Professional Documents

Culture Documents

Applications Note:An - Sy8101A/B/C/D: High Efficiency 400Khz, 0.6A/1A/1.5A/2A, 16V Input Synchronous Step Down Regulator

Uploaded by

Vansika MalhotraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applications Note:An - Sy8101A/B/C/D: High Efficiency 400Khz, 0.6A/1A/1.5A/2A, 16V Input Synchronous Step Down Regulator

Uploaded by

Vansika MalhotraCopyright:

Available Formats

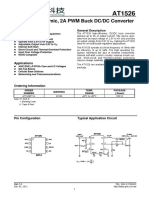

Applications Note:AN_SY8101A/B/C/D

High Efficiency 400kHz, 0.6A/1A/1.5A/2A, 16V Input

Synchronous Step Down Regulator

Preliminary Specification

General Description Features

The SY8101A, SY8101B, SY8101C and SY8101D are • Low RDS(ON) for internal switches (top/bottom)

high efficiency 400kHz synchronous step-down DC- ο SY8101A: 300/200 mΩ, 0.6A

DC converters capable of delivering 0.6A, 1A, 1.5A, ο SY8101B: 200/150 mΩ, 1A

2A output currents, respectively. SY8101A/B/C/D ο SY8101C: 150/120 mΩ, 1.5A

operate over a wide input voltage range from 4V to ο SY8101D: 120/90 mΩ, 2A

15V and integrate main switch and synchronous switch • 4-15V input voltage range

with very low RDS(ON) to minimize the conduction loss.

• 400kHz switching frequency

• Internal softstart limits the inrush current

Low output voltage ripple and small external inductor

• 2% 0.6V reference

and capacitor sizes are achieved with 400kHz

switching frequency. • RoHS Compliant and Halogen Free

• Compact package: SSOT23 6 pin

Ordering Information

SY8101□(□□)□

Temperature Code Applications

Package Code

Optional Spec Code • Set Top Box

Temperature Range: -40°C to 85°C • Portable TV

Ordering Number Package type Note • Access Point Router

SY8101AEBC SSOT23-6 0.6A • DSL Modem

SY8101BEBC SSOT23-6 1A • LCD TV

SY8101CEBC SSOT23-6 1.5A

SY8101DEBC SSOT23-6 2A

Typical Applications

98

VIN

BS 96

IN

94

Efficiency (%)

L

VOUT 92

CIN

LX 90

88

GND R1 86

COUT 84

FB

82 VIN=12V, VOUT=5V

EN R2

80

0 0.4 0.8 1.2 1.6 2

Load Current (A)

Figure 1. Schematic Diagram Figure 2. Efficiency vs Load Current

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Internal Use Only 1

AN_SY8101A/B/C/D

Pinout (top view)

(SSOT23-6)

Top Mark: CFxyz for SY8101A, BJxyz for SY8101B, BMxyz for SY8101C, CGxyz for SY8101D

(Device code: CF for SY8101A, etc.; x=year code, y=week code, z= lot number code)

Pin Name Pin Number Pin Description

BS 1 Boot-Strap Pin. Supply high side gate driver. Decouple this pin to LX pin with

0.1uF ceramic cap.

IN 5 Input pin. Decouple this pin to GND pin with at least 1uF ceramic cap

LX 6 Inductor pin. Connect this pin to the switching node of inductor

GND 2 Ground pin

FB 3 Output Feedback Pin. Connect this pin to the center point of the output resistor

divider (as shown in Figure 1) to program the output voltage:

VOUT=0.6*(1+R1/R2)

EN 4 Enable control. Pull high to turn on. Do not float.

