Professional Documents

Culture Documents

Process Name: CR FORK 3025R1

Uploaded by

piyushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Name: CR FORK 3025R1

Uploaded by

piyushCopyright:

Available Formats

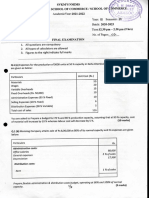

CR FORK 3025R1

Capacity Analysis Sheet

Part No. - 3025R1

Part Name - CR FORK

Operation Nos. 10 20 30 40 50 60 70 80

Tsugami, D-5 L-5 C-4 (AMS D-10, D-9 D-6 D-3,D-1 M-1,M-3

Miyano, Winner)

Type Of Machine Pinnacle

Chamfer &

Process name Drilling & Boring

Counter

Polishing Form Milling Drilling Spot Facing Tapping Slitting

Operation Time

Cycle time (seconds)

No. of parts / cycle 1 1 1 1 1 1 1 1

Production / Hr #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

No of shifts planned 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

Available hrs for planned shifts (exclude lunch break) 22 22 22 22 22 22 22 22

Avg. available Hrs /Shift 10.8 10.8 10.8 10.8 10.8 10.8 10.8 10.8

Production / Shift #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Day #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Week (6 days) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Month (25 days) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Production / Year (300 days) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Efficiency for capacity analysis 99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52%

Scrap rate 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0%

% OK parts (excluding scrap rate) 100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00%

Capacity for year #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Parts / Vehicle 1 1 1 1 1 1 1 1

No. of Vehicle sets / Yr #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Yuvraj NXT contracted requirement (Vehicles / year) 96,000 96,000 96,000 96,000 96,000 96,000 96,000 96,000

Assumptions for capacity analysis: We are using 2 We are using 2 We are using 2

Machines to Drilling For Machines to

Complete Complete The Complete The

8000/Month 8000/Month 8000/Month

Actual Working

Hrs: 10.5

Working days/ month = 25

Working days/ year = 300

Scrap Rate is based on rejections on H1 Line

Takt Time (s): 225

90 100 110 120 130

D-11 H-3,H-2

Final

Induction Checking and Oiling &

Deburing Levelling

Hardening Mandel Packing

Passing

1 1 1 1 1

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

2.0 2.0 2.0 2.0 2.0

22 22 22 22 22

10.8 10.8 10.8 10.8 10.8

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

99.52% 99.52% 99.52% 99.52% 99.52%

0.0% 0.0% 0.0% 0.0% 0.0%

100.00% 100.00% 100.00% 100.00% 100.00%

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

1 1 1 1 1

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

96,000 96,000 96,000 96,000 96,000

You might also like

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Process Name: Fork 1,2,3,4Document2 pagesProcess Name: Fork 1,2,3,4piyushNo ratings yet

- Diff Lock Fork H3: Process NameDocument2 pagesDiff Lock Fork H3: Process NamepiyushNo ratings yet

- Brake Lever CPTE LH/RH: Process NameDocument2 pagesBrake Lever CPTE LH/RH: Process NamepiyushNo ratings yet

- Cam High Low Gear ShiftingDocument1 pageCam High Low Gear ShiftingpiyushNo ratings yet

- Fork I-Ii-Iii-Iv Speed H3: Capacity Analysis SheetDocument3 pagesFork I-Ii-Iii-Iv Speed H3: Capacity Analysis SheetpiyushNo ratings yet

- Section Shifter 3 4 - 7709Document2 pagesSection Shifter 3 4 - 7709piyushNo ratings yet

- Shifter Block High Low Range H3: Capacity Analysis SheetDocument6 pagesShifter Block High Low Range H3: Capacity Analysis SheetpiyushNo ratings yet

- GSQT 004 Husqvarna Full Run Test Report Template Revision 0Document3 pagesGSQT 004 Husqvarna Full Run Test Report Template Revision 0Tien Dung Phan100% (1)

- Daily Production Report: Day Sund Date 23-Jul-17Document15 pagesDaily Production Report: Day Sund Date 23-Jul-17mohamadNo ratings yet

