Professional Documents

Culture Documents

Shifter Block High Low Range H3: Capacity Analysis Sheet

Uploaded by

piyushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shifter Block High Low Range H3: Capacity Analysis Sheet

Uploaded by

piyushCopyright:

Available Formats

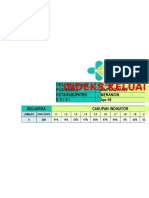

SHIFTER BLOC

Capac

Part No. - 000012075P04

Part Name - SHIFTER BLOCK HIGH LOW

RANGE H3

Operation Nos. 10 20 30

Type Of Machine Lathe

Drilling . Boring

Process name & Facing

Broaching Total Length

Opertion Time

Cycle time (seconds)

No. of parts / cycle 1 1 1

Production / Hr #DIV/0! #DIV/0! #DIV/0!

No of shifts planned 3.0 3.0 3.0

Available hrs for planned shifts (exclude lunch break) 22 22 22

Avg. available Hrs /Shift 7.3 7.3 7.3

Production / Shift #DIV/0! #DIV/0! #DIV/0!

Production / Day #DIV/0! #DIV/0! #DIV/0!

Production / Week (6 days) #DIV/0! #DIV/0! #DIV/0!

Production / Month (25 days) #DIV/0! #DIV/0! #DIV/0!

Production / Year (300 days) #DIV/0! #DIV/0! #DIV/0!

Efficiency for capacity analysis 99.52% 99.52% 99.52%

Scrap rate 0.0% 0.0% 0.0%

% OK parts (excluding scrap rate) 100.00% 100.00% 100.00%

Capacity for year #DIV/0! #DIV/0! #DIV/0!

Parts / Vehicle 1 1 1

No. of Vehicle sets / Yr #DIV/0! #DIV/0! #DIV/0!

Yuvraj NXT contracted requirement (Vehicles / year) 12,000 12,000 12,000

Yuvraj NXT peak requirement at 5% higher (Vehicle/

year) 12,600 12,600 12,600

Capacity % share #DIV/0! #DIV/0! #DIV/0!

Other customer requirements (Vehicles / year) 0 0 0

Capacity % share of other customers (5% extra) 0 0 0

Capacity % share of other customers (5% extra) #DIV/0! #DIV/0! #DIV/0!

Free capacity % #DIV/0! #DIV/0! #DIV/0!

Assumptions for capacity analysis:

Efficiency calculate based on:

Actual Working Hrs:

Working days/ month = 25

Working days/ year = 300

Scrap Rate is based on rejections on H1 Line

SHIFTER BLOCK HIGH LOW RANGE H3

Capacity Analysis Sheet

40 50 60 70 80 90 100

Gauge Induction

Cross Drill Tip Milling Gange Milling Deburring Tempring

Checking Hardening

1 1 1 1 1 1 1

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

3.0 3.0 3.0 3.0 3.0 3.0 3.0

22 22 22 22 22 22 22

7.3 7.3 7.3 7.3 7.3 7.3 7.3

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

99.52% 99.52% 99.52% 99.52% 99.52% 99.52% 99.52%

0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0%

100.00% 100.00% 100.00% 100.00% 100.00% 100.00% 100.00%

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

1 1 1 1 1 1 1

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

12,000 12,000 12,000 12,000 12,000 12,000 12,000

12,600 12,600 12,600 12,600 12,600 12,600 12,600

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

0 0 0 0 0 0 0

0 0 0 0 0 0 0

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Takt Time (s): 180

110 120 130

Gauge Final Checking Oiling &

Checking Dialing Packing

1 1 1

#DIV/0! #DIV/0! #DIV/0!

3.0 3.0 3.0

22 22 22

7.3 7.3 7.3

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

99.52% 99.52% 99.52%

0.0% 0.0% 0.0%

100.00% 100.00% 100.00%

#DIV/0! #DIV/0! #DIV/0!

1 1 1

#DIV/0! #DIV/0! #DIV/0!

12,000 12,000 12,000

12,600 12,600 12,600

#DIV/0! #DIV/0! #DIV/0!