Absolute Maximum Ratings (Note 1)

Supply Input Voltage ----------------------------------------------------------------------------------------- 16V

LX, EN Voltage------------------------------------------------------------------------------------------------ VIN + 0.3V

FB, BS-LX Voltage-------------------------------------------------------------------------------------------- 4V

Power Dissipation, PD @ TA = 25°C SSOT23-6, --------------------------------------------------------- 0.6W

Package Thermal Resistance (Note 2)

θ JA -----------------------------------------------------------------------------------------------------161°C/W

θ JC ----------------------------------------------------------------------------------------------------- 130°C/W

Junction Temperature Range --------------------------------------------------------------------------------- 125°C

Lead Temperature (Soldering, 10 sec.) --------------------------------------------------------------------- 260°C

Storage Temperature Range ---------------------------------------------------------------------------------- -65°C to 150°C

ESD Susceptibility (Note 2)

HBM (Human Body Mode) ----------------------------------------------------------------------------------- 2kV

MM (Machine Mode) ------------------------------------------------------------------------------------------ 200V

Recommended Operating Conditions (Note 3)

Supply Input Voltage ----------------------------------------------------------------------------------------- 4V to 15V

Junction Temperature Range -------------------------------------------------------------------------------- -40°C to 125°C

Ambient Temperature Range -------------------------------------------------------------------------------- -40°C to 85°C

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 2

AN_SY8101A/B/C/D

Electrical Characteristics

(VIN = 12V, VOUT = 2.5V, L = 2.2uH, COUT = 10uF, TA = 25°C, IOUT = 1A unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Input Voltage Range VIN 4 15 V

Quiescent Current IQ IOUT=0, VFB=VREF×105% 200 µA

Shutdown Current ISHDN EN=0 1 5 µA

Feedback Reference VREF 0.588 0.6 0.612 V

Voltage

FB Input Current IFB VFB=VIN -50 50 nA

Top FET RON RDS(ON)1 SY8101A 0.3 Ω

SY8101B 0.2 Ω

SY8101C 0.15 Ω

SY8101D 0.12 Ω

Bottom FET RON RDS(ON)2 SY8101A 0.2 Ω

SY8101B 0.15 Ω

SY8101C 0.12 Ω

SY8101D 0.09 Ω

Top FET Current Limit ILIM SY8101A 0.9 A

SY8101B 1.3 A

SY8101C 1.8 A

SY8101D 2.4 A

Line Regulation ∆VOUT/VOUT VIN=4V~15V, IOUT=0.2A 0.2 0.5 %

Load Regulation ∆VOUT/VOUT IOUT=0.2 to 2A 1 2 %

EN Rising Threshold VENH 1.5 V

EN Falling Threshold VENL 0.4 V

Input UVLO Threshold VUVLO 3.9 V

UVLO Hysteresis VHYS 0.3 V

Oscillator Frequency FOSC IOUT=200mA 400 kHz

Min ON Time 50 ns

Max Duty Cycle 90 %

Thermal Shutdown TSD 160 °C

Temperature

Note 1: Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device.

These are for stress ratings. Functional operation of the device at these or any other conditions beyond those

indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating

conditions for extended periods may remain possibility to affect device reliability.

Note 2: θ JA is measured in the natural convection at TA = 25°C on a low effective single layer thermal

conductivity test board of JEDEC 51-3 thermal measurement standard. Pin 2 of SSOT-23-6 packages is the case

position for θ JC measurement.

Note 3: The device is not guaranteed to function outside its operating conditions.

Note 4: Line Regulation and Load Regulation are tested on evaluation board.

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 3

AN_SY8101A/B/C/D

(SY8101C)

Typical Performance Characteristics( )

Efficiency (%)

Efficiency (%)

Efficiency (%)

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 4

AN_SY8101A/B/C/D

Block Diagram

EN BS

IN

PWM

Error

Control

AMP.

&

LX

FB Protection

Logic

0.6VREF

SGND PGND

Operation

SY8101 is a synchronous buck regulator IC that integrates the PWM control, top and bottom switches on the same die to

minimize the switching transition loss and conduction loss. With ultra low Rds(on) power switches and proprietary PWM control,

this regulator IC can achieve the highest efficiency and the highest switch frequency simultaneously to minimize the external

inductor and capacitor size, and thus achieving the minimum solution footprint.

Applications Information

Because of the high integration in the SY8101 IC, the application circuit based on this regulator IC is rather simple. Only input

capacitor CIN, output capacitor COUT, output inductor L and feedback resistors (R1 and R2) need to be selected for the targeted

applications specifications.

