Professional Documents

Culture Documents

Life Cycle Assessment of A Vaccine Patch

Uploaded by

api-375178431Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Life Cycle Assessment of A Vaccine Patch

Uploaded by

api-375178431Copyright:

Available Formats

Raw Materials Manufacturing

The vaccine patch would be made

The main waste that comes from The manufacturing process starts with a The energy present is

up of an adhesive polyethylene strip

the raw materials comes from the silicon mold and ends with a plastic mechanical energy through

layered with acrylic acid and ester

making of the adhesiveness of the protective film. The silicon mold is made machinery producing our

resin and microneedles made of a

patch. The patch is made of the master object, a baseplate, mold product and thermal energy

water-soluble hyaluronic acid outer

adhesive through acrylic acid and wall, the prepolymer and curative, and through workers overseeing

layer that encapsulates the vaccine.

ester resin, and those two the release agent. These molds will be production. Our main sources

Polyethylene is made from a

chemicals can leech plastics into filled with the polymer solution and the of waste will be from silicon

combination reaction between

the environment when disposed chosen vaccination and then attached to molds breaking, incorrect

ethylene and butene, and

of improerly. a polymer baseplate. The patch itself balances of the polymer and

hyaluronic acid is is obtained from

starts with the first two polyethylene vaccination, and faulty

the catalytic partial oxidation of

layers bonding together through a adhesive strips. All of this

propene which is a by-product of

covering layer. An adhesive coating of waste must be properly

ethylene and gasoline production.

acrylic acid and ester resin is then applied discarded.

to the layers and a cavity is created where

Recycling

the microneedles will be adhered to.

Lastly, a plastic film is attached.

Transportation + distribution

This patch itself cannot be The adhesive patch will contribute

recycled because it is made of to the overall waste. The

materials such as polyethylene. microneedles will dissolve and In order to insure safe Packaging is something that usually

Polyethylene is a plastic that create zero waste. The packaging transportation and distribution, we causes a lot of waste, but we will

cannot be recycled. On top of will need to be collected after need safe packaging, made to make the packaging eco-friendly

that, the microneedles dissolve, manufactured and moved to proper specifically fit each component of and recyclable. The part of

so those can’t be recycled either. facilities to recycle the paper the vaccine. The materials for this transportation/distribution that will

The packaging can be recycled materials for later use. would be an outer cardboard box cause the most waste would be

because it is 100% recyclable and an inner insert made of 100% shipping due to the fuel (petroleum)

materials. recycled materials. No new that creates greenhouse gases.

materials are added after

packaging.

Use and re-use Wastes and emissions

Most waste created during Most waste products will be

The patch is applied to the forearm Since there are no materials being manufacturing, distribution, and transported to landfills and sit to

and the microneedles dissolve into reused, there is no extra waste for administration will not be reusable slowly deteriorate while

the tissue and begin circulating the this section. or recyclable. In manufacturing, all contributing to GHG and CO2

body's system. Re-use of the biohazardous waste will be emissions. Most waste in the

product is not possible due to the discarded. Distribution will be heavy manufacturing process will be a

single use microneedles. Also due in pollution. In administration, the biohazard and will need proper

to the use of medicine, any form of adhesive patch will contribute to the handling. Waste after the

reuse of a vaccination is unsafe. overall waste. These will need to be administration process can be

shipped to a landfill through a normally discarded.

vehicle.

You might also like

- Lignocellulosic Polymer Composites: Processing, Characterization, and PropertiesFrom EverandLignocellulosic Polymer Composites: Processing, Characterization, and PropertiesNo ratings yet

- Lca ResearchDocument4 pagesLca Researchapi-375178431No ratings yet

- Production of Conventional Fuel From PlaDocument9 pagesProduction of Conventional Fuel From PlaManoj SahuNo ratings yet

- Design A Home Appliance Product For TheDocument5 pagesDesign A Home Appliance Product For TheM SalNo ratings yet

- Recycling Technology: For Post-Consumer PlasticsDocument16 pagesRecycling Technology: For Post-Consumer PlasticsTimur SuleymanovNo ratings yet