- Capex Depreciation: #REF! Projec T'S ReqmtDocument2 pagesCapex Depreciation: #REF! Projec T'S Reqmtjam mallillinNo ratings yet

- TPM - Kenji Takemura PDFDocument119 pagesTPM - Kenji Takemura PDFtrungNo ratings yet

- Project Profile For Coir Handicraft or Ornaments Production UnitDocument5 pagesProject Profile For Coir Handicraft or Ornaments Production Unitarka giftsNo ratings yet

- June OEEDocument57 pagesJune OEEAnthonyNo ratings yet

- Description Date: ShiftDocument5 pagesDescription Date: ShiftRamdas PaithankarNo ratings yet

- Kpi 2024Document8 pagesKpi 2024amatouryamatouryNo ratings yet

- Oee TemplateDocument4 pagesOee TemplateJeffrey FullerNo ratings yet

- Project Profile For Coir Pith Briquette Unit: - IntroductionDocument6 pagesProject Profile For Coir Pith Briquette Unit: - IntroductionSatish SatiNo ratings yet

- Equipment Productivity Periode: A. Hauling EquipmentDocument10 pagesEquipment Productivity Periode: A. Hauling Equipmentyusak billanNo ratings yet

- Copie de Xl0000021 TTRDocument10 pagesCopie de Xl0000021 TTROthmanNo ratings yet

- Profile For Coir Fiber or Dust Moulding UnitDocument7 pagesProfile For Coir Fiber or Dust Moulding UnitAnandh SharavanNo ratings yet

- Tops & Dress Division: "A Person Who Never Made A Mistake Never Tried Anything New."Document13 pagesTops & Dress Division: "A Person Who Never Made A Mistake Never Tried Anything New."Megha SharmaNo ratings yet

- Forecast MIS ReportDocument9 pagesForecast MIS ReportSameer SinghNo ratings yet

- Project Profile For Coco Log Making UnitDocument6 pagesProject Profile For Coco Log Making UnitRamanjaneyulu PoludasuNo ratings yet

- Pt. Era Perkasa Mining: Forecast MonthlyDocument10 pagesPt. Era Perkasa Mining: Forecast MonthlyEric ENo ratings yet

- Project Profile For Coir Geo Textiles Automatic Loom UnitDocument5 pagesProject Profile For Coir Geo Textiles Automatic Loom UnitathulkmmanikyanNo ratings yet

- LHPL-FMT-09 Break Down Hrs Monitoring Chart MTTR & MTBFDocument6 pagesLHPL-FMT-09 Break Down Hrs Monitoring Chart MTTR & MTBFDevendra SinghNo ratings yet

- Stoppages Study FormatDocument2 pagesStoppages Study Formatsachinsharma31No ratings yet

- Sample Downtime ReportDocument37 pagesSample Downtime ReportRidwanNo ratings yet

- Ecole National Superieur Des Travaux Publics 4EME ANNEE PROMOTION 2008/2009 Meriga BachirDocument3 pagesEcole National Superieur Des Travaux Publics 4EME ANNEE PROMOTION 2008/2009 Meriga BachirMeslem MazighNo ratings yet

- Capacity Analysis Sheet: Process NameDocument4 pagesCapacity Analysis Sheet: Process NamepiyushNo ratings yet

- Project Profile For Coir Paper or Paper Products Making UnitDocument6 pagesProject Profile For Coir Paper or Paper Products Making Unitavinash sainiNo ratings yet

- Examples For Brids StudyDocument4 pagesExamples For Brids StudyMunir HussainNo ratings yet

- Tact Time: TPS Group Toyota Kirloskar Motor PVT LTDDocument13 pagesTact Time: TPS Group Toyota Kirloskar Motor PVT LTDDisha ShahNo ratings yet

- Daily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateDocument1 pageDaily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateGokul KgsNo ratings yet

- (July 2019) - OT - AccomplishmentDocument2 pages(July 2019) - OT - AccomplishmentMark Kristoffer HilarionNo ratings yet