0 0 0

0 0 0

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

You might also like

- Cost Estimating Manual for Pipelines and Marine Structures: New Printing 1999From EverandCost Estimating Manual for Pipelines and Marine Structures: New Printing 1999Rating: 5 out of 5 stars5/5 (2)

- Multi-Function Instrument Installation Manual: 190-02246-00 November, 2019 Revision 1Document14 pagesMulti-Function Instrument Installation Manual: 190-02246-00 November, 2019 Revision 1joel alvarado100% (1)

- External Static Pressure Calculation SheetDocument2 pagesExternal Static Pressure Calculation SheetNidhin CletusNo ratings yet

- PC400 8 1Document549 pagesPC400 8 1Eka Anwar100% (1)

- Vertical Turbine Pumps Engineering Data: Effective April 1, 2003Document11 pagesVertical Turbine Pumps Engineering Data: Effective April 1, 2003Israel CastilloNo ratings yet

- Trading Journal BeginnersDocument48 pagesTrading Journal BeginnersadelinNo ratings yet

- Overall Equipment Effectiveness (O.E.E.) Monitoring Sheet: Shift 1Document28 pagesOverall Equipment Effectiveness (O.E.E.) Monitoring Sheet: Shift 1Sukhjot SinghNo ratings yet

- Fork I-Ii-Iii-Iv Speed H3: Capacity Analysis SheetDocument3 pagesFork I-Ii-Iii-Iv Speed H3: Capacity Analysis SheetpiyushNo ratings yet

- Section Shifter 3 4 - 7709Document2 pagesSection Shifter 3 4 - 7709piyushNo ratings yet

- Diff Lock Fork H3: Process NameDocument2 pagesDiff Lock Fork H3: Process NamepiyushNo ratings yet

- Brake Lever CPTE LH/RH: Process NameDocument2 pagesBrake Lever CPTE LH/RH: Process NamepiyushNo ratings yet

- Process Name: Fork 1,2,3,4Document2 pagesProcess Name: Fork 1,2,3,4piyushNo ratings yet

- Cam High Low Gear ShiftingDocument1 pageCam High Low Gear ShiftingpiyushNo ratings yet

- Process Name: CR FORK 3025R1Document2 pagesProcess Name: CR FORK 3025R1piyushNo ratings yet

- Setco Automotive LTD.: OEE Summary ReportDocument12 pagesSetco Automotive LTD.: OEE Summary ReportDisha ShahNo ratings yet

- Calculation Formula of Defect FabricDocument20 pagesCalculation Formula of Defect FabricMorshed MahamudNo ratings yet

- Forecast MIS ReportDocument9 pagesForecast MIS ReportSameer SinghNo ratings yet

- 7.0-P&L Report-简约财务报表Document5 pages7.0-P&L Report-简约财务报表anthonyyeoh9No ratings yet

- Diario de Trading CriptoDocument9 pagesDiario de Trading CriptoJeremy UrdayNo ratings yet

- Production Report FormatDocument2 pagesProduction Report FormatIshah ahamed KaziNo ratings yet

- MTD YTD Comp AnalysisDocument12 pagesMTD YTD Comp Analysisshuriken akunNo ratings yet

- Indikator Jam Visit Dokter IcuDocument126 pagesIndikator Jam Visit Dokter IcuTian ApriliantyNo ratings yet

- Jam Visit Dokter Spesialis di Unit Rawat InapDocument126 pagesJam Visit Dokter Spesialis di Unit Rawat InapTian ApriliantyNo ratings yet

- Indikator Jam Visit Dokter PicuDocument126 pagesIndikator Jam Visit Dokter PicuTian ApriliantyNo ratings yet

- QA ReportDocument28 pagesQA ReportVikas SharmaNo ratings yet

- Engineering Progress Total ProgressDocument4 pagesEngineering Progress Total ProgressIlyasse EL FAYDYNo ratings yet

- Engineering Progress Total ProgressDocument4 pagesEngineering Progress Total ProgressIlyasse EL FAYDYNo ratings yet

- RA Report August 2021 - SDO Pulau Laut RefineryDocument334 pagesRA Report August 2021 - SDO Pulau Laut RefineryPUJI ASTUTINo ratings yet

- SR No Project Test Case Review Review Time Test Execution Count Count Count Hrs Functional RegressionDocument6 pagesSR No Project Test Case Review Review Time Test Execution Count Count Count Hrs Functional RegressionG.C.ReddyNo ratings yet