- Making Waste Work: A Toolkit: How To Turn Mixed Plastic Waste and Bottles Into EcobricksDocument6 pagesMaking Waste Work: A Toolkit: How To Turn Mixed Plastic Waste and Bottles Into EcobricksIjadunola John BelovedNo ratings yet

- Packaging Materials and Details PDFDocument107 pagesPackaging Materials and Details PDFfgdgrte gdfsgdNo ratings yet

- HowgreenisyourbackpackDocument2 pagesHowgreenisyourbackpackapi-358389990No ratings yet

- Next Step For Automotive MaterialsDocument8 pagesNext Step For Automotive Materialshugo171630No ratings yet

- ArmaPET From Bottle To Foam 01Document7 pagesArmaPET From Bottle To Foam 01Somnath SekarNo ratings yet

- 2019_Cracking the problem of waste plasticsDocument2 pages2019_Cracking the problem of waste plasticsliliacul2000No ratings yet

- Biodegradable & Conducting PolymersDocument50 pagesBiodegradable & Conducting Polymersleela777No ratings yet

- 1 s2.0 S2666893921001419 Main1Document9 pages1 s2.0 S2666893921001419 Main1jadeshades12No ratings yet

- Plastics and The Environment: Recycling HandbookDocument20 pagesPlastics and The Environment: Recycling HandbookAbdul Quddus Mat IsaNo ratings yet

- Method 1Document2 pagesMethod 1balaNo ratings yet

- Formulation of a biodegradable polymer from yucca starchDocument7 pagesFormulation of a biodegradable polymer from yucca starchEmilio Wonder AlemanNo ratings yet

- Module 3Document10 pagesModule 3Palak MittalNo ratings yet

- Plastic ResearchDocument6 pagesPlastic ResearchJulian Aldrin MedinaNo ratings yet

- Plastics and Polymers Used in ConstructionDocument31 pagesPlastics and Polymers Used in ConstructionAvantikaNo ratings yet

- Industrial PolymersDocument30 pagesIndustrial PolymersH Janardan PrabhuNo ratings yet

- 5dbdcadfc4731 Hul TechtonicDocument1 page5dbdcadfc4731 Hul TechtonicARVINDNo ratings yet

- Biodegradable Films For Food PackagingDocument13 pagesBiodegradable Films For Food PackagingAnjal SinghNo ratings yet

- Khush Bakht Textile AssignmentDocument6 pagesKhush Bakht Textile AssignmentKhushbakht 2020-2873No ratings yet

- Why Recycle PlasticsDocument23 pagesWhy Recycle PlasticsRoshan NinaweNo ratings yet

- Recycling of Non Woven Waste: Usha Sayed, Sneha ParteDocument5 pagesRecycling of Non Woven Waste: Usha Sayed, Sneha Parteebi18750No ratings yet

- Biodegradable Polymers For Sustainable Packaging Applications - A ReviewDocument12 pagesBiodegradable Polymers For Sustainable Packaging Applications - A ReviewAngelito AraxielNo ratings yet

- Plastic Waste Management Rules 2016 PDFDocument6 pagesPlastic Waste Management Rules 2016 PDFPratul ChoudhuryNo ratings yet

- CynarPlc Turning Plastic Waste To Fuel PDFDocument3 pagesCynarPlc Turning Plastic Waste To Fuel PDFTrebob GardayaNo ratings yet

- RECYFIX Material EN 2014Document24 pagesRECYFIX Material EN 2014ThierryNo ratings yet

- Folio Chemistry 4SC2Document15 pagesFolio Chemistry 4SC2Nadia ZulkefliNo ratings yet

- Recycling PMC - 10.5772@intechopen.81281Document20 pagesRecycling PMC - 10.5772@intechopen.81281Nameira WulanNo ratings yet

- Composite Material - Wikipedia, The Free EncyclopediaDocument6 pagesComposite Material - Wikipedia, The Free EncyclopediaygraoNo ratings yet

- Chem423FL1-5Polymer ProcessingDocument33 pagesChem423FL1-5Polymer ProcessingMd Mehrab Alam ShayikhNo ratings yet

- 1 Biodegradable Polymersfor Sustainable Packaging ApplicationsDocument12 pages1 Biodegradable Polymersfor Sustainable Packaging ApplicationswareenNo ratings yet

