Professional Documents

Culture Documents

DPR BWPRP4 Ocean303 01.04.18

Uploaded by

KRISHNAN ELANGOVANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DPR BWPRP4 Ocean303 01.04.18

Uploaded by

KRISHNAN ELANGOVANCopyright:

Available Formats

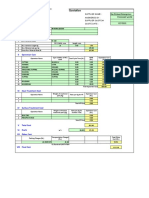

CLIENT : M/s.

ONGC

Contractor : M/s. LTHE

Sub‐Contractor : M/s DOEPL

PROJECT : Balance work for Pipeline Replacement Project ‐ 4

CA : M/S. ABSIV (India) Pvt.Ltd. PRODUCTION DATE: 01.04.2018

TPI : M/S. DNV‐GL REPORTING DATE : 02.04.2018

Location : North Field Outer Anchorage ( N7 Platform)

Barge: Ocean303

Achieved Cumulative Balance Achieved % Cumulative

Sr. no Description UOM Scope Alloted % Balance % Remarks

Qty.Today Qty. Qty. Today %

Over all Progress ( A+B+C) 100.00% 0.00% 100.00% 0.00%

A) Piping

1 Erection of piping spools Nos 14 20.00% 0 14 0 0.00% 20.00% 0.00%

Fit up of (Field Joints) Nos 27 13.00% 0 27 0 0.00% 13.00% 0.00%

2

Fit up of (Modification joints) Nos 7 0.00% 0 7 0 0.00% 0.00% 0.00%

3 Fit up Adiitional work Nos N/A N/A N/A N/A N/A NA N/A N/A

Welding (Field Joints) Inch Dia 83.5 29.00% 0 83.5 0 0.00% 29.00% 0.00%

4

Welding (Modification joints) Inch Dia 42 0.00% 0 42 0 0.00% 0.00% 0.00%

5 Welding of Additional work Inch Dia N/A N/A N/A N/A N/A NA N/A N/A

6 Installation of Piping Supports Nos. 6 7.00% 0 6 0 0.00% 7.00% 0.00%

NDT of (Field Joints) Nos 27 12.00% 0 27 0 0.00% 12.00% 0.00%

7

NDT of (Modification Joints) Nos 7 0.00% 0 7 0 0.00% 0.00% 0.00%

8 Hydrotesting of Piping Loops Nos. 2 4.00% 0 2 0 0.00% 4.00% 0.00%

9 Hook up/Tie in points Nos. 2 4.00% 0 2 0 0.00% 4.00% 0.00%

10 Painting Touch-up work lot 1 1.00% 0 1 0 0.00% 1.00% 0.00%

11 Insulation lot N/A N/A N/A N/A N/A NA N/A N/A

TOTAL-A 90.00% 0.00% 90.00% 0.00%

B) DEMOLITION

1 NIL lot 0 0.00% 0 0 0 0.00% 0.00% 0.00%

TOTAL-B 0 0.00% 0.00% 0.00% 0.00%

C) ELECTRICAL & INSTRUMENTATION

1 Instrument Installation No 4 3.50% 0 4 0 0.00% 3.50% 0.00%

2 Impulse Tubing mtr 20 1.00% 0 20 0 0.00% 1.00% 0.00%

3 Cable Tray mtr 50 1.00% 0 50 0 0.00% 1.00% 0.00%

4 Cable laying mtr 300 1.50% 0 300 0 0.00% 1.50% 0.00%

5 Cable termination and glanding No 8 1.00% 0 8 0 0.00% 1.00% 0.00%

6 Calibration No 4 1.00% 0 4 0 0.00% 1.00% 0.00%

7 Loop checking No 4 1.00% 0 4 0 0.00% 1.00% 0.00%

TOTAL-C 10.00% 0 0 0.00% 10.00% 0.00%

Distribution and Contact List

ABSIV sekumaran@eagle.org, pramanathan@absconsulting.com, dbhujbal@absconsulting.com

ONGC pandey_ak5@ongc.co.in, khanra_Rajat@ongc.co.in, Thakur_Ashish@ongc.co.in

DNV‐GL birju.jaiswal@dnvgl.com, mani.choudhary@dnvgl.com, merlyn.menezes@dnvgl.com