Feedback resistor dividers R1 and R2:

Choose R1 and R2 to program the proper output voltage. To minimize the power consumption under light loads, it is desirable to

choose large resistance values for both R1 and R2. A value of between 10k and 1M is highly recommended for both resistors. If

R2=120k is chosen, then R1 can be calculated to be:

(V − 0.6 V) ⋅ (R2)

R1 = OUT

0.6V

Input capacitor CIN:

With the maximum load current at 2A, the maximum ripple current through input capacitor is about 0.6Arms. A

typical X7R or better grade ceramic capacitor with 6V rating and greater than 4.7uF capacitance can handle this

ripple current well. To minimize the potential noise problem, place this ceramic capacitor really close to the IN and

GND pins. Care should be taken to minimize the loop area formed by CIN, and IN/GND pins.

Output capacitor COUT:

The output capacitor is selected to handle the output ripple noise requirements. Both steady state ripple and transient

requirements must be taken into consideration when selecting this capacitor. For the best performance, it is

recommended to use X7R or better grade ceramic capacitor with 6V rating and greater than 4.7uF capacitance.

Output inductor L:

There are several considerations in choosing this inductor.

1) Choose the inductance to provide the desired ripple current. It is suggested to choose the ripple current to be

about 40% of the maximum output current. The inductance is calculated as:

V (1 − VOUT /VIN, MAX )

L = OUT

FSW × I OUT, MAX × 40%

where Fsw is the switching frequency and IOUT, max is the maximum load current.

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 5

AN_SY8101A/B/C/D

The SY8101 regulator IC is quite tolerant of different ripple current amplitude. Consequently, the final choice of

inductance can be slightly off the calculation value without significantly impacting the performance.

2) The saturation current rating of the inductor must be selected to be greater than the peak inductor current under

full load conditions.

VOUT(1-VOUT/VIN,MAX)

ISAT, MIN > IOUT, MAX +

2 ⋅ FSW ⋅ L

3) The DCR of the inductor and the core loss at the switching frequency must be low enough to achieve the desired

efficiency requirement. It is desirable to choose an inductor with DCR<50mohm to achieve a good overall efficiency.

Layout Design:

The layout design of SY8101 regulator is relatively simple. For the best efficiency and minimum noise problems, we

should place the following components close to the IC: CIN, L, R1 and R2.

1) It is desirable to maximize the PCB copper area connecting to GND pin to achieve the best thermal and noise

performance. If the board space allowed, a ground plane is highly desirable.

2) CIN must be close to Pins IN and GND. The loop area formed by CIN and GND must be minimized.

3) The PCB copper area associated with LX pin must be minimized to avoid the potential noise problem.

3) The components R1 and R2, and the trace connecting to the FB pin must NOT be adjacent to the LX net on the

PCB layout to avoid the noise problem.

4) If the system chip interfacing with the EN pin has a high impedance state at shutdown mode and the IN pin is

connected directly to a power source such as a Li-Ion battery, it is desirable to add a pull down 1Mohm resistor

between the EN and GND pins to prevent the noise from falsely turning on the regulator at shutdown mode.

Load Transient Considerations:

The SY8101 regulator IC integrates the compensation components to achieve good stability and fast transient

responses. In some applications, adding a 22pF ceramic cap in parallel with R1 may further speed up the load

transient responses and is thus recommended for applications with large load transient step requirements.

Other Application Examples

Figure 3 to 8 show other application examples of using SY8101.

Figure 3. White LED Driver for Li-Ion Battery Input or 3.3V Input

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 6

AN_SY8101A/B/C/D

Figure 4. Step Up Regulator for Li-Ion Battery Input or 3.3V Input

Figure 5 . Negative Output Supply for Li-Ion Battery Input or 3.3V Input

Figure 6 . Positive and Negative Output Supply for Li-Ion Battery Input or 3.3V Input

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 7

AN_SY8101A/B/C/D

Figure 7. Positive and Negative Output Supply with LED Back Light for 3.3V Input or Li-Ion Battery Input

Figure 8. Positive To Negative Supply

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 8

AN_SY8101A/B/C/D

SSOT23-6 Package outline & PCB layout design

1.90

2.50 - 3.00

2.30 - 2.50

2.40

1.00

0.95 0.60 0.25 - 0.40

Recommended Pad Layout

2.95 - 3.10

0.01 - 0.10

0.90 - 1.00

0.10 - 0.20

0.30 - 0.60 0.95 TYP

Notes: All dimensions are in millimeters.