- GM BreakDownDocument3 pagesGM BreakDowncmena87No ratings yet

- JournalDocument48 pagesJournalTaha SbaaiNo ratings yet

- Total Profit 43.96 Capital Incial Total % 47.27 Capital ActualDocument9 pagesTotal Profit 43.96 Capital Incial Total % 47.27 Capital ActualLeonar SanchezNo ratings yet

- KPI 2024Document8 pagesKPI 2024amatouryamatouryNo ratings yet

- Engineering Progress Total ProgressDocument7 pagesEngineering Progress Total ProgressIlyasse EL FAYDYNo ratings yet

- Fan Motor Power - Office HupDocument3 pagesFan Motor Power - Office HupMahmoud Khaled123No ratings yet

- Penilaian AkhirDocument3 pagesPenilaian AkhirMhala ElkaNo ratings yet

- Annual Invesment Cost Unit Laboratorium 2014: No Nama Alat Harga PembelianDocument90 pagesAnnual Invesment Cost Unit Laboratorium 2014: No Nama Alat Harga PembelianwiyasikaNo ratings yet

- جميع طلبات الصين نون 2023Document287 pagesجميع طلبات الصين نون 2023Wael ShehataNo ratings yet

- Daily Production Report: Day Sund Date 23-Jul-17Document15 pagesDaily Production Report: Day Sund Date 23-Jul-17mohamadNo ratings yet

- Indikator Jam Visit Dokter Lt.2Document121 pagesIndikator Jam Visit Dokter Lt.2Tian ApriliantyNo ratings yet

- Indikator Jam Visit Dokter VKDocument126 pagesIndikator Jam Visit Dokter VKTian ApriliantyNo ratings yet

- Indikator Jam Visit DokterDocument125 pagesIndikator Jam Visit DokterTian ApriliantyNo ratings yet

- Uraian 2011 % Neraca Aktiva: Analisa Laporan Keuangan Pt. AskrindoDocument33 pagesUraian 2011 % Neraca Aktiva: Analisa Laporan Keuangan Pt. AskrindoJanah JuliawatiNo ratings yet

- ABE 114 Class RecordDocument13 pagesABE 114 Class RecordJomarie EstorgioNo ratings yet

- Sr. Node No Length UGL UIL DIL Pipe Pipe WC Bc/2H L/2H WSC C/s WW Total Pipe Load Type No From TO Dia. THK Cutting Soil (S.I. L) Area (Water) Load Strength Factor of Bedding H/B C CDocument3 pagesSr. Node No Length UGL UIL DIL Pipe Pipe WC Bc/2H L/2H WSC C/s WW Total Pipe Load Type No From TO Dia. THK Cutting Soil (S.I. L) Area (Water) Load Strength Factor of Bedding H/B C CSuvranil BanerjeeNo ratings yet

- DESADocument854 pagesDESAmayaNo ratings yet

- Financial Model TemplateDocument25 pagesFinancial Model TemplateAakriti JainNo ratings yet

- Red Hidraulica H-W y DarcyDocument13 pagesRed Hidraulica H-W y DarcyJina Paola Alvarez HernandezNo ratings yet

- Stocks LTP Buy Sell ProfitDocument4 pagesStocks LTP Buy Sell Profitshekhar2681No ratings yet

- Week 3 Cover MiftaDocument13 pagesWeek 3 Cover Miftamiftahul jannahNo ratings yet

- Serial number and authorization key documentDocument2 pagesSerial number and authorization key documentKeith WilliamsNo ratings yet

- DROGUERÍA PRODUCTOS FARMACÉUTICOS ESTRUCTURA DE COSTO OCTUBRE 2015Document6 pagesDROGUERÍA PRODUCTOS FARMACÉUTICOS ESTRUCTURA DE COSTO OCTUBRE 2015arguello sanchez S.C.No ratings yet

- Name: Key Indicators ParticularsDocument10 pagesName: Key Indicators Particularsinfo.aksharadesignsNo ratings yet

- Laporan Bulanan Sasaran dan Cakupan BIAS (CAMPAK, DT & TT/Td) Puskesmas Kunir 2017Document4 pagesLaporan Bulanan Sasaran dan Cakupan BIAS (CAMPAK, DT & TT/Td) Puskesmas Kunir 2017kamidinNo ratings yet