- Problem Set IvDocument87 pagesProblem Set IvTir MahatirNo ratings yet

- Form Monitoring E2E Motoris 7 AGUSTUS 2021Document5 pagesForm Monitoring E2E Motoris 7 AGUSTUS 2021randaNo ratings yet

- Lotac Daily Bread 12 Months Projected Cash Flow and P&L AccountDocument16 pagesLotac Daily Bread 12 Months Projected Cash Flow and P&L AccountAaron Chidi JudeNo ratings yet

- Weekly ReportDocument39 pagesWeekly Reportirtanto holmesNo ratings yet

- Als Dmea Q3 Cy 2023Document91 pagesAls Dmea Q3 Cy 2023Nilo ZolinaNo ratings yet

- Grinding Cost Calculation - Summary: Annual Production Quantity Annual Consumption - QuantityDocument6 pagesGrinding Cost Calculation - Summary: Annual Production Quantity Annual Consumption - QuantitynanthaidNo ratings yet

- Liquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Document65 pagesLiquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Sanzar Rahman 1621555030No ratings yet

- FA2 - ExcelDocument1 pageFA2 - ExcelGretchen MontoyaNo ratings yet

- Engineering Progress Total ProgressDocument7 pagesEngineering Progress Total ProgressIlyasse EL FAYDYNo ratings yet

- RD Enterprises CMA DataDocument31 pagesRD Enterprises CMA DataCA Ankit KumarNo ratings yet

- Form Monitoring E2E Motoris 4 AGUSTUS 2021Document5 pagesForm Monitoring E2E Motoris 4 AGUSTUS 2021randaNo ratings yet

- Management Accounting989 DqNgYxv2GjDocument3 pagesManagement Accounting989 DqNgYxv2GjPrekshit KalashdharNo ratings yet

- Manpower Plan FormatDocument421 pagesManpower Plan FormatROHAN NAIKNo ratings yet

- Manpower Plan Dated 03.01.2020Document421 pagesManpower Plan Dated 03.01.2020ROHAN NAIKNo ratings yet

- Ssliquidurea Formaldehyderesinmanufacturingindustry 181201131452Document65 pagesSsliquidurea Formaldehyderesinmanufacturingindustry 181201131452mikaela05No ratings yet

- Cost Accounting985 Cxa9nf2nks PDFDocument6 pagesCost Accounting985 Cxa9nf2nks PDFjay gargNo ratings yet

- R01-Production ReportDocument1 pageR01-Production ReportISO CERTIFICATION-ROHSNo ratings yet

- Production PlanningDocument27 pagesProduction PlanninggebrekidanNo ratings yet

- QA ReportDocument28 pagesQA ReportVikas SharmaNo ratings yet

- Business Scenario - Round 3Document4 pagesBusiness Scenario - Round 3spikey125No ratings yet

- Car M120BC013Document1 pageCar M120BC013Hương Dương100% (1)

- Cashew Processing, Granding PackingDocument8 pagesCashew Processing, Granding PackingAshis Kumar MuduliNo ratings yet

- PLTP Dieng Unit 1: Weekly Report #1Document9 pagesPLTP Dieng Unit 1: Weekly Report #1Totok Blegoh WasqithoNo ratings yet

- Mining DataDocument16 pagesMining DataMuhammad ANo ratings yet

- Gajanan Precision Pvt. LTD.: Packaging ReportDocument1 pageGajanan Precision Pvt. LTD.: Packaging ReportpiyushNo ratings yet

- Shifter Block High Low Range H3: Capacity Analysis SheetDocument6 pagesShifter Block High Low Range H3: Capacity Analysis SheetpiyushNo ratings yet

- Capacity Analysis Sheet: Process NameDocument4 pagesCapacity Analysis Sheet: Process NamepiyushNo ratings yet

- List of OperationsDocument4 pagesList of OperationspiyushNo ratings yet

- Section Shifter 3 4 - 7709Document2 pagesSection Shifter 3 4 - 7709piyushNo ratings yet