- Improving Plastic Recycling Supply ChainDocument2 pagesImproving Plastic Recycling Supply ChainKomal ShahNo ratings yet

- Use of Waste Polyethylene in Bituminous Concrete Mixes Pradeep SoyalDocument3 pagesUse of Waste Polyethylene in Bituminous Concrete Mixes Pradeep SoyalBUNTI MNNo ratings yet

- Thermosetting PrashantDocument11 pagesThermosetting PrashantSaloniNo ratings yet

- Polymer Adhesives Note - DR Akinsiku PDFDocument15 pagesPolymer Adhesives Note - DR Akinsiku PDFGlory UsoroNo ratings yet

- Optimizing Properties of Recycled HDPE-LLDPE Composite PipesDocument8 pagesOptimizing Properties of Recycled HDPE-LLDPE Composite PipesDr. Saravanan RNo ratings yet

- Fabrication and Thermal Conductivity Testing of Coir FiberDocument72 pagesFabrication and Thermal Conductivity Testing of Coir FiberCatherineNo ratings yet

- Antimicrobial Finish of Textiles by Chitosan UV-Curing: Journal of Nanoscience and Nanotechnology June 2012Document9 pagesAntimicrobial Finish of Textiles by Chitosan UV-Curing: Journal of Nanoscience and Nanotechnology June 2012Federico SandroniNo ratings yet

- 11 March 2016Document46 pages11 March 2016Reena SinghalNo ratings yet

- Material Science ContentDocument23 pagesMaterial Science ContentHoongNo ratings yet

- Polyester Properties, Preparation and Applications by Hina Yamashita, Yui Nakano PDFDocument259 pagesPolyester Properties, Preparation and Applications by Hina Yamashita, Yui Nakano PDFVasile LeniucNo ratings yet

- Material Science ContentDocument24 pagesMaterial Science ContentHoongNo ratings yet

- Adhesive From Petrol and ThermocolDocument3 pagesAdhesive From Petrol and ThermocolEditor IJTSRD100% (1)

- Plastics - Manufacturing MethodsDocument2 pagesPlastics - Manufacturing MethodsPassmore DubeNo ratings yet

- Plastic ManufacturingDocument31 pagesPlastic ManufacturingDipika KumariNo ratings yet

- Recycling On PlasticsDocument15 pagesRecycling On PlasticskunalNo ratings yet

- FPF Factsheet Multimaterial v1Document2 pagesFPF Factsheet Multimaterial v1Mohamed AliNo ratings yet

- Binders in Textile PrintingDocument4 pagesBinders in Textile PrintingAkshay Bhagat100% (1)

- Voxetal AIIA2013 Pag221-225Document8 pagesVoxetal AIIA2013 Pag221-225arkan alsirenNo ratings yet

- 1st Partial Delivery PDFDocument10 pages1st Partial Delivery PDFjavier cedillo sanchezNo ratings yet

- BiliLux Phototherapy Light V1.0 enDocument7 pagesBiliLux Phototherapy Light V1.0 enXing LiuNo ratings yet

- CONAI Report Sostenibilità 2018 EngDocument84 pagesCONAI Report Sostenibilità 2018 EngLuca GarzilliNo ratings yet

- Biodegradable Composite ResearchDocument6 pagesBiodegradable Composite ResearchNkem OkonkwoNo ratings yet

- Starch Based Biodegradable Blends ReviewDocument18 pagesStarch Based Biodegradable Blends Reviewsoheil farshbafNo ratings yet

- Chemistry Plastic BreakdownDocument9 pagesChemistry Plastic BreakdownAndre ThomasNo ratings yet

- 2020 - Manufacture of A Bio-Tissue Based On Nanocrystalline Cellulose From Chilean Bamboo Chusquea QuilaDocument8 pages2020 - Manufacture of A Bio-Tissue Based On Nanocrystalline Cellulose From Chilean Bamboo Chusquea QuilaPatricia OliveiraNo ratings yet

- Biodegradable Polymers For Food Packagin PDFDocument10 pagesBiodegradable Polymers For Food Packagin PDFMirelaNo ratings yet