All dimensions don’t include mold flash & metal burr.

AN_SY8101 Rev0.92 Silergy Corp. Confidential-prepared for Customer Use Only 9

www.s-manuals.com

You might also like

- High Efficiency 1.5MHz/1MHz, 1.5A/2A Synchronous Step Down RegulatorDocument9 pagesHigh Efficiency 1.5MHz/1MHz, 1.5A/2A Synchronous Step Down RegulatorMiller CostaNo ratings yet

- Sy8009A/Sy8009B: High Efficiency 1.5Mhz/1Mhz, 1.5A/2A Synchronous Step Down RegulatorDocument6 pagesSy8009A/Sy8009B: High Efficiency 1.5Mhz/1Mhz, 1.5A/2A Synchronous Step Down RegulatorRenato HernandezNo ratings yet

- AL8861EV1 User GuideDocument8 pagesAL8861EV1 User GuideHans ClarinNo ratings yet

- Sy8008A/Sy8008B/Sy8008C: High Efficiency 1.5Mhz, 0.6A/1A/1.2A Synchronous Step Down RegulatorDocument5 pagesSy8008A/Sy8008B/Sy8008C: High Efficiency 1.5Mhz, 0.6A/1A/1.2A Synchronous Step Down RegulatorAnil BpsNo ratings yet

- SY8201Document10 pagesSY8201relmasNo ratings yet

- AL8860EV2 User GuideDocument8 pagesAL8860EV2 User GuideHans ClarinNo ratings yet

- AN SY8063 SilergyDocument13 pagesAN SY8063 Silergyzigmund zigmundNo ratings yet

- Silergy Corp SY8213FCC - C178246Document9 pagesSilergy Corp SY8213FCC - C178246Thai LamNo ratings yet

- L6565 Sample SchematicsDocument9 pagesL6565 Sample SchematicsНикита АндронкинNo ratings yet

- XC9110 XC9111Document35 pagesXC9110 XC9111alllim88No ratings yet

- RP108J Series: Low Input Voltage 3A LDO Regulator OutlineDocument29 pagesRP108J Series: Low Input Voltage 3A LDO Regulator OutlineArie DinataNo ratings yet

- XC9110 XC9111Document36 pagesXC9110 XC9111German DfrNo ratings yet

- SSC9512SDocument2 pagesSSC9512SSamaro RodriguezNo ratings yet

- DAC0800/DAC0802 8-Bit Digital-to-Analog Converters: General DescriptionDocument11 pagesDAC0800/DAC0802 8-Bit Digital-to-Analog Converters: General Descriptionmariano_74No ratings yet

- PV PanelDocument17 pagesPV PanelMuhammad RiazNo ratings yet

- Toshiba TB6500AH Bipolar Stepper and DC Motor Driver ICDocument18 pagesToshiba TB6500AH Bipolar Stepper and DC Motor Driver ICJavier CuraNo ratings yet

- Sy8105 Tsot23-6 Mark NyxyzDocument11 pagesSy8105 Tsot23-6 Mark NyxyzrammerDankovNo ratings yet

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 pagesEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84No ratings yet

- AD9mark PDFDocument14 pagesAD9mark PDFLe DungNo ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- DatasheetDocument11 pagesDatasheetGeorges TaradauxNo ratings yet

- LED Step-Up Converter Drives Up to Five White LEDsDocument9 pagesLED Step-Up Converter Drives Up to Five White LEDsBudi PrayitnoNo ratings yet

- XC9110Document35 pagesXC9110Loc ManucianNo ratings yet

- 60V Step-Down DC/DC Converter Maintains High Effi Ciency: Design Note 269 Mark W. MarosekDocument2 pages60V Step-Down DC/DC Converter Maintains High Effi Ciency: Design Note 269 Mark W. MarosekMes BenNo ratings yet