- Experiment No:1 Aim:WAP To Demonstrate Strings in Python:: Name:Pratiksha D. Laldas SE Comps A Roll No:53 Batch A3Document5 pagesExperiment No:1 Aim:WAP To Demonstrate Strings in Python:: Name:Pratiksha D. Laldas SE Comps A Roll No:53 Batch A3piyushNo ratings yet

- OstlDocument8 pagesOstlpiyushNo ratings yet

- For in If and Elif and Elif and Else: "Enter A String"Document2 pagesFor in If and Elif and Elif and Else: "Enter A String"piyushNo ratings yet

- OstlDocument8 pagesOstlpiyushNo ratings yet

- Ostl 1Document11 pagesOstl 1piyushNo ratings yet

- Ostl EXP 5BDocument8 pagesOstl EXP 5BpiyushNo ratings yet

- Pratiksha D.Laldas SE Computer A Roll No. 53 Exiperiment No: 05 Aim: Implementation of Polygon Filling Algorithm. 1. Boundary-Fill Algorithm CodeDocument8 pagesPratiksha D.Laldas SE Computer A Roll No. 53 Exiperiment No: 05 Aim: Implementation of Polygon Filling Algorithm. 1. Boundary-Fill Algorithm CodepiyushNo ratings yet

- CG Exp-1 Case Study2Document4 pagesCG Exp-1 Case Study2piyushNo ratings yet

- Neel Sanjay Bhatt SE Computer A Roll No:-07Document8 pagesNeel Sanjay Bhatt SE Computer A Roll No:-07piyushNo ratings yet

- Name: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParametersDocument8 pagesName: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParameterspiyushNo ratings yet

- Experiment No.04: Neel Sanjay Bhatt Se Comps-A Roll NO.07Document3 pagesExperiment No.04: Neel Sanjay Bhatt Se Comps-A Roll NO.07piyushNo ratings yet

- Experiment No.03: Neel Sanjay Bhatt Se Comps-A Roll NO.07Document3 pagesExperiment No.03: Neel Sanjay Bhatt Se Comps-A Roll NO.07piyushNo ratings yet

- CG Exp-7Document3 pagesCG Exp-7piyushNo ratings yet

- Experiment No: 6A: Neel Sanjay Bhatt Roll No:-07 SE Computer ADocument11 pagesExperiment No: 6A: Neel Sanjay Bhatt Roll No:-07 SE Computer ApiyushNo ratings yet

- CG Exp-9Document6 pagesCG Exp-9piyushNo ratings yet

- CG Exp-10Document4 pagesCG Exp-10piyushNo ratings yet

- Experiment No.02: Pratiksha D. Laldas SE Computer A Roll NO.53Document4 pagesExperiment No.02: Pratiksha D. Laldas SE Computer A Roll NO.53piyushNo ratings yet

- Name: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParametersDocument8 pagesName: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParameterspiyushNo ratings yet

- Neel Sanjay Bhatt Roll No:-07 Div:ADocument7 pagesNeel Sanjay Bhatt Roll No:-07 Div:ApiyushNo ratings yet

- Ostl EXP 5BDocument8 pagesOstl EXP 5BpiyushNo ratings yet

- Sales PPT - GRP 3Document14 pagesSales PPT - GRP 321324jesikaNo ratings yet

- Pertemuan 7 Akuntansi BiayaDocument33 pagesPertemuan 7 Akuntansi BiayaHanif MusyaffaNo ratings yet

- Vega Helmet Project 2010Document82 pagesVega Helmet Project 2010kittya135748988% (8)

- CMMI Adoption Transition Guidance PDFDocument53 pagesCMMI Adoption Transition Guidance PDFYadira VargasNo ratings yet

- Construction Disputes and R.A. 9184 Provisions On Government InfrastructureDocument1 pageConstruction Disputes and R.A. 9184 Provisions On Government InfrastructureQueenie PerezNo ratings yet