Activities performed

1 Towing from NLM10 platform and reached North Field outer Anchorage

Planned activities(Next Day) :‐

1 Attend meeting with ONGC at North Process Platform

2 Anchor Handling

Area of Concern if any :

1 According to ONGC Specification 2009F Rev.7 Clause No. 1.3 " Gamma rays can be used with permission from Company". LTHE yet to be submit the ONGC Approval for using Gamma rays at Barge Ocean303

According to BID Document , ONGC Specification No. 2005 Rev.No. 5.1 to be followed for Protective Coating. But the existing Blasting & Protective coating procedure No.PRP4‐DAS‐GN00‐QUA‐PRC‐0013 Rev.No.1 follows the ONGC Specification

2

No. 2005 Rev.No.4. LTHE yet to submit the updated approved Painting procedure.

Bhabesh Porel Vipin James EL.Krishnan

DNV ‐Mech. ( ONGC‐TPI) DNV‐E&I (ONGC‐TPI) ABSIV‐Mech. (ONGC‐CA) ABSIV‐E & I (ONGC‐CA) (ONGC REP.)

You might also like

- DPR BWPRP4 Ocean303 30.03.18Document1 pageDPR BWPRP4 Ocean303 30.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 02.04.18Document1 pageDPR BWPRP4 Ocean303 02.04.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 09.04.18Document1 pageDPR BWPRP4 Ocean303 09.04.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 10.04.18Document1 pageDPR BWPRP4 Ocean303 10.04.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 12.03.18Document1 pageDPR BWPRP4 Ocean303 12.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 27.03.18Document1 pageDPR BWPRP4 Ocean303 27.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 14.03.18Document1 pageDPR BWPRP4 Ocean303 14.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR-Saujana Tiga-02.02.2016Document1 pageDPR-Saujana Tiga-02.02.2016KRISHNAN ELANGOVANNo ratings yet

- This Month % ProgressDocument43 pagesThis Month % ProgressHikari Teknologi IndonesiaNo ratings yet

- Bill of Quantities BlankDocument10 pagesBill of Quantities Blankkomiks0609No ratings yet

- DPR Oq Pipemill 19 May 2021Document125 pagesDPR Oq Pipemill 19 May 2021kbpatel123No ratings yet

- Unit Cost Analysis As of April 2003: Sub Total (Materials)Document42 pagesUnit Cost Analysis As of April 2003: Sub Total (Materials)mymian1315No ratings yet

- Bob 0601 2015 00Document12 pagesBob 0601 2015 00Prashant MoreNo ratings yet

- Weekly Report JettyDocument1 pageWeekly Report Jettyfajargaluhwijaya09No ratings yet

- DED Workshop File NC1 JipapadDocument55 pagesDED Workshop File NC1 JipapadJohn Mark GlobioNo ratings yet

- Highways Research Station, Regional Laboratory, Madurai 12Document22 pagesHighways Research Station, Regional Laboratory, Madurai 12SAMUTHIRAKANINo ratings yet

- Load Data TemplateDocument21 pagesLoad Data TemplateIkha ZuNo ratings yet

- Total Cost of Accounts $6,224.30 Value of Accounts $9,600.00 (DATE) Difference $ $3,375.70 Difference % 54.2%Document3 pagesTotal Cost of Accounts $6,224.30 Value of Accounts $9,600.00 (DATE) Difference $ $3,375.70 Difference % 54.2%BenchNo ratings yet

- Sample Gant ChartDocument1 pageSample Gant Chartkenneth reyesNo ratings yet

- Dangote Fertilizer Project NDT Analysis For U/G: Radiographic Test - Ultrasonic TestDocument6 pagesDangote Fertilizer Project NDT Analysis For U/G: Radiographic Test - Ultrasonic Testaakash100% (1)

- Weekly RFA Rejection Analysis Updated On 11-Oct-2020Document1 pageWeekly RFA Rejection Analysis Updated On 11-Oct-2020Toy worldNo ratings yet

- ARCOSON-e SOLAR SYSTEM EVAL SHEET With AM-PM Usage - Barangay Tubod, Badian DD1 - 102448Document1 pageARCOSON-e SOLAR SYSTEM EVAL SHEET With AM-PM Usage - Barangay Tubod, Badian DD1 - 102448Emcee WaterNo ratings yet