- A6211 Datasheet PDFDocument18 pagesA6211 Datasheet PDFNestor GlezNo ratings yet

- Operating Instructions: LCD Display Counters E5024C SeriesDocument20 pagesOperating Instructions: LCD Display Counters E5024C SeriesFernando BarraganNo ratings yet

- 1-2-4-Bit Bidirectional Voltage-Level Translator With Automatic Direction Sensing and 15kV ESD ProtectionDocument1 page1-2-4-Bit Bidirectional Voltage-Level Translator With Automatic Direction Sensing and 15kV ESD ProtectionSabeur ShabouNo ratings yet

- Bay Linear Current Mode PWM Controller SpecificationsDocument11 pagesBay Linear Current Mode PWM Controller SpecificationsShashikant PatilNo ratings yet

- CAT7105 2.0A High Efficiency Step-Down DC/DC Converter Datasheet SummaryDocument12 pagesCAT7105 2.0A High Efficiency Step-Down DC/DC Converter Datasheet Summarymonitores culpinaNo ratings yet

- Ultra High Frequency PrescalerDocument4 pagesUltra High Frequency PrescalerPadmajan YesodharanNo ratings yet

- Tps 40222Document28 pagesTps 40222Banupriya BalasubramanianNo ratings yet

- Datasheet - Aoz1280 Simple Buck RegulatorDocument13 pagesDatasheet - Aoz1280 Simple Buck RegulatorCesar ServidoneNo ratings yet

- Operation: Demo Manual Dc326BDocument5 pagesOperation: Demo Manual Dc326BMes BenNo ratings yet

- Skhi 22B DatasheetDocument9 pagesSkhi 22B DatasheetRakesh RoyNo ratings yet

- 300mA LDO REGULATOR RP114x SERIES DATA SHEETDocument28 pages300mA LDO REGULATOR RP114x SERIES DATA SHEETSol De GabrielNo ratings yet

- ADC0801, ADC0802, ADC0803, ADC0804, ADC0805: ADC0801/ADC0802/ADC0803/ADC0804/ADC0805 8-Bit P Compatible A/D ConvertersDocument43 pagesADC0801, ADC0802, ADC0803, ADC0804, ADC0805: ADC0801/ADC0802/ADC0803/ADC0804/ADC0805 8-Bit P Compatible A/D ConvertersPiyush JainNo ratings yet

- Controller IC For Current Resonant Type Switching Power Supply With Half-Bridge Resonance, High Efficiency and Low NoiseDocument2 pagesController IC For Current Resonant Type Switching Power Supply With Half-Bridge Resonance, High Efficiency and Low Noisejoil alvesNo ratings yet

- AT1526 GlobalMixed ModetechnologyDocument2 pagesAT1526 GlobalMixed ModetechnologyFafa MangstabNo ratings yet

- 6 N 139Document15 pages6 N 1391867468No ratings yet

- Mecl PLL Components 64/65, 128/129 Dual Modulus Prescaler: Semiconductor Technical DataDocument7 pagesMecl PLL Components 64/65, 128/129 Dual Modulus Prescaler: Semiconductor Technical DatabezasamiNo ratings yet

- AT9917 Automotive LED Driver IC With High Current Accuracy Data Sheet 20005557ADocument20 pagesAT9917 Automotive LED Driver IC With High Current Accuracy Data Sheet 20005557AJohnNo ratings yet

- 3-Phase Brushless Fan Motor DriverDocument30 pages3-Phase Brushless Fan Motor DriverAravind Prasad Sounder RajNo ratings yet

- BL1117XXXDocument15 pagesBL1117XXXedgarlibanioNo ratings yet

- Single-Phase Power Supply Unit, Primary Switched For Universal Use QUINT-PS-100-240AC/48DC/20Document10 pagesSingle-Phase Power Supply Unit, Primary Switched For Universal Use QUINT-PS-100-240AC/48DC/20toseruNo ratings yet

- Application Note: AN - SY8881: General Description FeaturesDocument9 pagesApplication Note: AN - SY8881: General Description Featuressluz2000No ratings yet