- Aud4033 Isa - 220Document17 pagesAud4033 Isa - 220ALYA AFIQAH BINTI MAT RAMLANNo ratings yet

- 5-Reducing Project DurationDocument12 pages5-Reducing Project DurationRaunak Yadav100% (1)

- Impact of Information Technology Integration and Lean/Just-In-Time Practices On Lead-Time PerformanceDocument27 pagesImpact of Information Technology Integration and Lean/Just-In-Time Practices On Lead-Time PerformanceSachen KulandaivelNo ratings yet

- Raftar Express India PVT LTD Profile.Document8 pagesRaftar Express India PVT LTD Profile.mohdmashaallah5No ratings yet

- Practical Guide To SAP Material - Rosana Fonseca PDFDocument209 pagesPractical Guide To SAP Material - Rosana Fonseca PDFidevaldo100% (6)

- First Five Pages of ProjectDocument5 pagesFirst Five Pages of ProjectVicky JainNo ratings yet

- Internal ControlDocument2 pagesInternal Controlmimouh nouhailaNo ratings yet

- Nit No.: Juidco/ Nit/ RFP/ Jhb/394Document37 pagesNit No.: Juidco/ Nit/ RFP/ Jhb/394Akhil VermaNo ratings yet

- AWS PortafolioDocument27 pagesAWS PortafolioMiguel RomeroNo ratings yet

- Audit Itinerary and Checklist - StatusDocument28 pagesAudit Itinerary and Checklist - StatusMaria Cristina CoNo ratings yet

- Sunflower IncorporatedDocument2 pagesSunflower Incorporatedzokaze33% (3)

- Operation Costing, Just-In-Time System, and Backflush CostingDocument15 pagesOperation Costing, Just-In-Time System, and Backflush CostingJeremy Cyrus TrinidadNo ratings yet

- Test Certificate NDT / Inspection: - YOKRIDocument9 pagesTest Certificate NDT / Inspection: - YOKRIikponmwonsaNo ratings yet

- FSA QuestionsDocument1 pageFSA QuestionsNadeemNo ratings yet

- CH 10 NotesDocument13 pagesCH 10 NotesmohamedNo ratings yet

- Characteristics of Supply Chain Management and The Implication For Purchasing and Logistics StrategyDocument22 pagesCharacteristics of Supply Chain Management and The Implication For Purchasing and Logistics StrategyNguyen Quoc Chuong100% (1)

- Accurate Industrial Controls PVT LTD: Job DescriptionDocument2 pagesAccurate Industrial Controls PVT LTD: Job DescriptionANIRBAN BISWASNo ratings yet

- Shahzad Farrukh - 00704963 - 1535-Qanmos College - IG-1Document11 pagesShahzad Farrukh - 00704963 - 1535-Qanmos College - IG-1Rashid Jamil100% (3)

- Hoshin Kanri and A3 - A Proposal For Integrating Variability Into The Policy Deployment ProcessDocument18 pagesHoshin Kanri and A3 - A Proposal For Integrating Variability Into The Policy Deployment ProcessNoé HumbertoNo ratings yet

- Project Audit MethodologyDocument2 pagesProject Audit MethodologyFariha AktarNo ratings yet

- Global Supplier Manual Appendix I - Mahindra and Mahindra Customer Specific Requirements For SuppliersDocument5 pagesGlobal Supplier Manual Appendix I - Mahindra and Mahindra Customer Specific Requirements For SuppliersPravin Balasaheb GunjalNo ratings yet

- Sama Sama LipDocument4 pagesSama Sama LipAnesa SimamoraNo ratings yet

- Chapter 3 - Engineering ManagementDocument6 pagesChapter 3 - Engineering ManagementJohn Philip Molina NuñezNo ratings yet

- Apc 301 Week 8Document2 pagesApc 301 Week 8Angel Lourdie Lyn HosenillaNo ratings yet

- Supply Chain Management at H&MDocument7 pagesSupply Chain Management at H&MYasha voraNo ratings yet