaNo ratings yet

- Fingerprint ManualDocument11 pagesFingerprint ManualEdgar A CanizalezNo ratings yet

- Multicolumn Blast Valve PV-KKDocument2 pagesMulticolumn Blast Valve PV-KKyousufbashaNo ratings yet

- Grade 10 Math Q2 FULL Week 1 - WatermarkDocument28 pagesGrade 10 Math Q2 FULL Week 1 - WatermarkSophia Junelle100% (1)

- Technology & BankingDocument15 pagesTechnology & Bankingswati100491% (11)

- GRID Integration of Renewable Energy SourcesDocument9 pagesGRID Integration of Renewable Energy SourcesmanasasurendraNo ratings yet

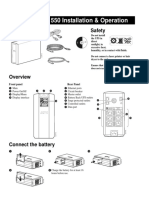

- Back-UPS RS 550 Installation & Operation: Inventory SafetyDocument7 pagesBack-UPS RS 550 Installation & Operation: Inventory SafetyAndrej VukalovicNo ratings yet

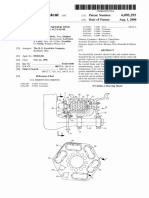

- Aircraft Brake and Method With Electromechanical Actuator ModulesDocument8 pagesAircraft Brake and Method With Electromechanical Actuator ModulesHassanNo ratings yet

- Tekapur Pistolska Mega 65 Zimska enDocument2 pagesTekapur Pistolska Mega 65 Zimska enEzeval GráficaNo ratings yet

- Four Different Levels of MeasurementDocument2 pagesFour Different Levels of MeasurementMaria Isabella RuaYanaNo ratings yet

- Joost Network ArchitectureDocument29 pagesJoost Network Architecturegholkr100% (2)

- Solved Problem - Critical Path MethodDocument6 pagesSolved Problem - Critical Path MethoddyingasNo ratings yet

- Partex EnglishDocument16 pagesPartex EnglishDaniyal ParvezNo ratings yet

- Upload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowDocument2 pagesUpload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowMasoud MonjeziNo ratings yet

- KEI - Cable List Price - April 2021Document5 pagesKEI - Cable List Price - April 2021smithNo ratings yet

- Motionbert: Unified Pretraining For Human Motion AnalysisDocument15 pagesMotionbert: Unified Pretraining For Human Motion AnalysisMaxNo ratings yet

- Asme BPVC III D 1 NF 2015Document226 pagesAsme BPVC III D 1 NF 2015Tino OrtizNo ratings yet

- Role of IctDocument19 pagesRole of IctJann ericka Jao100% (1)