- Electronic Tuning-Use FM Front End For Car Radio, Home StereosDocument8 pagesElectronic Tuning-Use FM Front End For Car Radio, Home StereosVeronicaGonzalezNo ratings yet

- 3-Phase Brushless Fan Motor DriverDocument30 pages3-Phase Brushless Fan Motor DriverAravind Prasad Sounder RajNo ratings yet

- Dac 08Document11 pagesDac 08Adlan MessaoudNo ratings yet

- Bd9g341aefj eDocument30 pagesBd9g341aefj eEng:ehab AlmkhlafiNo ratings yet

- Single-Channel: 6N138, 6N139 Dual-Channel: HCPL-2730, HCPL-2731 Low Input Current High Gain Split Darlington OptocouplersDocument15 pagesSingle-Channel: 6N138, 6N139 Dual-Channel: HCPL-2730, HCPL-2731 Low Input Current High Gain Split Darlington Optocouplersdevrim.kosalNo ratings yet

- 3-Phase Brushless Fan Motor DriverDocument30 pages3-Phase Brushless Fan Motor DriverAravind Prasad Sounder RajNo ratings yet

- GMT Global Mixed Mode Tech G2898KD1U - C356810Document8 pagesGMT Global Mixed Mode Tech G2898KD1U - C356810ziya tutuNo ratings yet

- Audio Digital Resistor: DS1666, DS1666SDocument8 pagesAudio Digital Resistor: DS1666, DS1666SMuhammad WaqasNo ratings yet

- EL2020Document14 pagesEL2020api-3825669No ratings yet

- AP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterDocument24 pagesAP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterAarsol AdvanceNo ratings yet

- Charge Pump DC-to-DC Voltage Converter: Features Package TypesDocument20 pagesCharge Pump DC-to-DC Voltage Converter: Features Package TypesTomás CuetoNo ratings yet

- L 6928D - ReguladorDocument9 pagesL 6928D - ReguladorTiago LeonhardtNo ratings yet

- Annexure - C (Technical BOM)Document5 pagesAnnexure - C (Technical BOM)Darshit VyasNo ratings yet

- Unisonic Technologies Co., LTD: Low Voltage Audio Power AmplifierDocument5 pagesUnisonic Technologies Co., LTD: Low Voltage Audio Power Amplifieressen999No ratings yet

- Exelente Amplificador de 100w TDA7294Document17 pagesExelente Amplificador de 100w TDA7294Everson CorreaNo ratings yet

- Application Form PDFDocument1 pageApplication Form PDFRavin P100% (1)

- Samsung Gt-E2152Document59 pagesSamsung Gt-E2152Bhupender SiwachNo ratings yet

- D D D D D D D: Description/ordering InformationDocument15 pagesD D D D D D D: Description/ordering InformationVansika MalhotraNo ratings yet

- DAN222 Common Cathode Silicon Dual Switching Diode: Rating Symbol Value UnitDocument5 pagesDAN222 Common Cathode Silicon Dual Switching Diode: Rating Symbol Value UnitBhupender SiwachNo ratings yet

- Online Payment ReceiptDocument1 pageOnline Payment ReceiptVansika MalhotraNo ratings yet

- Datasheet PDFDocument14 pagesDatasheet PDFBhupender SiwachNo ratings yet

- EXERCISE - (JEE Main) Chemical Equilibrium - CombinedDocument24 pagesEXERCISE - (JEE Main) Chemical Equilibrium - CombinedKeerthana Reddy DomaNo ratings yet

- ECSS Q ST 70 02C (15november2008)Document45 pagesECSS Q ST 70 02C (15november2008)jsadachiNo ratings yet

- Measuring Instruments Temperature GuideDocument52 pagesMeasuring Instruments Temperature GuidemohammedhanafyNo ratings yet

- Wolf Gone Wild - Juliette CrossDocument312 pagesWolf Gone Wild - Juliette CrossAbdelhediNo ratings yet

- Discover the training secrets of legendary bodybuildersDocument129 pagesDiscover the training secrets of legendary bodybuildersfatmir100% (7)