- Experiment PlanningDocument4 pagesExperiment Planningapi-375178431No ratings yet

- Capstone Project Final PresentationDocument35 pagesCapstone Project Final Presentationapi-375178431No ratings yet

- Prototype Testing ReportDocument6 pagesPrototype Testing Reportapi-375178431No ratings yet

- Step 8 Design ReportDocument14 pagesStep 8 Design Reportapi-375178431No ratings yet

- Capstone Lab ReportDocument10 pagesCapstone Lab Reportapi-375178431No ratings yet

- Design SelectionsDocument2 pagesDesign Selectionsapi-375178431No ratings yet

- Edited Project ProposalDocument9 pagesEdited Project Proposalapi-375178431No ratings yet

- Design DefenseDocument22 pagesDesign Defenseapi-375178431No ratings yet

- Vaccine Patch Classification SchemeDocument3 pagesVaccine Patch Classification Schemeapi-375178431No ratings yet

- Lucille Ostrowski - Define The Problem Initial Demand and Wishlist D W ListDocument3 pagesLucille Ostrowski - Define The Problem Initial Demand and Wishlist D W Listapi-375178431No ratings yet

- Decision MatrixDocument5 pagesDecision Matrixapi-375178431No ratings yet

- Wat-Er We DrinkingDocument15 pagesWat-Er We Drinkingapi-386094460No ratings yet

- Vaccine Patch Classification SchemeDocument3 pagesVaccine Patch Classification Schemeapi-375178431No ratings yet

- Chemisty Art ProjectDocument11 pagesChemisty Art Projectapi-375178431No ratings yet

- Final ProjectDocument12 pagesFinal Projectapi-375178431No ratings yet

- Protein To Disease 5 2f6 Table 7Document6 pagesProtein To Disease 5 2f6 Table 7api-375178431No ratings yet

- Break It ApartDocument14 pagesBreak It Apartapi-375178431No ratings yet

- Ecology PosterDocument1 pageEcology Posterapi-375178431No ratings yet

- Saving The African SavannaDocument30 pagesSaving The African Savannaapi-376373994No ratings yet

- Photon ShuffleDocument2 pagesPhoton Shuffleapi-375178431No ratings yet

- Build A BandDocument8 pagesBuild A Bandapi-375178431No ratings yet

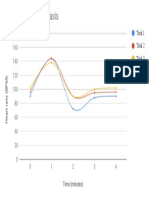

- Heart Rate Homeostasis 1Document1 pageHeart Rate Homeostasis 1api-375178431No ratings yet

- Heart Rate HomeostasisDocument9 pagesHeart Rate Homeostasisapi-375178431No ratings yet

- Lucille Ostrowski - Electric Field Hockey and Electric Charge Calculation QuestionsDocument3 pagesLucille Ostrowski - Electric Field Hockey and Electric Charge Calculation Questionsapi-375178431No ratings yet

- Untitled DocumentDocument9 pagesUntitled Documentapi-375178431No ratings yet

- Accusations Against Madam NormalDocument15 pagesAccusations Against Madam Normalapi-375178431No ratings yet

- Power NovatoDocument12 pagesPower Novatoapi-375178431No ratings yet

- Code For Arduino Programming Mary Had A Little LambDocument5 pagesCode For Arduino Programming Mary Had A Little Lambapi-375178431No ratings yet

- UOMP Feasibility-Study Samoa 0Document125 pagesUOMP Feasibility-Study Samoa 0ZHHHNo ratings yet

- Vishwaniketan Institute of Management, Entrepreneurship and Engineering Technology KHALAPUR-410202Document12 pagesVishwaniketan Institute of Management, Entrepreneurship and Engineering Technology KHALAPUR-410202piyush sapkalNo ratings yet

- Preventing Bread Waste - A National Success Story From TurkeyDocument4 pagesPreventing Bread Waste - A National Success Story From TurkeyMilling and Grain magazineNo ratings yet

- Community Diagnosis of Purok Teresita, Barangay Buhangin Proper 1, Buhangin Davao CityDocument80 pagesCommunity Diagnosis of Purok Teresita, Barangay Buhangin Proper 1, Buhangin Davao CitySabesh DhoniNo ratings yet