- Specialist Switch Requirement BoQDocument6 pagesSpecialist Switch Requirement BoQLohit YadavNo ratings yet

- Estimation ReportDocument3 pagesEstimation ReportAE MDHalliNo ratings yet

- Gage RRDocument2 pagesGage RREdward_Dane_Bo_5933No ratings yet

- Monthly Executive ReportDocument3 pagesMonthly Executive Reportm-ravNo ratings yet

- ANOF Fiorenza - STD P2 B24 L38Document4 pagesANOF Fiorenza - STD P2 B24 L38Allen MendozaNo ratings yet

- General Basement BoqDocument82 pagesGeneral Basement BoqMuarleedharan RajanNo ratings yet

- Daily Progress Report: Engineering, Procurement and Construction of Sarqala-3 Well Connection To CPF at Sarqala-1Document12 pagesDaily Progress Report: Engineering, Procurement and Construction of Sarqala-3 Well Connection To CPF at Sarqala-1rashid kNo ratings yet

- Cross Piece BayonetDocument2 pagesCross Piece BayonetVilasNo ratings yet

- Progress ReportDocument7 pagesProgress ReportRizki LazuardiNo ratings yet

- PommelDocument3 pagesPommelVilasNo ratings yet

- Daily Progress Report: Engineering, Procurement and Construction of Sarqala-3 Well Connection To CPF at Sarqala-1Document12 pagesDaily Progress Report: Engineering, Procurement and Construction of Sarqala-3 Well Connection To CPF at Sarqala-1rashid kNo ratings yet

- BladeDocument3 pagesBladeVilasNo ratings yet

- Progress Phase 1: Environment, Safety & HealthDocument9 pagesProgress Phase 1: Environment, Safety & HealthMajdi Jerbi67% (3)

- DPR-008 - TWK Network Upgrade 240122Document7 pagesDPR-008 - TWK Network Upgrade 240122Abdullah DhiaNo ratings yet

- SPC Check SheetDocument10 pagesSPC Check Sheetambikaamjv2400No ratings yet

- Blank Well Control Toolbox SheetDocument8 pagesBlank Well Control Toolbox SheetAhmedNo ratings yet

- Dimensionamentos - Corrente AlternadaDocument31 pagesDimensionamentos - Corrente AlternadaJoão LucasNo ratings yet

- Input For QPR Apr - June 2022Document2 pagesInput For QPR Apr - June 2022Saswat RathNo ratings yet

- Programa de Mantenimiento ActualizadoDocument24 pagesPrograma de Mantenimiento ActualizadoOscar Alejandro Rosas CasillasNo ratings yet

- LightingDocument3 pagesLightingGuendouz GuendouzNo ratings yet

- 11-Construction Progress Summary by Discipline (FWBS L1)Document64 pages11-Construction Progress Summary by Discipline (FWBS L1)Jun Urbano100% (1)

- 8 16 19Document258 pages8 16 19John Eduard GallegoNo ratings yet

- ATNM Handrail 2277 DPR 12 04 2023 Report13Document1 pageATNM Handrail 2277 DPR 12 04 2023 Report13vasantha kumarNo ratings yet

- 1) Análisis Del Sistema de Medición: Gage R&R Study - ANOVA Method Two-Way ANOVA Table With InteractionDocument10 pages1) Análisis Del Sistema de Medición: Gage R&R Study - ANOVA Method Two-Way ANOVA Table With InteractionItziar Lopez-Vailo MadinaNo ratings yet

- Mlng-Final Documentation Progress CompilationDocument104 pagesMlng-Final Documentation Progress Compilationcheehoong82100% (1)

- Work Order No 4780244944 Dhone (Narute)Document4 pagesWork Order No 4780244944 Dhone (Narute)arunnarute368No ratings yet

- HVAC System - Duct Quantity Take Off (Example Explained)Document1 pageHVAC System - Duct Quantity Take Off (Example Explained)Rudy Jesus Capa IlizarbeNo ratings yet

- Daily Progress Report: SR No Activity Unit ProgressDocument1 pageDaily Progress Report: SR No Activity Unit ProgressLokabhiram DikshitNo ratings yet

