Professional Documents

Culture Documents

Pages From Process STD 201

Uploaded by

MOHSENOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From Process STD 201

Uploaded by

MOHSENCopyright:

Available Formats

PROCESS STD 201

FOSTER WHEELER FLUID FLOW Page 32 of 105

SINGLE PHASE Revision 2

PROCESS PLANTS DIVISION

Date 05/05/2004

TABLE 5 GUIDELINES FOR SIZING LIQUID LINES

‘Recommended’ High Limits

Item $P/100 Feet $P bar/100m Velocity ft/Sec Velocity m/sec

PSI

A. Pump Suction Lines (1) (5)

- Bubble point fluids (<8”) 0.5 0.11 6.0 1.8

- Bubble point fluids (>8”) 0.5 0.11 6.0 1.8

- Subcooled liquids (<8”) 2.0 0.45 8.0 2.4

- Subcooled liquids (>8”) 2.0 0.45 12.0 3.7

B. Pump Discharge Lines (CS) 4.0 0.91 20.0 6.1

Pump Discharge lines (Alloy/SS) 4.0 0.91 25.0 7.62

C. Liquid Transfer Lines 1.5 (2) 0.34 12.0 (2) 3.7

D. Cooling Water Lines 1.5 0.34 12.0 3.7

E. Steam Condensate Lines (2) (liquid) - - 2.0 0.61

F. Reboiler Trapout Lines (3) 0.3 0.07 5.0 1.5

G. Reboiler Return Lines 0.3 0.07 - -

Notes:

(1) Pump suction line diameters should normally not be more than two (2)

standard line sizes larger than the pump suction nozzle. Exceptions to this

rule should be approved by the respective chief engineer.

(2) Or as required by system pressure balance. Sour water line maximum velocity

may be lower depending upon temperature and metallurgy.

(3) See standard 103, Section 3.0, for tower draw-offs.

(4) If the liquid velocity is too high, swaged-up meter runs may be required.

Velocities for lines containing orifice plates should be limited to the following

values:

2” (0.05m) and up < 11.1 ft/sec (3.4 m/s)

except

14” (0.356m) and up sch. 80 < 10.2 ft/sec (3.1m/s)

If it is considered essential to use higher velocities, Instrument Group should

be consulted.

(5) Critical pump suction pressures should be checked using isometrics at the

earliest opportunity.

You might also like

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Line Sizing and Pressure Drop PhilosophyDocument30 pagesLine Sizing and Pressure Drop PhilosophyBelos SahajiNo ratings yet

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarNo ratings yet

- Flow Meter Data SheetDocument2 pagesFlow Meter Data SheetjlirazuritaNo ratings yet

- No. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Document32 pagesNo. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Hilmi Haidar AlifNo ratings yet

- No. 1 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Document32 pagesNo. 1 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Hilmi Haidar AlifNo ratings yet

- Water Systems - Maximum Flow VelocitiesDocument1 pageWater Systems - Maximum Flow VelocitiesIbrahim Ahmed FarrukhNo ratings yet

- Flowcon SM 15-40Mm: Dynamic Self Balancing Control ValveDocument6 pagesFlowcon SM 15-40Mm: Dynamic Self Balancing Control Valvefmelman 04No ratings yet

- 2.6. Line and Nozzle Sizing Criteria A. General A.1 The Fluid Quantities To Be Used in Determining Line SizesDocument7 pages2.6. Line and Nozzle Sizing Criteria A. General A.1 The Fluid Quantities To Be Used in Determining Line SizesNastaran BagheriNo ratings yet

- Line Sizing CriteriaDocument5 pagesLine Sizing CriteriaBILAL ILYASNo ratings yet

- Cbe-6 1Document16 pagesCbe-6 1Luiz RibeiroNo ratings yet

- RV RV RV RV: Product Data Sheet Product Data Sheet Product Data Sheet Product Data SheetDocument2 pagesRV RV RV RV: Product Data Sheet Product Data Sheet Product Data Sheet Product Data SheetIndra PutraNo ratings yet

- 2.0 Process Liquid Lines PrefaceDocument23 pages2.0 Process Liquid Lines PrefaceCristhianNo ratings yet

- Line Sizing Criteria PDFDocument8 pagesLine Sizing Criteria PDFwaelNo ratings yet