- 21.22 HSG THPT de FinalVersionDocument16 pages21.22 HSG THPT de FinalVersionNguyễn Hưng Thịnh - 30No ratings yet

- User Manual TLBDocument49 pagesUser Manual TLBJose Luna100% (1)

- Multipurpose Shredder CompactorDocument3 pagesMultipurpose Shredder CompactorMok GonzalesNo ratings yet

- Innovation Essay: Industrial and Digital RevolutionDocument3 pagesInnovation Essay: Industrial and Digital RevolutionYash TekwaniNo ratings yet

- Part 1. Access To Basic Safe Water Supply and Use of Safely Managed Drinking-Water ServicesDocument9 pagesPart 1. Access To Basic Safe Water Supply and Use of Safely Managed Drinking-Water ServicesFanelyn Lambus GravamenNo ratings yet

- Memorandum of Agreement - MenroDocument2 pagesMemorandum of Agreement - MenroALBASIR KUSAINNo ratings yet

- ENR Top 500 2018Document59 pagesENR Top 500 2018ApaxATONo ratings yet

- Akhtar Project ReportDocument22 pagesAkhtar Project ReportMd.Shadid Ur RahmanNo ratings yet

- Solid Waste ManagementDocument26 pagesSolid Waste ManagementPamela MendozaNo ratings yet

- User Manual: 8 SeriesDocument324 pagesUser Manual: 8 SeriesTsamis IoannisNo ratings yet

- Environment Accounting in IndiaDocument7 pagesEnvironment Accounting in Indiaadiantonugroho100% (5)

- Due Diligence Checklist Real EstateDocument33 pagesDue Diligence Checklist Real Estatevhkprasad100% (3)

- TanzaniaDocument13 pagesTanzaniaRaúl Bernardo CarrascoNo ratings yet

- 7 Types of Waste Guidance ExplainedDocument20 pages7 Types of Waste Guidance ExplainedjogedhayalNo ratings yet

- Case Study of Zero Waste Trivandrum Railway Station 47848718Document38 pagesCase Study of Zero Waste Trivandrum Railway Station 47848718SREERAGNo ratings yet

- Season of Creation 2023 ProgramDocument11 pagesSeason of Creation 2023 ProgramDJ DaveNo ratings yet

- Requirements Before Issuance of Sanitary Permit: For Food EstablishmentsDocument4 pagesRequirements Before Issuance of Sanitary Permit: For Food EstablishmentsSheryl MH-PradaNo ratings yet

- Advocacy Plan: Plastic Waste Zero Plastic: Patricia Falejo 1st Year GED104 Sir Hector BrizuelaDocument9 pagesAdvocacy Plan: Plastic Waste Zero Plastic: Patricia Falejo 1st Year GED104 Sir Hector BrizuelaAisuru FukushimaNo ratings yet

- MSDS Sanosil S003 ENDocument10 pagesMSDS Sanosil S003 ENFaridul IslamNo ratings yet

- Sustainability Toolkit HospitalityDocument60 pagesSustainability Toolkit HospitalityAlanRichardsonNo ratings yet

- "East Kolkata Wetland" Ecosystem - The Need Assessment Study - Mr. Asesh Sengupta.Document112 pages"East Kolkata Wetland" Ecosystem - The Need Assessment Study - Mr. Asesh Sengupta.Abhijit Kundu100% (2)

- Internal Test-II SPA AnswerDocument4 pagesInternal Test-II SPA AnswerIndujaa PadmanaabanNo ratings yet

- Minimization of Construction Waste in Chennai Construction IndustryDocument7 pagesMinimization of Construction Waste in Chennai Construction Industryatem agootNo ratings yet

- Green Team Work PlanDocument2 pagesGreen Team Work PlanScott FranzNo ratings yet

- Smart Digital Dustbin: Dustbin (SDD) - Keywords-Incinerated Solid WastesDocument6 pagesSmart Digital Dustbin: Dustbin (SDD) - Keywords-Incinerated Solid WastesUma TamilNo ratings yet

- Earth Day celebration and environmental protection efforts over timeDocument2 pagesEarth Day celebration and environmental protection efforts over timeAissamNo ratings yet