- U170 Notenliste FPDocument33 pagesU170 Notenliste FPapi-25967053No ratings yet

- Book 1Document8 pagesBook 1Wanthy NainggolanNo ratings yet

- MProfit Desktop Portfolio Management SoftwareDocument15 pagesMProfit Desktop Portfolio Management SoftwareNikhil BhatiaNo ratings yet

- Controle Peças Aprovadas 07 06 22Document2 pagesControle Peças Aprovadas 07 06 22alvaro duarteNo ratings yet

- Static Pressure Calculation-1Document12 pagesStatic Pressure Calculation-1sunii19847908No ratings yet

- Analisis Granulometrico Relave Febrero 2022Document1 pageAnalisis Granulometrico Relave Febrero 2022Fernando Junior Baca GarciaNo ratings yet

- Trade Journal V2Document48 pagesTrade Journal V2MaxNo ratings yet

- Trade JournalDocument48 pagesTrade Journalmathgtr25No ratings yet

- Pump CalculationsDocument8 pagesPump CalculationsDarren James JudiNo ratings yet

- Gajanan Precision Pvt. LTD.: Packaging ReportDocument1 pageGajanan Precision Pvt. LTD.: Packaging ReportpiyushNo ratings yet

- Capacity Analysis Sheet: Process NameDocument4 pagesCapacity Analysis Sheet: Process NamepiyushNo ratings yet

- List of OperationsDocument4 pagesList of OperationspiyushNo ratings yet

- OstlDocument8 pagesOstlpiyushNo ratings yet

- Ostl 1Document11 pagesOstl 1piyushNo ratings yet

- Experiment No:1 Aim:WAP To Demonstrate Strings in Python:: Name:Pratiksha D. Laldas SE Comps A Roll No:53 Batch A3Document5 pagesExperiment No:1 Aim:WAP To Demonstrate Strings in Python:: Name:Pratiksha D. Laldas SE Comps A Roll No:53 Batch A3piyushNo ratings yet

- Ostl EXP 5BDocument8 pagesOstl EXP 5BpiyushNo ratings yet

- For in If and Elif and Elif and Else: "Enter A String"Document2 pagesFor in If and Elif and Elif and Else: "Enter A String"piyushNo ratings yet

- Process Name: CR FORK 3025R1Document2 pagesProcess Name: CR FORK 3025R1piyushNo ratings yet

- Cam High Low Gear ShiftingDocument1 pageCam High Low Gear ShiftingpiyushNo ratings yet

- Experiment No.03: Neel Sanjay Bhatt Se Comps-A Roll NO.07Document3 pagesExperiment No.03: Neel Sanjay Bhatt Se Comps-A Roll NO.07piyushNo ratings yet

- OstlDocument8 pagesOstlpiyushNo ratings yet

- CG Exp-1 Case Study2Document4 pagesCG Exp-1 Case Study2piyushNo ratings yet

- Experiment No.04: Neel Sanjay Bhatt Se Comps-A Roll NO.07Document3 pagesExperiment No.04: Neel Sanjay Bhatt Se Comps-A Roll NO.07piyushNo ratings yet

- Implementation of Koch Curve Fractal in CDocument3 pagesImplementation of Koch Curve Fractal in CpiyushNo ratings yet

- Name: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParametersDocument8 pagesName: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParameterspiyushNo ratings yet

- Computer Graphics ExperimentDocument8 pagesComputer Graphics ExperimentpiyushNo ratings yet

- CG Exp-9Document6 pagesCG Exp-9piyushNo ratings yet

- CG Exp-10Document4 pagesCG Exp-10piyushNo ratings yet

- Experiment No: 6A: Neel Sanjay Bhatt Roll No:-07 SE Computer ADocument11 pagesExperiment No: 6A: Neel Sanjay Bhatt Roll No:-07 SE Computer ApiyushNo ratings yet

- Experiment No.02: Pratiksha D. Laldas SE Computer A Roll NO.53Document4 pagesExperiment No.02: Pratiksha D. Laldas SE Computer A Roll NO.53piyushNo ratings yet

- Neel Sanjay Bhatt Roll No:-07 Div:ADocument7 pagesNeel Sanjay Bhatt Roll No:-07 Div:ApiyushNo ratings yet