- Chevron Line Sizing GuidelinesDocument6 pagesChevron Line Sizing GuidelinesWayne Monnery0% (1)

- Line SizingDocument2 pagesLine SizingHarryBouterNo ratings yet

- Issue On CT Pipe SizingDocument1 pageIssue On CT Pipe SizingFaris BahauddinNo ratings yet

- Waters Spherisorb Columns: (Care and Use Manual)Document11 pagesWaters Spherisorb Columns: (Care and Use Manual)AyuNo ratings yet

- Line Sizing For Systems PDFDocument13 pagesLine Sizing For Systems PDFCua TranNo ratings yet

- 225-002 - Piping Hydraulics and Specification - Book 1Document114 pages225-002 - Piping Hydraulics and Specification - Book 1antemio hernandezNo ratings yet

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- Philmac Orbitor Challenger - Spec Sheet PDFDocument4 pagesPhilmac Orbitor Challenger - Spec Sheet PDFEko RuddyNo ratings yet

- Parts and Materials: Shell and Tube Marine Water ExchangerDocument1 pageParts and Materials: Shell and Tube Marine Water ExchangerAnonymous lIJl27QBXLNo ratings yet

- Section 5 Equipment Selection, Sizing & DesignDocument43 pagesSection 5 Equipment Selection, Sizing & Designgad480No ratings yet

- Duct Element Duct Section Width (MM) Height (MM) Air Flow RATE (CFM) AIR Flow Rate (L/S) AIR Flow Rate (m3/s) Duct Length (M) No - of Fittings Friction Loss For St. Duct (Pa/m)Document7 pagesDuct Element Duct Section Width (MM) Height (MM) Air Flow RATE (CFM) AIR Flow Rate (L/S) AIR Flow Rate (m3/s) Duct Length (M) No - of Fittings Friction Loss For St. Duct (Pa/m)ibnrafeeqNo ratings yet

- ES-2184 Lube Oil FlushingDocument9 pagesES-2184 Lube Oil Flushingwaheed100% (1)

- Fluid Flow Pipe LabDocument7 pagesFluid Flow Pipe LabPaula HoNo ratings yet

- Line SizingDocument16 pagesLine SizingAkshay bhuranNo ratings yet

- CoolersDocument65 pagesCoolersUmut KurtNo ratings yet

- Jet Grouting PresentationDocument132 pagesJet Grouting PresentationMatthew KarabelaNo ratings yet

- Slimhole CementingDocument33 pagesSlimhole CementingTariqNo ratings yet

- JVCVReport1215 PDFDocument1 pageJVCVReport1215 PDFUlises BadilloNo ratings yet

- Standard Pilot Assisted Load ControlDocument28 pagesStandard Pilot Assisted Load ControlOscar GuaricalloNo ratings yet

- Kvaerner C-300-2001-011 - Pipe Velocity StandardsDocument2 pagesKvaerner C-300-2001-011 - Pipe Velocity StandardsdhlinvaNo ratings yet

- Pipe Work, Valves and Fittings: ChapterDocument16 pagesPipe Work, Valves and Fittings: Chapterpriya singhNo ratings yet

- Pds-Extreme Problaster Acc. Combo 12v 5902-2212Document2 pagesPds-Extreme Problaster Acc. Combo 12v 5902-2212musebladeNo ratings yet

- 1 6 Presentation Echometer Pump SlippageDocument29 pages1 6 Presentation Echometer Pump SlippageRezha Aditya PratamaNo ratings yet

- Sewerage Design Calculation For CO4Document6 pagesSewerage Design Calculation For CO4Mohd RafiqNo ratings yet

- Manual de Taller Peugeot Partner (2008-2017) 2doDocument1,592 pagesManual de Taller Peugeot Partner (2008-2017) 2doJose Luis Orozco Robledo100% (3)

- 08 - 2 Phase SeparatorDocument21 pages08 - 2 Phase SeparatorNoman AslamNo ratings yet

- PneumaticsDocument23 pagesPneumaticskarikalan vNo ratings yet

- Pipe Size Rules of ThumbDocument6 pagesPipe Size Rules of ThumbIndunil Warnasooriya100% (1)

- Piping BOQDocument4 pagesPiping BOQm 418No ratings yet

- Wang Xiaojun2018Document7 pagesWang Xiaojun2018Ebrahim MohamadikhahNo ratings yet