- Electricity ReconciliationDocument31 pagesElectricity Reconciliationghulam murtazaNo ratings yet

- Process Name: Fork 1,2,3,4Document2 pagesProcess Name: Fork 1,2,3,4piyushNo ratings yet

- Progress Per Activities (Till 03/10/2019) : EZZ#9 Related Pipes GridDocument2 pagesProgress Per Activities (Till 03/10/2019) : EZZ#9 Related Pipes GridMajdi Jerbi100% (1)

- Daily Progress Report 30 - 10 - 2020Document2 pagesDaily Progress Report 30 - 10 - 2020Jagadeesan S MNo ratings yet

- ArfDocument3 pagesArflina komalasariNo ratings yet

- CPF - GANDHAR, ONGC, Ankleshwar Daily Progress Report Site ProgressDocument6 pagesCPF - GANDHAR, ONGC, Ankleshwar Daily Progress Report Site ProgressSunil KumarNo ratings yet

- Project ReportDocument8 pagesProject ReportPritam685No ratings yet

- # Activity List: Date of Last Update: 8/3/2019 Updated By: Abdul Fathah K ADocument10 pages# Activity List: Date of Last Update: 8/3/2019 Updated By: Abdul Fathah K AValesh MonisNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- DPR-C8MFP - LTS3000 - 008 Dated On 11.03.2020Document1 pageDPR-C8MFP - LTS3000 - 008 Dated On 11.03.2020KRISHNAN ELANGOVANNo ratings yet

- Bdp-Bcpa3 & BLQ3 - DPR 04-07-2017Document2 pagesBdp-Bcpa3 & BLQ3 - DPR 04-07-2017KRISHNAN ELANGOVANNo ratings yet

- Bdp-Bcpa3 & BLQ3 - DPR 07-07-2017Document2 pagesBdp-Bcpa3 & BLQ3 - DPR 07-07-2017KRISHNAN ELANGOVANNo ratings yet

- Bdp-Bcpa3 & BLQ3 - DPR 05-07-2017Document2 pagesBdp-Bcpa3 & BLQ3 - DPR 05-07-2017KRISHNAN ELANGOVANNo ratings yet

- Bdp-Bcpa3 & BLQ3 - DPR 05-07-2017Document2 pagesBdp-Bcpa3 & BLQ3 - DPR 05-07-2017KRISHNAN ELANGOVANNo ratings yet

- DPR-C8MFP - LTS3000 - 008 Dated On 11.03.2020Document1 pageDPR-C8MFP - LTS3000 - 008 Dated On 11.03.2020KRISHNAN ELANGOVANNo ratings yet

- DPR-C8MFP - LTS3000 - 008 Dated On 11.03.2020Document1 pageDPR-C8MFP - LTS3000 - 008 Dated On 11.03.2020KRISHNAN ELANGOVANNo ratings yet

- Bdp-Bcpa3 & BLQ3 - DPR 03-07-2017Document2 pagesBdp-Bcpa3 & BLQ3 - DPR 03-07-2017KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 14.03.18Document1 pageDPR BWPRP4 Ocean303 14.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 14.03.18Document1 pageDPR BWPRP4 Ocean303 14.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 14.03.18Document1 pageDPR BWPRP4 Ocean303 14.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR-Saujana Tiga-02.02.2016Document1 pageDPR-Saujana Tiga-02.02.2016KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 09.03.18Document1 pageDPR BWPRP4 Ocean303 09.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR-Saujana Tiga-02.02.2016Document1 pageDPR-Saujana Tiga-02.02.2016KRISHNAN ELANGOVANNo ratings yet

- DPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020Document1 pageDPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020KRISHNAN ELANGOVANNo ratings yet

- DPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020Document1 pageDPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020KRISHNAN ELANGOVANNo ratings yet

- DPR-Saujana Tiga-02.02.2016Document1 pageDPR-Saujana Tiga-02.02.2016KRISHNAN ELANGOVANNo ratings yet

- DPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020Document1 pageDPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020KRISHNAN ELANGOVANNo ratings yet

- DPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020Document1 pageDPR-C8MFP - LTS3000 - 002 Dated On 20.02.2020KRISHNAN ELANGOVANNo ratings yet