- RMO NO. 66-2016 - DigestDocument2 pagesRMO NO. 66-2016 - DigestJuliannaMendozaMaleNo ratings yet

- The Four Common Types of Parenting StylesDocument11 pagesThe Four Common Types of Parenting StylesIka_Dyah_Purwa_1972100% (3)

- Bab 06 PindahPanasDocument41 pagesBab 06 PindahPanasPurna Satria NugrahaNo ratings yet

- Tapping Volcanic Energy for Human UseDocument9 pagesTapping Volcanic Energy for Human UseThartson Oliveros MagdadaroNo ratings yet

- Humic Substances As Electron Acceptor For Microbial RespirationDocument4 pagesHumic Substances As Electron Acceptor For Microbial RespirationNed FlandersNo ratings yet

- Storage Tank: Data Sheet ForDocument2 pagesStorage Tank: Data Sheet ForAmanNo ratings yet

- The QuestionnaireDocument3 pagesThe QuestionnaireMaximo C. Nayanga Jr.No ratings yet

- GER Bangladesh EngDocument12 pagesGER Bangladesh Engfarhan.anjum20032004No ratings yet

- Group 3Document11 pagesGroup 3Sharp MIER TVNo ratings yet

- Volcanic Eruption Types and ProcessDocument18 pagesVolcanic Eruption Types and ProcessRosemarie Joy TanioNo ratings yet

- Reactor & Impeller Design in Hydrogenation: GBHE Technical Bulletin CTB #79Document13 pagesReactor & Impeller Design in Hydrogenation: GBHE Technical Bulletin CTB #79manuNo ratings yet

- Jadwal Oral Presentation Peserta FIT-VIIIDocument26 pagesJadwal Oral Presentation Peserta FIT-VIIIKlinik FellitaNo ratings yet

- Refrigeration and Air Conditioning Laboratory: Lab Session 3 Absorption Refrigeration Demonstrator 816 ObjectivesDocument10 pagesRefrigeration and Air Conditioning Laboratory: Lab Session 3 Absorption Refrigeration Demonstrator 816 Objectivesjhon milliNo ratings yet

- Health Behaviour: Current Issues and ChallengesDocument13 pagesHealth Behaviour: Current Issues and ChallengesK.A.No ratings yet

- 3 - 2017 - Superia X 5 StarDocument26 pages3 - 2017 - Superia X 5 Starsomnath serviceNo ratings yet

- Recommended Abma & Asme Boiler Water Limits Drum Operating Pressure (Psig) SteamDocument9 pagesRecommended Abma & Asme Boiler Water Limits Drum Operating Pressure (Psig) Steammaoc4vnNo ratings yet

- Maximize muscle gains with reverse pyramid trainingDocument8 pagesMaximize muscle gains with reverse pyramid trainingMusadiq Ahmed100% (1)

- Diane Derzis Motion To Dismiss Complaint by The Alabama State Board of Health To Stop Her From Operating An Abortion Clinic Closed by The State.Document8 pagesDiane Derzis Motion To Dismiss Complaint by The Alabama State Board of Health To Stop Her From Operating An Abortion Clinic Closed by The State.Tom CiesielkaNo ratings yet

- 3023 History Cuisine WorksheetDocument6 pages3023 History Cuisine WorksheetFlor HenríquezNo ratings yet

- Low Noise Pseudomorphic HEMT Technical DataDocument4 pagesLow Noise Pseudomorphic HEMT Technical Datahendpraz88No ratings yet

- 0210 Pop Labels BSDocument1 page0210 Pop Labels BSThe London Free PressNo ratings yet

- Continuous Renal Replacement TherapyDocument9 pagesContinuous Renal Replacement Therapydoc_next_doorNo ratings yet

- 2009 IECC Residential Code Requirements Apr 14 Draft InspectorsDocument4 pages2009 IECC Residential Code Requirements Apr 14 Draft Inspectorsbcap-oceanNo ratings yet

- Listing of Equipment For Network DesignDocument3 pagesListing of Equipment For Network DesignJake D La MadridNo ratings yet

- Method of Statement For Pipeline WorkDocument15 pagesMethod of Statement For Pipeline WorkHalil Güney100% (3)