- Pump Design - 2Document1 pagePump Design - 2kapsarcNo ratings yet

- Pump System Total Head Calculation Example Complete (Imperial Units)Document16 pagesPump System Total Head Calculation Example Complete (Imperial Units)Mayur KhirodeNo ratings yet

- Pump System Total Head Calculation Example Complete (Imperial Units)Document16 pagesPump System Total Head Calculation Example Complete (Imperial Units)Vismael SantosNo ratings yet

- Pump System Total Head Calculation Example Complete (Imperial Units)Document16 pagesPump System Total Head Calculation Example Complete (Imperial Units)Nitish BelgiNo ratings yet

- Pump System Total Head Calculation Example Complete (Imperial Units)Document16 pagesPump System Total Head Calculation Example Complete (Imperial Units)Maxmore KarumamupiyoNo ratings yet

- No Service Class Rating Pipe Material Corrosion AllowanceDocument4 pagesNo Service Class Rating Pipe Material Corrosion AllowanceAllif ArrozynNo ratings yet

- Different Pressure Control DN15-50 FlowCon EDP Tech NoteDocument7 pagesDifferent Pressure Control DN15-50 FlowCon EDP Tech Notehvacvn1984No ratings yet

- Lecture No.14 (Pipe)Document8 pagesLecture No.14 (Pipe)Mohsen HassanNo ratings yet

- Varian DS102VanePumpDocument2 pagesVarian DS102VanePumpRobinson BangueroNo ratings yet

- Pump System Total Head Calculation Example Complete (Imperial Units)Document17 pagesPump System Total Head Calculation Example Complete (Imperial Units)dilip matalNo ratings yet

- HF 525 Series: Tank Mounted Return and Suction Line FiltersDocument16 pagesHF 525 Series: Tank Mounted Return and Suction Line FilterssitnikovsNo ratings yet

- Sayalat-Mostofi (WWW Icivil Ir) 0011Document18 pagesSayalat-Mostofi (WWW Icivil Ir) 0011Anon YmousNo ratings yet

- 3.0 Water Lines Preface: Bechtel ConfidentialDocument6 pages3.0 Water Lines Preface: Bechtel ConfidentialCristhianNo ratings yet

- TCX TTDSeriesDocument2 pagesTCX TTDSeriespaachangaNo ratings yet

- Temperature Regulating Valve: Model 2470Document6 pagesTemperature Regulating Valve: Model 2470HotnCrispy CrispyNo ratings yet

- Gas Ultrasonic Meter Sizing ReportDocument4 pagesGas Ultrasonic Meter Sizing ReportWUMINGNo ratings yet

- MKNS PFA Lined Magnetic Drive PumpsDocument6 pagesMKNS PFA Lined Magnetic Drive PumpsMOHSENNo ratings yet

- Te) ",:lel : E9 - 1 - Hewitt - Simulation - Edr E9 - 1 - Hewitt - Simulation - BJTDocument7 pagesTe) ",:lel : E9 - 1 - Hewitt - Simulation - Edr E9 - 1 - Hewitt - Simulation - BJTMOHSENNo ratings yet

- Priming Chamber Centrifugal PumpsDocument2 pagesPriming Chamber Centrifugal PumpsMOHSENNo ratings yet

- A 71.1 M U 16.7 W/ (M K) (UA) 1,187.37 W/K Aspen HTFS+ Aerotran Design Weight%Document3 pagesA 71.1 M U 16.7 W/ (M K) (UA) 1,187.37 W/K Aspen HTFS+ Aerotran Design Weight%MOHSENNo ratings yet

- LPM045 PDFDocument1 pageLPM045 PDFMOHSENNo ratings yet

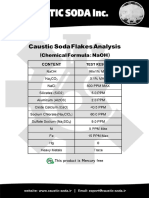

- Caustic Soda Flakes 98 Caustic Soda Inc Analysis2Document1 pageCaustic Soda Flakes 98 Caustic Soda Inc Analysis2MOHSENNo ratings yet

- ضمائم خام قرارداد - 09-98Document22 pagesضمائم خام قرارداد - 09-98MOHSENNo ratings yet

- Proposal Lab 5Document4 pagesProposal Lab 5darkzainiNo ratings yet

- Selecting Centrifugal Slurry Pump BasedDocument6 pagesSelecting Centrifugal Slurry Pump BasedRodrigo GarcíaNo ratings yet