- Destructive Ray: Bioluminescent Wizard's FamiliarDocument2 pagesDestructive Ray: Bioluminescent Wizard's FamiliarBen LNo ratings yet

- Flex-10 Virtual ConnectDocument2 pagesFlex-10 Virtual ConnectArif HusainNo ratings yet

- Harmony of The GospelsDocument11 pagesHarmony of The GospelsJesus LivesNo ratings yet

- Class 8 Imo 5 Years e Book l2 2017 (PDF - Io)Document7 pagesClass 8 Imo 5 Years e Book l2 2017 (PDF - Io)JaySharan50% (2)

- Lisa-Operation Manual: Installation and Operation Instructions (Part B)Document41 pagesLisa-Operation Manual: Installation and Operation Instructions (Part B)majdNo ratings yet

- The Empire in FlamesDocument73 pagesThe Empire in FlamesSergio Esperalta Gata100% (2)

- Hardware Catalog No Prices (PTHW0208.1C) PDFDocument11 pagesHardware Catalog No Prices (PTHW0208.1C) PDFAhmed TahaNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakaJohny Iskandar Arsyad NstNo ratings yet

- Infertility NotesDocument41 pagesInfertility NotesPrasadNo ratings yet

- MCM (ENGLISH) Product SheetDocument4 pagesMCM (ENGLISH) Product SheetArdi PratamaNo ratings yet

- Capacitor and DielectricDocument29 pagesCapacitor and DielectricMaam Leslie AguilarNo ratings yet

- Essay Test 2021 (Practice Test)Document3 pagesEssay Test 2021 (Practice Test)Philani HadebeNo ratings yet

- Consumer Studies GR 11 Revision Term 1 2023 FinalDocument20 pagesConsumer Studies GR 11 Revision Term 1 2023 FinalCerboh MazibukoNo ratings yet

- Chapter 22-The Pre Cam Brian EarthDocument38 pagesChapter 22-The Pre Cam Brian Earthncl12142No ratings yet

- Identifing Legends and CultureDocument2 pagesIdentifing Legends and CultureHezekaiah AstraeaNo ratings yet

- CS923 Service ManualDocument1,066 pagesCS923 Service ManualkenNo ratings yet

- Reviewer 3RD Exam FinalDocument14 pagesReviewer 3RD Exam FinalReane Romblon GerozagaNo ratings yet

- Reverse Circulation DrillingDocument6 pagesReverse Circulation DrillingHabib Ur Rahman100% (1)

- 80 MT Crawler CraneDocument40 pages80 MT Crawler CraneramyaNo ratings yet

- BEAM PlusDocument219 pagesBEAM PlusEdwinLeungNo ratings yet

- Chapter 1 Tutorial IlluminationDocument9 pagesChapter 1 Tutorial IlluminationFemi PrinceNo ratings yet

- Classification of AntibioticsDocument5 pagesClassification of AntibioticsdenaNo ratings yet

- OCDM2223 Tutorial7solvedDocument5 pagesOCDM2223 Tutorial7solvedqq727783No ratings yet

- Staircase & Ramps Duration (DAYS) Appendix StaircaseDocument7 pagesStaircase & Ramps Duration (DAYS) Appendix StaircaseLai ChungyiNo ratings yet

- Engineering Economy 15th Edition Sullivan Test BankDocument25 pagesEngineering Economy 15th Edition Sullivan Test BankDannyStaffordctbi100% (53)

- DIO 20. ZAŠTITA PRI RADU I SMJEŠTAJ POSADE Jan 2015Document44 pagesDIO 20. ZAŠTITA PRI RADU I SMJEŠTAJ POSADE Jan 2015Samo SpontanostNo ratings yet

- ISolutions Lifecycle Cost ToolDocument8 pagesISolutions Lifecycle Cost ToolpchakkrapaniNo ratings yet

- Australian Mathematics Competition 2017 - SeniorDocument7 pagesAustralian Mathematics Competition 2017 - SeniorLaksanara KittichaturongNo ratings yet

- Fusibles NHDocument4 pagesFusibles NHPaul SchaefferNo ratings yet

- Critical Planning Issues in MTODocument2 pagesCritical Planning Issues in MTOAzhar QadriNo ratings yet