- Polygon Filling Algorithms ImplementationDocument8 pagesPolygon Filling Algorithms ImplementationpiyushNo ratings yet

- Name: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParametersDocument8 pagesName: Pratiksha D. Laldas SE Computer A Roll No:53 Experiment:5A AIM: A Python Program To Calculate BMI Index Using The Following ParameterspiyushNo ratings yet

- Ostl EXP 5BDocument8 pagesOstl EXP 5BpiyushNo ratings yet

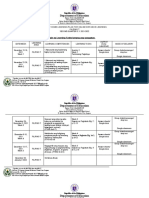

- Department of Education: Republic of The PhilippinesDocument4 pagesDepartment of Education: Republic of The PhilippinesTotoy AbnoyNo ratings yet

- Tez PortalDocument1 pageTez Portalkiran BawadkarNo ratings yet

- POTS telephone service and local subscriber loopDocument2 pagesPOTS telephone service and local subscriber loopjeevanNo ratings yet

- Circuit Symbols PDFDocument9 pagesCircuit Symbols PDFStefanos Duris100% (1)

- Algebra Terms and DefinitionsDocument6 pagesAlgebra Terms and DefinitionssNo ratings yet

- Guia de Configuracion de Firewall Basico en GWN7000 Grandstream PDFDocument16 pagesGuia de Configuracion de Firewall Basico en GWN7000 Grandstream PDFmiguel pcNo ratings yet

- Standards Summary Sheet - ANSI A10.8-2011Document2 pagesStandards Summary Sheet - ANSI A10.8-2011DwiCahyoAgustino100% (1)

- Labour Productivity - WoodworkDocument1 pageLabour Productivity - WoodworkInfo Oasis GroupNo ratings yet

- Labview Thesis ProjectsDocument5 pagesLabview Thesis Projectsdwm7sa8p100% (2)

- SERBIAN - UOU 4-7-2 Limestone System Rev ADocument139 pagesSERBIAN - UOU 4-7-2 Limestone System Rev ADalibor SimicNo ratings yet

- Information Engineering Facility Tool for Software DevelopmentDocument56 pagesInformation Engineering Facility Tool for Software DevelopmentVivianNo ratings yet

- Automotive Industry Innovation TrendsDocument5 pagesAutomotive Industry Innovation TrendsKESAVANNo ratings yet

- Simplify and Automate Connectivity To AWS With Prisma SD-WANDocument4 pagesSimplify and Automate Connectivity To AWS With Prisma SD-WANAishwarya PradhanNo ratings yet

- Assignment & LabDocument5 pagesAssignment & LabXyus PoudelNo ratings yet

- Quantel Optimis II Service Manual 11 20Document10 pagesQuantel Optimis II Service Manual 11 20Vladimir LevchenkoNo ratings yet

- Ac6905a DatasheepDocument10 pagesAc6905a DatasheepMUSIC ELECNo ratings yet

- Hospitality Industry Mini Project Sem IIndDocument18 pagesHospitality Industry Mini Project Sem IIndSatyam JadonNo ratings yet

- PartnerDocument14 pagesPartnerLeo van GorkumNo ratings yet

- How Digital Tech Affects MemoryDocument3 pagesHow Digital Tech Affects MemoryfatimaNo ratings yet

- Mentorpaper 36762Document24 pagesMentorpaper 36762Sarath BondaruNo ratings yet

- Energy Hakan Aygun MakaleDocument18 pagesEnergy Hakan Aygun MakaleIsmail EkmekciNo ratings yet

- Tb5661en Ultimus Film Tech Brief MsDocument4 pagesTb5661en Ultimus Film Tech Brief MsImran AsgharNo ratings yet

- Cioks DC7Document2 pagesCioks DC7Mac MiñaNo ratings yet

- Strand & Funtowicz Springer2017Document14 pagesStrand & Funtowicz Springer2017Roger StrandNo ratings yet

- Deep Learning Approach for Fuzzy String MatchingDocument8 pagesDeep Learning Approach for Fuzzy String MatchingngolethaovyNo ratings yet

- Maths (Ist yr)Document4 pagesMaths (Ist yr)MEMES WORLDNo ratings yet

- 300nb Fire Water Line - BEEL - 071953Document2 pages300nb Fire Water Line - BEEL - 071953irshadiiitNo ratings yet