- 06 Water and The HydrosphereDocument23 pages06 Water and The HydrosphereGeorgiana BălaşNo ratings yet

- Advanced Fluid MechanicsDocument15 pagesAdvanced Fluid MechanicsmmilyasNo ratings yet

- SOP For ViscosityDocument7 pagesSOP For Viscositytribo technicalNo ratings yet

- University Septic Tanks TextDocument68 pagesUniversity Septic Tanks Textdkm455No ratings yet

- Drainage Pipe Flow Chart PDFDocument7 pagesDrainage Pipe Flow Chart PDFPatel KalingaNo ratings yet

- A Numerical Simulation of Vortex Shedding From An Oscillating Circular CylinderDocument22 pagesA Numerical Simulation of Vortex Shedding From An Oscillating Circular CylinderAshish PawarNo ratings yet

- RHEOLOGY CompleteDocument95 pagesRHEOLOGY CompleteHuma Hameed Dogar40% (5)

- Lab 7Document4 pagesLab 7Talha JuttNo ratings yet

- Urban River RestorationDocument22 pagesUrban River RestorationMichelle Erasmus100% (1)

- API 576 Study NotesDocument5 pagesAPI 576 Study NotesabdoNo ratings yet

- Mechanics: Confirming Archimedes' PrincipleDocument2 pagesMechanics: Confirming Archimedes' PrincipleFattihiEkhmalNo ratings yet

- PSV-1203 - 3632-I-DS-31001 WorkingDocument1 pagePSV-1203 - 3632-I-DS-31001 Workinganamaria ursuNo ratings yet

- PV SeriesDocument43 pagesPV SeriesramabhplNo ratings yet

- Simulation of Full-Bore Tube Rupture in Shell&Tube Heat ExchangerDocument6 pagesSimulation of Full-Bore Tube Rupture in Shell&Tube Heat ExchangerMoca PhoenixNo ratings yet

- CE141-2 HW #1 - TejadaDocument2 pagesCE141-2 HW #1 - TejadaDenver John TejadaNo ratings yet

- Roof Top Rain Water Harvesting in Remote Rural Schools: An Approach For Global ReplicationDocument8 pagesRoof Top Rain Water Harvesting in Remote Rural Schools: An Approach For Global ReplicationFadi SyraiNo ratings yet

- Hydraulic Calculations Fire ProtectionDocument16 pagesHydraulic Calculations Fire ProtectionGabriel LopezNo ratings yet

- Comparative Chart For Industrial Lubricants: Iso VG / Nlgi Gulf BP Mobil Total Shell VortaDocument1 pageComparative Chart For Industrial Lubricants: Iso VG / Nlgi Gulf BP Mobil Total Shell VortamuhammadNo ratings yet

- Design Sewer & Physical & Biological Waste Water TreatmentDocument86 pagesDesign Sewer & Physical & Biological Waste Water TreatmentĄlmost ĄwhisperNo ratings yet

- Flow Around A Rectangular Cylinder-2dDocument26 pagesFlow Around A Rectangular Cylinder-2dDeniz ümit BayraktutarNo ratings yet

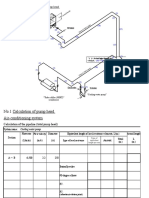

- No.1 Calculation of Pump Head.: "Cooling Tower"Document20 pagesNo.1 Calculation of Pump Head.: "Cooling Tower"GandiPermanaNo ratings yet

- Module 8-Operation of Canal and Pipe SystemsDocument12 pagesModule 8-Operation of Canal and Pipe SystemsAhmedNo ratings yet

- AerationDocument92 pagesAerationGigih HaryNo ratings yet

- Advanced ECLIPSE Course: Saturation Functions and Endpoint ScalingDocument42 pagesAdvanced ECLIPSE Course: Saturation Functions and Endpoint ScalingiskanderNo ratings yet

- Reverse EngineeringDocument3 pagesReverse EngineeringRahul SureshNo ratings yet

- The Complete Programme For High Pressure TechnologyDocument28 pagesThe Complete Programme For High Pressure TechnologyRafael EspinosaNo ratings yet

- Chap1F Scale UpDocument19 pagesChap1F Scale Upmohan804No ratings yet

- LP PDFDocument8 pagesLP PDFEshanth RajNo ratings yet